0

15

30

45

SawStop

10” Contractor Saw

!

WARNING

!

ADVERTENCIA

!

AVERTISSEMENT

Parasupropiaseguridad,lea el manual de

instrucciónantesde usar la sierra.

1.Use las gafas de seguridad.

2.Use el dispositivo de seguridad de la

cuchillay

separadorparacualquier operación para la

cual

peudaserutilizada incluyendo todas las

operacionesdeserrar completo o a través.

3.Mantenga las manos fuera de la trayectoria

de

lacuchillade la sierra.

4.Utilice una vara de empujar cuando está

necesario.

5.Sepa reducir el riesgo del retroceso.

6.No realice ninguna operación a mano

alzada.

7.No ponga la mano alrededor o detrás de la

cuchilla.

8.Nunca trate de experimentar con el sistema

de

frenos.

9.Nunca ajuste la posición del cartucho del

freno

mientrasquela cuchilla está girando.

10.Notratede desconectar el sistema de

frenos.

11.Siempredesenchufela sierra antes de

cambiar

lacuchilla,el cartucho del freno, o de

mantenerla.

12.Noconecteel motor directamente con un

abastecimiento.

13.Utiliceelinterruptor del bypass solamente

cuandoestánecesario.

14.Noexpongaa la lluvia o al uso en

localizacioneshúmedas.

15.Nopongalas manos

Pourvotre propre sécurité, lisez le manuel

d’instructionavantd’utiliser la scie.

1.Portez des lunettes de sécurité.

2.Utilisez le protecteur de lame quel

quesoitle

typed'opération.

3.Gardez les mains à l’écart de la

lamelorsqu’elletourne.

4.Utilisez un poussoir de fin de

passesi

nécessaire.

5.Limitez au maximum le risque de

rejet.

6.Ne travaillez pas à la volée.

7.Ne passez pas votre bras

par-dessusouautourde la lame.

8.N’essayez jamais d'effectuer un

essaiducircuitde freinage.

9.N’ajustez jamais la position de la

cartouchedefreinlorsque la lame

tourne.

10.N’essayezpasde neutraliser le

circuitde

freinage.

11.Débranchezlascie avant de

changerlalame,la cartouche de frein,

oud’enfairel’entretien.

12.Nebranchezpas directement le

moteuràuneprise de courant.

13.N'utilisezl’interrupteurde by-pass

qu'encasdenécessité.

14.Nepasexposer a la pluie et ne pas

utiliserdanslesemplacements

humides.

15.Nemettezpas les mains à

l’intérieuron

au-dessousdecabinet lorsque la

lametourne.

Foryourown safety,read the instruction

manualbeforeoperating this saw.

1.Wear eye protection.

2.Use the blade guard and spreader

forevery

operationfor which it can be used,

includingallhroughsawing.

3.Keep hands out of the line of the

sawblade.

4.Use a push-stick when required.

5.Know how to reduce the risk of

kickback.

6.Do not perform any operation

freehand.

7.Never reach around or over the

sawblade.

8.Never try to test fire the brake

system.

9.Never adjust the position of the

brakecartridgewhilethe blade is

spinning.

10.Donottry to disable the brake

system.

11.Unplugthesaw before changing

theblade,

changingthebrake cartridge or

servicing.

12.Donotconnect the motor directly

toa powersupply.

13.Usethebypass switch only when

necessary.

14.Donotexpose to rain or use in

damplocations.

15.Donotput your hands inside or

underneaththecabinetwhile the

MadeinTaiwan

SawStop,LLC

www.sawstop.com

TCP

10¨Contractor Saw

SawStop

®

ModelNo.CNS175

SerialNo.C074012345

Electrical/Electricidad/ Électricité

115/230Volts,60Hz

15/7.5Amps

1Phase

1.75HP

3500RPM

®

cUS

175370

SawStop

SawStop

0

15

30

45

SawStop

10” Contractor Saw

!

WARNING

!

ADVERTENCIA

!

AVERTISSEMENT

Parasupropiaseguridad,leaelmanualde

instrucciónantesdeusarla sierra.

1.Use las gafas de seguridad.

2.Use el dispositivo de seguridad de la

cuchillay

separadorparacualquier operación para la

cual

peudaserutilizada incluyendo todas las

operacionesdeserrar completo o a través.

3.Mantenga las manos fuera de la trayectoria

de

lacuchillade la sierra.

4.Utilice una vara de empujar cuando está

necesario.

5.Sepa reducir el riesgo del retroceso.

6.No realice ninguna operación a mano

alzada.

7.No ponga la mano alrededor o detrás de la

cuchilla.

8.Nunca trate de experimentar con el sistema

de

frenos.

9.Nunca ajuste la posición del cartucho del

freno

mientrasquela cuchilla está girando.

10.Notratede desconectar el sistema de

frenos.

11.Siempredesenchufela sierra antes de

cambiar

lacuchilla,el cartucho del freno, o de

mantenerla.

12.Noconecteel motor directamente con un

abastecimiento.

13.Utiliceelinterruptor del bypass solamente

cuandoestánecesario.

14.Noexpongaa la lluvia o al uso en

localizacioneshúmedas.

15.Nopongalas manos

Pourvotre propre sécurité, lisez le manuel

d’instruction avant d’utiliser la scie.

1.Portez des lunettes de sécurité.

2.Utilisez le protecteur de lame quel

quesoitle

typed'opération.

3.Gardez les mains à l’écart de la

lamelorsqu’elletourne.

4.Utilisez un poussoir de fin de

passesi

nécessaire.

5.Limitez au maximum le risque de

rejet.

6.Ne travaillez pas à la volée.

7.Ne passez pas votre bras

par-dessusouautourde la lame.

8.N’essayez jamais d'effectuer un

essaiducircuitde freinage.

9.N’ajustez jamais la position de la

cartouchedefreinlorsque la lame

tourne.

10.N’essayezpasde neutraliser le

circuitde

freinage.

11.Débranchezlascie avant de

changerlalame,la cartouche de frein,

oud’enfairel’entretien.

12.Nebranchezpas directement le

moteuràuneprise de courant.

13.N'utilisezl’interrupteurde by-pass

qu'encasdenécessité.

14.Nepasexposer a la pluie et ne

pasutiliserdansles emplacements

humides.

15.Nemettezpas les mains à

l’intérieuron

au-dessousdecabinet lorsque la

lametourne.

Foryour own sa fety,read the instruction

manualbefore operating this s aw.

1.Wear eye protection.

2.Use the blade guard and spreader

forevery

operationfor which it can be used,

includingallhroughsawing.

3.Keep hands out of the line of the

sawblade.

4.Use a push-stick when required.

5.Know how to reduce the risk of

kickback.

6.Do not perform any operation

freehand.

7.Never reach around or over the

sawblade.

8.Never try to test fire the brake

system.

9.Never adjust the position of the

brakecartridgewhilethe blade is

spinning.

10.Donottry to disable the brake

system.

11.Unplugthesaw before changing

theblade,

changingthebrake cartridge or

servicing.

12.Donotconnect the motor directly

toa powersupply.

13.Usethebypass switch only when

necessary.

14.Donotexpose to rain or use in

damplocations.

15.Donotput your hands inside or

underneaththecabinetwhile the

MadeinTaiwan

SawStop,LLC

www.sawstop.com

TCP

10¨Contractor Saw

SawStop

®

ModelNo.CNS175

SerialNo.C074012345

Electrical/Electricidad/ Électricité

115/230Volts,60Hz

15/7.5Amps

1Phase

1.75HP

3500RPM

®

c

US

175370

SawStop

SawStop

8SawStop®Contractor Saw Mobile Cart

Assembling Your Contractor Saw Mobile Cart

Fig. 12

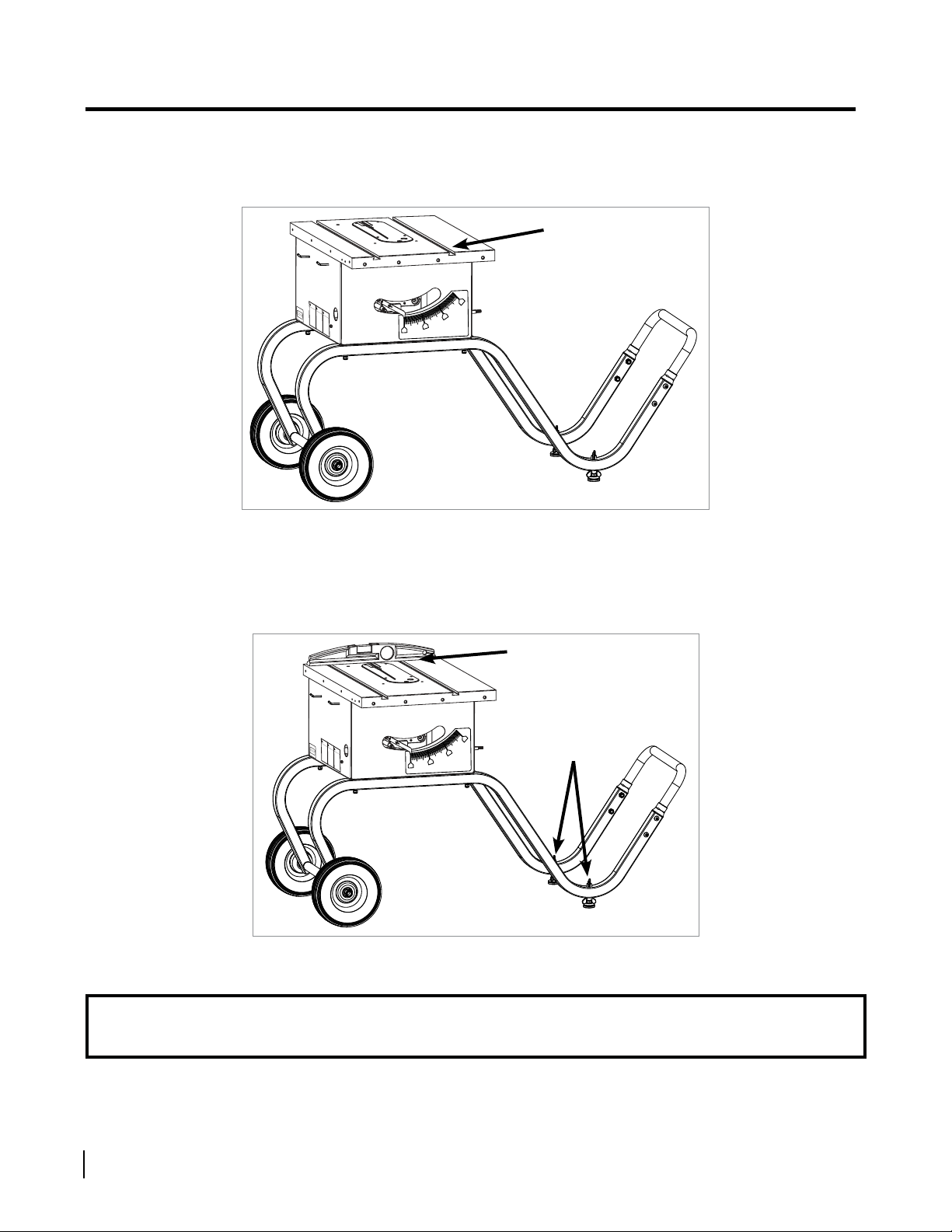

12. If your saw is new, remove the plastic covering from the cast iron table top and remove the yellow label from

the top of the table insert. Wipe the oil o the table top with a soft, clean cloth (see Fig. 12). The table top is

shipped with a coating of oil to prevent the cast iron from rusting.

Fig. 13

Congratulations, your mobile cart is now assembled. If your saw is new, proceed to step 15 in

your contractor saw assembly instructions to complete the assembly of your saw.

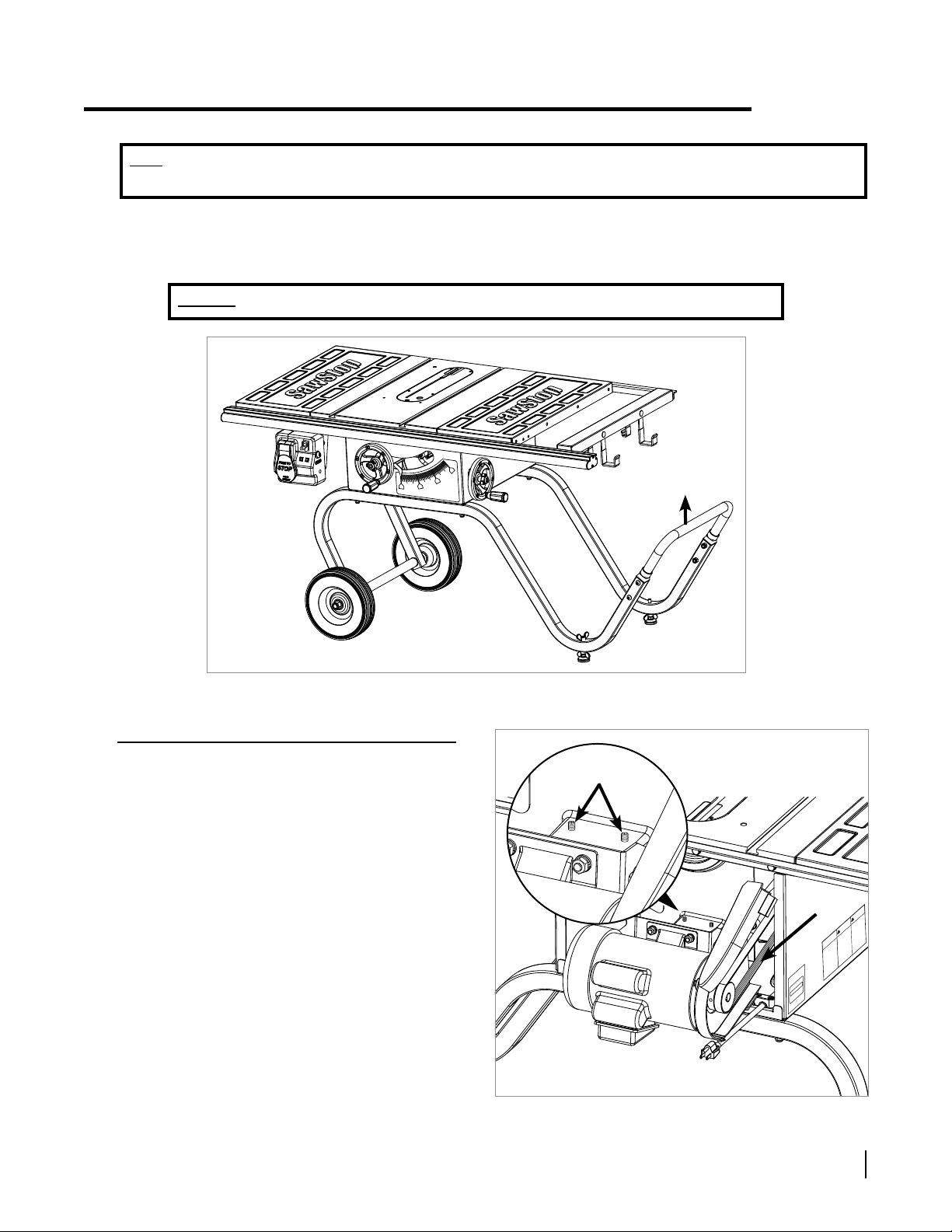

13. Place a level across the table top and adjust the two leveling feet of the mobile cart by turning the lower wing

nuts until the table top is level (you may need to loosen the upper wing nuts). When the saw is level, tighten

the four wing nuts by hand (see Fig. 13).

wipe the table top with

a soft, clean cloth

level the table top

tighten the wing

nuts in the feet