Schlosser

Aufzugtechnologie GmbH

Felix-Wankel-Straße 4

85221 Dachau

T +49 8131 / 5186-0

www.schlosser.de

Ausgabe

edition

06.09.2018

Seiten

pages

2/7

Bearbeiter

person in charge

Kepplinger

Zeichnung Nr.

drawing nr.

5370.800.002

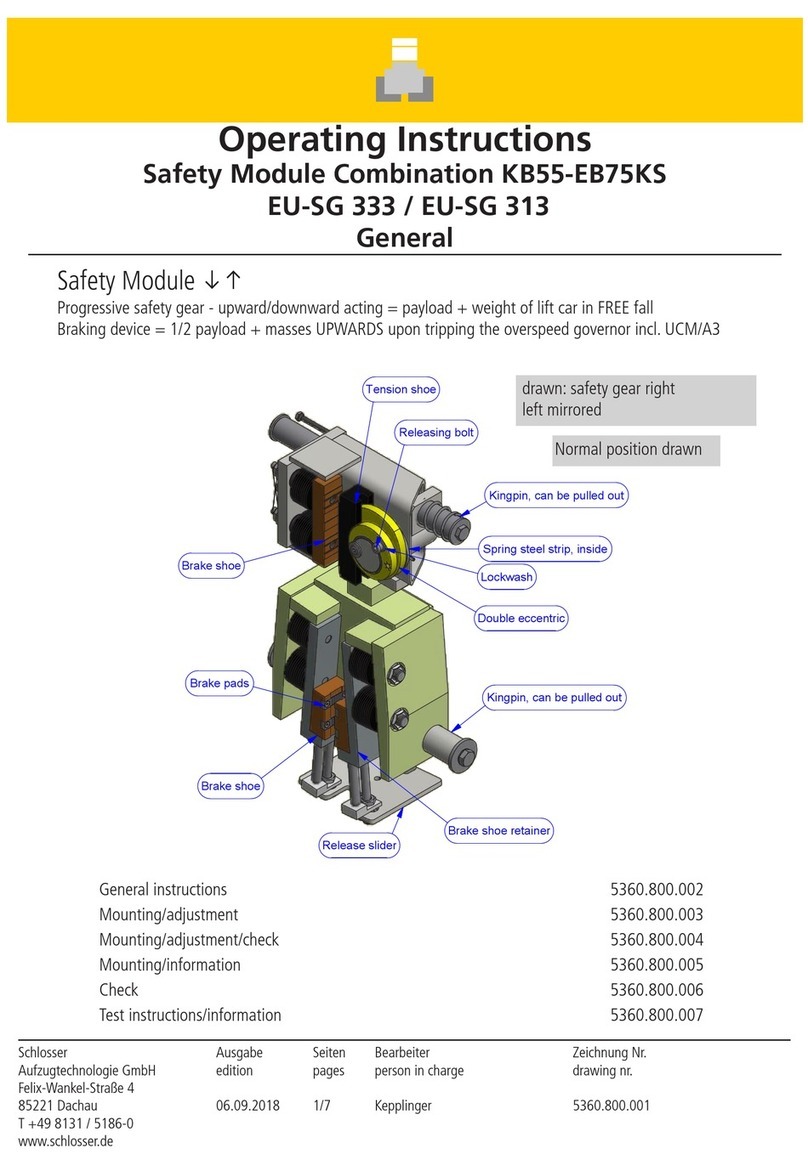

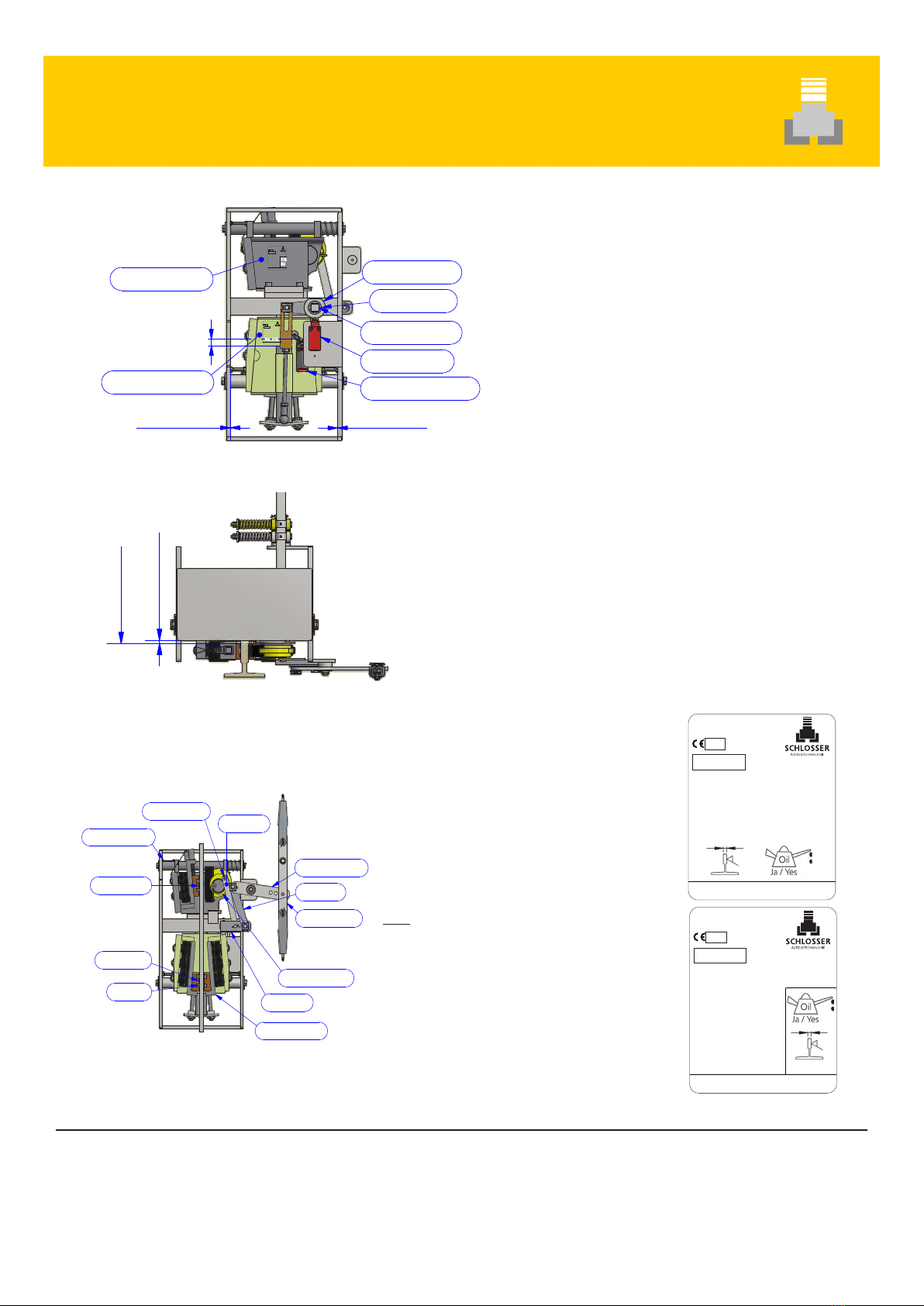

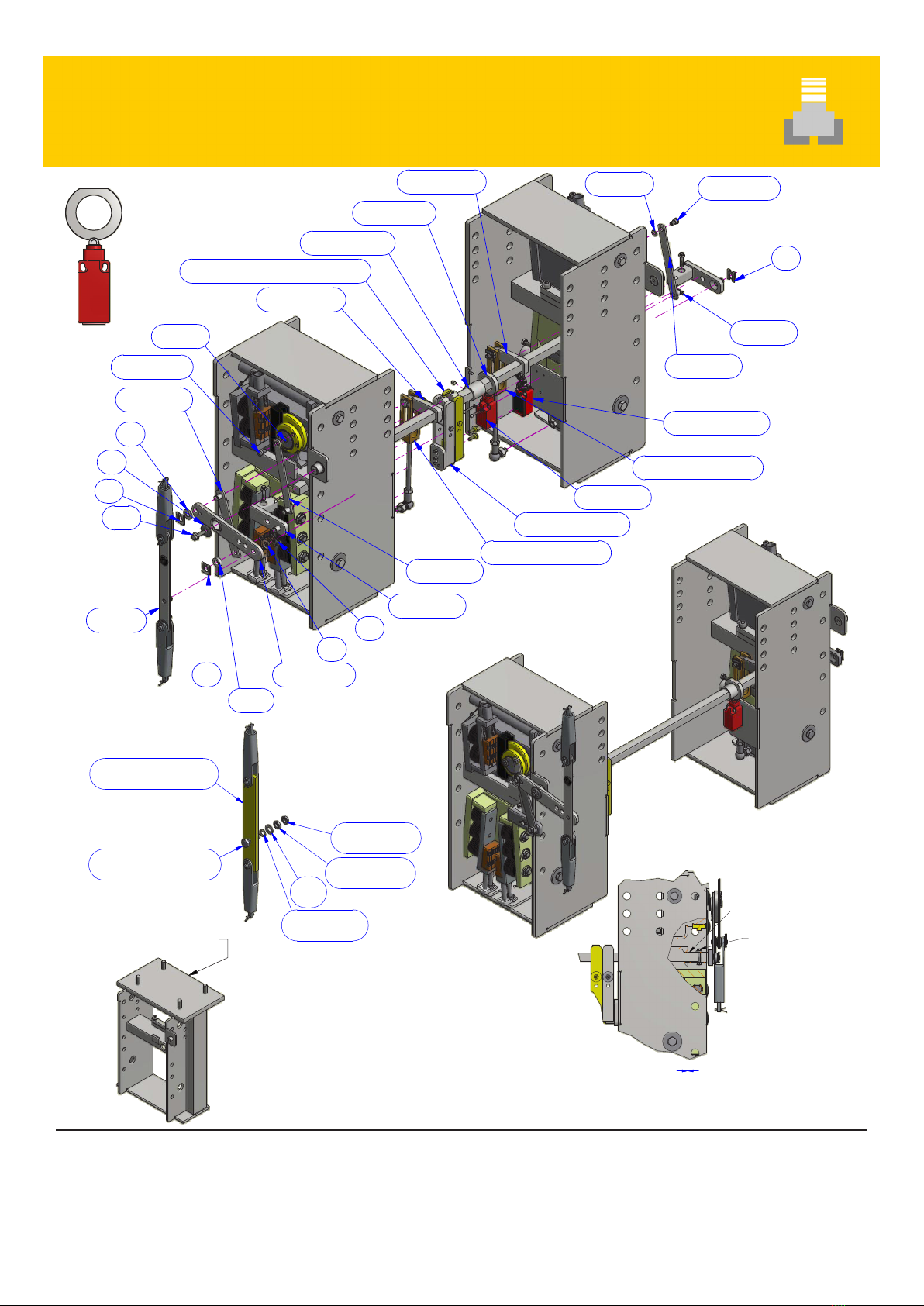

Combination KB55S/SS-EB75GS

General instructions

!Maintenance!

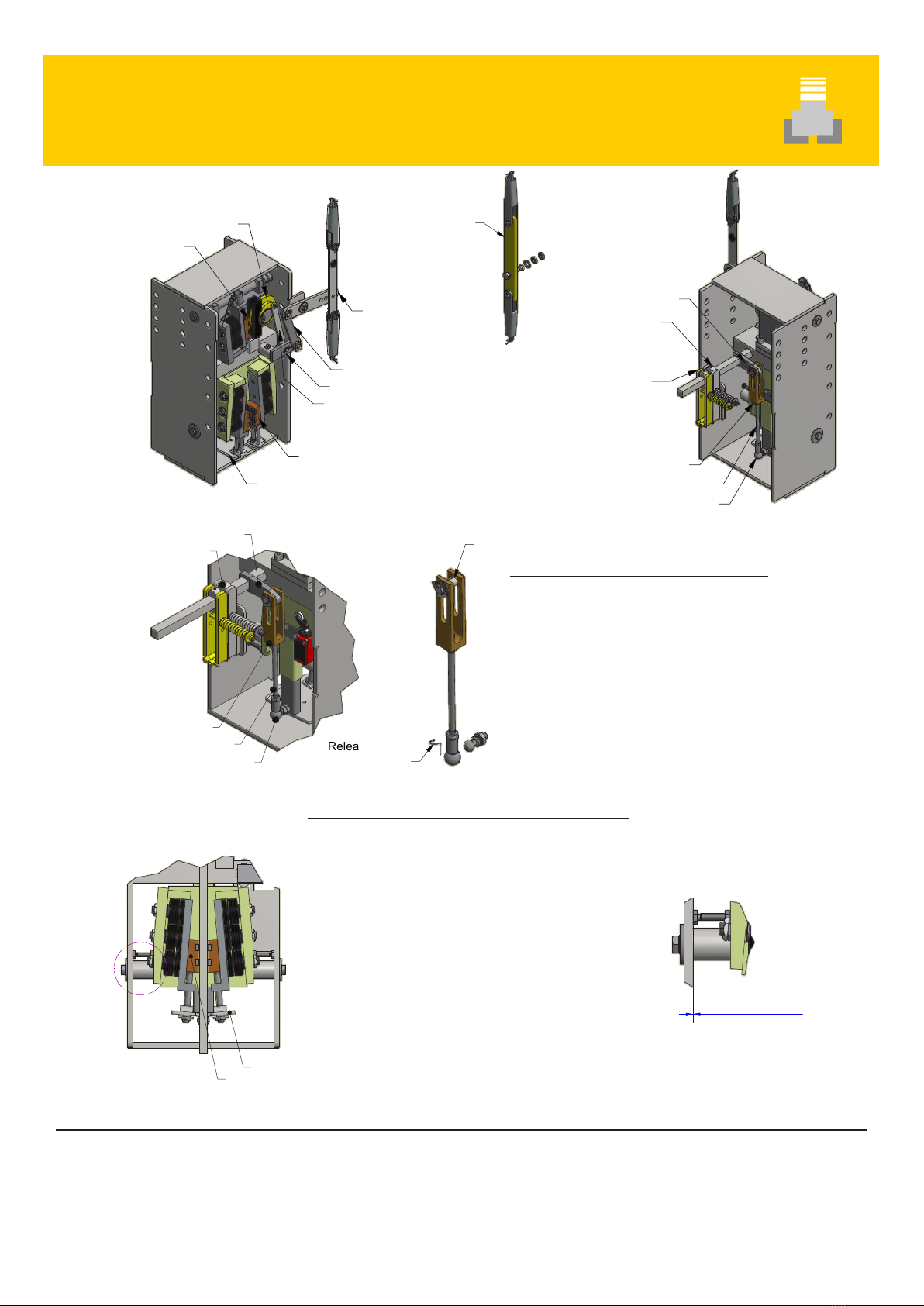

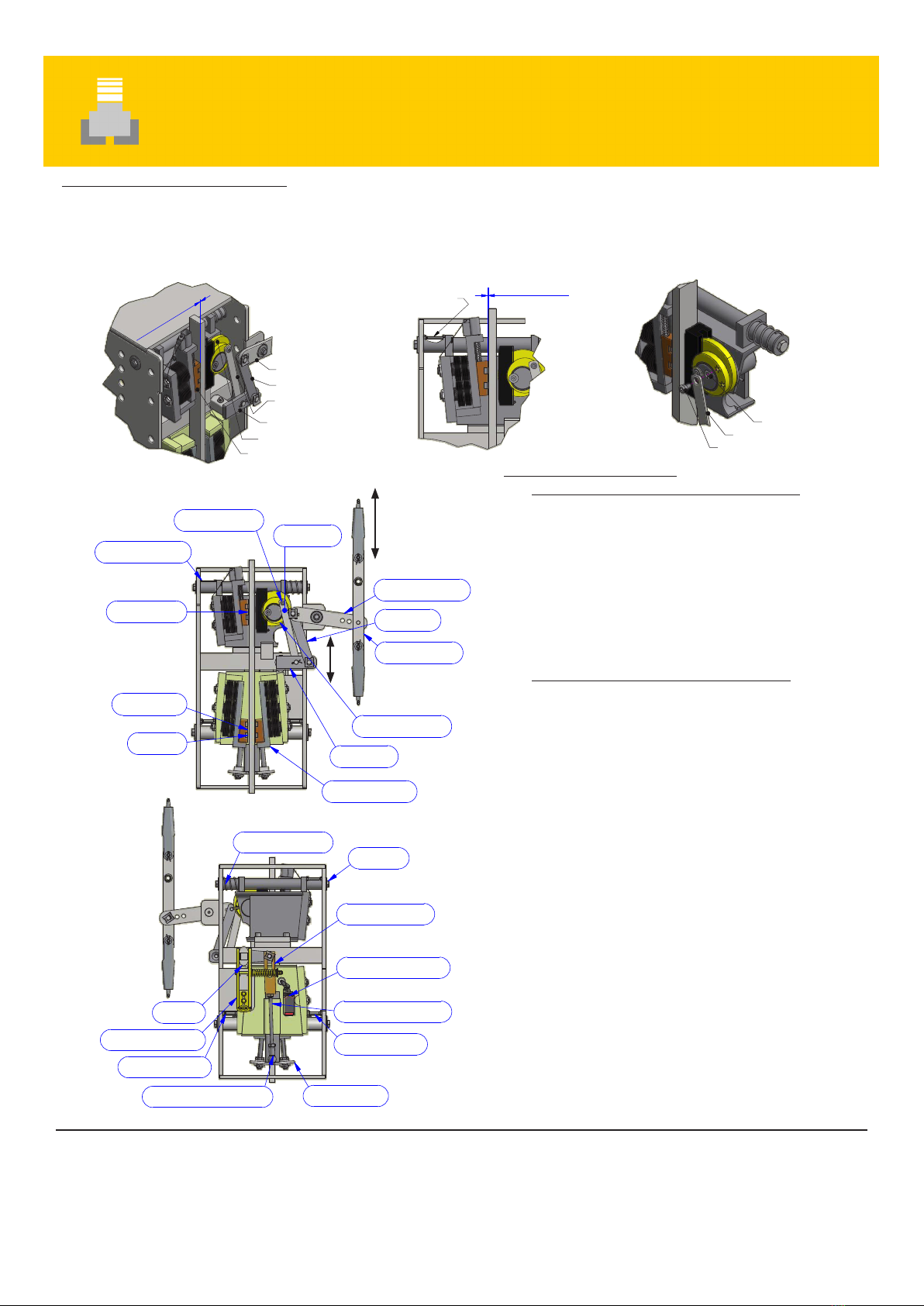

1. It must be possible to turn the actuating shaft manually until the gripping eccentric engages and the

safety gear switch must be actuated. When pulled out from the braking position, the actuating shaft

(gripping eccentric) must turn back into neutral position.

2. The guide rails must only be oiled with specified lubricants. (Observe EC-type examination certificate). No

greases, oils which become resinous etc.

3. Maintenance at least once annually (or operating hours or

contamination).

4. Avoid rust by cleaning and lubricating the moving parts.

5.

6.

7. Check the tractive force of the overspeed governor with required tractive force of the safety gear/safety

module (at least statically).

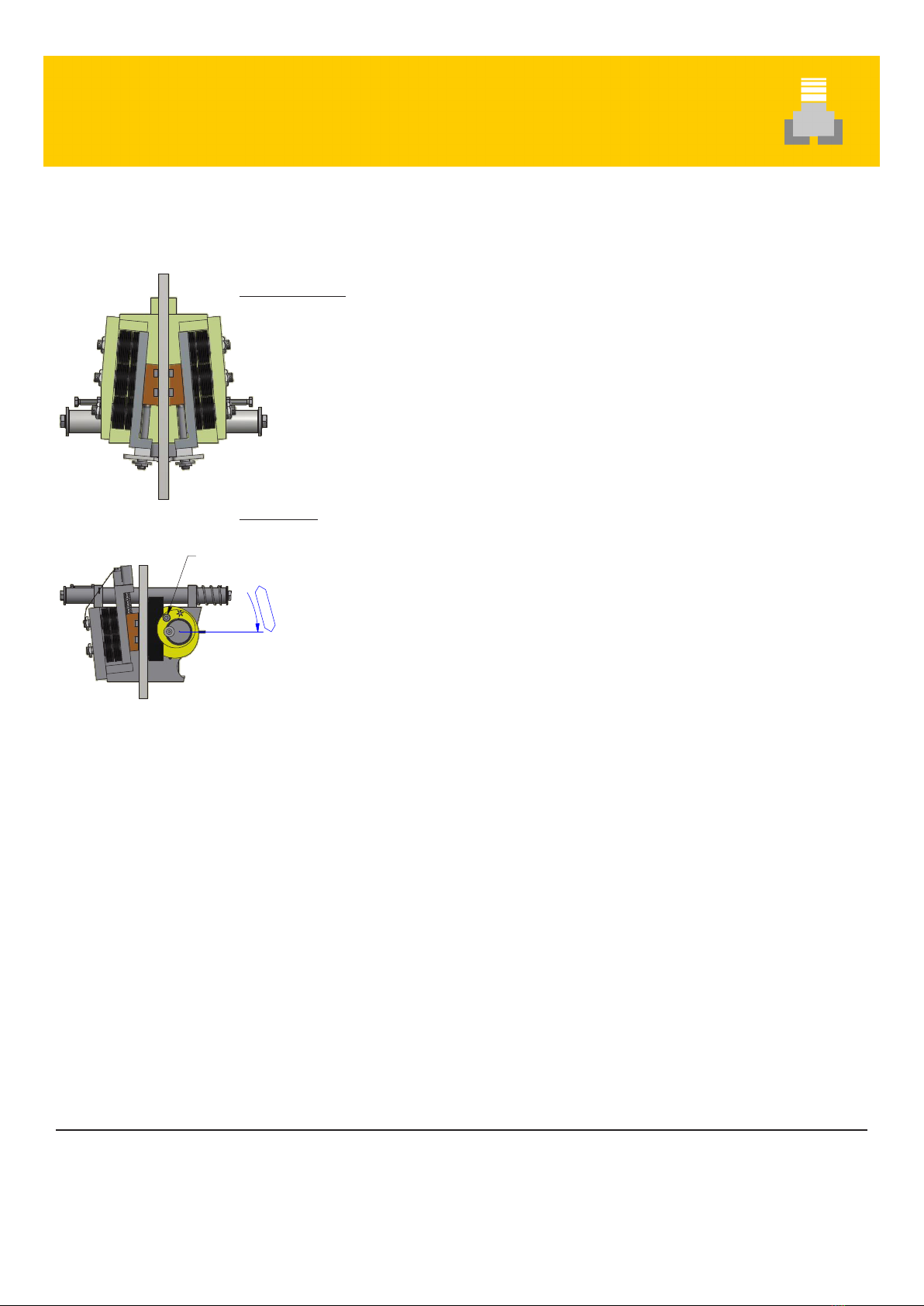

Lubricate all joints, in particular the

spring and the gripping eccentric (if

they are not moving smoothly).

Lubricate between eccentric

and spring steel strip

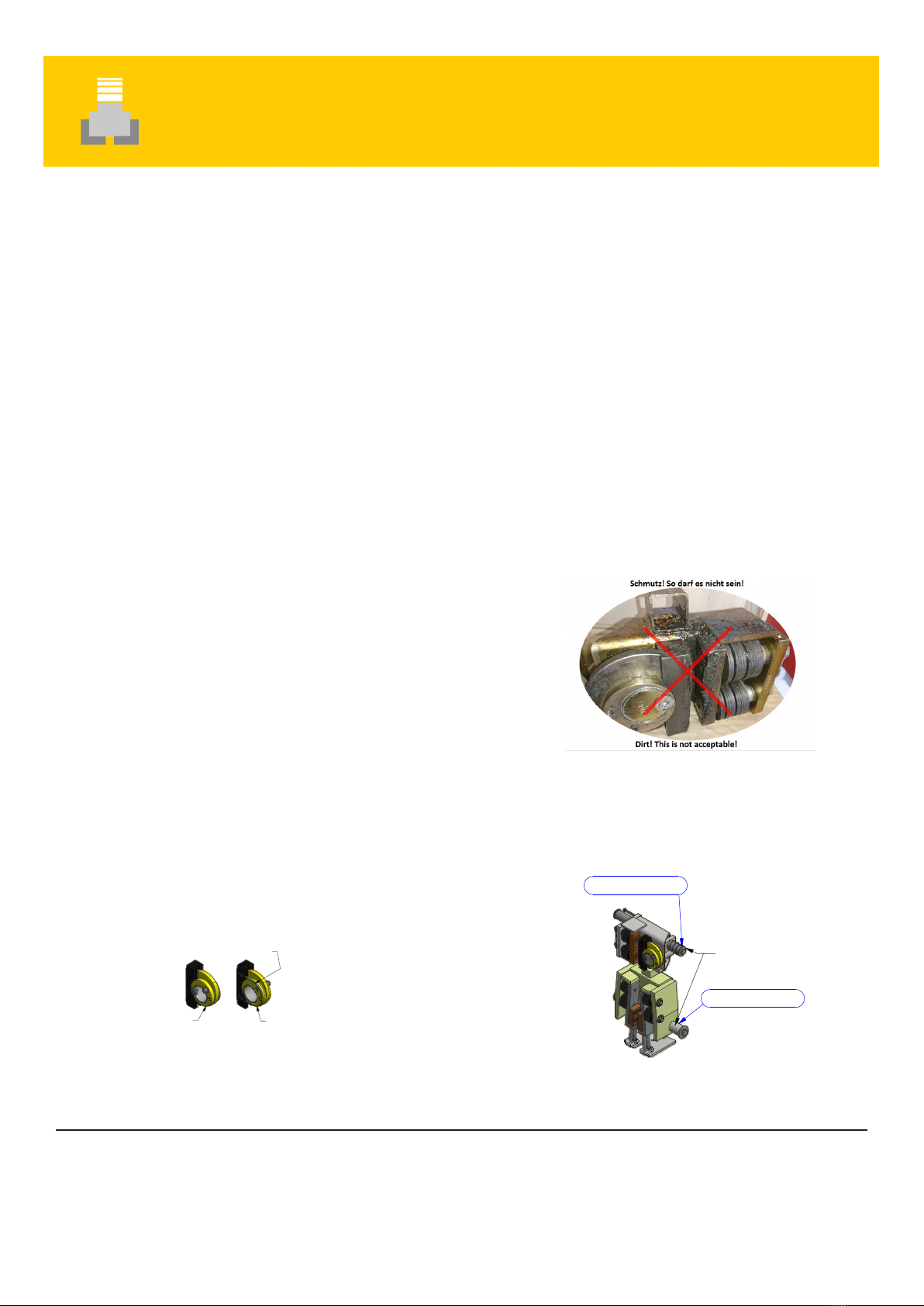

Kingpin, can be pulled out

Kingpin, can be pulled out

It must be easy to move

the safety gear smoothly

on the kingpin.

6.

!Important!

Prior to commissioning:

1. Before commissioning and testing the guide rails must be cleaned thoroughly prior to installation!

Whether „old“ or „new“, (due to dirt, old lubricant or protective agents in case of new rails!), they must

be kept clean both before and after commissioning!!!

2. Should this not take place, negative changes in the braking force etc. can/will occur: In this case, any

potential claim will be rejected.

3. Should „old“ guide rails show very long skid marks or many and deep marks (e.g. from safety gear), they

have to be replaced by new guide rails – of the same type.

4. After recommended test check (only functional test - low speed/empty lift car) a safety test (engagement

test) must be carried out according to the applicable guidelines (e.g. EN 81-20/50), also for „SRMs“

(conveyors), or according to the manufacturer‘s specifications.

Should none of the above provisions apply, the test must be executed in the „downward“ direction at

least with nominal speed and nominal load without any braking of the drive unit (e.g. keep operational

brake open!), otherwise no performance record! In the event of uncertainties, please contact us - as

manufacturer - immediately.

Periodical tests (engagement tests) must also be carried out

at regular intervals.

5. The brake power is assessed by persons with professional

expertise (e.g. inspection bodies etc.).

It must be possible to move the safety gear/safety module

smoothly on the kingpin (floating system).