EB 6116 EN 7

General safety instructions

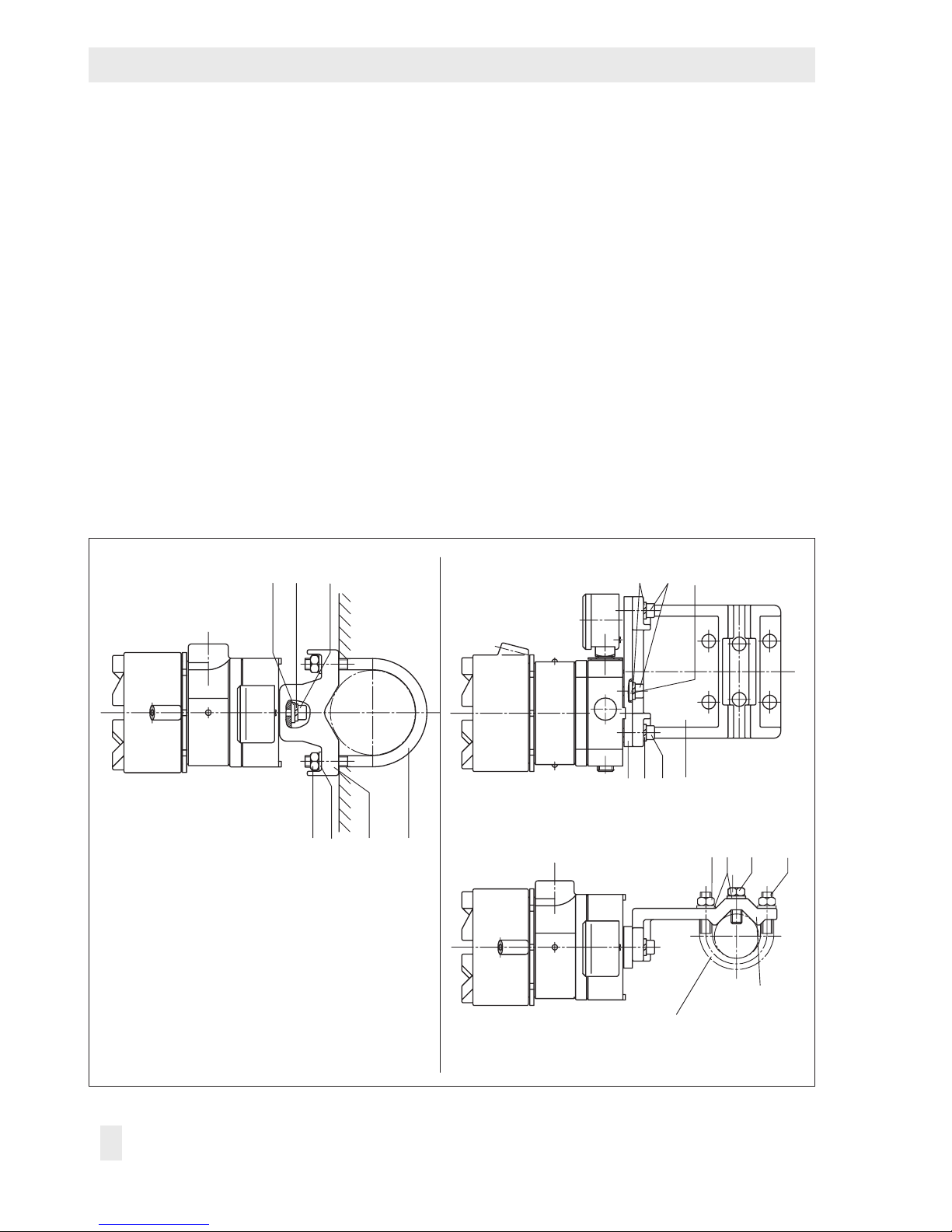

2.3 Principle of operation

See Fig.2 on page 6.

The device consists of an i/p converter mod-

ule and a downstream volume booster.

When operated, the supplied direct current i

ows through the plunger coil (2) located in

the eld of a permanent magnet (3). At the

balance beam (1), the force of the plunger

coil, which is in proportion to the current, is

balanced against the force of the dynamic

backpressure. The backpressure is produced

on the apper plate (6) by the air jet leaving

the nozzle (7).

The supply air (SUPPLY 8) ows to the bot-

tom chamber of the volume booster (8) and

a certain amount of air determined by the

diaphragm position ows past the sleeve (9)

and leaves through the output (OUTPUT 36).

As the input current and the forces acting on

the plunger coil increase, the apper (6)

moves closer to the nozzle (7). This causes

the backpressure and the cascade pressure

pK upstream of the restriction (8.2) to in-

crease until the cascade pressure corre-

sponds with the input current.

The increasing cascade pressure pushes the

diaphragm (10) and the plug sleeve (9)

downwards. As a result, the supply air caus-

es the output pressure pA to increase until a

new state of equilibrium is reached in the di-

aphragm chambers.

When the cascade pressure drops, the dia-

phragm moves upwards, releasing the plug

sleeve and thus allowing the output pressure

pA to escape through the venting (EXHAUST)

until the forces are equal again.

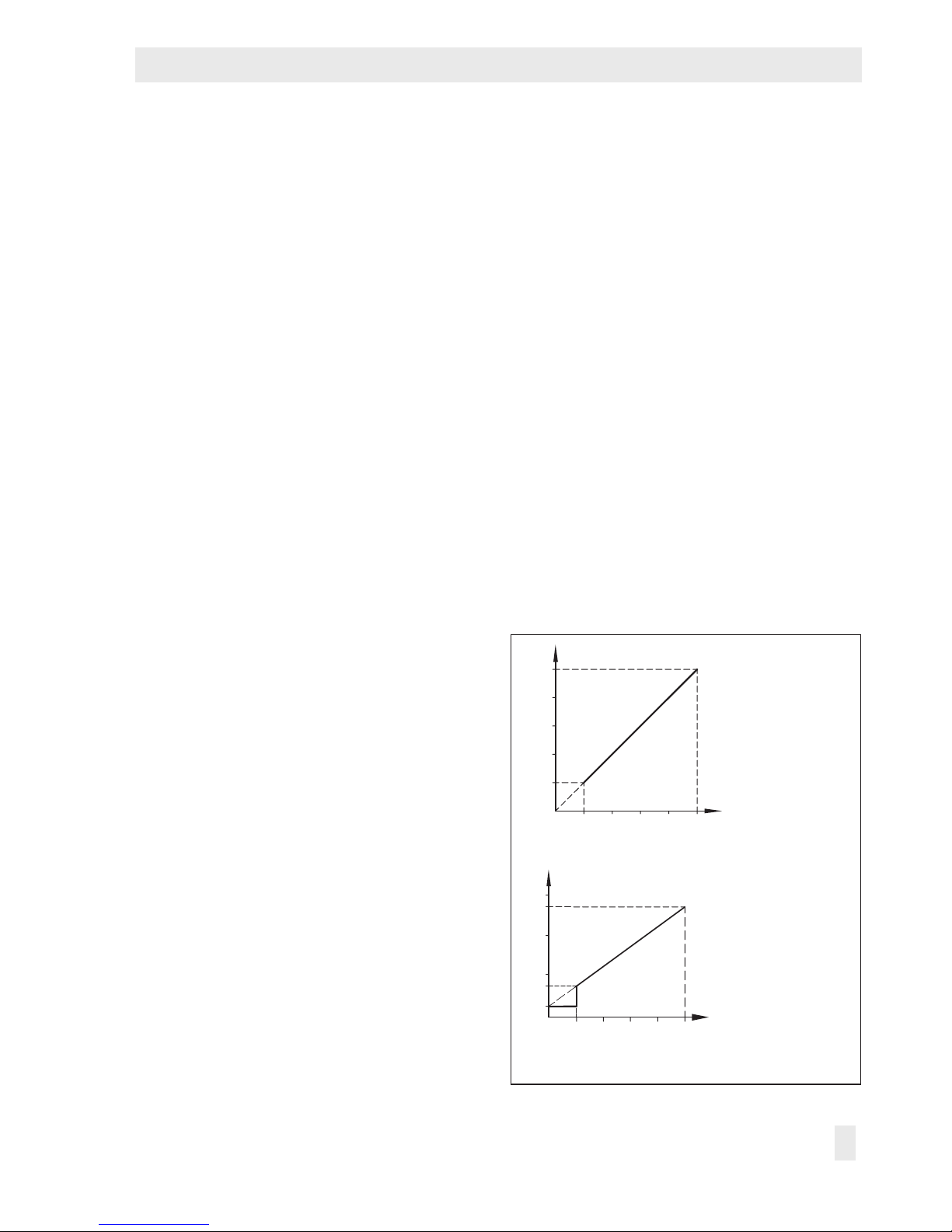

Switch-off electronics (see Fig.3)

Devices with an input range from 4 to

20mA have a slide switch which activates

the switch-off electronics. This function allows

the input signal to be set to 0mA when the

signal falls below the switching point of

4.08± tolerance. This causes the pneumatic

output to be vented to approximately

100mbar. This guarantees, for example, the

tight shut-off function of a valve.

This function requires a characteristic which

passes through the zero point, for example,

for the version with 4 to 20mA/0.2 to 1bar.

If the characteristic line does not pass

through zero, for example, for an allocated

output signal from 0.8 to 2.7bar, then the

pneumatic output is vented to a remaining

pressure of approx. 0.3bar when the

switch-off electronics are activated.

4812 16 20 m