Unpacking Your T-Glide Fence System

While unpacking your saw, verify that you have all the components shown below for your specic fence

system. The T-Glide Fence System – Professional Series is available in either a 52” system or a 36” system. The

components pictured below are from the 52” system, although the components from the 36” system are similar.

front tube

front rail

rear rail

extension table

installation instructions poster owner’s manual

SawStop

®

OWNER’S MANUAL

T-GlideTM Fence System-

Professional Series

(four for 52” system,

two for 36” system)

angle bracket fence handle

T-Glide table

hardware pack

18

Countersunk Socket

Head Bolts, M8 x 25 (6)

Washers,

M8.5 x 23 (6) 19

Lock Washers,

M8 (6) 20

Philips Head Screws,

M4 x 16 (12) 17

Foot,

(2) 13

Hex Head Bolts,

M10 x 45 (4) 15

Hex Nuts,

M8 (8) 14

Nylon Lock Nuts,

M10 (4) 16

T-Glide 52” Table Hardware Pack

T-Glide rails

hardware pack

T-Glide Rails Hardware Pack

1

Countersunk Socket Head Bolts,

M8 x 25 (8)

Lock Washers,

M8 (8) 3

Hex Nuts,

M8 (8) 4

Hex Head Screws with Attached

Washers, M8 x 16 (9) 6

Washers,

M8.5 x 23 (8) 2

Countersunk Socket

Head Screws, M8 x 16 (4) 5

SawStop

T-Glide fence

Assembling Your T-Glide Fence System

SawStop Service Department

503-682-6222

www.sawstop.com

Before assembling your T-Glidefence system,

make sure that you have all the necessary

components identified on page 1 in the Owner’s

Manual, including the two hardware packs. Call the

SawStop Service Department at 503-682-6222 if

any components are missing. Youwill also need the

following tools to complete the fence installation:

1. a 5 mm hex key

2. a 13 mm wrench

3. two 17 mm wrenches (or adjustable wrenches)

4. a Phillips head screwdriver

5. a level or straight-edge

Note: The drawings in the installation poster

illustrate the T-Gliderails and extension table for

the 52” system. The instructions for assembling

and using the 36” system are the same. 12

345

678

910 11

Flip to

Other Side

© SawStop, LLC

TM

1

0

15

30

SawStop

10”ContractorSaw

1

2

3

4

SawStop

SystemStatusCodes

StatusRedGrn

¯¯¯

WetWood

OverloadDueTo

DuringBypass

ContactDetected

DuringStandby

ContactDetected

Brake

AdjustPositionof

Doors

CloseAccess

KeyTo“On”

TurnCartridge

To“Off”

TurnStartSwitch

BypassModeOn

CoastingDown

ReplaceCartridge

SystemReady

SystemInitializing

••••••

¯¯¯

¯¯¯

••

••••

¯¯¯

••••••

•••••• ••••••

••••••

¯¯¯

••••••

0

15

30

45

SawStop

10”ContractorSaw

5

MadeinTaiwan

SawS

top,LLCwww.sawstop.comTCP

10¨ContractorSaw

SawStop

®

ModelNo.CNS17

5

SerialNo.C074012345

E

le

ctrical/Electricidad/Électricité

1

15/230Volts,60Hz

15/7.5Amps

1Phase

1.75HP

3500RPM

®

cUS

175370

Movingbeltsand

parts

canpinch,cutorcrush.

Donotoperatewith

b

eltguardopen.

MadeinTaiwan

SawStop,LL

Cwww.

sawstop.comTC

P

10¨ContractorSaw

SawStop

®

ModelN

o.CNS175

SerialNo.C0

74012345

Electrical/Electricidad/É

lectricité

115/230Volts,60Hz

15/7.5Amps

1Phase

1.75HP

3500RPM

®

cUS

1

753

7

0

Movingbeltsandparts

canpinch,cutorcrush.

Donotoperatewith

beltguardopen.

1

23

4

1

SawStop,theSawStopbladelogo, and the

configur

ationof

thisproduct

areeitherregistered

tradema

rksortrademarksofSawStop, LLC.

Softwa

recopyright2

003-2006bySawStop,LLC.

Allrightsreserved.Protectedbyoneor more of

thefoll

owingU.S.patents6813983,6826988,

6857345

,6877410,6880440,6920814,6945148,

6945149

,6957601,6994004,6997090,7000514,

7024975

,7055417,7077039,7098800,7100483,

7137326

,7171879,7197969,721

0383,7225712,

7228772

,7231856andTaiwanpatent143466.

Additio

nalU.S.an

dforeignpatentspending.

!

WARNING

Donotremovethedust shroud because

thebladewillbeexposed.Ifyouconta

ctthe

bladeunderthetable,theblademayretract

towardyouandcause a severe injury.

13

14

15

16

17

frontrail

levelthe top of

thefront rail with

thelower edge

• Locate the front rail, the rear rail, and theT-Glide rails hardware

pack.All of the hardware needed to install the rails is located on

theT-Glide rails hardware pack and is shipped in the T-Glide

fence box. In order to easily identify the hardware used in each

of the following steps, the differentpieces of hardware are

numbered on the hardware pack and in the figures.

•Align the front rail (the larger of the two rails) with the front edge

of the table top so the cut-outs at the top of the rail are centered

on the miter gauge slots in the table and so the holes in the rail

align with the holes along the front edge of the table and

extension wings. Remove six M8 x 25 countersunk socket

head bolts from the T-Glide rails hardware pack and insert

one through each of the holes in the rail and table.

1

• Place an M8.5 x 23 washer and an M8 lock washer

on the back of each of the six M8 x 25 countersunk

socket head bolts , and then thread an M8 hex nut on

each bolt. Hand tighten the nuts; do not fully tighten them.

2 3

14

•The holes in the front edge of the table and extension wings are

slightly larger than the bolts they receive to allow you to level the

front rail and extension wings to the table top.Align the top of

the front rail with the lower edge of the bevel on the front edge

of the table top. Use a 5 mm hex key and a 13 mm wrench to

fully tighten the nuts on the back of the four bolts that extend

through the table top. Do not tighten the nuts on the bolts that

extend through the extension wings.

levelthe extension

wingand tighten the

nuton this bolt

• Use a straight-edge to level the front edge of the left extension

wing to the cast iron table top.You may have to pull up or push

down on the outer edge of the extension wing to level it. Once

the front edge of the left extension wing is level, use a 5 mm hex

key and a 13 mm wrench to fully tighten the nut on the bolt that

mounts the left extension wing to the front rail. Repeat this

process to level the front edge of the right extension wing.

•Align the rear rail (the smaller of the two rails) with the rear

edge of the table top so the cut-outs at the top of the rail are

centered on the miter gauge slots in the table and so the holes

in the rail align with the holes along the back edge of the table

and extension wings. Notice that the holes in the table are

threaded but the holes in the extension wings are not. Remove

four M8 x 16 countersunk socket head screws from the

T-Gliderails hardware pack and thread one through each of the

holes in the rail and into the threaded holes in the table.

Tightenthe four screws using a 5 mm hex key.

5

1

•Take two M8 x 25 countersunk socket head bolts andinsert

one through each hole in each extension wing. Place an

M8.5 x 23 washer and an M8 lock washer on the

back of each bolt and then thread an M8 hex nut on

each bolt. Hand tighten the nuts; do not fully tighten them.

1

23

4

• Use a straight-edge to level the rear edge of the left extension

wing to the cast iron table top.You may have to pull up or push

down on the outer edge of the extension wing to level it. Once

the rear edge of the left extension wing is level, use a 5 mm hex

key and a 13 mm wrench to fully tighten the nut on the bolt that

mounts the left extension wing to the rear rail. Repeat this

process to level the rear edge of the right extension wing.

wingand tighten the

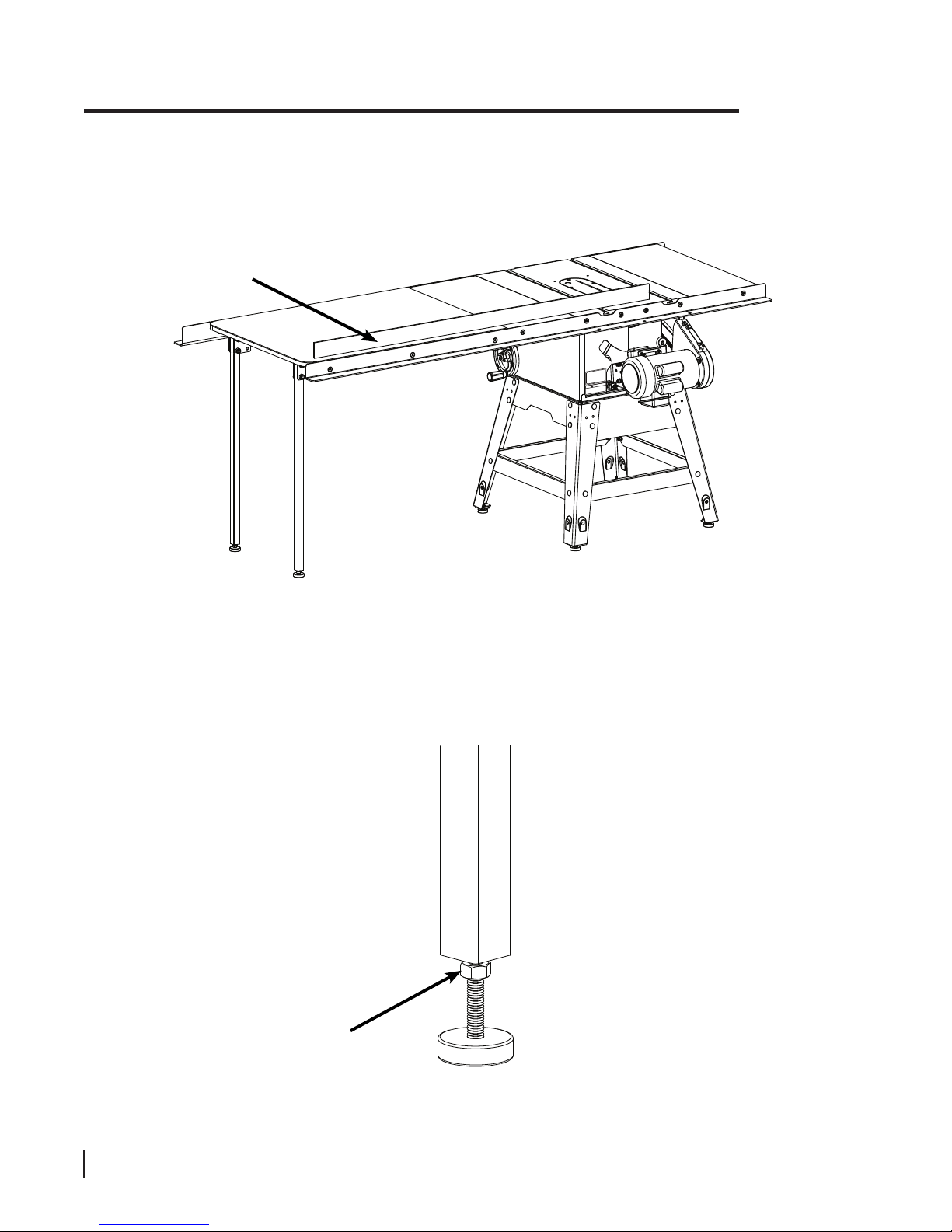

• Once the rails are in place you can mount the extension table to

the rails, but first you must mount the support leg or legs to the

extension table.The extension table for the 36” fence system has

one support leg and the extension table for the 52” fence system

has two. Locate the support legs, the angle brackets, and the

T-Glidetable hardware pack. Begin by installing the adjustable

foot in the bottom of each support leg.Thread an M8 nut onto

the threaded shaft of the foot as close to the rubber base as

possible, and then thread the foot into the bottom of the support

leg as far as possible.

14

13

• Each support leg is mounted to the underside of the extension

table using two angle brackets.Align the two holes in the

support leg to the two holes in the brackets. Put one of the

M10 x 45 hex head bolts through each hole in the leg and

brackets.Thread an M10 nylon lock nut on each bolt and

tighten with a 17 mm wrench.You will need to hold the head of

the hex bolt with another 17 mm wrench to tighten the lock nut.

Do not fully tighten the nuts; leave them just loose enough to be

able to move the brackets.

16

15

• Mount the angle brackets to the underside of the extension

table using three M4 x 16 Phillips head screws per bracket.

The underside of the extension table is pre-drilled to receive the

screws. Be careful not to overtighten the screws because you

may strip the threads in the wood. Once all the brackets

have been mounted to the table, fully tighten the

M10 nyl on lock nuts that secure the legs to the brackets.

17

T-GlideRails Hardware Pack

1

CountersunkSocketHeadBolts,

M8x25(8)

LockWashers,

M8(8) 3

HexNuts,

M8(8) 4

HexHeadScrewswith Attached

Washers,M8x16 (9) 6

Washers,

M8.5x23(8) 2

CountersunkSocket

HeadScrews,M8x 16 (4) 5

18

CountersunkSocket

HeadBolts,M8x 25 (6)

Washers,

M8.5x23(6) 19

LockWashers,

M8(6) 20

PhilipsHeadScrews,

M4x16(12) 17

Foot,

(2) 13

HexHeadBolts,

M10x45(4) 15

HexNuts,

M8(8) 14

NylonLockNuts,

M10(4) 16

T-Glide52”Table Hardware Pack

support leg

(two for 52” system,

one for 36” system)

SawStop T-Glide Fence System - Professional Series 1