COPYRIGHT ©2015, SAYFA SYSTEMS 6 FDIM-01- REV D-DA300- NO INSPECTION 15/09/15

•Moving equipment, materials

•Weather & Climate factors

•Environmental contaminants, Chemicals

•Moving materials, unguarded openings & Unstable/uneven surfaces Slippery surfaces

•Heat-producing operations, Sparks or flames & hot objects

Confined space hazards Foreseeable changes in any of these conditions, taken individually or

collectively, must be identified.

The materials and construction of the folding davit and associated equipment must be

considered in the selection process such that these workplace conditions are suitably addressed

and responded to. The equipment must match the work situation and workplace environmental

factors.

The workplace assessment must identify all paths of intended user movement and all hazards

along such paths. The user must identify the required range of mobility in each hazard zone and

note the location and distance to all obstructions in potential fall paths. Lateral obstructions

which could be contacted in a pendulum fall arrest must be noted. If the folding davit and

mounting base are to be used for personnel-riding system, it must be backed up by a personal

fall arrest system incorporating a shock absorbing Lanyard (SAL). The SAL connecting the user's

harness to the folding davit anchorage connection must be selected so as to satisfactory limit

total fall distance. If the folding davit and mounting base are to be used for confined space entry

operations, the workplace assessment must comply with the requirements of the Confined

Spaces Regulations 1997.

3. DESCRIPTION OF FOLDING DAVIT

3.1. FOLDING DAVIT

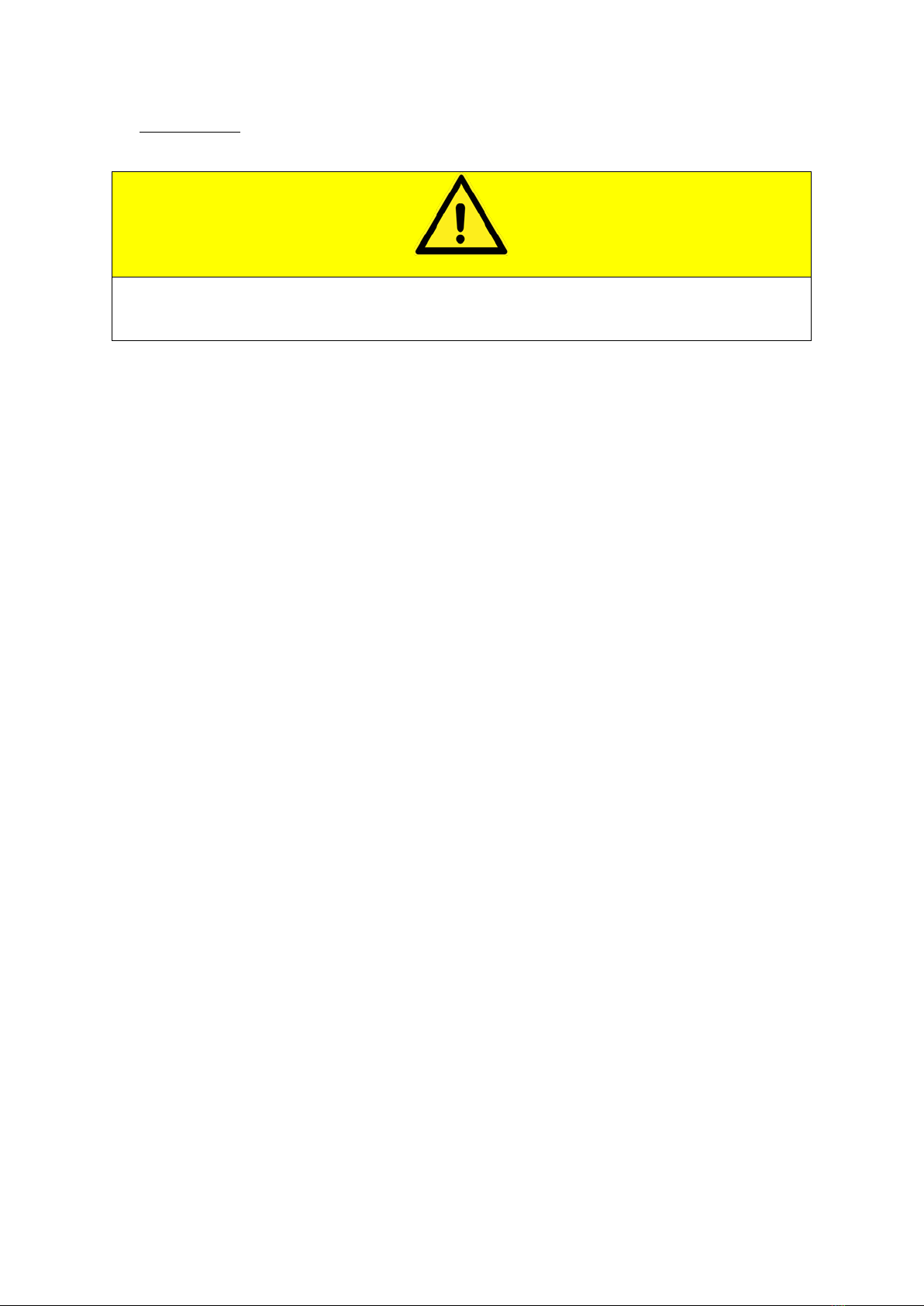

The folding davit consists of a Clear coated (can be coloured) 6082 T6 aluminium Vertical CHS

and horizontal SHS connected by a high strength aluminium hinge bracket. It is supported in the

vertical position by the S275 steel mounting base. The hinged bracket design permits folding of

the unit to permit easy transportability when removed from the base. The davit will swivel until

bolted in position which MUST be done before a load is applied, thereby holding the davit in

position for lifting and lowering. There is an eyebolt at the base to provide an anchorage

connector for fall arrest capability. See fig 1. (Part No. DA-300)

3.2. MOUNTING BASE

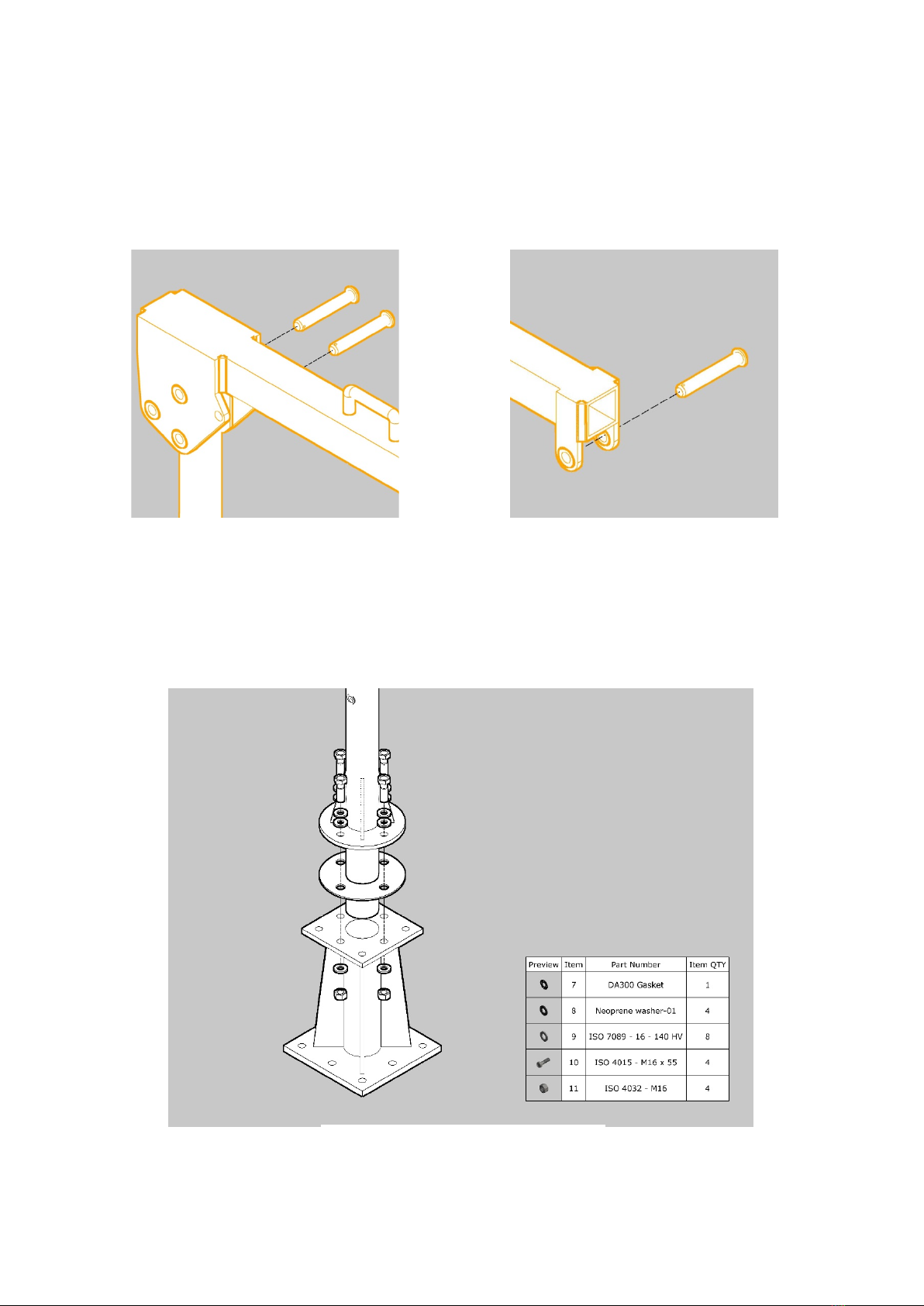

The mounting base is the means by which the folding davit is attached to a structural anchorage.

The base is permanently secured to the anchorage at floor level by eight (8) chemical fix studs,

16mm diameter, Stainless Steel Grade 8.8 A2. The tube, welded to the base is constructed of

S355; the plates are made from S275 Structural steel. Galvanized to BS EN ISO 1461. A stainless

steel mounting base is available for highly corrosive environments. See Fig2. (Part No. DB150,

DB-250 & DB-350)