Warning: This equipment complies with the requirements in Part 15 of FCC rules for a Class A

computing device. Operation of this equipment in a residential area may cause unacceptable

interference to radio and television reception requiring the operator to take whatever steps nec-

essary to correct the interference.

All rights reserved. This document, nor any part of it, may be reproduced or issued to third parties

in any form without the express permission of SATO America, Inc. The material in this document

is provided for general information only and is subject to change without notice. SATO America,

Inc. does not assume responsibility for any errors or omissions.

06 Nov 03

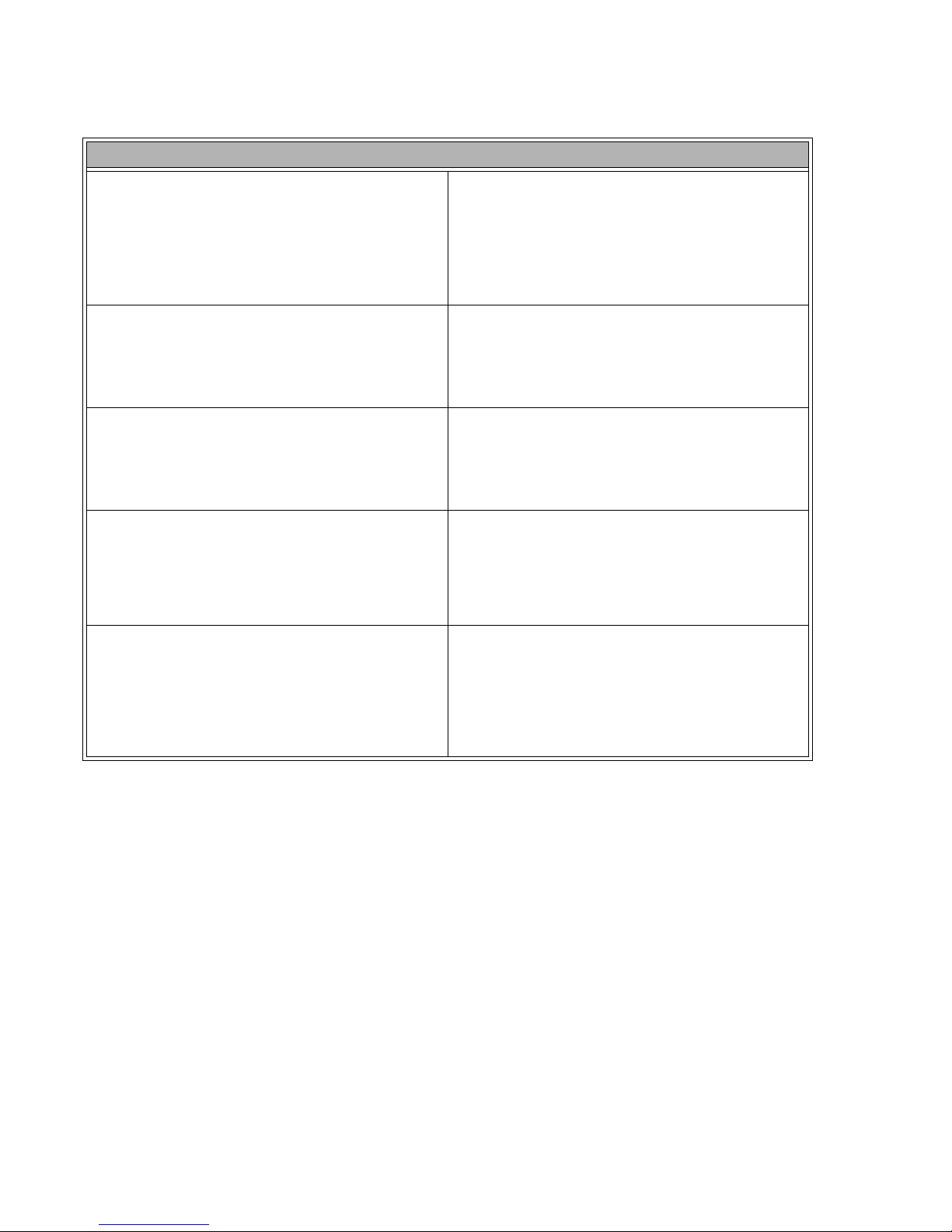

SATO GROUP OF COMPANIES

BARCODE SATO

INTERNATIONAL PTE LTD

438A Alexandra Road #05-01/ 02,

Alexandra Technopark,

Singapore 119967

Tel: 65-6271-2122

Fax: 65-6271-2151

Website: www.barcodesato.com

SATO AMERICA INC.

10350 Nations Ford Road Suite A,

Charlotte, NC 28273

Tel: 1-704-644-1650

Fax: 1-704-644-1662

Website: www.satoamerica.com

SATO UK LTD

Valley Road, Harwich, Essex England

Co12 4RR, United Kingdom

Tel: 44-1255-240000

Fax: 44-1255-240111

Website: www.satouk.com

Email: enquiries@satouk.com

SATO EUROPE NV

Leuvensesteenweg 369, 1932 Sint- Stevens-Woluwe, Brussels, Belgium

Tel: 32 (0)-2-788-80-00

Fax: 32 (0)-2-788-80-80

Website: www.sato-europe.com

SATO DEUTSCHLAND GMBH

Schaberweg 28, 61348

Bad Homburg, Germany

Tel: 49 (0)-6-1726-8180

Fax: 49 (0)-6-1726-818-199

Website: www.sato-europe.com

SATO POLSKA SP Z O.O.

Ul Okolna 2, 50-422 Wroclaw

Tel: 48-71-335-23-20

Fax: 48-71-335-23-25

Website: www.sato-europe.com

SATO SHANGHAI CO, LTD

11 Floor, D, Pudong South Road 1111,

Pudong New Area, Shanghai,

China 200120

Tel: 86 (0)-21-58307080

Fax: 86 (0)-21-58307978

Website: www.barcodesato.com

BAR CODE SATO ELECTRONICS (S) PTE LTD

438A Alexandra Road #05-01/02,

Alexandra Technopark, Singapore 119967

Tel: 65-6271-5300

Fax: 65-6273-6011

Website: www.barcodesato.com

www.satosingapore.com

Email: sales@satosingapore.com

SATO BAR CODE & LABELLING

SDN BHD

Suite B-08-11&12, Block B Plaza Mont' Kiara, No.2, Jalan Kiara Mont'

Kiara,

50480 Kuala Lumpur, Malaysia

Tel: 60-3-6203-5950

Fax: 60-3-6203-1209

Website: www.barcodesato.com

BARCODE SATO (THAILAND) CO., LTD

370/8 Supattra Building, 5th Floor, Rama9 Road, Bangkapi, Huay Kwang

Bangkok 10320, Thailand

Tel: 662-719-7780-3

Fax: 662-719-7784

Website: www.barcodesato.com

Email: sales@satothailand.co.th