Contents

EB 6111 EN 3

1 Safety instructions and measures ...................................................................5

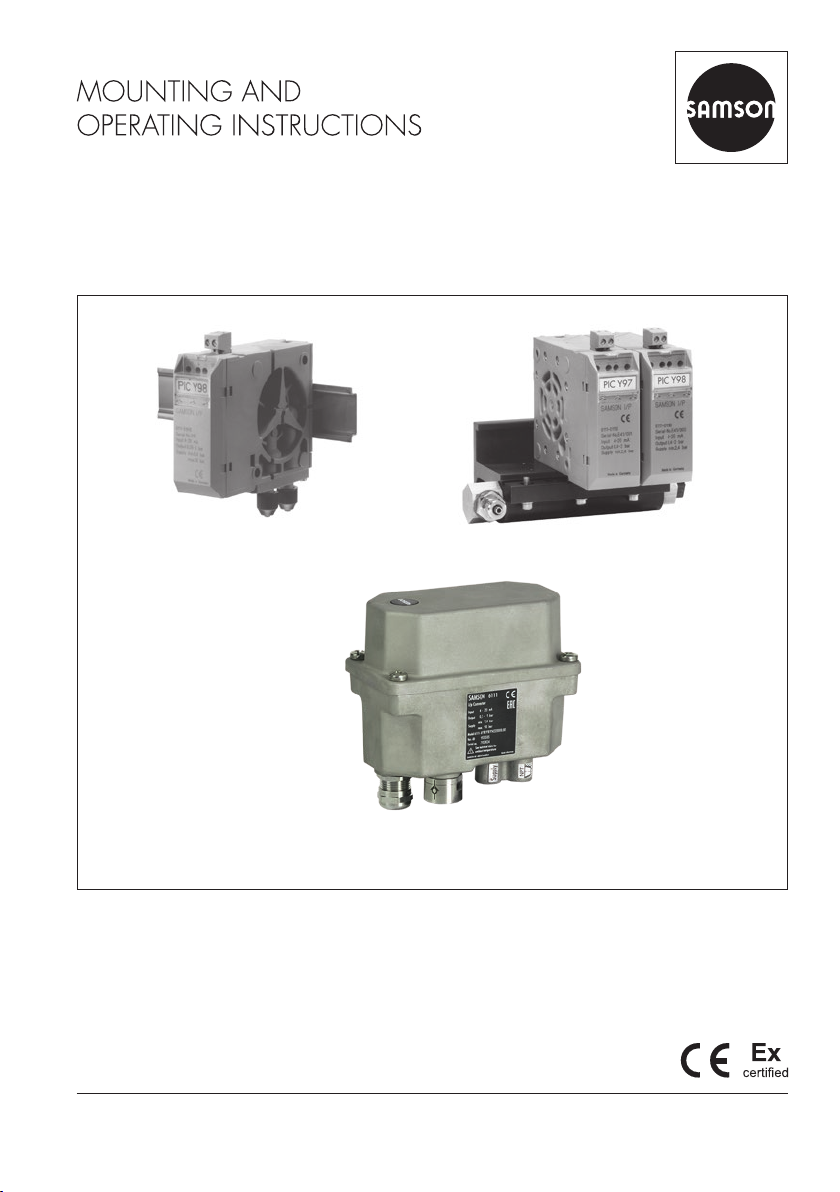

1.1 Notes on possible severe personal injury .........................................................7

1.2 Notes on possible personal injury ...................................................................8

1.3 Notes on possible property damage................................................................8

2 Markings on the device .................................................................................9

2.1 Nameplate ....................................................................................................9

2.2 Article code.................................................................................................10

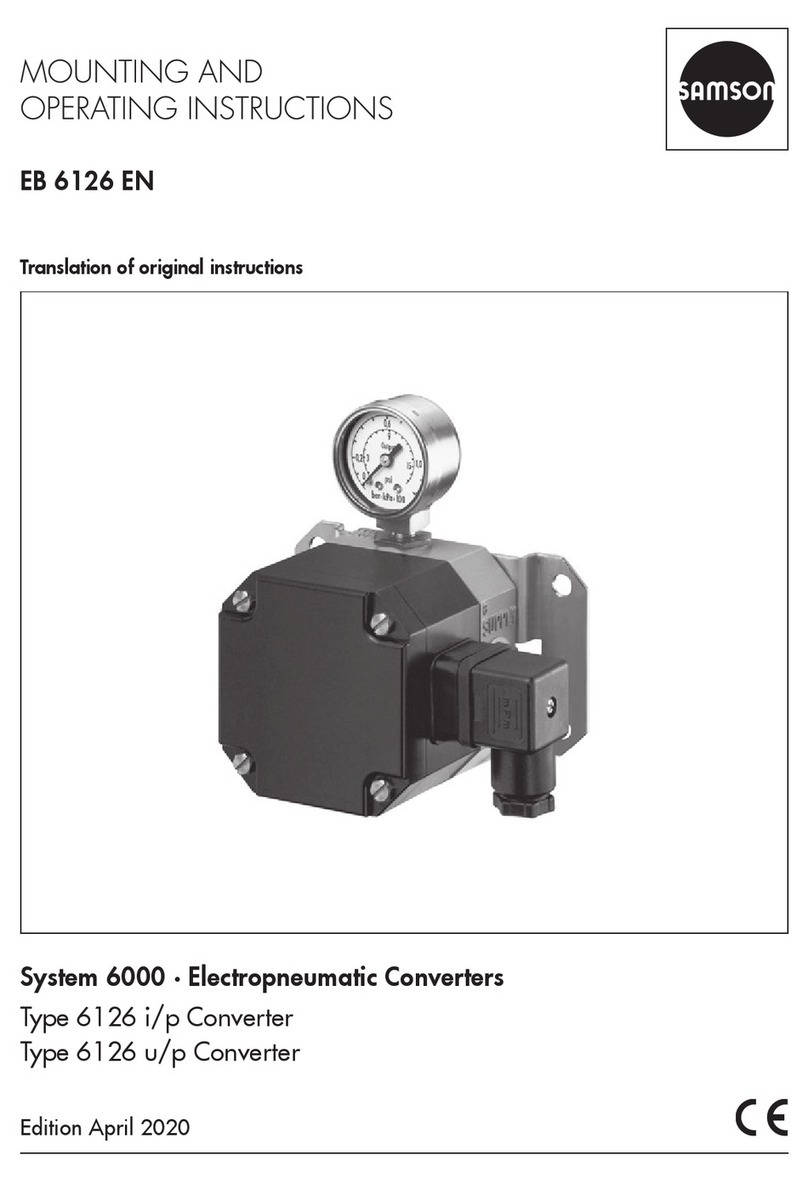

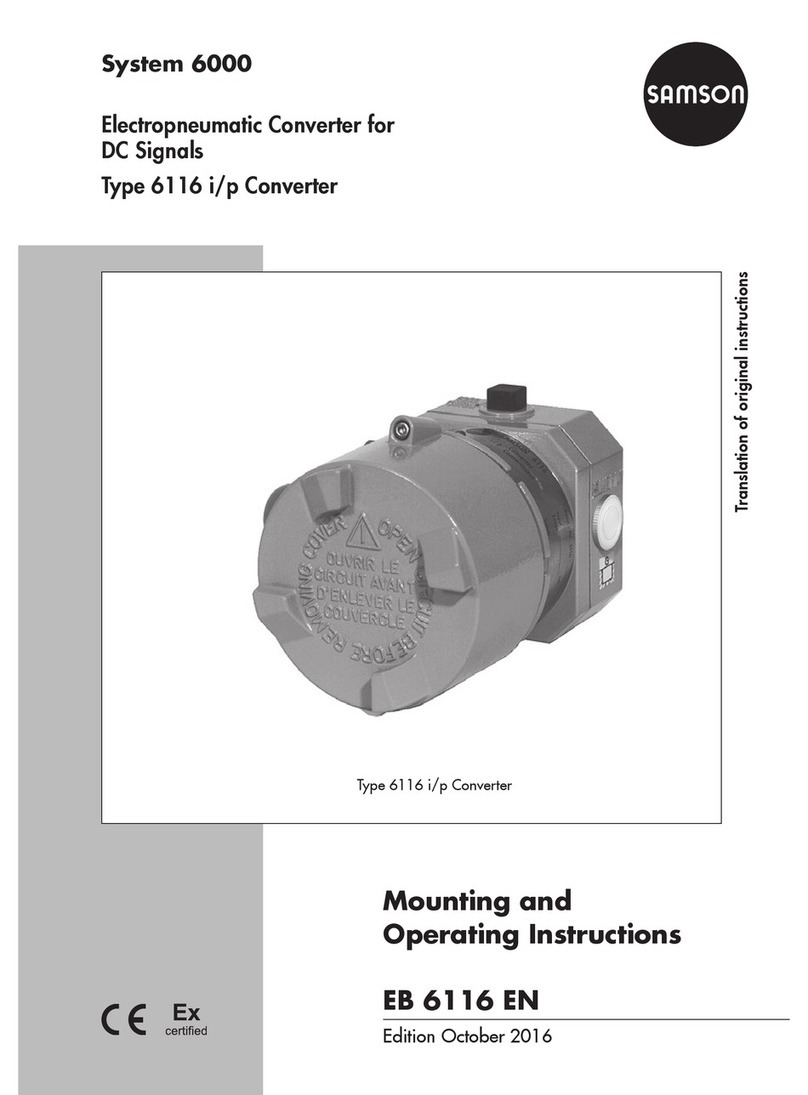

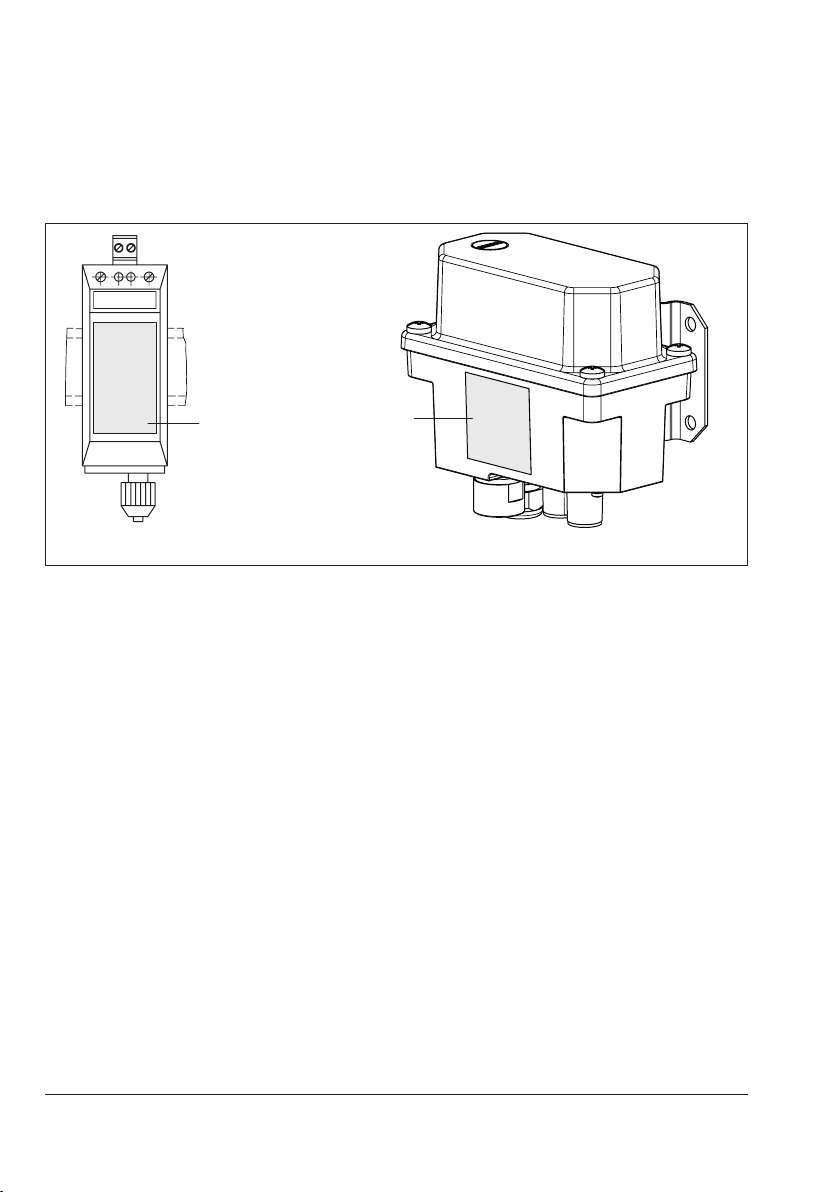

3 Design and principle of operation ................................................................12

3.1 Versions ......................................................................................................14

3.2 Technical data .............................................................................................16

3.3 Accessories .................................................................................................20

4 Measures for preparation............................................................................22

4.1 Unpacking ..................................................................................................22

4.2 Transporting and lifting ................................................................................22

4.3 Storage.......................................................................................................22

4.4 Preparation for installation............................................................................22

5 Mounting and start-up.................................................................................24

5.1 Installing i/p converters................................................................................24

5.1.1 Installing the rail-mounting unit .....................................................................24

5.1.2 Installing the eld unit...................................................................................24

5.2 Electrical connection.....................................................................................24

5.3 Pneumatic connection...................................................................................25

5.3.1 Connecting the rail-mounting unit..................................................................25

5.3.2 Connecting the eld unit...............................................................................25

5.4 Mounting the supply air manifold for rail-mounting units.................................25

5.4.1 Fastening the supply air manifold..................................................................26

5.4.2 Assembling the supply air manifold...............................................................26

5.4.3 Connecting several supply air manifolds ........................................................26

5.4.4 Mounting the i/p converter on the manifold ...................................................28