INTEGRA Installer Manual 3

•Monitoring effected by means of built-in telephone communicator to two monitoring

stations (four telephone numbers).

•Optional connection of additional communication modules, enabling monitoring with the

use of Ethernet (TCP/IP), GSM (GPRS technology) or ISDN networks.

•The control panel allows for monitoring in Contact ID format, as well as in several other

formats.

•Alarm messaging to telephones by means of voice messages or to a pager with text

messages. Reception of a message can be acknowledged with a code entered from the

telephone set keyboard (DTMF).

•Function of phone call answering, which enables checking the status of all control panel

partitions and controlling the status of outputs. It is performed after user identification

(each user may be assigned a special “telephone" password/code).

•Extended function of events printing, which enables the events to be sorted. Event

descriptions are in accordance with the Contact ID standard, hence the printouts from the

control panel correspond to those from the monitoring station. Besides, the names of

zones, modules and users are printed as they are defined in the system.

•Additional function of the control panel RS-232 port, i.e. controlling the external analog

modem, ISDN modem, GSM module, ISDN module and ETHM-1 module of SATEL

manufacture, enables communication to be established with the service computer. In this

case, the remote programming via telephone network or Ethernet as well as the service

are as quick as direct programming from the computer via RS-232 port.

•Possibility of time-based control owing to timers that operate on week work cycle, with an

option to define exception periods. Additionally, each partition is provided with its own

timer (based on week or day cycle), programmed by the suitably authorized user, to

secure automatic arming and disarming.

•Facilitated performance of non-standard functions due to a possibility to make complex

logic operations at outputs.

•High-capacity event log where, in addition to the monitored events, also other events (like

user access, functions used, etc.) are stored.

•Internal program structure allows to process all the incoming events. Because of the

processing power, there's no need to individually prioritize particular signals.

•Shared indicators (like the LCD display) use the following display priority for the zone state

(listed from highest to lowest priority): Bypass, Fault, Tamper Alarm, Intruder Alarm,

Tamper violation, Intruder violation, Tamper memory, Intruder memory, Zone OK.

3. System Components

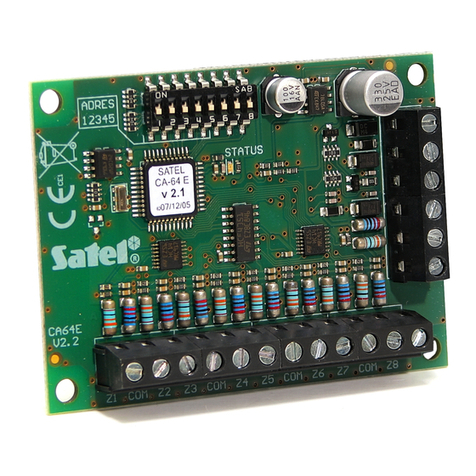

3.1 Mainboards

Show in the table below are technical parameters of the alarm systems based on particular

control panels of the INTEGRA family.

Technical parameter (quantity) INTEGRA

24

INTEGRA

32

INTEGRA

64

INTEGRA

128

Security Grade 3

Available messaging options A, B, C

Zones, mainboard 4 8 16 16

Zones, system 24 32 64 128

High-current outputs, programmable,

mainboard 2 2 4 4