PANEL SAW INSTRUCTION MANUAL

1

Table of Contents

General Information …………………………………………………………………………………….

2

Safety R les………………………………………………………………………………………………….

2

Wiring diagram…………………………………………………………………………………………….

3

Specification Sheet……………………………………………………………………………………….

4

Main Feat res………………………………………………………………………………………………

5

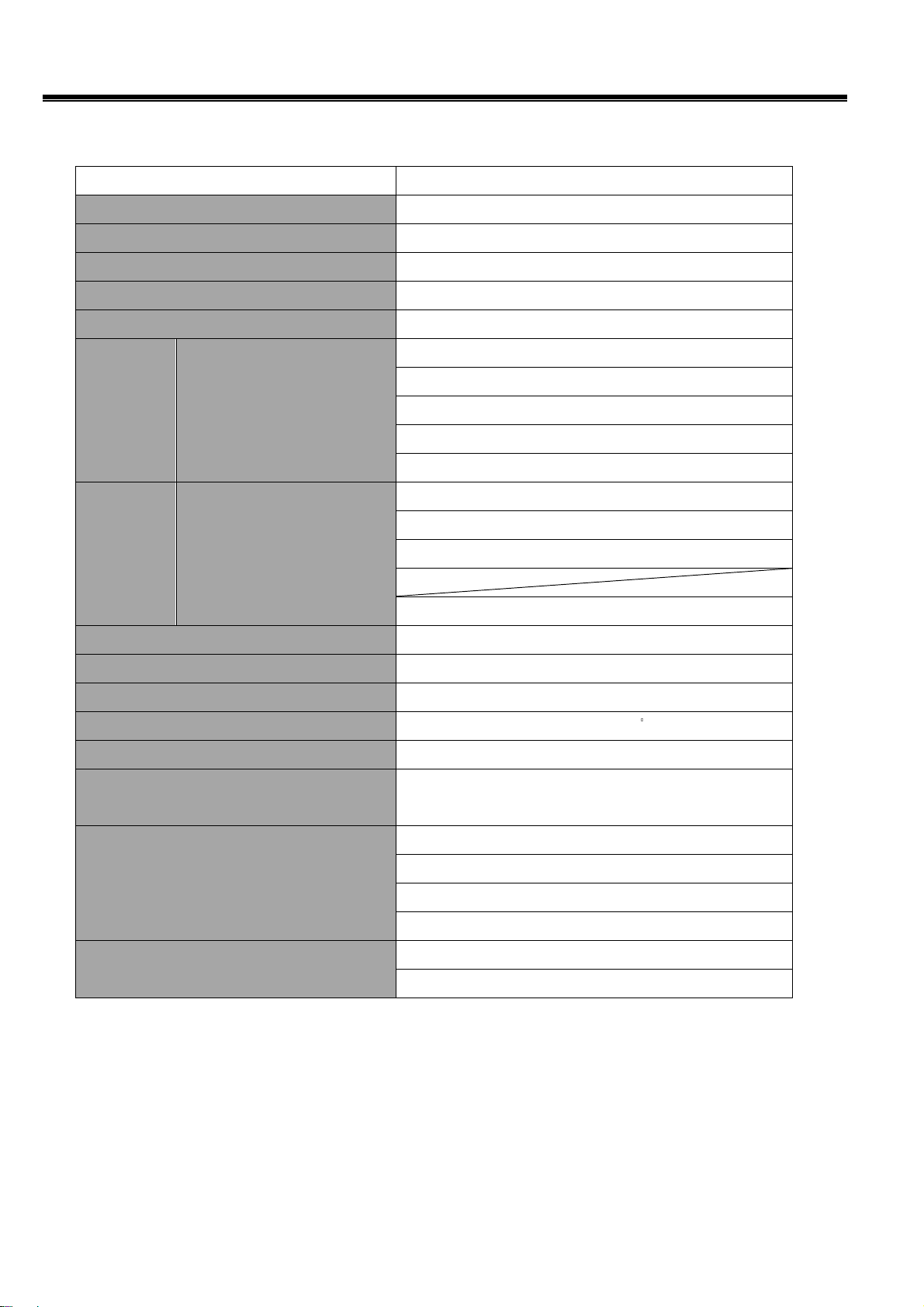

(1) Control Panel…………………………………………………………………………………….

6

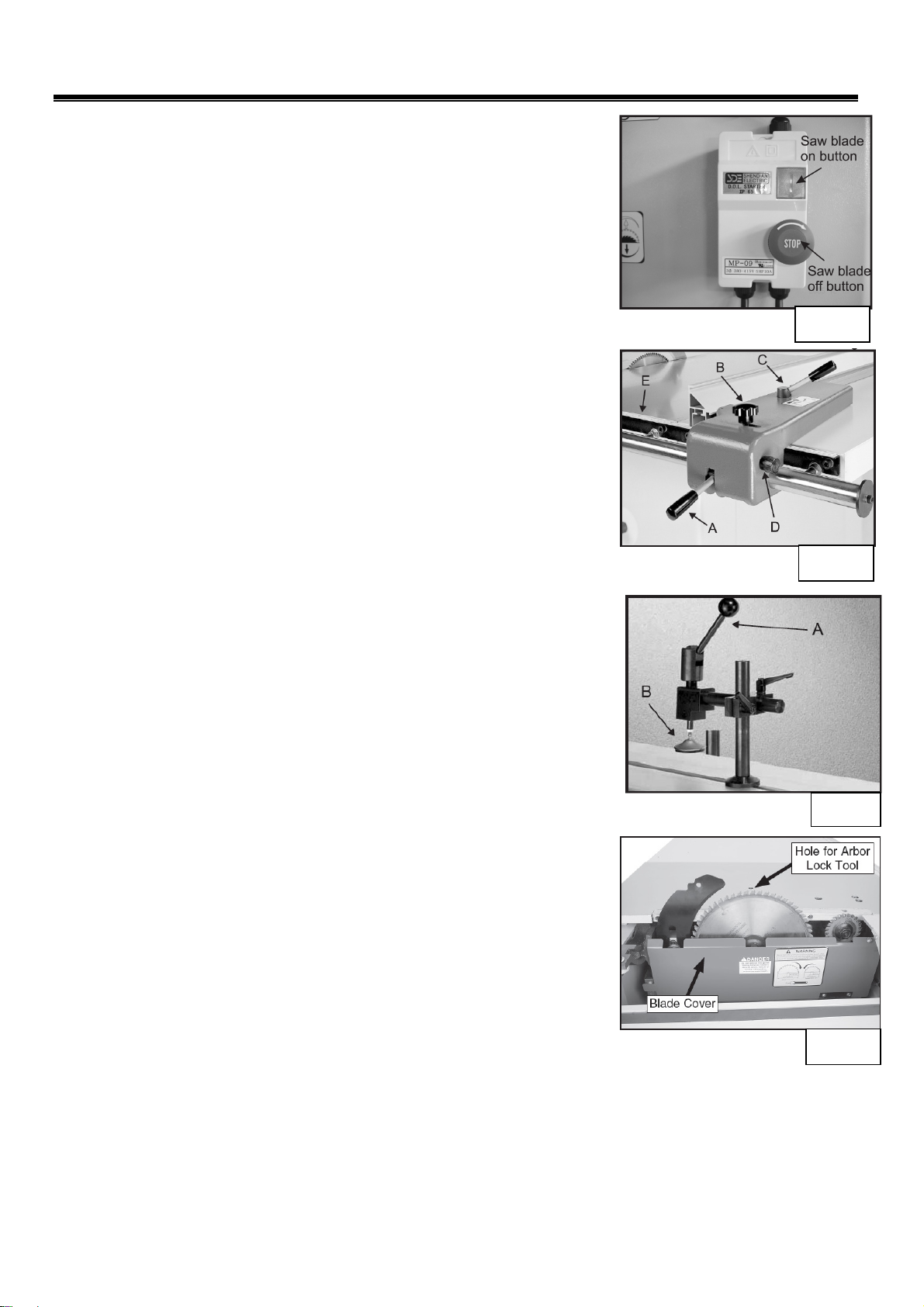

(2) Rip Fence…………………………………………………………………………………………..

6

(3) Hold Down…………………………………………………………………………………………

6

(4) Riving Knife Saw Blade……………………………………………………………………

6

Assembly And Set Up……………………………………………………………………………………

6

(1) Sliding Table ……………………………………………………………………………………..

6

(2) Extension Table (large small) …………………………………………………………..

7

(3) Scale Adjustment……………………………………………………………………………….

8

(4) Rip Fence…………………………………………………………………………………………..

8

(5) Cross Table………………………………………………………………………………………..

9

(6) Cross Fence……………………………………………………………………………………….

9

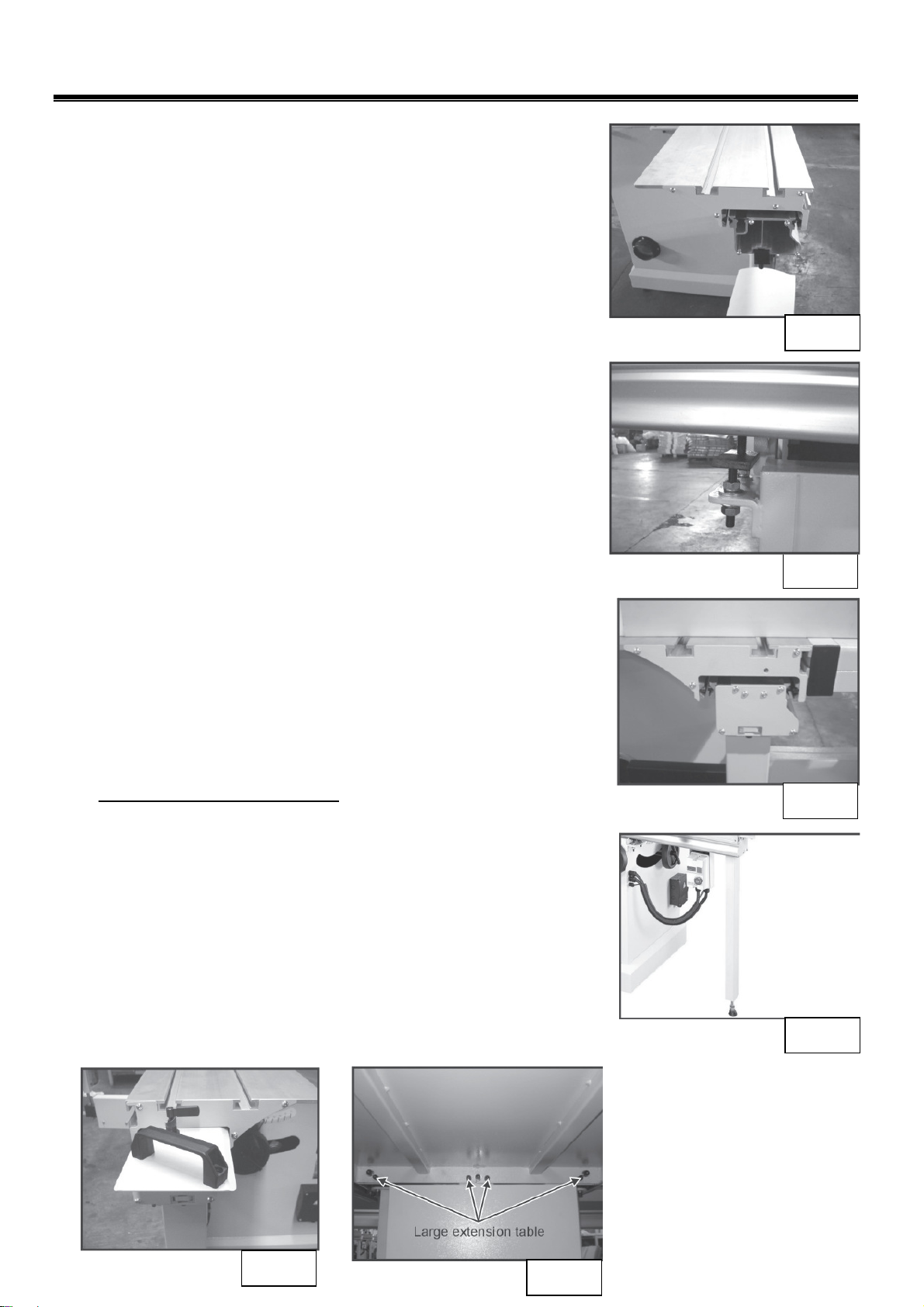

(7) Main Blade…………………………………………………………………………………………

10

(8) Scoring Blade……………………………………………………………………………………..

11

(9) Fence Scale Alignment……………………………………………………………………….

12

(10) Dust Collection…………………………………………………………………………………

12

(11) Power Cord………………………………………………………………………………………

13

(12) Test Run…………………………………………………………………………………………..

13

Operation……………………………………………………………………………………………………..

14

(1) Change Main Blade…………………………………………………………………………….

14

(2) Riving Knife Adjustment……………………………………………………………………..

15

(3) Change Scoring Blade…………………………………………………………………………

15

(4) Rip Cutting…………………………………………………………………………………………

15

(5) Crosscutting……………………………………………………………………………………….

16

(6) Miter Cutting……………………………………………………………………………………..

17

(7) Lubrication………………………………………………………………………………………..

18

(8) Replace Belts……………………………………………………………………………………..

18

(9) Blade Tilt……………………………………………………………………………………………

19

(10) Sliding Table Parallel Adjustment………………………………………………………..

20

(11) Squaring Crosscut Fence to Blade……………………………………………………….

20

(12) Trouble Shooting……………………………………………………………………………….

21