Table of Contents

CG4 Series ServiceManual Page i

TABLE OF CONTENTS

Introduction................................................................................................................1 - 1

1.1 About this Manual........................................................................................................ 1 - 2

1.2 Features of the Printer................................................................................................. 1 - 2

1.3 Parts Identification ....................................................................................................... 1 - 3

General Specifications..............................................................................................2 - 1

2.1 Printer Basic Specifications ......................................................................................... 2 - 1

2.2 Optional Accessories Specifications............................................................................ 2 - 7

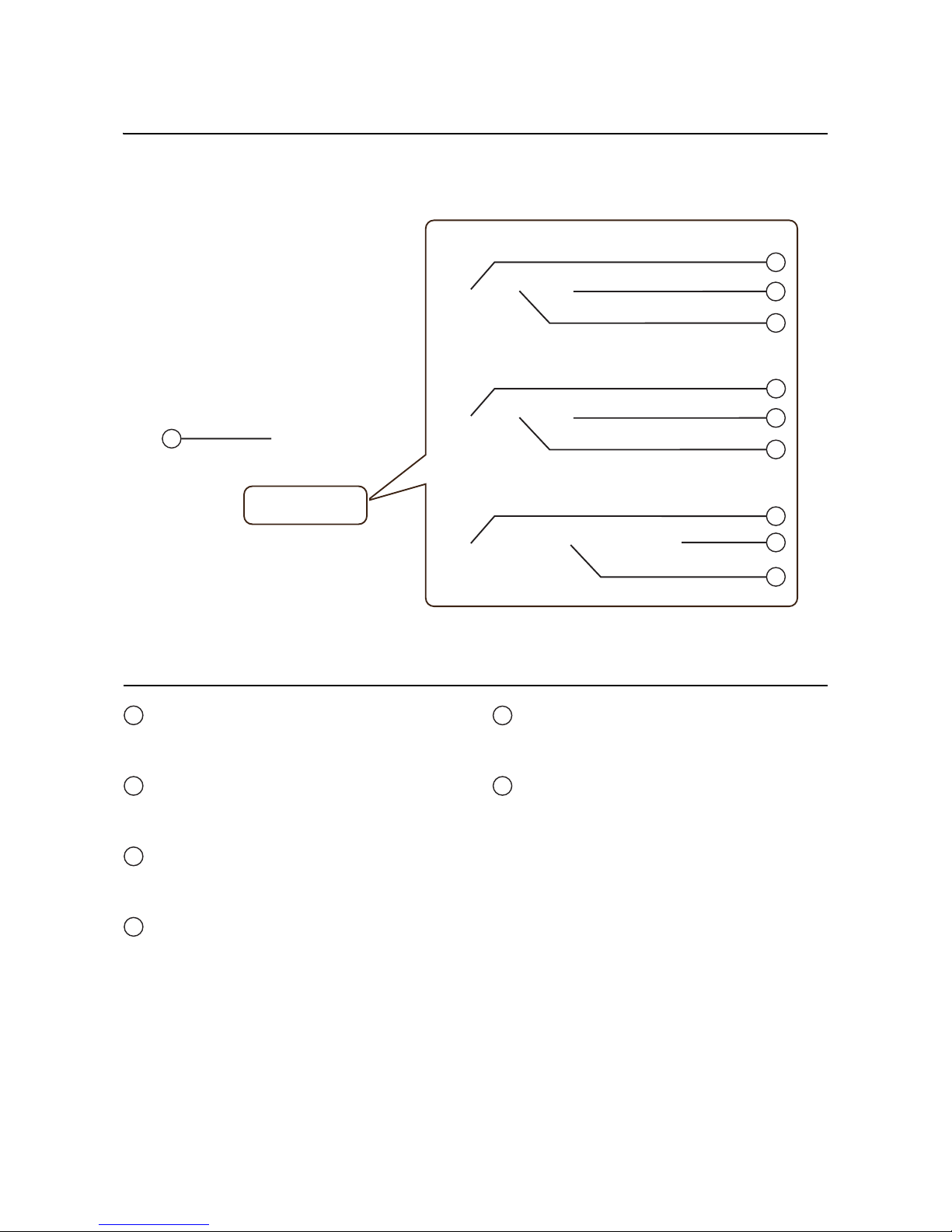

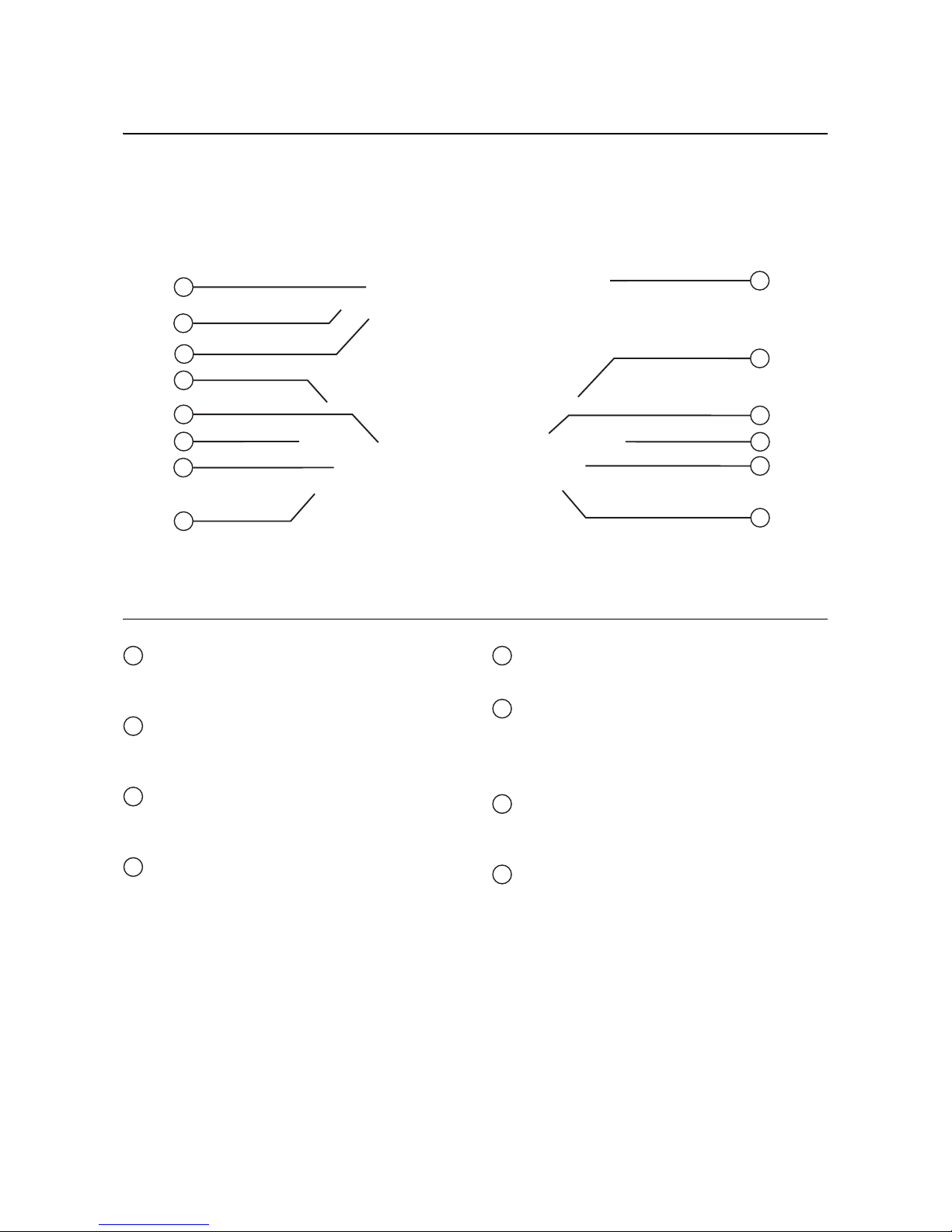

Interface Specifications............................................................................................3 - 1

3.1 Interface types ............................................................................................................. 3-1

3.2 RS232C Serial Interface.............................................................................................. 3 - 2

3.3 IEEE 1284 Parallel Interface........................................................................................ 3 - 8

3.4 Universal Serial Bus (USB) Interface......................................................................... 3 - 13

3.5 Local Area Network (LAN) Ethernet........................................................................... 3 - 15

Operation and Configuration....................................................................................4 - 1

4.1 Operator Panel............................................................................................................. 4 - 2

4.2 Operating Modes ......................................................................................................... 4 - 3

4.3 User Test Print Mode................................................................................................... 4 - 6

4.4 Factory Test Print Mode............................................................................................. 4 - 10

4.5 Operation Setting Mode............................................................................................. 4 - 13

4.6 Program Download Mode.......................................................................................... 4 - 15

4.7 Font Download Mode................................................................................................. 4 - 17

4.8 Default Setting Mode ................................................................................................. 4 - 18

4.9 HEX Dump Mode....................................................................................................... 4 - 18

4.10 Boot Download Mode............................................................................................... 4 - 19

4.11 Error Occurrence While Downloading...................................................................... 4 - 20

4.12 Factory Clear Mode ................................................................................................. 4 - 21

4.13 Factory Adjustment Mode........................................................................................ 4 - 24

4.14 Factory USB Interface Mode.................................................................................... 4 - 28

4.15 Factory USB Boot Download Mode......................................................................... 4 - 29

4.16 Printer Configurations Setting.................................................................................. 4 - 30

Troubleshooting........................................................................................................5 - 1

5.1 Error Signal Troubleshooting....................................................................................... 5 - 2

5.2 Troubleshooting Flowchart........................................................................................... 5 - 4

5.3 Interface Troubleshooting.......................................................................................... 5 - 14

5.4 Test Print Troubleshooting......................................................................................... 5 - 15

Checks and Adjustment Procedures.......................................................................6 - 1

6.1 Checking the Power Supply......................................................................................... 6 - 2

6.2 Automatic Adjustment of I-Mark and GAP Sensor Outputs ......................................... 6 - 3

6.3 Sensor checks ............................................................................................................. 6 - 3

6.4 Ribbon Tension Adjustment (For CG408TT, CG412TT only)...................................... 6 - 4

6.5 Pitch position Adjustment............................................................................................. 6 - 5

6.6 Offset position Adjustment........................................................................................... 6 - 6

6.7 Print Darkness Adjustment .......................................................................................... 6 - 7