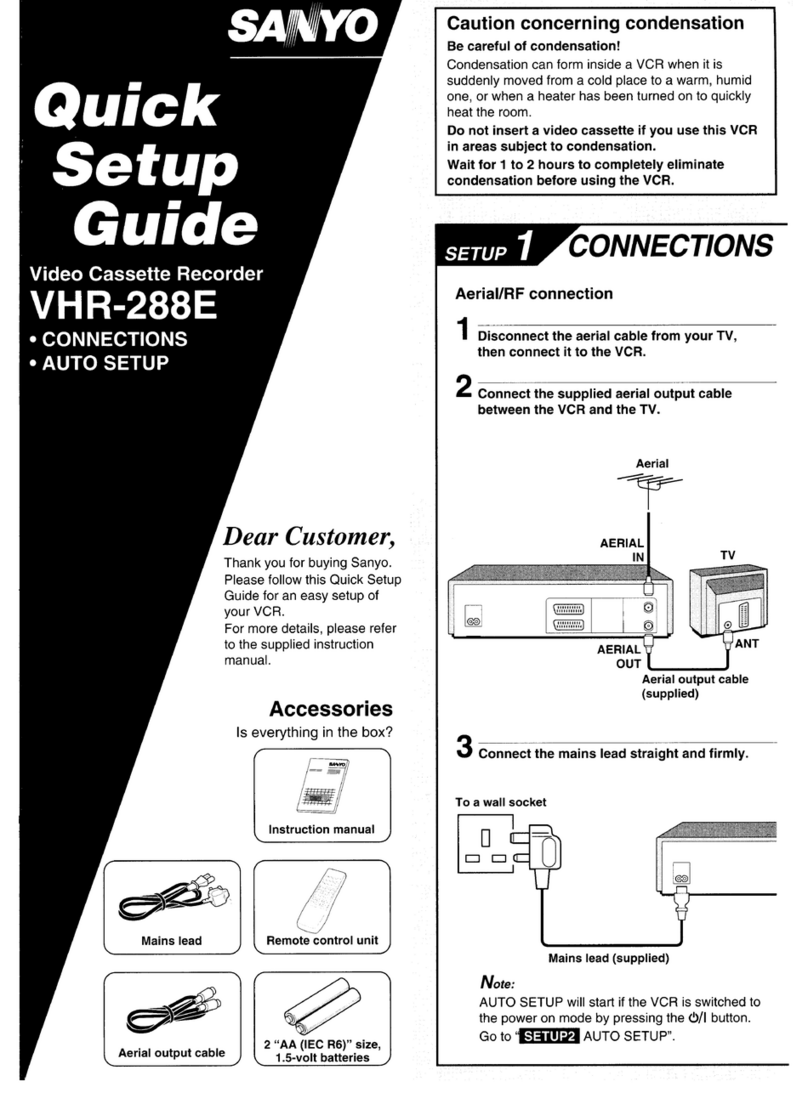

Sanyo VHR-495E User manual

Other Sanyo VCR System manuals

Sanyo

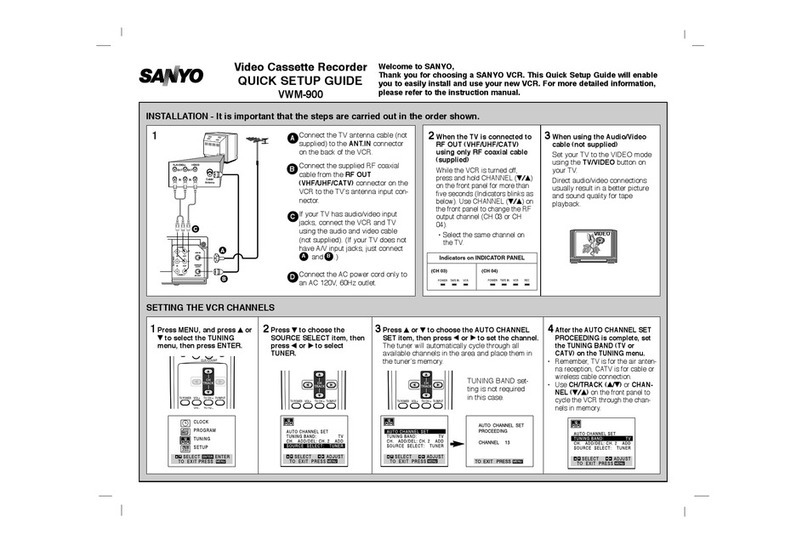

Sanyo VWM-900 User manual

Sanyo

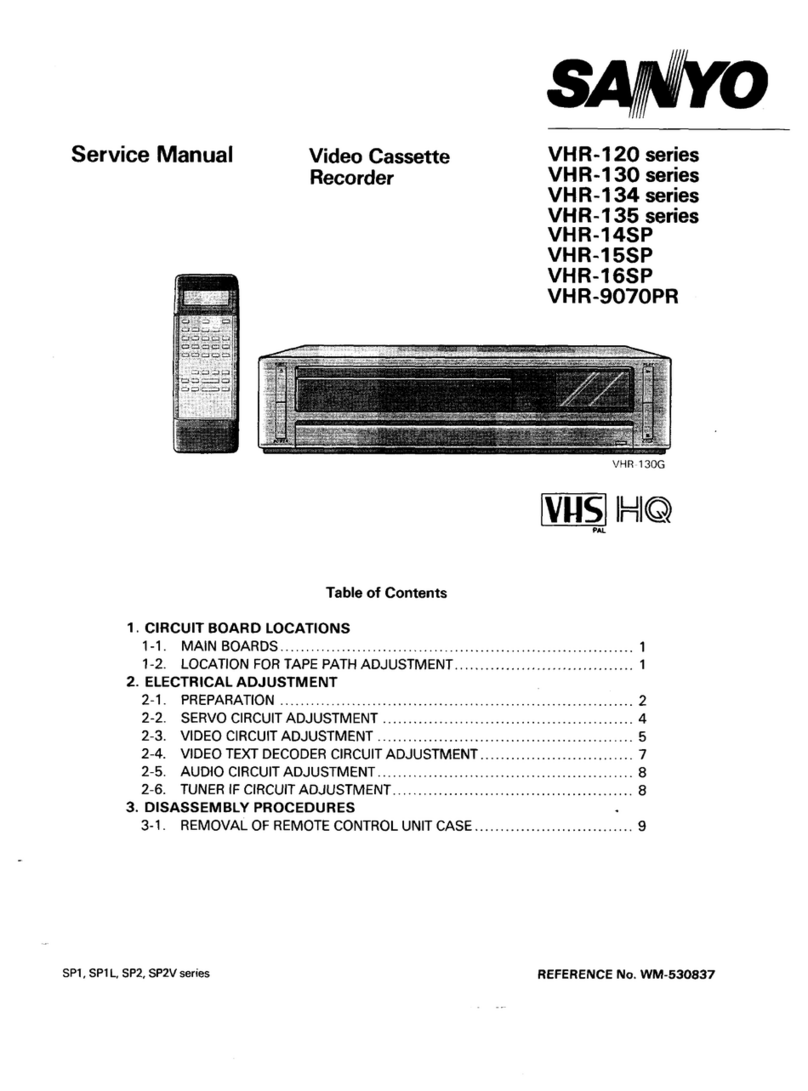

Sanyo VHR-120 Series User manual

Sanyo

Sanyo SRT-612DC User manual

Sanyo

Sanyo VHR-VK210A User manual

Sanyo

Sanyo HR-VX200 Manual

Sanyo

Sanyo VHR-770 User manual

Sanyo

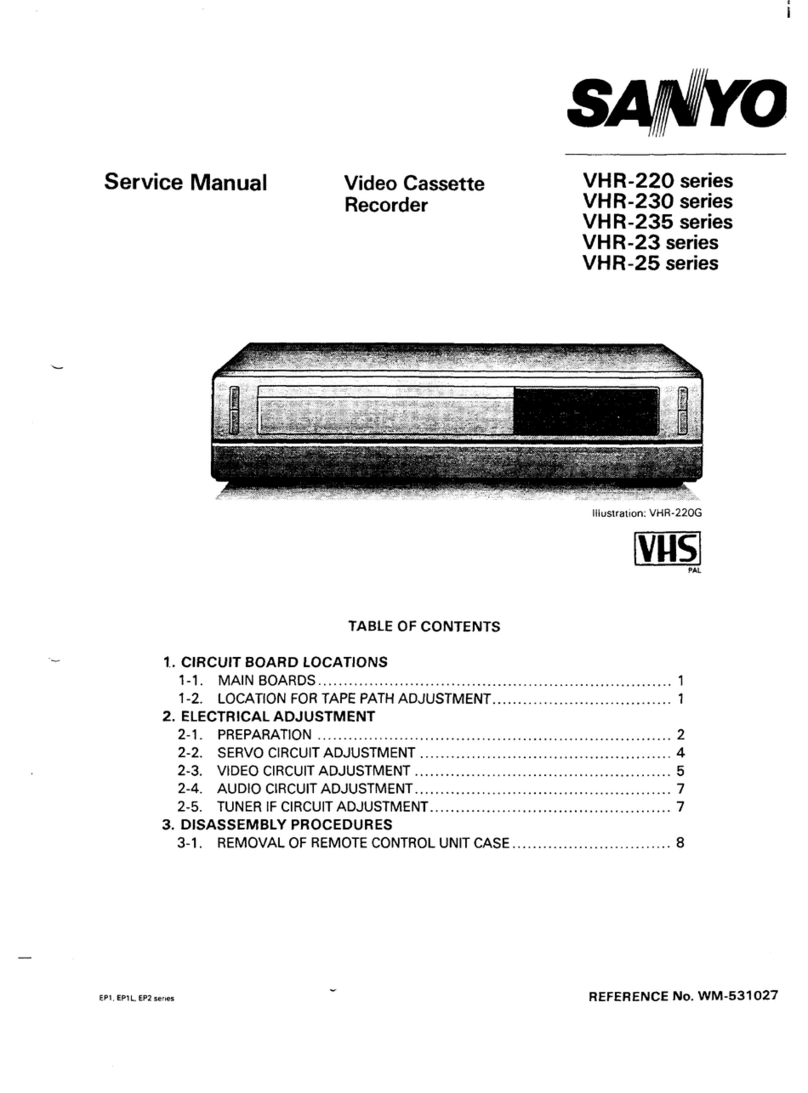

Sanyo VHR-220 series User manual

Sanyo

Sanyo VHR-150 User manual

Sanyo

Sanyo VWM-950 User manual

Sanyo

Sanyo VHR-650 User manual

Sanyo

Sanyo DTL-4800 Manual

Sanyo

Sanyo VHR-M262EV User manual

Sanyo

Sanyo 5300 - SCP Cell Phone User manual

Sanyo

Sanyo VHR-870 User manual

Sanyo

Sanyo SRC-850A User manual

Sanyo

Sanyo TLS-9960 User manual

Sanyo

Sanyo VHR-VX400 User manual

Sanyo

Sanyo SRC-850 User manual

Sanyo

Sanyo TLS-224P User manual

Sanyo

Sanyo VWM-900 User manual