3/33

Table of Contents

1. General Information ................................................................................................................................................................. 4

1.1. Short Description ....................................................................................................................................................................................4

1.2. Intended Use.............................................................................................................................................................................................4

1.3. Copyright and Intellectual Property Rights...................................................................................................................................4

1.4. Safety Precautions ..................................................................................................................................................................................5

1.5. Obligation of the Plant Owner / Operating Company...............................................................................................................7

1.6. Commitment of the Sta......................................................................................................................................................................7

1.7. Training of the Sta ................................................................................................................................................................................7

1.8. Additional documents relevant for the mounting......................................................................................................................8

2. Transportation, Loading and Unloading .............................................................................................................................. 8

2.1. Delivery of the components................................................................................................................................................................8

2.2. Preparing the delivery...........................................................................................................................................................................8

2.3. Provide forklift trucks and hoisting equipment...........................................................................................................................9

2.4. Check the scope of delivery (for completeness)..........................................................................................................................9

2.5. Storage of the components.................................................................................................................................................................9

3. Technical data...........................................................................................................................................................................10

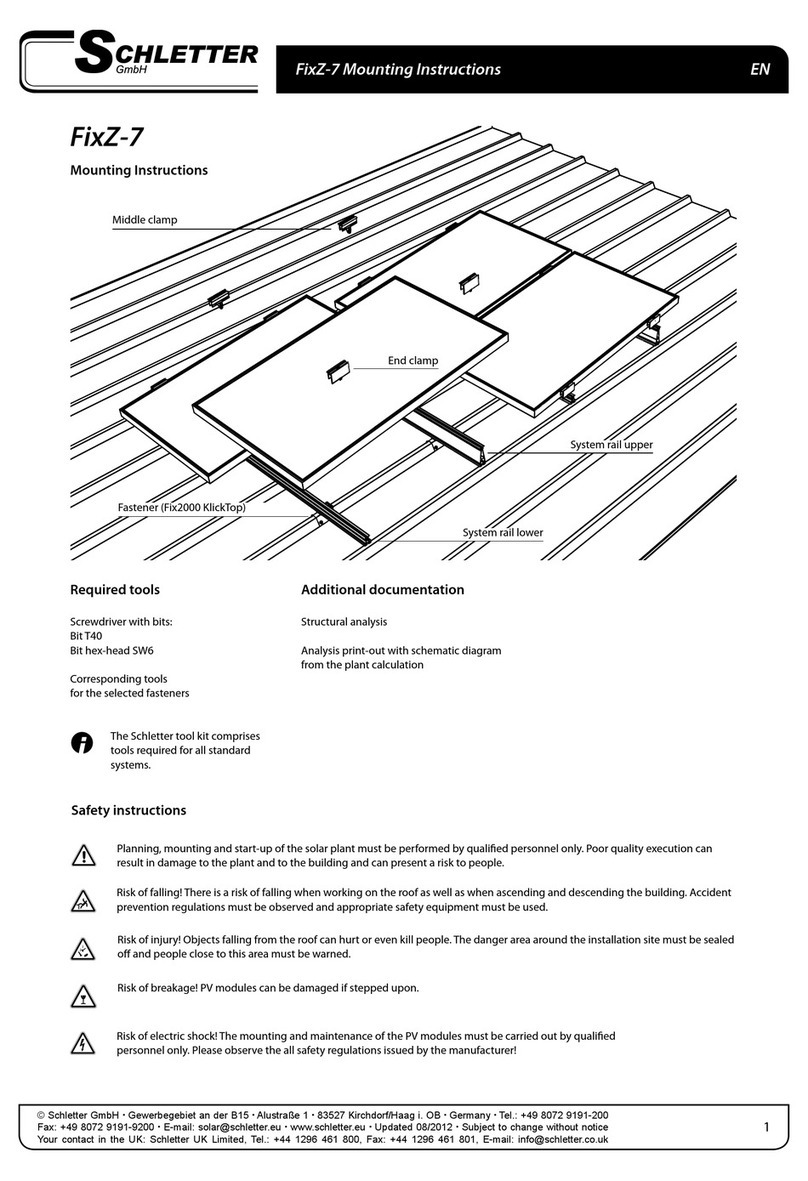

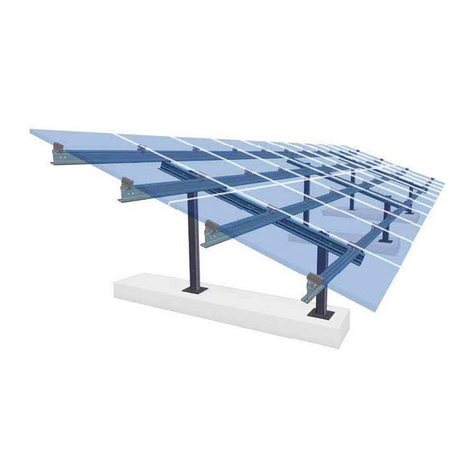

3.1. System description and properties ............................................................................................................................................... 10

3.2. Rack tolerances ..................................................................................................................................................................................... 10

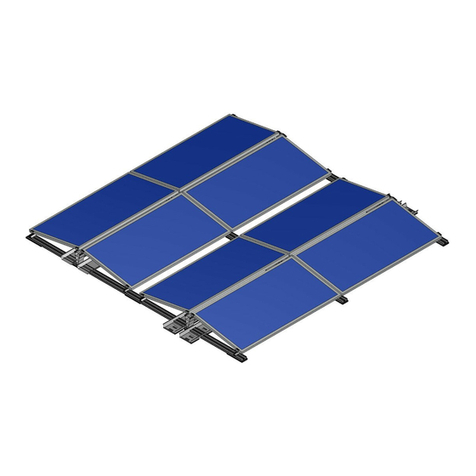

3.3. Systems overview................................................................................................................................................................................. 11

3.4. Components .......................................................................................................................................................................................... 12

3.4.1. Foundation posts.................................................................................................................................................................... 12

3.4.2. Module-bearing rails and connection elements......................................................................................................... 12

3.4.3. Strut assembly ......................................................................................................................................................................... 12

3.4.4. Girder assemblies and components................................................................................................................................ 13

3.4.5. Module clamps for vertical module mounting............................................................................................................ 14

3.4.6. Module clamps for horizontal module mounting...................................................................................................... 15

3.4.7. Module clamp adapter and connection elements for module clamps .............................................................. 15

3.4.8. Screws for standard module clamps ............................................................................................................................... 16

3.4.9. Auxiliary equipment / accessories.................................................................................................................................... 16

4. Mounting information............................................................................................................................................................17

4.1. Terrain....................................................................................................................................................................................................... 17

4.2. Foundation ............................................................................................................................................................................................. 18

4.2.1. Ramming (pile-driving) tolerances ................................................................................................................................... 18

4.2.2. Pile-driving obstacles and concreting ............................................................................................................................. 18

4.3. Tools .......................................................................................................................................................................................................... 19

4.3.1. Dening the positions of the foundation posts and marking these positions (staking).............................. 19

4.3.2. Pile-driving (ramming) ......................................................................................................................................................... 19

4.3.3. Rack mounting ........................................................................................................................................................................ 19

4.3.4. Module mounting .................................................................................................................................................................. 20

4.4. Torque specications .......................................................................................................................................................................... 20

4.4.1. Bolted connections in the substructure......................................................................................................................... 20

4.4.2. Fastening of the module clamps ...................................................................................................................................... 20

5. Assembly steps ........................................................................................................................................................................21

5.1. Pile-driving of foundation posts and applying corrosion protection.............................................................................. 21

5.2. Mounting the girder assembly....................................................................................................................................................... 23

5.3. Mounting the module-bearing rail (purlin)............................................................................................................................... 24

5.4. Mounting the purlin connectors (optional) .............................................................................................................................. 25

5.5. Mounting the module clamp adapter (optional) .................................................................................................................... 25

6. Module mounting and module clamping ..........................................................................................................................27

6.1. Module mounting and clamping in the case of vertical module bearing....................................................................... 28

6.2. Module mounting and clamping in the case of horizontal module bearing................................................................. 29

6.3. Module mounting and clamping in the case of combined module bearing................................................................. 30

7. Disassembly and disposal......................................................................................................................................................31

8. Maintenance and care ............................................................................................................................................................32

9. Warranty and liability .............................................................................................................................................................32