VENTILATION FAN

WARNING

READ AND SAVE THESE INSTRUCTIONS

Installer: Leave this manual with the homeowner.

Model: PCD110M

CAUTION

CLEANING & MAINTENANCE

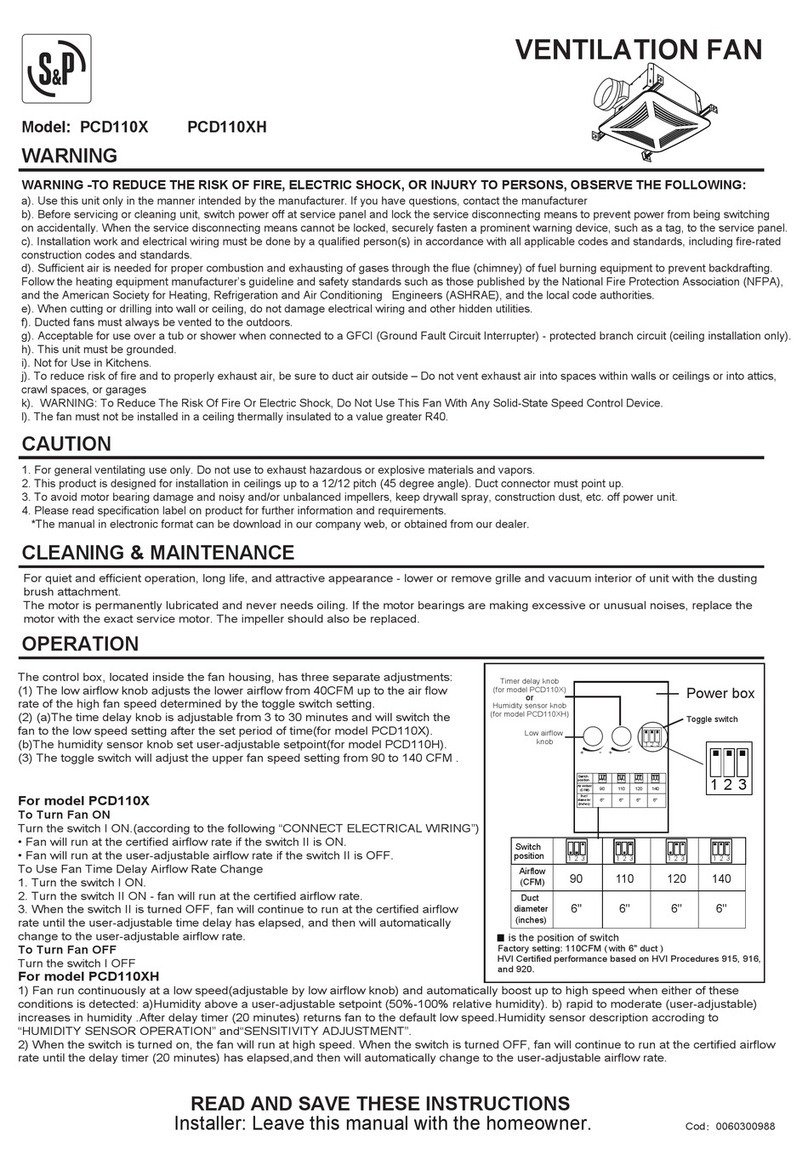

OPERATION

For quiet and efficient operation, long life, and attractive appearance - lower or remove grille and vacuum interior of unit with the dusting

brush attachment.

The motor is permanently lubricated and never needs oiling. If the motor bearings are making excessive or unusual noises, replace the

motor with the exact service motor. The impeller should also be replaced.

-

+-

+1 2 3

1 2 3

Toggle

switch

Power box

Low airflow

knob

Timer delay

knob

2 function wall control switch for fan and LED night light control respectivtly

80 90 110 120 90 110 120 140

1 2 31 2 31 2 31 2 31 2 31 2 31 2 31 2 3

6"

Switch

position

Duct

diameter

(inches)

Airflow

(CFM)

6"

6"

6"4"4"4"4"

80 90 110 120 90 110 120 140

1 2 31 2 31 2 31 2 31 2 31 2 31 2 31 2 3

6"

Switch

position

Duct

diameter

(inches)

Air deliver

(CFM)

6"

6"

6"4"4"4"4"

is the position of switch

Other airflow reference performance based on HVI

Procedures 915, 916, and 920.

Factory setting: 110CFM ( )

HVI Certified performance based on HVI Procedures 915,

916, and 920.

The control box, located inside the fan housing, has three separate

adjustments:

(1) The low airflow knob adjusts the lower airflow from 30CFM up to

the air flow rate of the high fan speed determined by the toggle switch

setting.

(2) The time delay knob is adjustable from 3 to 30 minutes and will

switch the fan to the low speed setting after motion is no longer

detected in the room for the set period of time.

(3) The toggle switch will adjust the upper fan speed setting from 80

to 120 CFM using a 4" duct, or 90 to 140 CFM using a 6" duct.

Both 4" & 6" duct adaptors are included.

with 6" duct

WARNING -TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

a). Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer

b). Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means to prevent power from being switching

on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

c). Installation work and electrical wiring must be done by a qualified person(s) in accordance with all applicable codes and standards, including fire-rated

construction codes and standards.

d). Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning equipment to prevent backdrafting.

Follow the heating equipment manufacturer’s guideline and safety standards such as those published by the National Fire Protection Association (NFPA),

and the American Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

e). When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

f). Ducted fans must always be vented to the outdoors.

g). Acceptable for use over a tub or shower when connected to a GFCI (Ground Fault Circuit Interrupter) - protected branch circuit (ceiling installation only).

h). This unit must be grounded.

i). Not for Use in Kitchens.

j). Install Fan At Least 2.5 m (8.2 feet) Above The Floor

k). To reduce risk of fire and to properly exhaust air, be sure to duct air outside – Do not vent exhaust air into spaces within walls or ceilings or into attics,

crawl spaces, or garages

l). WARNING: To Reduce The Risk Of Fire Or Electric Shock, Do Not Use This Fan With Any Solid-State Speed Control Device.

m). The fan must not be installed in a ceiling thermally insulated to a value greater R40

1. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

2. This product is designed for installation in ceilings up to a 12/12 pitch (45 degree angle). Duct connector must point up. DO NOT MOUNT THIS

PRODUCT IN A WALL.

3. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall spray, construction dust, etc. off power unit.

4. Please read specification label on product for further information and requirements.

*The manual in electronic format can be download in our company web, or obtained from our dealer.

Max 30CFM Max 3min

S T

-

+-

+

Max. 30CFM 30min 3min

S T