8

3.2 Safety instructions

When using the Centerless grinding attachment the existing safety rules must be kept in

order to avoid personal or material injury when working with the belt grinder.

A. User

Do not wear loose clothing, gloves, rings, bracelets, or other jewellery to get caught in

moving parts. None slip foot wear is recommended. Wear protective hair covering to

contain long hair.

Always wear eye protection and face or dust mask if the operation is dusty. Ordinary

glasses cannot replace eye protection.

Don’t overreach. Keep proper footing and balance at all times.

Never leave tool running unattended. Turn power off. Don’t leave tool until it comes to a

complete stop.

Don’t operate tool while under influence of drugs, alcohol, or any medication.

B. Use of Machine

Use right tool. Don’t force tool or attachment to do a job for which it was not designed.

Use recommended accessories. Consult the owner’s manual for recommended

accessories. The use of improper accessories may cause hazards.

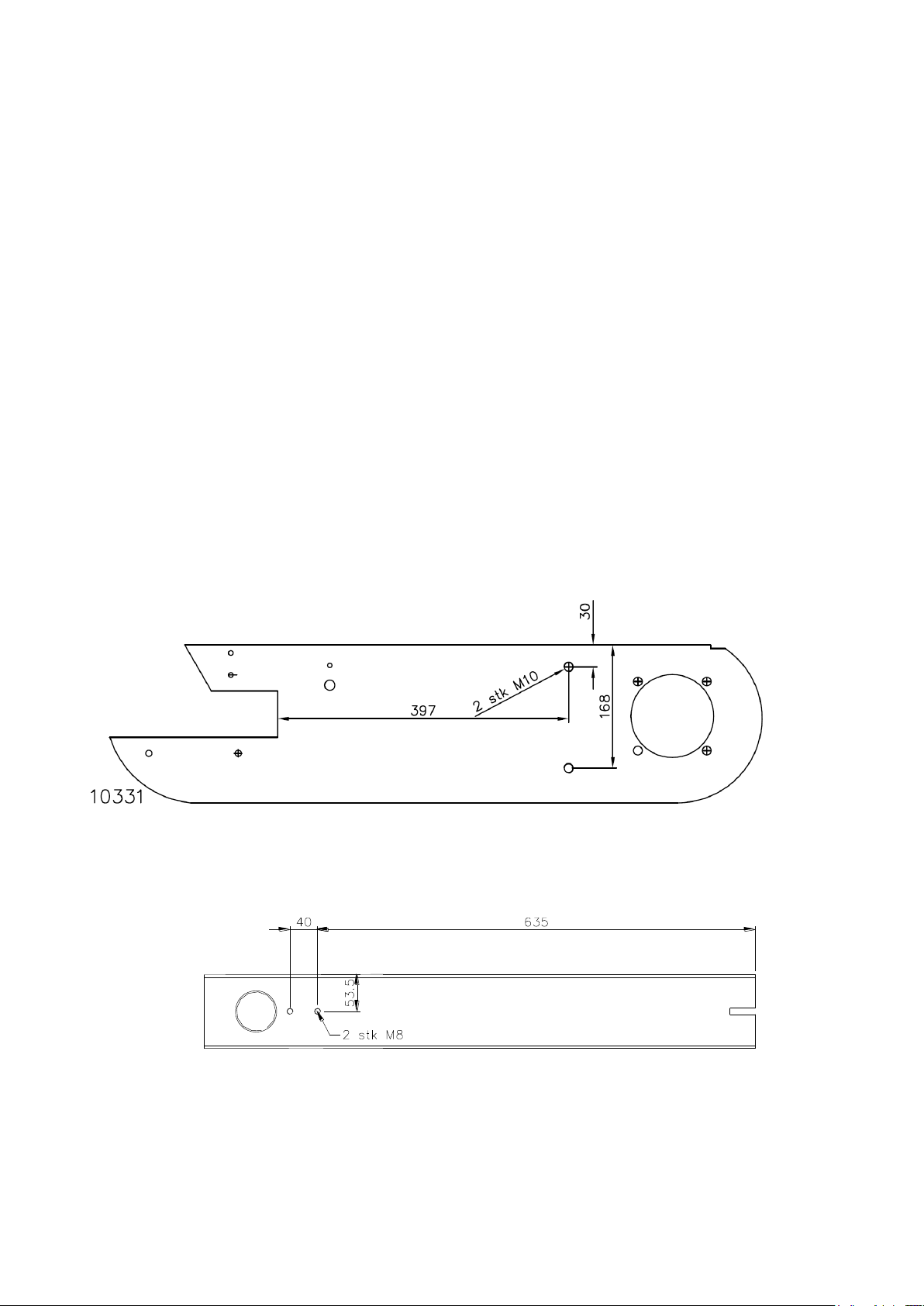

C. Adjustment

Make all adjustments with the power off. In order to obtain the machine precision and

correct ways of adjustment while assembling, the user should read the detailed instruction

in this manual.

D. Working Environment

Keep work area clean. Cluttered areas and benches invite accidents.

Don’t use in dangerous environment. Don’t use power tools in damp or wet locations, or

expose them to rain. Keep work area well-lighted.

Keep children and visitors away. All children and visitors should be kept a safe distance

from work area.

E. Maintenance

Disconnect machine from power source when making repairs.

Check damaged parts. To read every details of trouble shooting, repair it very carefully

and make sure the operator won’t get injured and damage the machine.