7 Specifications for Use

CAUTION

During machining, dust is released into the environment and can enter the respiratory tract.

Danger to health

4Use suction equipment or cover the machining area to ensure that no dust is released into the

environment.

4If necessary, wear a breathing mask in accordance with class FFP1 or higher.

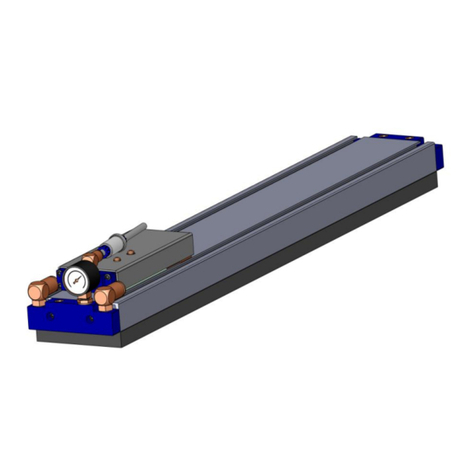

1. Monitor the vacuum value that is reached as close as possible to the vacuum block (e.g. with a gauge).

2. Ensure that the operating vacuum is ≥ 600 mbar before machining the workpiece.

3. Before each machining process, clean chips and dust from the console and vacuum block to achieve the re-

quired accuracy and adhesion as well as to prevent leakage.

4. Check the sealing gasket and sealing frame for wear and replace if necessary.

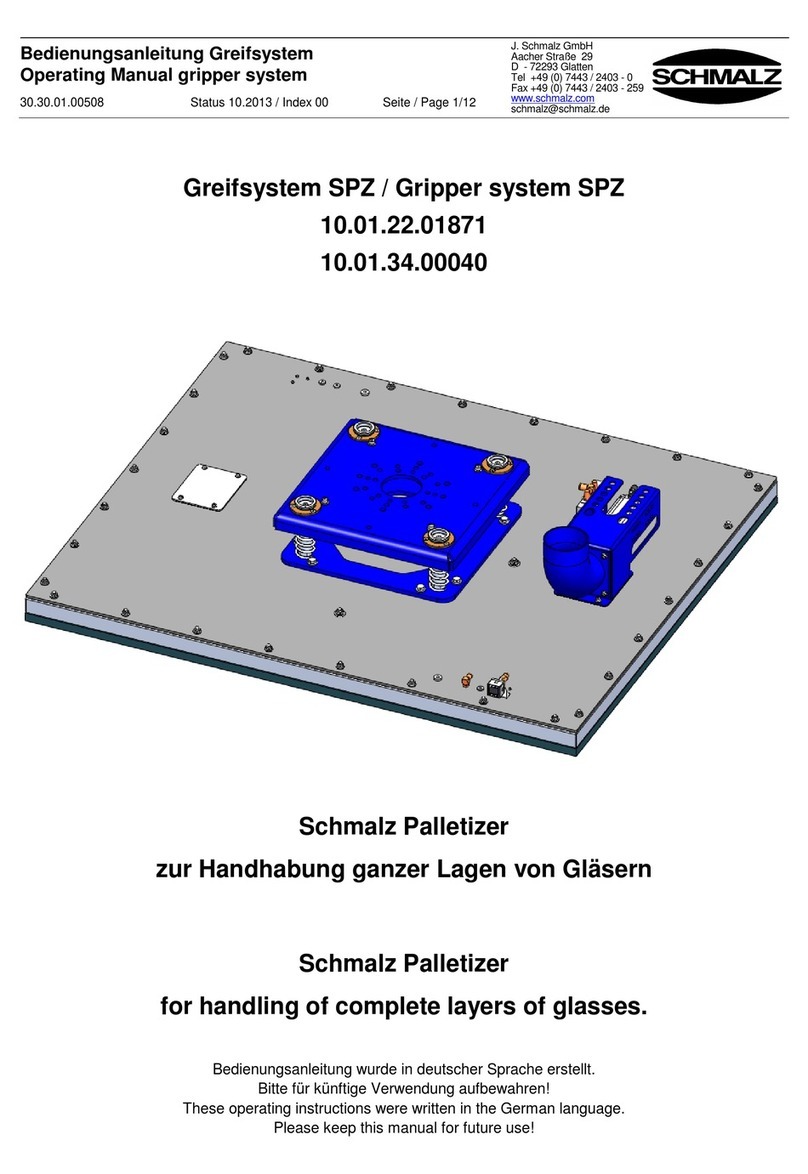

8 Using the Vacuum Blocks

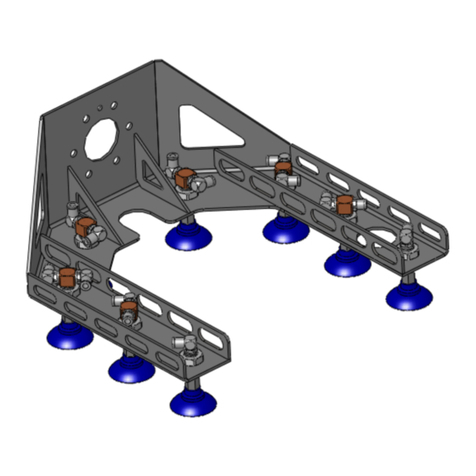

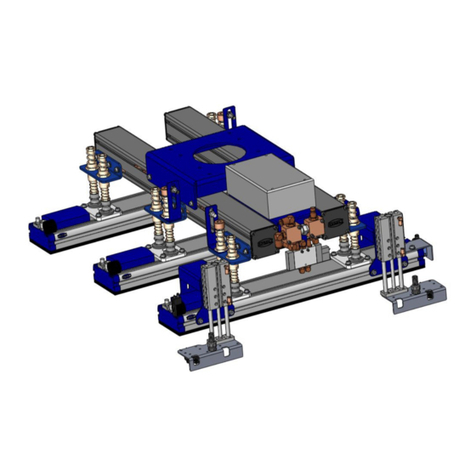

Depending on the console system (single-circuit, two-circuit), the individual vacuum block types are used as follows:

• Single-circuit console (VCBL-A-K1)

– Vacuum blocks for single-circuit consoles are pre-fixed using mechanical clamps when placed on the con-

sole. By switching on the operating vacuum and placing the workpiece on the vacuum block, the workpiece

is fixed on the vacuum block, as is the vacuum block on the console. By switching off the operating vacuum,

the workpiece is released and the fixing of the vacuum block on the console is also released. The pre-fixing

(mechanical clamp) is retained.

• Two-circuit console (VCBL-A-K2)

– Vacuum blocks for two-circuit consoles are fixed to the console by supplying operating vacuum at the first

vacuum circuit. By switching on the operating vacuum at the second vacuum circuit, the workpiece placed

on the vacuum block is fixed. By switching off the second vacuum circuit, the workpiece is released and the

vacuum block remains fixed. When switching off the first vacuum circuit, the vacuum block is released from

the console. You can also optionally attach a mechanical clamping device here. In addition to the first vac-

uum circuit, this serves as a fixing.

4Before starting the machining process, check that the vacuum block(s) and workpiece are securely fastened.

9 Machining Limitations

WARNING

The workpiece comes loose during machining and is flung away by the machine.

Risk of injury from flying parts.

4Ascertain the maximum machining parameters and observe them.

The holding force is limited, meaning that it can withstand machining forces only up to a certain point. Accord-

ingly, the operator of the vacuum block is obligated to establish for themselves (by experiment, slowly and care-

fully increasing the machining forces) the optimal settings and number of vacuum blocks necessary to ensure that

the workpiece does not slip or even come loose during the machining process.

This procedure should be performed in particular for new workpieces that have never been machined before or for

uncertain cases with regard to the holding force.

Schmalz assumes no liability for damages resulting from slippage or release of workpieces due to faulty adjustment

of machining parameters.

EN-US · 30.30.01.02385 · 00 · 04/20 9 / 10