Contents

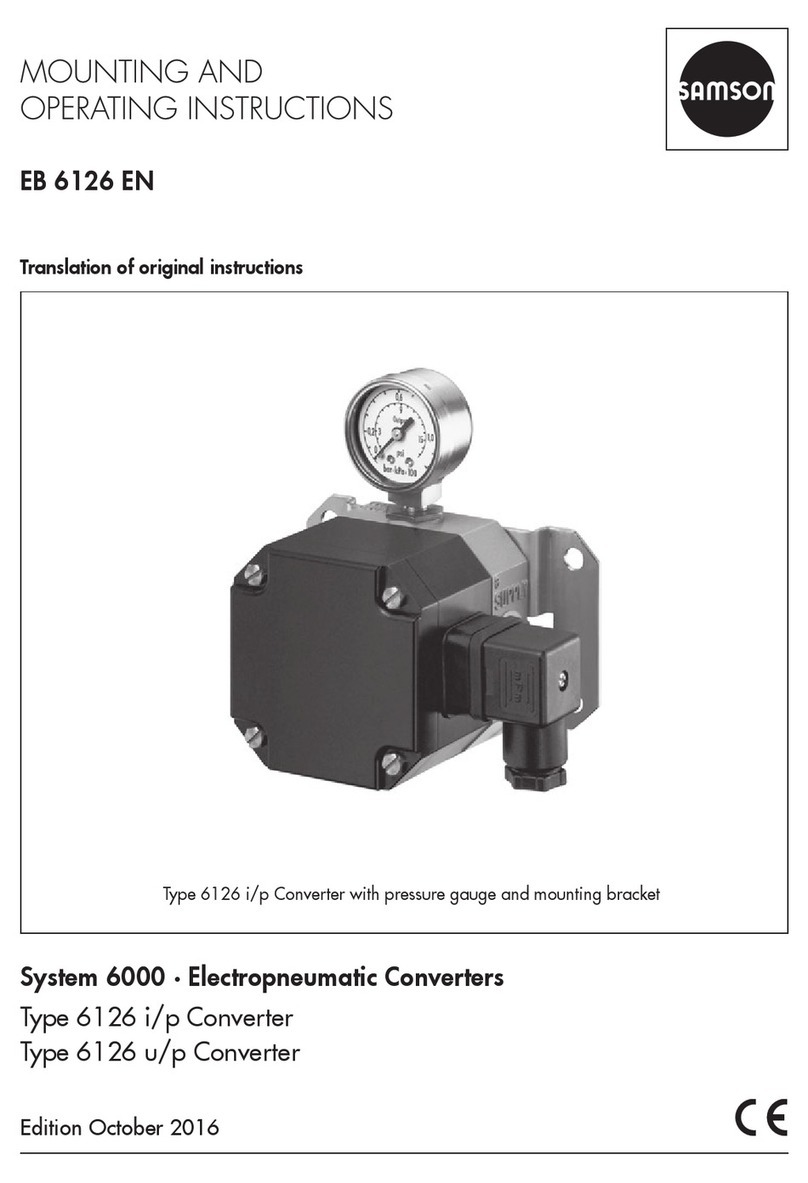

EB 6126 EN

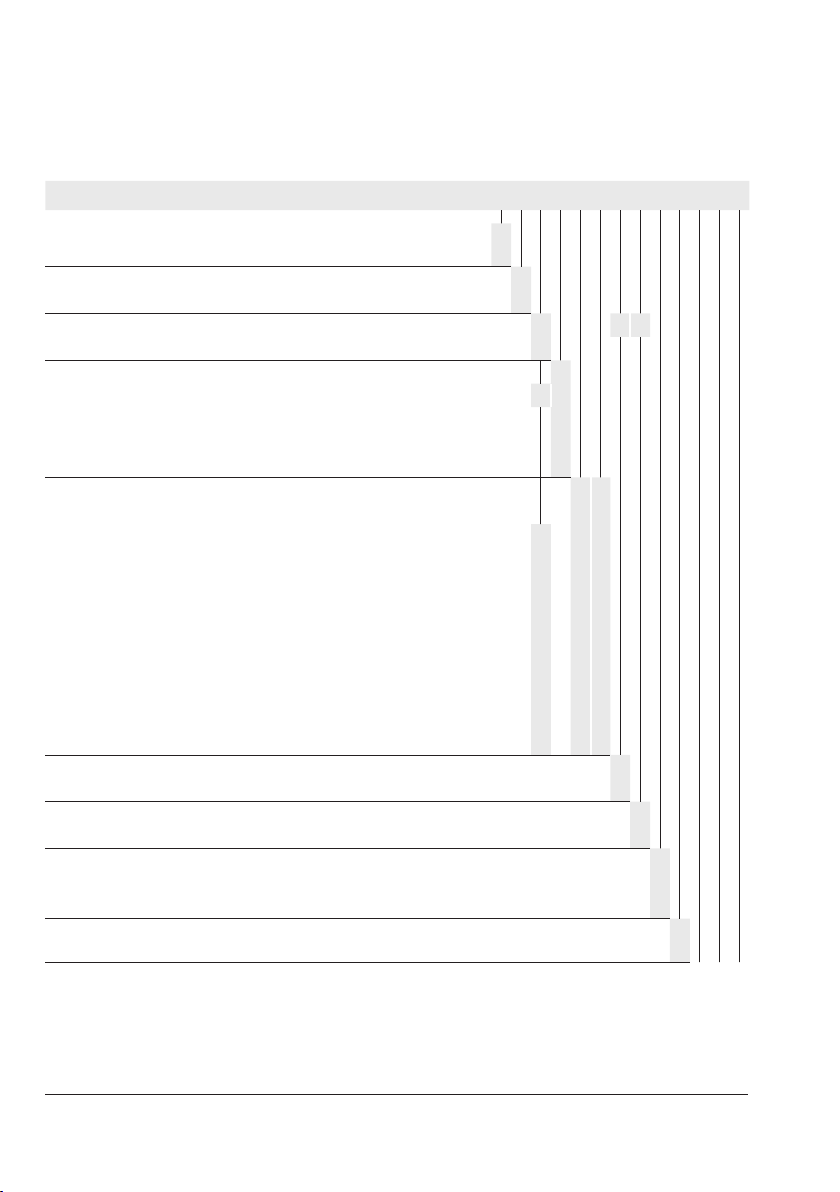

1 Safety instructions and measures ................................................................1-1

1.1 Notes on possible personal injury ................................................................1-3

1.2 Notes on possible property damage .............................................................1-4

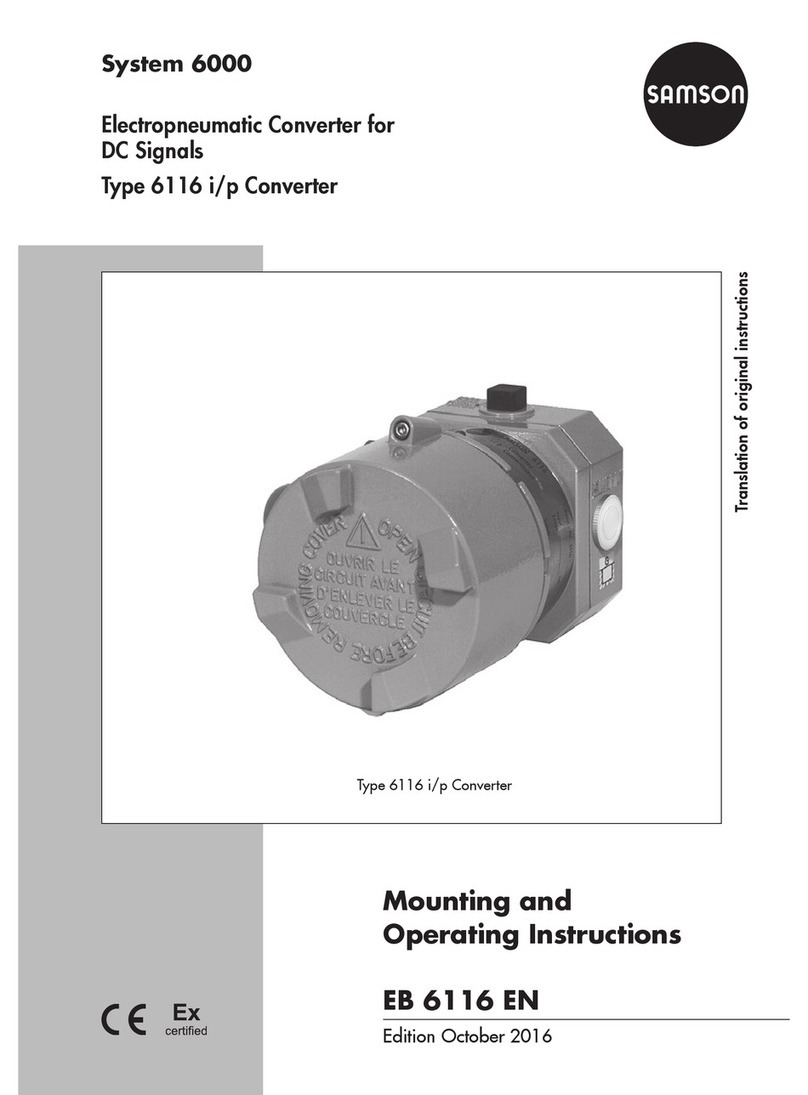

2 Marking on the device................................................................................2-1

2.1 Nameplate .................................................................................................2-1

2.2 Article code ................................................................................................2-2

3 Design and principle of operation ...............................................................3-1

3.1 Technical data ............................................................................................3-3

4 Shipment and on-site transport ...................................................................4-1

4.1 Accepting the delivered goods .....................................................................4-1

4.2 Remove the packaging from the converter. ....................................................4-1

4.3 Transporting the converter ...........................................................................4-1

4.4 Storing the converter ...................................................................................4-1

5 Installation.................................................................................................5-1

5.1 Installation conditions ..................................................................................5-1

5.2 Preparation for installation ...........................................................................5-1

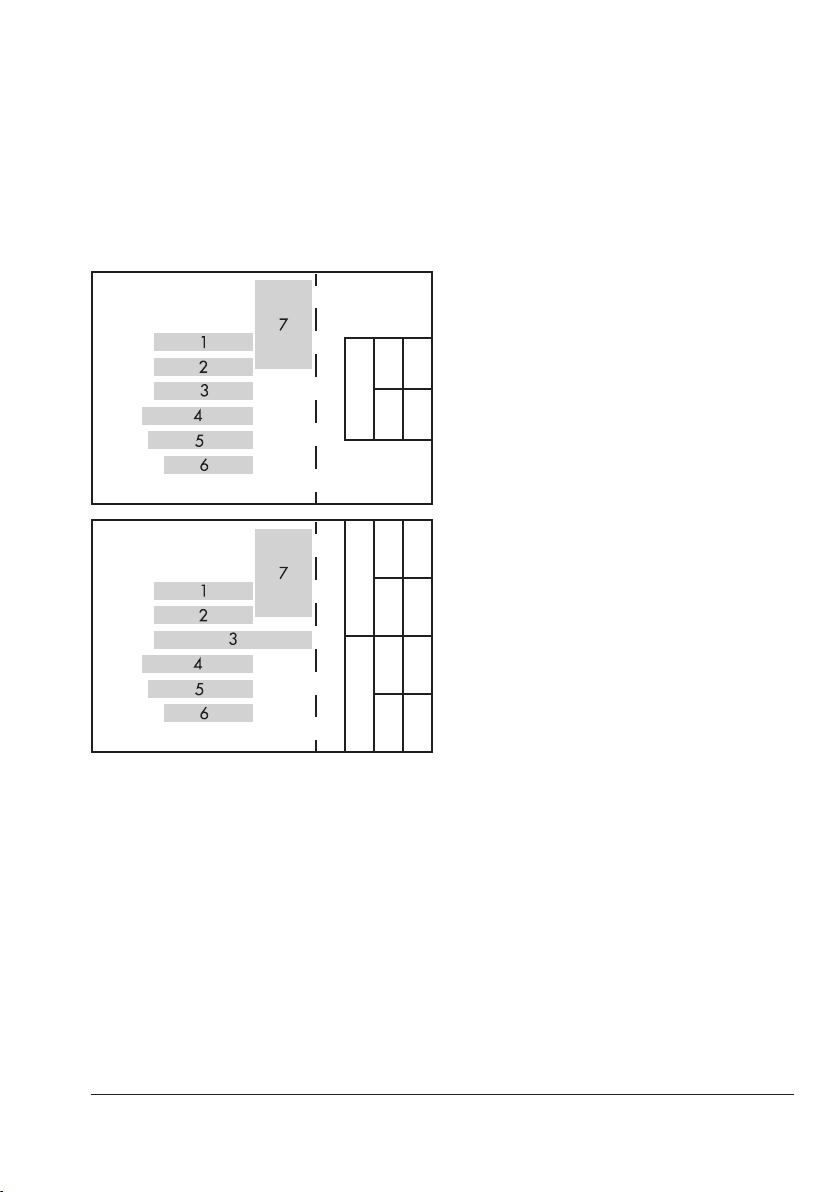

5.3 Mounting the converter ................................................................................5-2

5.4 Mounting accessories ..................................................................................5-4

6 Connections ...............................................................................................6-1

6.1 Establishing pneumatic connections ..............................................................6-1

6.2 Establishing electrical connections ................................................................6-1

7 Start-up .....................................................................................................7-1

7.1 Tuning zero and span ..................................................................................7-1

8 Operation..................................................................................................8-1

9 Malfunctions ..............................................................................................9-1

9.1 Troubleshooting ..........................................................................................9-1

9.2 Emergency action .......................................................................................9-2

10 Servicing..................................................................................................10-1

10.1 Periodic testing .........................................................................................10-1

11 Decommissioning .....................................................................................11-1

12 Removal ..................................................................................................12-1

13 Repairs ....................................................................................................13-1

13.1 Returning devices to SAMSON ..................................................................13-1