Operating esign

To set a parameter:

●Press the Qor qsoft key repeatedly

until the desired setting is selected

(displayed inversely)

●Confirm your selection:

press the lsoft key

To change the numeric value of

a parameter:

●Press the Qor qsoft key repeatedly,

if necessary, until the desired setting is

selected (displayed inversely)

●Enter a new value or character:

use the 0 1 … 9 . keys or the

akey and enter the desired letters

●Confirm your selection:

press the lsoft key

To exit Setup: press the oo soft key

Input

Bar Code Scanner or Keyboard Input

You can use a ar code scanner or an

external key oard to input alphanumer-

ic values. These inputs are processed

in the same manner as keypad inputs

on the display and control unit of the

scale. Bar code and key oard inputs

are only displayed; they cannot activate

any function.

To assign a ar code scanner or

key oard input to a function, press one

of the following soft keys:

– Lot

– Samples

– Measured values

– Sample num er

– Tare value

– Initial weight

– Backweighed value

– Sample ID

Foot or Hand Switch Input

You can connect a foot switch or a

hand switch to the scale to have this

device perform a keypad function

(such as cor t).

PC Input

You can use a computer to control

the functions of the weighing cell and

display and control unit via the com-

munications port (see the “Data Output

Function” section in the chapter

entitled “Operation”).

ata Output

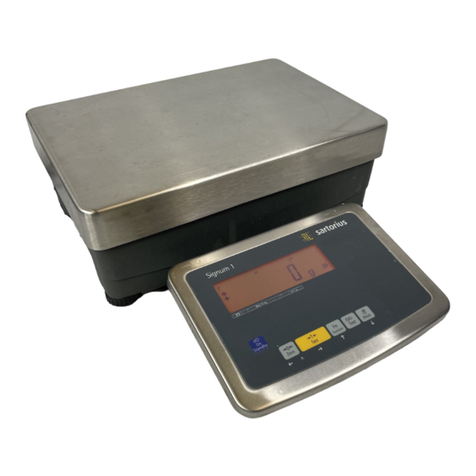

Your Factory scale is equipped with

an interface port for connecting your

choice of the following:

– Printer

– Peripheral device (e.g., computer)

– Universal remote control switch

Printer

You can configure the print functions

to meet your individual requirements y

selecting the corresponding menu code.

You can have printouts generated

automatically, or y pressing p;

dependent on or independent of the

sta ility or time parameters; with or

without IDs; and as standard or

ISO/GMP-compliant printouts.

ISO: International Organization for

Standardization

GMP: Good Manufacturing Practice

See the section on “Data Output

Functions” in the chapter entitled

“Operation” for a detailed description

of data output options.

Interface Port

Instead of a printer, you may choose

to connect a different peripheral device,

e.g. a computer (PC). With an on-line

PC you can control oth the weighing

cell and the display unit of the Factory

scale.

Request messages are sent via the

interface to initiate functions in the

weighing cell and in the display unit.

Some of the functions generate

response messages.

See the chapter entitled “Operation”

under the section on “Data Output” for

a detailed description of the interface

port.

Error Codes

If you press a key that has no function,

or which is locked at a certain point

in an application program, this error is

indicated as follows:

– a dou le- eep is sounded as an

acoustic signal if the key has no

function

– a dou le- eep is sounded and a

message is displayed for 2 seconds

in

the text line if the key function is not

availa le at that time

The response to an operator error is

identical in all models of the Factory

series. See the chapter entitled “Error

Codes” for a detailed description.

Storing Settings

Storing Parameter Settings

The settings configured are stored

in the scale’s non-volatile memory. The

most recent parameter settings are

active when you switch on the scale.

Saving Parameter Settings

You can assign passwords in order to

lock access to:

– Weighing parameters

– Device parameters

– Application parameters

– Factory settings

6