4 5

Instruction Manual SC 2700 CentrifugeInstruction Manual SC 2700 Centrifuge

This symbol signals safety-relevant information and indicates possibly dangerous situations.

Only use the centrifuge if you have read this safety information.

Failure to observe this information can result in injury or damage.

Intended use includes compliance with all information in the instruction manual and

performance of required service and maintenance work. The centrifuge must be placed on a horizontal, vibration-free and levelled laboratory bench.

According to the recommendations of EN 61010-2-020, during centrifuging a clear safety

area of 30cm must be maintained, in which there are no objects whose destruction could

cause damage.

Under no circumstances must the centrifuge be placed in front of a window which is

exposed to intensive sunlight or in front of heating elements, as the attainable sample

temperatures are related to an average room temperature of +23°C.

1. Product description

1.1 Safety Information

1.2 Intended use

ThisHERMLEcentrifugeisusedtoseparatemixturesofsubstanceswithdierentdensities,especiallyforthe

preparation and processing of samples from the human body in the context of an in-vitro diagnostic application,

in order to enable the use of in-vitro diagnostic agents for their intended purpose. As an in-vitro diagnostic agent

(e.g. blood sample vial) can be used in the centrifuge, the centrifuge is considered to be an in-vitro diagnostic

device according to Directive (EU) 2017/746.

HERMLEcentrifugesareexclusivelyintendedforuseindoorsandforoperationbytrainedandqualied

personnel.

Only use original HERMLE rotors and accessories. Any other or further use is not deemed to be intended use.

HERMLE Labortechnik GmbH does not accept any liability for damage due to this cause.

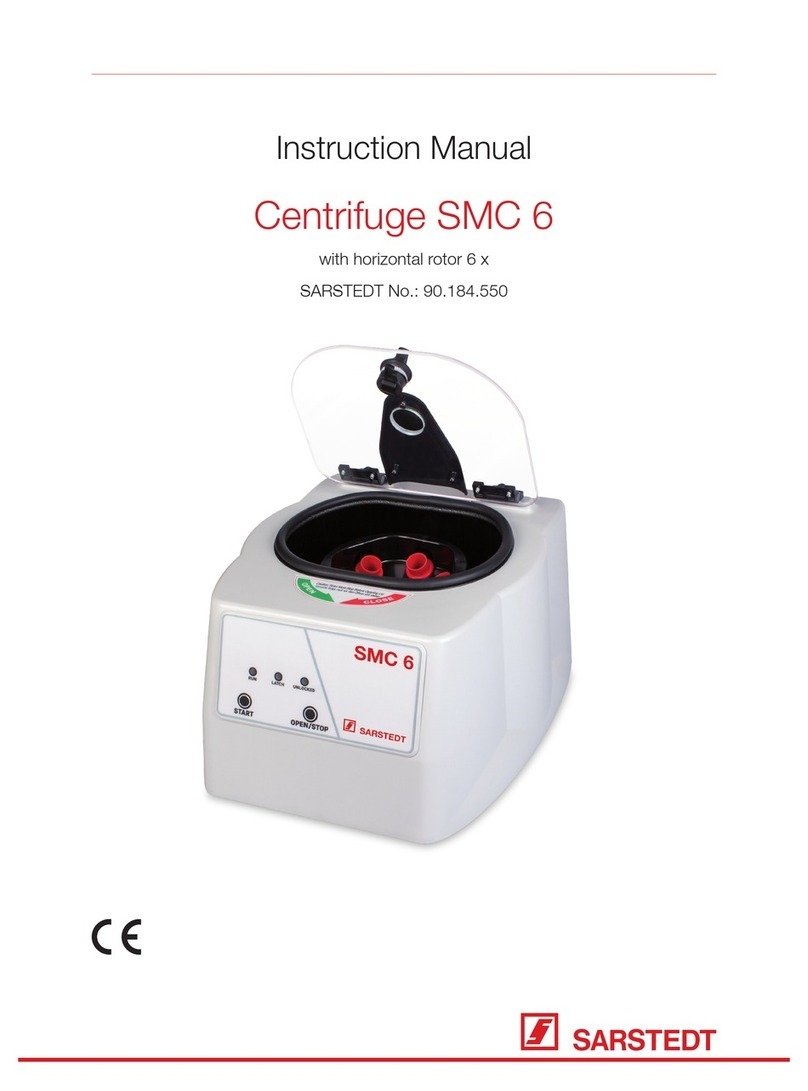

1.3 Brief Description

The SC 2700 device is a non-cooled centrifuge which can be operated with mains voltages of 100 - 230 V using

theappropriatemainscableforthespeciccountry.

A swing-out rotor is used in this centrifuge.

Allrelevantprogramswithxedorvariableparameterscanbecalledupwithkeys.Allsetvaluesarepermanently

displayed in the LCD display.

The centrifuge is powered by a maintenance-free brush-type motor.

Please refer to “Table 1: Technical data“ (see ANNEX Pg. 29) for detailed technical data.

1.4 Scope of Delivery

• 1 SC 2700 centrifuge

• 1 SC 2700 Instruction Manual

• 1 Swing-out rotor, 6-cavity

• 1 Set of sleeves

• 1 Mains cable

1.5 Installing the centrifuge

1.5.1 Unpacking

The SC 2700 centrifuge is delivered in a carton.

Remove the straps, open the carton and remove the centrifuge. The instruction manual which is enclosed with

the centrifuge must be kept at the installation location!

1.5.2 Space requirement

1.5.3 Installation

Proceed as follows:

- Check that the mains voltage matches the details on the type plate.

- The mains connection for the centrifuge must be equipped with a 10 A fuse

(Type K triggering characteristic for appliances).

- In case of emergency, mains disconnection with an emergency switch must be installed,

if possible outside of the room.

- Connect the mains plug to the mains (plug socket) (the plug socket for the connection cable

must be freely accessible or able to be disconnected at all times). Set the mains switch to

position I (see 2.2). Open the lid by pressing the LID / STOP key.

- Remove the transportation protective packaging from the chamber.