SATO CL408/412 Service Manual

Table Of Contents

SECTION 1. INTRODUCTION Page

Installation Considerations............................................ 1-1 1

Ribbon.............................................................................. 1-2 2

Dimensions...................................................................... 1-3 2

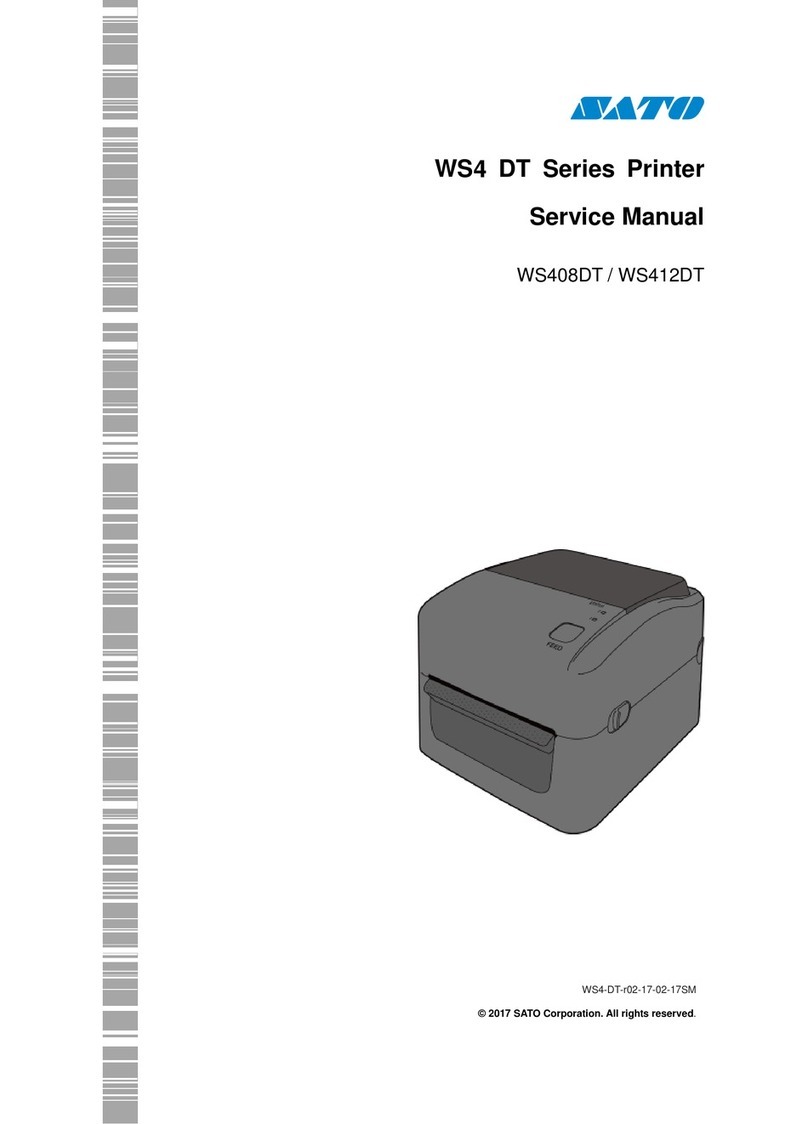

Component Designations............................................... 1-4 3

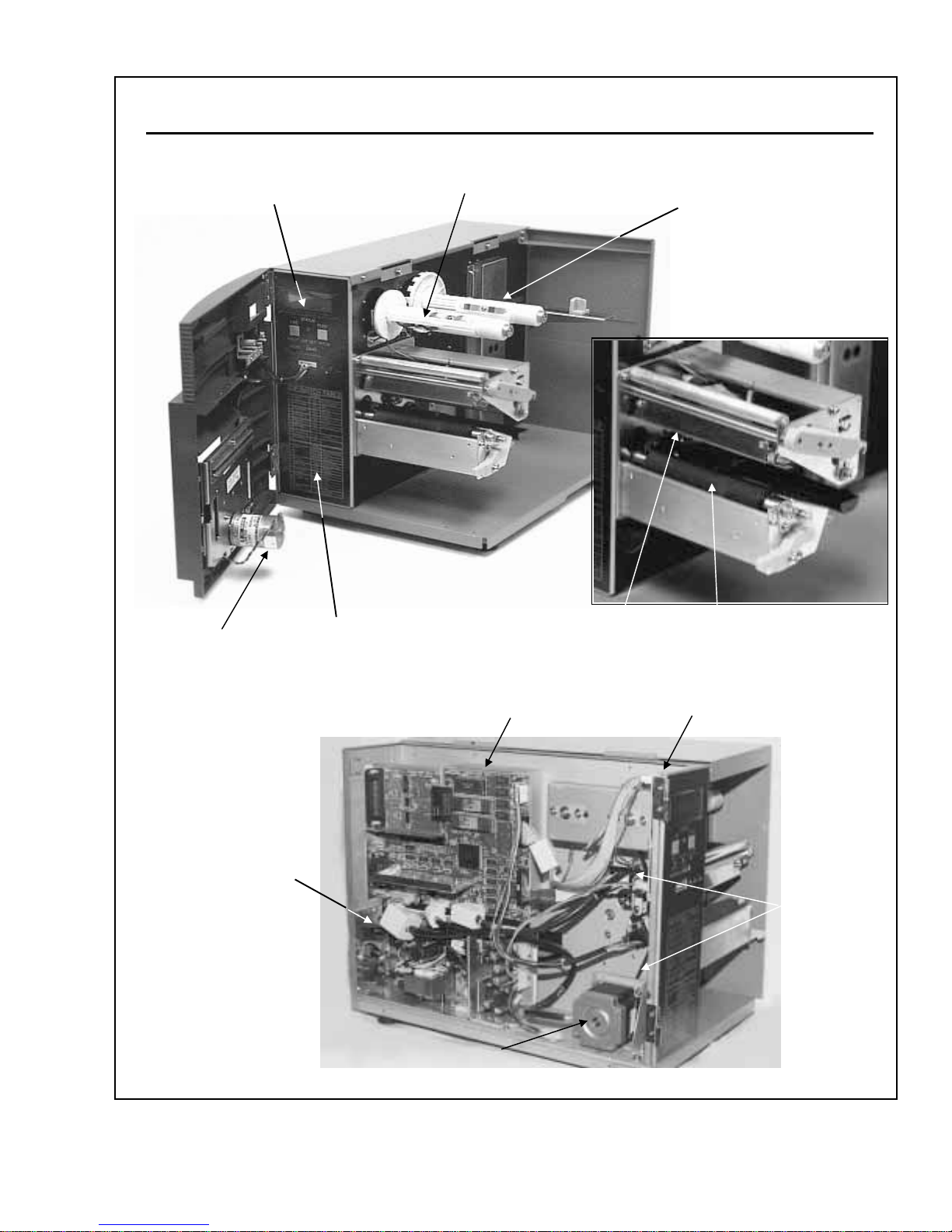

Interface Connections, Input Output Panel .................. 1-5 4

Switches and Sensors.................................................... 1-6 5

SECTION 2. PRINTER CONFIGURATION

Dip Switch Settings ........................................................ 2-1 9

Default Settings.............................................................. 2-2 19

Printer Adjustments........................................................ 2-3 20

Printing Test Labels........................................................ 2-4 33

SECTION 3. SPECIFICATIONS

Print.................................................................................. 3-1 35

Media, Sensing and Ribbon........................................... 3-2 36

Printer Controls and Signals, Adjustments and

Interface Connections ................................................... 3-3 37

Processing ...................................................................... 3-4 38

Character Fonts .............................................................. 3-5 38

Bar Codes and Other Features...................................... 3-6 39

Physical ........................................................................... 3-7 40

Optional Accessories..................................................... 3-8 41

SECTION 4. TROUBLESHOOTING

Troubleshooting Tables ................................................. 4-1 43

Head Pattern Examples.................................................. 4-2 47

SECTION 5. ELECTRICAL CHECKS AND ADJUSTMENTS

Power Supply Checks .................................................... 5-1 52

Reflective Label Pitch Sensor Adjustment................... 5-2 54

See Through Label Pitch Sensor Adjustment.............. 5-3 55