4

3. RECIRCULATION LOOP ADJUSTMENT

A. All bar guns are preset to the minimum ow level at the factory prior to shipment.

B. If additional cooling is required, turn the plug adjust “IN or Clockwise” to obtain additional ow on

the R “IN” valve assembly.

C. If additional ow is still required, turning the plug adjust (green) “Counter Clockwise or OUT” on

the R “OUT” valve will provide additional adjustment control.

D. Check the temperature of the product after 30 mins. If additional cooling is required, repeat

steps A through C. Should the cooling be too much (caused sweating) adjust R “IN” in a Counter

Clockwise fashion half the amount as opened on the previous step.

4. BUTTERFLY PLATE REMOVAL/REASSEMBLY

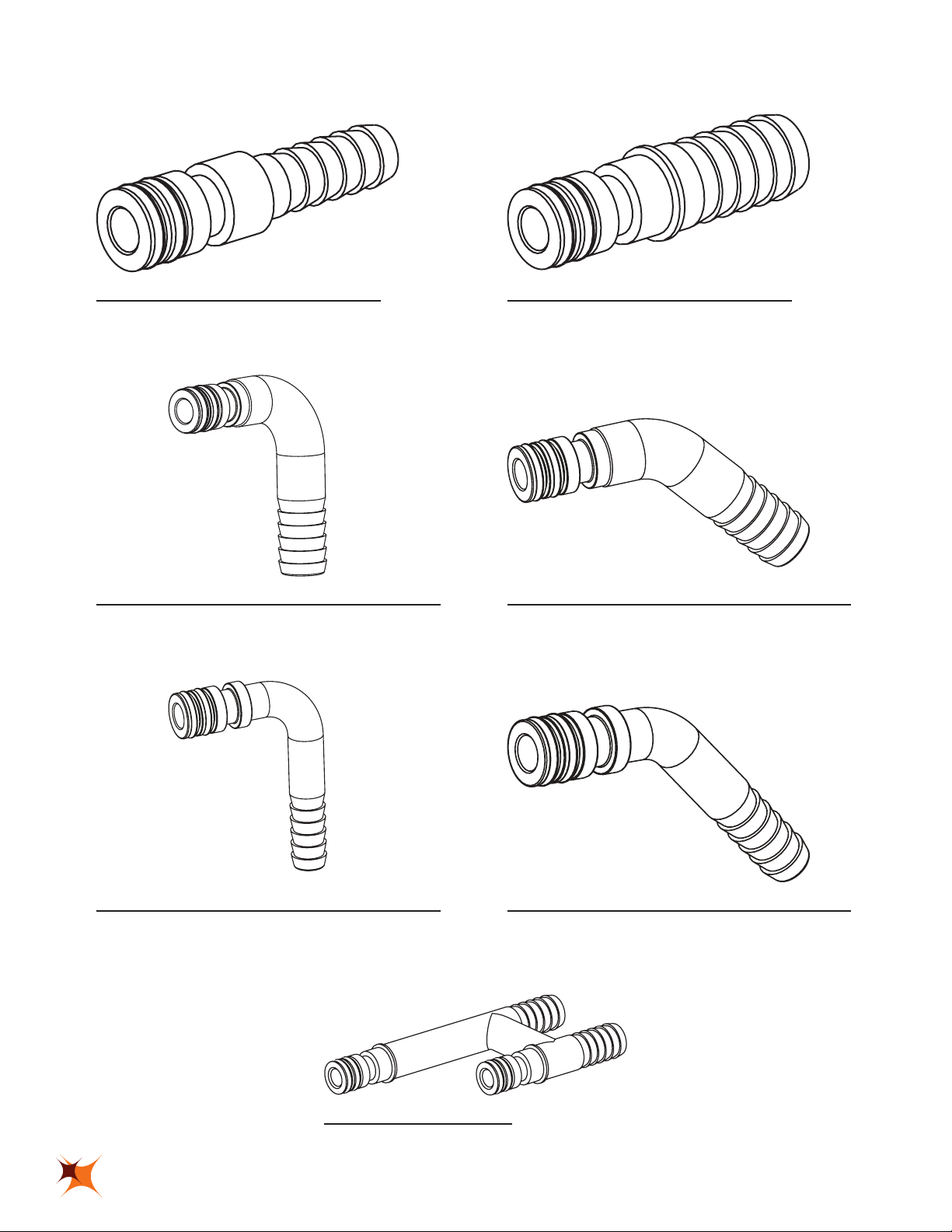

Schroeder Bar Gun can be congured in numerous combinations. All combinations can be made

without shutting down the product and soda/water support system.

The button plate can be removed while the bar dispenser is pressurized. Remove the two screws

on the bar dispenser head. To change the button, place a slotted screw driver under the button and

pry button off of button stem. Select a different button and snap onto the button stem.

To change congurations or combinations, the buttery plates located below the button plate may

need to be changed. Refer to the button plate diagrams in this manual on Page 12.

A. To change buttery plate remove button plate.

B. Remove both Phillips screws and special washers.

C. Lift buttery plates out of handle.

D. Select desired buttery conguration, (refer to back of manual for congurations).

E. Align the pivot balls, located on the bottom of the buttery plate, with the depressions in the bar

gun handle.

NOTE:

The pivot balls on the buttery plate must align with the dents in the bar gun handle for the bar gun

dispenser to work properly.

F. Secure buttery plates in position using the Phillips screws and special washers, (be careful not

to overtighten).

G. Replace button plate and reattach with Phillips screws.

5. REMOVE AND REPLACE STEM O-RING

A. Rotate yellow Shut-off stem 90 degrees, on module assembly, to turn off water/product.

B. Place bar gun handle on at surface, nozzle facing up.

C. Remove (5) Phillips screws and the bottom plate.

NOTE:

Carefully remove bottom plate, by lifting straight up. Small springs are located below the plate.

D. Remove the small loose springs.

E. Using a small pin or paper clip, push valve stem down and out of the handle.

F. To remove the water or soda valve stem, it will be necessary to remove the buttery plates. The

water and soda valve stems are located under the plates.

G. Use the spear end of the o-ring tool (P.N. 316-0003) to remove the o-ring (P.N. 208-1003) to be

replaced.