8

2 SETTING UP

2.1 Using the 275 user interface

Operationkeys

Thesixoperationkeysarelocatedabovethealphanumeric

keyboard:

The ON/OFF key (I/O) switches the user interface on and

off. When you switch the user interface on, it starts looking

for a HART®transmitter connected to it. If the transmitter is

not found, the message “No Device Found. Press OK”

will be displayed.

TheONLINEmenuisdisplayedwhentheuserinterface

findsthetransmitter.

(^) This key allows you to move upwards in menus and

scroll lists forwards.

(v) This key allows you to move downwards in menus and

scroll lists backwards.

(<) This two-function key allows you to move the cursor to

the left and to go back to a previous menu.

(>) This two-function key allows you to move the cursor to

the right and to select a menu option.

(>>>) The quick-selection key will start the user interface

and display the quick-selection menu. You can define the

desiredmenuasquick-selectionmenu.

Functionkeys

With function keys F1, F2, F3 and F4 you can perform the

programfunctionsdisplayedaboveeachfunctionkey.When

youmove in the softwaremenus,the functions of these

keys will change in accordance with the currently selected

menu.

2.2 Setting up through HART® 275 user

interface

After installing and connecting the transmitter, connect the

userinterfacetothetransmitter.Thefollowingmenu is

displayed:

1 Measurement

2 Configuration

3 Information

4 Diagnostics

Tochangethe measuringrange,unitdampingtimeconstant

tooutputmode(linear/square-root),selectConfiguration.

Thefollowingmenuisthendisplayed:

1 Range values

2 Detailed config

To change the measuring range, select Range values.

Theselectiondisplaysthe followingmenu:

1 LRV (lowerrangevalue)

2 URV (upperrangevalue)

3 LSL (lowersensorlimit)

4 USL (uppersensorlimit)

5 Min span (minimumspan)

6 Apply values

To change the measurementunit, damping timeconstant or

output mode, select Detailed config from the Configura-

tionmenu.

Theselectiondisplays thefollowingmenu:

1 Damping

2 Pres. unit

3 Tempr. unit

4 Alarm current

5 Write protect

6 Lin. func

7 DiffElstatus

8 Burst mode

9 Burst option

Poll addr

Tag

User function

User funct. setup

After these activities or if the transmitter is supplied with the

ready configuration youmust correct a zeroerror of the

transmitter in a final installation position.

Press Diagnostics and PV Zero calibr.

The selection displays the following menu: Give correct

value for Zero pressure in ...

The current zero point will be shown in display and the final

zeroerrorcorrectioncanbedone.

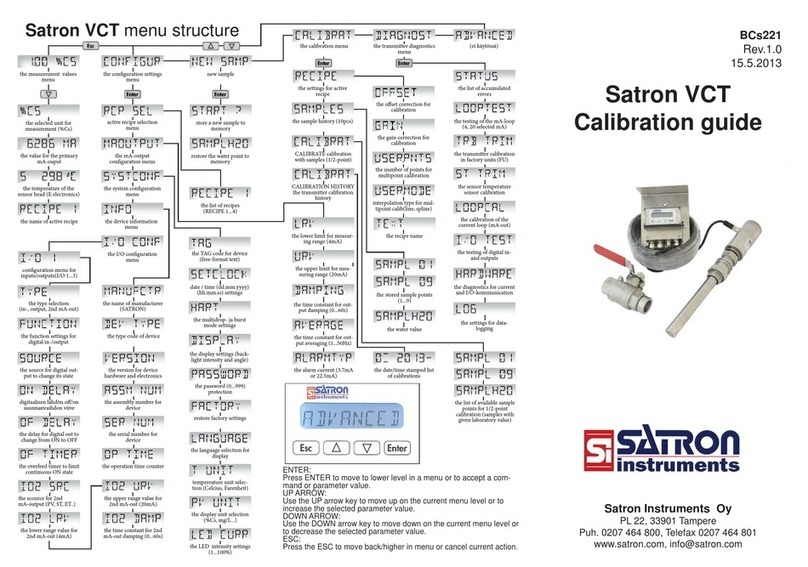

Figure 2-1

275userinterface

BPLV700AV

2006-12-19SATRON VG pressure transmitter