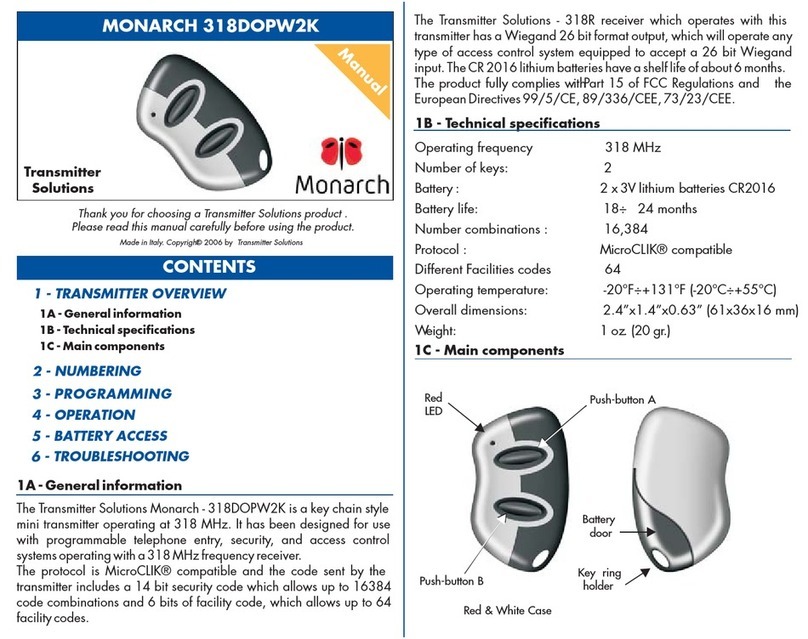

Programming with HART modem.

UK

Programmering med HART-modem.

DK Programmation par modem HART.

FR

Programmierung mit HART-Modem.

DE

13 (23)

12 (22)

FileProductInputOutputCommunicationLanguageOption08:30:00

PRetop5331

Date:1994-8-10

943201594

PRelectronics

AnaloginputAnalogoutput

Serialno:

Inputtype:Outputtype:4-20mA

Upscale

Sensorerror:

Pt100DIN/IEC

0.00-50.00C

3-wire

1.00sec

------

Inputrange:

Connection:

Coldjunctioncomp:

Responsetime:

Tagno:

6335

44

43

42

41

51

12

111

2

1

3

1

4

+Vsupply

Input

Receiving

equipment

Rload > 250 Ω, < 1100 Ω

HARTmodem

63xx

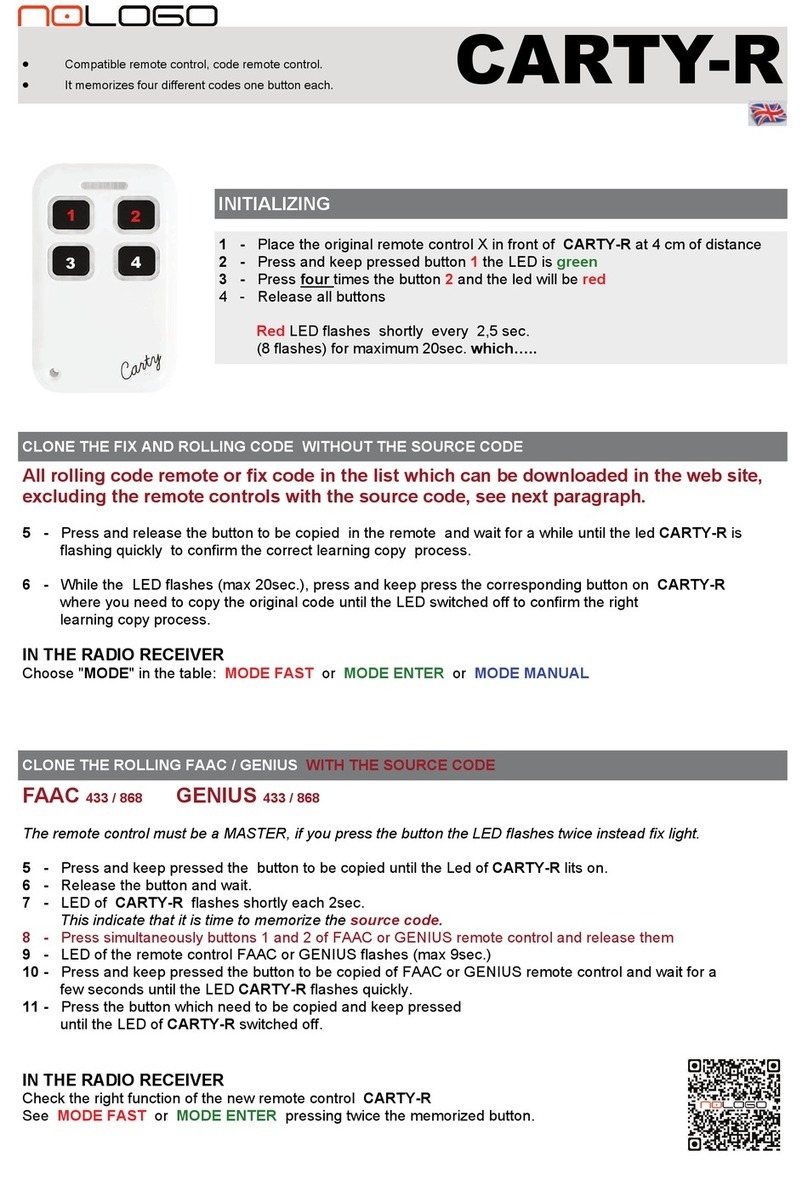

Programming with HART communicator.

UK

Programmering med HART-kommunikator.

DK Programmation par communicateur HART.

FR

Programmierung mit HART-Kommunicator.

DE

6335

44

43

42

41

51

12

111

2

1

3

1

4

13 (23)

12 (22)

Safearea

+Vsupply

Input

Receiving

equipment

area

Rload > 250 Ω, < 1100 Ω

63xx

6334

13 (23)

11 (21)

*

*

Loop

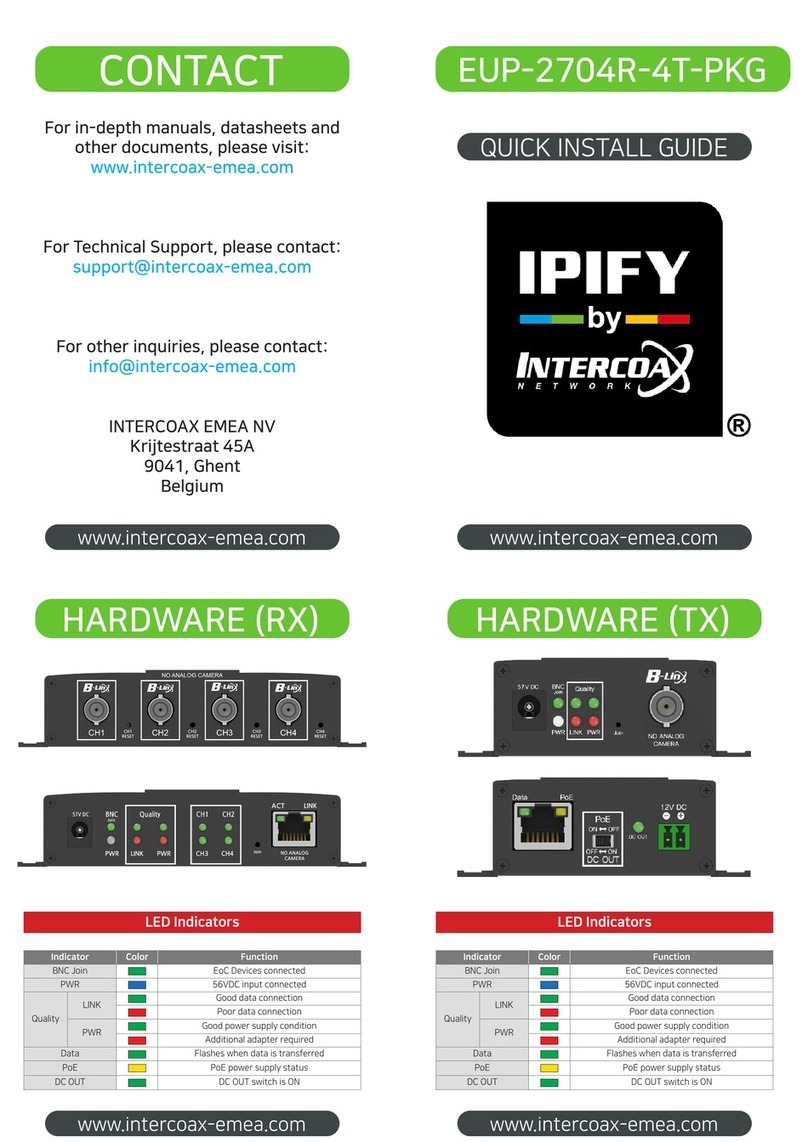

Link 5909 - USB

FileProductInputOutputCommunication LanguageOption08:30:00

PRetop5331

Date:2004-8-10

043201594

PRelectronics

AnaloginputAnalogoutput

Serialno:

Inputtype:Outputtype:4-20mA

Upscale

Sensorerror:

Pt100DIN/IEC

0.00-50.00C

3-wire

1.00sec

------

Inputrange:

Connection:

Coldjunctioncomp:

Responsetime:

Tagno:

Disconnect

+Vsupply

*Connected onlyfor

on-lineprogramming

Black

Red Yellow

Green

Input

Receiving

equipment

Connector

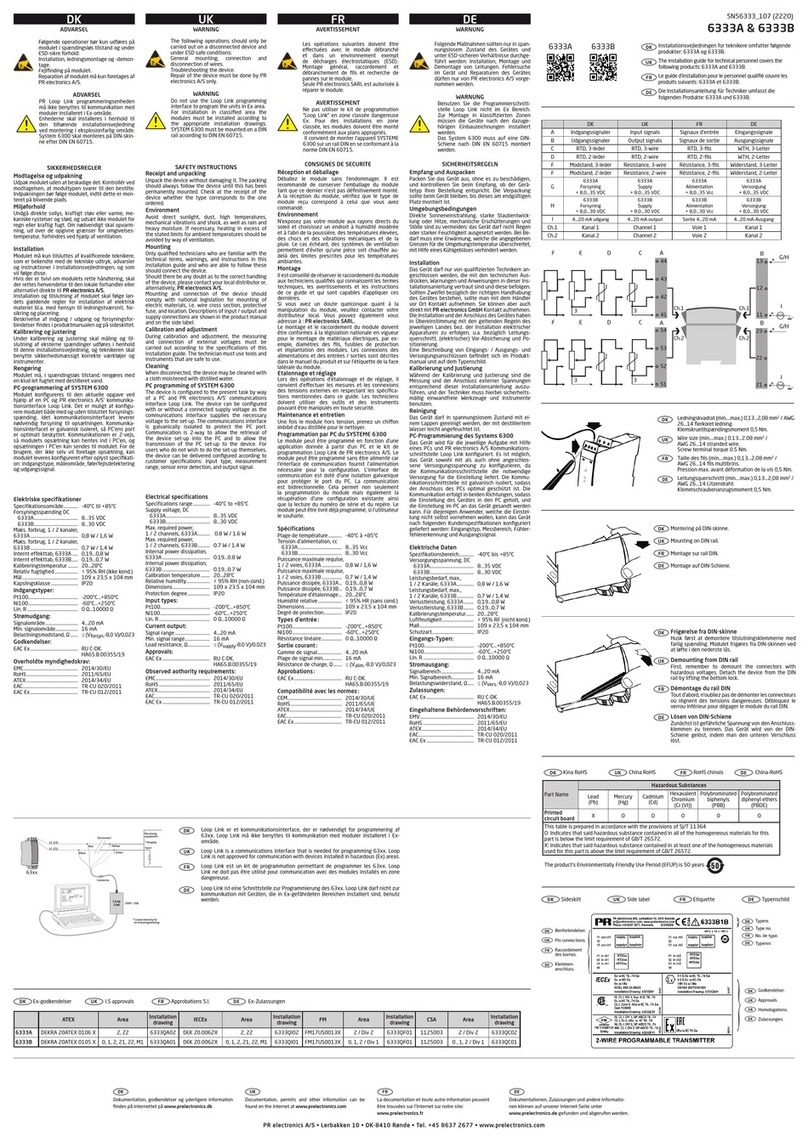

Loop Link er et kommunikationsinterface, der er nødvendigt for programmering af 63xx. Loop Link må ikke

benyttes til kommunikation med moduler installeret i Ex-område.

Loop Link is a communications interface that is needed for programming 63xx. Loop Link is not approved

for communication with devices installed in hazardous (Ex) areas.

Loop Link est un kit de programmation permettant de programmer les 63xx. Loop Link ne doit pas être

utilisé pour communication avec des modules installés en zone dangereuse.

Loop Link ist eine Schnittstelle zur Programmierung des 63xx. Loop Link darf nicht zur kommunikation mit

Geräten, die in Ex-gefährdeten Bereichen installiert sind, benutz werden.

UK

DK

FR

DE

63xx

DK UK FR DE

Ledningskvadrat (min....max.) 0,13...2,08 mm2/ AWG

26...14 flerkoret ledning.

Klemskruetilspændingsmoment 0,5 Nm.

Wire size (min....max.) 0.13...2.08 mm2/

AWG 26...14 stranded wire.

Screw terminal torque 0.5 Nm.

Taille des fils (min....max.) 0,13...2,08 mm2/

AWG 26...14 fils multibrins.

Pression max. avant déformation de la vis 0,5 Nm.

Leitungsquerschnitt (min....max.) 0,13...2,08 mm2/

AWG 26...14 Litzendraht.

Klemmschraubenanzugsmoment 0,5 Nm.

DK

UK

FR

DE

ADVARSEL

Følgende operationer bør kun udføres på modulet i

spændingsløs tilstand og under ESD-sikre forhold:

Installation, ledningsmontage og -demontage.

Fejlfinding på modulet.

Reparation af modulet må kun foretages af PR

electronics A/S.

ADVARSEL

PR Loop Link programmeringsenheden må ikke

benyttes til kommunikation med moduler installeret

i Ex-område.

Enhederne skal installeres i henhold til den til-

hørende installationsvejledning ved montering i

eksplosionfarlig område.System 6300 skal monteres

på DIN-skinne efter DIN EN 60715.

SIKKERHEDSREGLER

Modtagelse og udpakning

Udpak modulet uden at beskadige det. Kontrollér ved

modtagelsen, at modultypen svarer til den bestilte. Indpakningen

bør følge modulet, indtil dette er monteret på blivende plads.

Miljøforhold

Undgå direkte sollys, kraftigt støv eller varme, mekaniske

rystelser og stød, og udsæt ikke modulet for regn eller kraftig

fugt. Om nødvendigt skal opvarmning, ud over de opgivne

grænser for omgivelsestemperatur, forhindres ved hjælp af

ventilation.

Installation

Modulet må kun tilsluttes af kvalificerede teknikere, som er

bekendte med de tekniske udtryk, advarsler og instruktioner i

installationsvejledningen, og som vil følge disse.

Hvis der er tvivl om modulets rette håndtering, skal der rettes

henvendelse til den lokale forhandler eller alternativt direkte til

PR electronics A/S.

Installation og tilslutning af modulet skal følge landets gældende

regler for installation af elektrisk materiel bl.a. med hensyn til

ledningstværsnit, for-sikring og placering.

Beskrivelse af indgang / udgang og forsyningsforbindelser findes

i produktmanualen og på sideskiltet.

Kalibrering og justering

Under kalibrering og justering skal måling og tilslutning af

eksterne spændinger udføres i henhold til denne installations-

vejledning, og teknikeren skal benytte sikkerhedsmæssigt

korrekte værktøjer og instrumenter.

Rengøring

Modulet må, i spændingsløs tilstand, rengøres med en klud let

fugtet med destilleret vand.

PC-programmering af SYSTEM 6300

Modulet konfigureres til den aktuelle opgave ved hjælp af en PC

og PR electronics A/S’ kommunikationsinterface Loop Link. Det

er muligt at konfigurere modulet både med og uden tilsluttet

forsyningsspænding, idet kommunikationsinterfacet leverer

nødvendig forsyning til opsætningen. Kommunikationsinterfacet

er galvanisk isoleret, så PC’ens port er optimalt beskyttet.

Kommunikationen er 2-vejs, så modulets opsætning kan hentes

ind i PC’en, og opsætningen i PC’en kan sendes til modulet. For

de brugere, der ikke selv vil foretage opsætning, kan modulet

leveres konfigureret efter oplyst specifikation: indgangstype,

måleområde, følerfejlsdetektering og udgangssignal.

Elektriske specifikationer

Specifikationsområde................. -40°C til +85°C

Forsyningsspænding,

6335A & 6337A .......................... 8,0...35 VDC

Max. forbrug, 6335A &

6337A, 1 / 2 kanaler.................. 0,8 W / 1,6 W

Forsyningsspænding,

6335D & 6337D .......................... 8,0...30 VDC

Max. forbrug, 6335D &

6337D, 1 / 2 kanaler.................. 0,7 W / 1,4 W

Isolationsspænding,

test / arbejds- ................................ 1,5 kVAC / 50 VAC

Kalibreringstemperatur ............. 20...28°C

Relativ fugtighed......................... < 95% RH (ikke kond.)

Mål ..................................................... 109 x 23,5 x 104 mm

Kapslingsklasse............................ IP20

Indgangstyper:

Pt100................................................ -200°C...+850°C

Ni100................................................ -60°C...+250°C

TC-indgang ..................................... B, E, J, K, L, N, R, S, T,

U, W3, W5, Lr

Lin. R................................................. 0 Ω...7000 Ω

Spænding........................................ -800...+800 mV

Strømudgang:

Signalområde................................. 4...20 mA

Min. signalområde........................ 16 mA

Belastningsmodstand, Ω........... ≤ (Vforsyn.-8,0 V)/0,023

Godkendelser:

EAC Ex.............................................. RU C-DK.НА65.В.00355/19

Overholdte myndighedskrav:

EMC.................................................... 2014/30/EU & UK SI 2016/1091

ATEX.................................................. 2014/34/EU & UK SI 2016/1107

RoHS ................................................. 2011/65/EU & UK SI 2012/3032

EAC..................................................... TR-CU 020/2011

EAC Ex.............................................. TR-CU 012/2011

WARNING

The following operations should only be carried

out on a disconnected device and under ESD safe

conditions:

General mounting, connection and disconnection of

wires.

Troubleshooting the device.

Repair of the device must be done by PR electronics

A/S only.

WARNING

Do not use the Loop Link programming interface to

program the units in Ex area.

For installation in classified area the modules must

be installed according to the appropriate installation

drawings. SYSTEM 6300 must be mounted on a DIN

rail according to DIN EN 60715.

SAFETY INSTRUCTIONS

Receipt and unpacking

Unpack the device without damaging it. The packing should

always follow the device until this has been permanently

mounted. Check at the receipt of the device whether the type

corresponds to the one ordered.

Environment

Avoid direct sunlight, dust, high temperatures, mechanical

vibrations and shock, as well as rain and heavy moisture. If

necessary, heating in excess of the stated limits for ambient

temperatures should be avoided by way of ventilation.

Mounting

Only qualified technicians who are familiar with the technical

terms, warnings, and instructions in this installation guide and

who are able to follow these should connect the device.

Should there be any doubt as to the correct handling of the

device, please contact your local distributor or, alternatively, PR

electronics A/S.

Mounting and connection of the device should comply with

national legislation for mounting of electric materials, i.e. wire

cross section, protective fuse, and location. Descriptions of input/

output and supply connections are shown in the product manual

and on the side label.

Calibration and adjustment

During calibration and adjustment, the measuring and connection

of external voltages must be carried out according to the

specifications of this installation guide. The technician must use

tools and instruments that are safe to use.

Cleaning

When disconnected, the device may be cleaned with a cloth

moistened with distilled water.

PC programming of SYSTEM 6300

The device is configured to the present task by way of a PC

and PR electronics A/S’ communications interface Loop Link.

The device can be configured with or without a connected

supply voltage as the communications interface supplies the

necessary voltage to the set-up. The communications interface

is galvanically isolated to protect the PC port. Communication

is 2-way to allow the retrieval of the device set-up into the PC

and to allow the transmission of the PC set-up to the device. For

users who do not wish to do the set-up themselves, the device

can be delivered configured according to customer specifications:

input type, measurement range, sensor error detection, and output

signal.

Electrical specifications

Specifications range................... -40°C to +85°C

Supply voltage,

6335A & 6337A .......................... 8.0...35 VDC

Max. required power, 6335A

& 6337A, 1 / 2 channels .......... 0.8 W / 1.6 W

Supply voltage,

6335D & 6337D .......................... 8.0...30 VDC

Max. required power, 6335D

& 6337D, 1 / 2 channels.......... 0.7 W / 1.4 W

Isolation voltage, test / oper.... 1.5 kVAC / 50 VAC

Calibration temperature ............ 20...28°C

Relative humidity......................... < 95% RH (non-cond.)

Dimensions..................................... 109 x 23.5 x 104 mm

Protection degree........................ IP20

Input types:

Pt100................................................ -200°C...+850°C

Ni100................................................ -60°C...+250°C

TC input............................................ B, E, J, K, L, N, R, S, T,

U, W3, W5, Lr

Lin. R................................................. 0 Ω...7000 Ω

Voltage............................................. -800...+800 mV

Current output:

Signal range................................... 4...20 mA

Min. signal range.......................... 16 mA

Load resistance, Ω........................ ≤ (Vsupply-8.0 V)/0.023

Approvals:

EAC Ex.............................................. RU C-DK.НА65.В.00355/19

Observed aothority requirements:

EMC.................................................... 2014/30/EU & UK SI 2016/1091

ATEX.................................................. 2014/34/EU & UK SI 2016/1107

RoHS ................................................. 2011/65/EU & UK SI 2012/3032

EAC..................................................... TR-CU 020/2011

EAC Ex.............................................. TR-CU 012/2011

AVERTISSEMENT

Les opérations suivantes doivent être eectuées

avec le module débranché et dans un environnement

exempt de décharges électrostatiques (ESD):

Montage général, raccordement et débranchement de

fils et recherche de pannes sur le module.

Seule PR electronics SARL est autorisée à réparer le

module.

AVERTISSEMENT

Ne pas utiliser le kit de programmation “Loop Link” en

zone classée dangereuse Ex. Pour des installations

en zone classée, les modules doivent être monté

conformément aux plans appropriés.

Il convient de monter l’appareil SYSTEME 6300 sur un

rail DIN en se conformant à la norme DIN EN 60715.

CONSIGNES DE SECURITE

Réception et déballage

Déballez le module sans l’endommager. Il est recommandé de

conserver l’emballage du module tant que ce dernier n’est pas

définitivement monté. A la réception du module, vérifiez que le

type de module reçu correspond à celui que vous avez commandé.

Environnement

N’exposez pas votre module aux rayons directs du soleil et

choisissez un endroit à humidité modérée et à l’abri de la

poussière, des températures élevées, des chocs et des vibrations

mécaniques et de la pluie. Le cas échéant, des systèmes de

ventilation permettent d’éviter qu’une pièce soit chauée au-

delà des limites prescrites pour les températures ambiantes.

Montage

Il est conseillé de réserver le raccordement du module aux

techniciens qualifiés qui connaissent les termes techniques,

les avertissements et les instructions de ce guide et qui sont

capables d’appliquer ces dernières.

Si vous avez un doute quelconque quant à la manipulation du

module, veuillez contacter votre distributeur local. Vous pouvez

également vous adresser à : PR electronics SARL.

Le montage et le raccordement du module doivent être conformes

à la législation nationale en vigueur pour le montage de matéri-

aux électriques, par exemple, diamètres des fils, fusibles de

protection et implantation des modules. Les connexions des

alimentations et des entrées / sorties sont décrites dans le

manuel du produit et sur l’étiquette de la face latérale du module.

Etalonnage et réglage

Lors des opérations d’étalonnage et de réglage, il convient

d’eectuer les mesures et les connexions des tensions externes

en respectant les spécifications mentionnées dans ce guide. Les

techniciens doivent utiliser des outils et des instruments pouvant

être manipulés en toute sécurité.

Maintenance et entretien

Une fois le module hors tension, prenez un chion imbibé d’eau

distillée pour le nettoyer.

Programmation par PC du SYSTEME 6300

Le module peut être programmé en fonction d’une application

donnée à partir d’un PC et le kit de programmation Loop Link de

PR electronics A/S. Le module peut être programmé sans être

alimenté car l’interface de communication fournit l’alimentation

nécessaire pour la configuration. L’interface de communication

est doté d’une isolation galvanique pour protéger le port du PC. La

communication est bidirectionnelle. Cela permet non seulement

la programmation du module mais également la récupération

d’une configuration existante ainsi que la lecture du numéro de

série et du repère. Le module peut être livré déjà programmé, si

l’utilisateur le souhaite.

Spécifications

Plage de température................ -40°C à +85°C

Tension d’alimentation,

6335A & 6337A .......................... 8,0...35 Vcc

Puissance maximale requise,

6335A & 6337A, 1/2 voies..... 0,8 W / 1,6 W

Tension d’alimentation,

6335D & 6337D .......................... 8,0...30 Vcc

Puissance maximale requise,

6335D & 6337D, 1/2 voies..... 0,7 W / 1,4 W

Tension d’isolation test/opér..... 1,5 kVca / 50 Vca

Température d’étalonnage....... 20...28°C

Humidité relative ......................... < 95% HR (sans cond.)

Dimensions..................................... 109 x 23,5 x 104 mm

Degré de protection.................... IP50/IP20

Types d’entrée :

Pt100................................................ -200°C...+850°C

Ni100................................................ -60°C...+250°C

Entrée TC......................................... B, E, J, K, L, N, R, S, T,

U, W3, W5, Lr

Résistance linéaire...................... 0 Ω...7000 Ω

Tension............................................. -800...+800 mV

Sortie courant :

Gamme de signal.......................... 4...20 mA

Plage de signal min..................... 16 mA

Résistance de charge, Ω............ ≤ (Valim.-8,0 V)/0,023

Approbations :

EAC Ex.............................................. RU C-DK.НА65.В.00355/19

Compatibilité avec les normes :

CEM.................................................... 2014/30/UE & UK SI 2016/1091

ATEX.................................................. 2014/34/EU & UK SI 2016/1107

RoHS ................................................. 2011/65/UE & UK SI 2012/3032

EAC..................................................... TR-CU 020/2011

EAC Ex.............................................. TR-CU 012/2011

WARNUNG

Folgende Maßnahmen sollten nur in spannungslosem

Zustand des Gerätes und unter ESD-sicheren Verhält-

nisse durchgeführt werden: Installation, Montage und

Demontage von Leitungen. Fehlersuche im Gerät

und Reparaturen des Gerätes dürfen nur von PR

electronics A/S vorgenommen werden.

WARNUNG

Benutzen Sie die Programmierschnittstelle Loop Link

nicht im Ex Bereich. Zur Montage in klassifizierten

Zonen müssen die Geräte nach den dazugehörigen

Einbauzeichnungen installiert werden.

Das System 6300 muss auf eine DIN-Schiene nach

DIN EN 60715 montiert werden.

SICHERHEITSREGELN

Empfang und Auspacken

Packen Sie das Gerät aus, ohne es zu beschädigen, und

kontrollieren Sie beim Empfang, ob der Gerätetyp Ihrer Bestellung

entspricht. Die Verpackung sollte beim Gerät bleiben, bis dieses

am endgültigen Platz montiert ist.

Umgebungsbedingungen

Direkte Sonneneinstrahlung, starke Staubentwicklung oder

Hitze, mechanische Erschütterungen und Stöße sind zu

vermeiden; das Gerät darf nicht Regen oder starker Feuchtigkeit

ausgesetzt werden. Bei Bedarf muss eine Erwärmung, welche

die angegebenen Grenzen für die Umgebungstemperatur

überschreitet, mit Hilfe eines Kühlgebläses verhindert werden.

Installation

Das Gerät darf nur von qualifizierten Technikern angeschlossen

werden, die mit den technischen Ausdrücken, Warnungen und

Anweisungen in dieser Installationsanleitung vertraut sind und

diese befolgen.

Sollten Zweifel bezüglich der richtigen Handhabung des

Gerätes bestehen, sollte man mit dem Händler vor Ort Kontakt

aufnehmen. Sie können aber auch direkt mit PR electronics

GmbH Kontakt aufnehmen.

Die Installation und der Anschluss des Gerätes haben in Über-

einstimmung mit den geltenden Regeln des jeweiligen Landes

bez. der Installation elektrischer Apparaturen zu erfolgen, u.a.

bezüglich Leitungsquerschnitt, (elektrischer) Vor-Absicherung

und Positionierung.

Eine Beschreibung von Eingangs- / Ausgangs- und Versorg-

ungsanschlüssen befindet sich im Produktmanual und auf dem

Typenschild.

Kalibrierung und Justierung

Während der Kalibrierung und Justierung sind die Messung

und der Anschluss externer Spannungen entsprechend

dieser Installationsanleitung auszuführen, und der Techniker

muss hierbei sicherheitsmäßig einwandfreie Werkzeuge und

Instrumente benutzen.

Reinigung

Das Gerät darf in spannungslosem Zustand mit einem

Lappen gereinigt werden, der mit destilliertem Wasser leicht

angefeuchtet ist.

PC-Programmierung des Systems 6300

Das Gerät wird für die jeweilige Aufgabe mit Hilfe eines PCs

und PR electronics A/S Kommunikationsschnittstelle Loop Link

konfiguriert. Es ist möglich, das Gerät sowohl mit als auch ohne

angeschlossene Versorgungsspannung zu konfigurieren, da die

Kommunikationsschnittstelle die notwendige Versorgung für die

Einstellung liefert. Die Kommunikationsschnittstelle ist galvanisch

isoliert, sodass der Anschluss des PCs optimal geschützt ist.

Die Kommunikation erfolgt in beiden Richtungen, sodass die

Einstellung des Gerätes in den PC geholt, und die Einstellung

im PC an das Gerät gesandt werden kann. Für diejenigen

Anwender, welche die Einstellung nicht selbst vornehmen

wollen, kann das Gerät nach folgenden Kundenspezifikationen

konfiguriert geliefert werden: Eingangstyp, Messbereich,

Fühlerfehlererkennung und Ausgangssignal.

Elektrische Daten

Spezifikationsbereich................. -40°C bis +85°C

Versorgungsspannung,

6335A & 6337A .......................... 8,0...35 VDC

Leistungsbedarf, 6335A &

6337A, 1 / 2 Kanäle................... 0,8 W / 1,6 W

Versorgungsspannung,

6335D & 6337D .......................... 8,0...30 VDC

Leistungsbedarf, 6335D &

6337D, 1 / 2 Kanäle................... 0,7 W / 1,4 W

Isolationsspannung,

Test / Betrieb................................. 1,5 kVAC / 50 VAC

Kalibrierungstemperatur........... 20...28°C

Luftfeutigkeit................................ < 95% RF (nicht kond.)

Maß.................................................... 109 x 23,5 x 104 mm

Schutzart......................................... IP50/IP20

Eingangs-Typen:

Pt100................................................ -200°C...+850°C

Ni100................................................ -60°C...+250°C

TE-Eingang..................................... B, E, J, K, L, N, R, S, T,

U, W3, W5, Lr

Lin. R................................................. 0 Ω...7000 Ω

Spannung........................................ -800...+800 mV

Stromausgang:

Signalbereich................................. 4...20 mA

Min. Signalbereich........................ 16 mA

Belastungswiderstand, Ω.......... ≤ (VVers.-8,0 V)/0,023

Zulassungen:

EAC Ex.............................................. RU C-DK.НА65.В.00355/19

Eingehaltene Behördenvorschriften:

EMV.................................................... 2014/30/EU & UK SI 2016/1091

ATEX.................................................. 2014/34/EU & UK SI 2016/1107

RoHS ................................................. 2011/65/EU & UK SI 2012/3032

EAC..................................................... TR-CU 020/2011

EAC Ex.............................................. TR-CU 012/2011

Frigørelse fra DIN-skinne

Husk først at demontere tilslutningsklemmerne med farlig

spænding. Modulet frigøres fra DIN-skinnen ved at løfte i

den nederste lås.

Demounting from DIN rail

First, remember to demount the connectors with

hazardous voltages. Detach the device from the DIN rail

by lifting the bottom lock.

Démontage du rail DIN

Tout d’abord, n’oubliez pas de démonter les connecteurs où

règnent des tensions dangereuses. Débloquez le verrou

inférieur pour dégager le module du rail DIN.

Lösen von DIN-Schiene

Zunächst ist gefährliche Spannung von den Anschluss-

klemmen zu trennen. Das Gerät wird von der DIN-Schiene

gelöst, indem man den unteren Verschluss löst.

DK

UK

FR

DE

Montering på DIN-skinne.

Mounting on DIN rail.

Montage sur rail DIN.

Montage auf DIN-Schiene.

DK

UK

FR

DE

SN6300-2_108 (2307)

6335A, 6335D,

6337A & 6337D

PR electronics A/S • Lerbakken 10 • DK-8410 Rønde • Tel. +45 8637 2677 • www.prelectronics.com

UK importer: PR electronics (UK) Ltd • Middle Barn, Oak Lane • Apuldram, Chichester • West Sussex, PO20 7FD • Tel. +44 (0) 1243 776 450

DK

Dokumentation, godkendelser og yderligere information

findes på internettet på www.prelectronics.dk

UK

Documentation, permits and other information can be

found on the internet at www.prelectronics.com

FR

La documentation et toute autre information peuvent

être trouvées sur l’Internet sur notre site:

www.prelectronics.fr

DE

Dokumentationen, Zulassungen und andere

Informationen können auf unserer Internet-Seite unter

www.prelectronics.de gefunden und abgerufen werden.

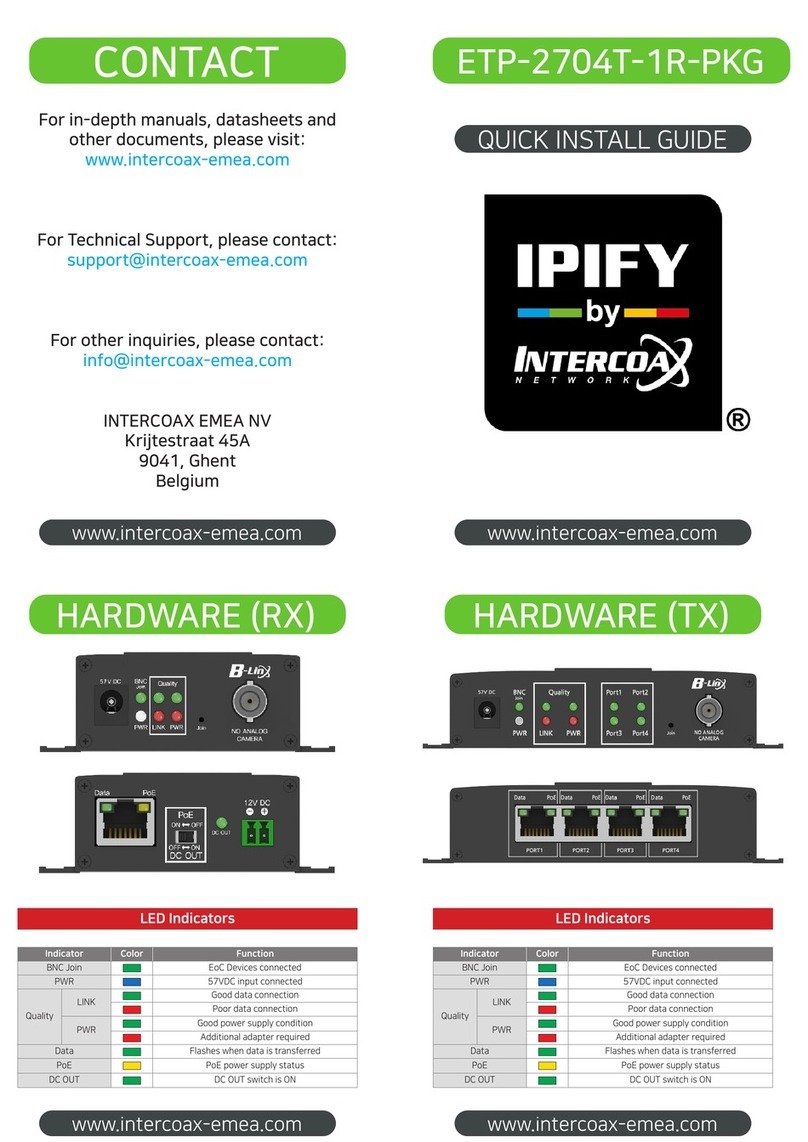

DK Ex-godkendelser UK I.S approvals FR Approbations S.I. DE Ex-Zulassungen

ATEX Area Installation

drawing IECEx Area Installation

drawing

6335A & 6337A DEKRA 20ATEX0109 X 2, 22 6335QA02 DEK 20.0063X 2, 22 6335QI02

6335D & 6337D DEKRA 20ATEX0108 X 0, 1, 2, 21, 22, M1 6335QA01 DEK 20.0063X 0, 1, 2, 21, 22, M1 6335QI01

FM Area Installation

drawing CSA Area Installation

drawing

6335A & 6337A 1125003 2 / Div 2 6337QC02

6335D & 6337D FM17US0013X 0, 1, 2 / Div 1 6335QF01 1125003 0 , 1, 2 / Div 1 6335QC02

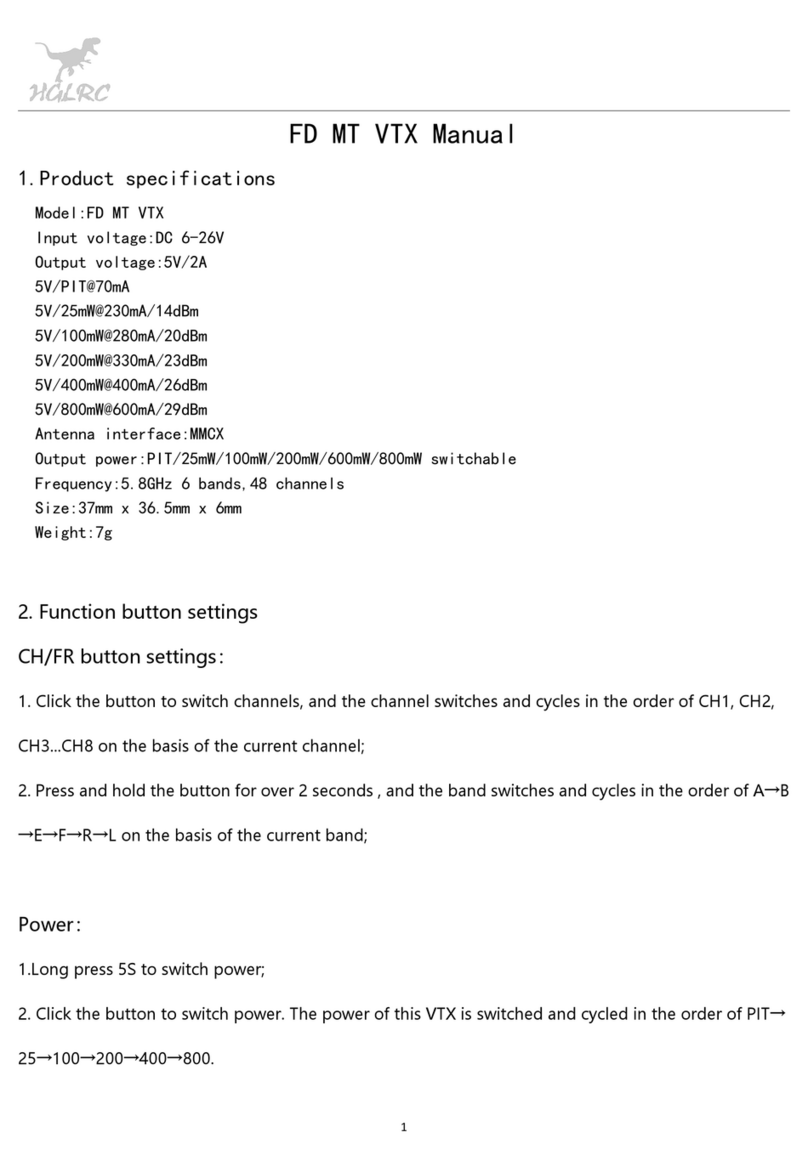

Part Name

Hazardous Substances

Lead

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Hexavalent

Chromium

(Cr (VI))

Polybrominated

biphenyls

(PBB)

Polybrominated

diphenyl ethers

(PBDE)

Printed

circuit board X O O O O O

This table is prepared in accordance with the provisions of SJ/T 11364

O: Indicates that said hazardous substance contained in all of the homogeneous materials for this part is

below the limit requirement of GB/T 26572.

X: Indicates that said hazardous substance contained in at least one of the homogeneous materials used

for this part is above the limit requirement of GB/T 26572.

The product’s Environmentally Friendly Use Period (EFUP) is 50 years 50

DK Kina RoHS UK China RoHS FR RoHS chinois DE China-RoHS