03 Contents.

1. Preparation. ................................................................................ 05

1.1 Delivery............................................................................................................................05

1.2 Safety measures prior to use ..............................................................................05

1.3 Safe disposal...............................................................................................................05

1.3.1 Packaging...........................................................................................................05

1.3.2 Product................................................................................................................05

1.4 Where to store the Instructions for use..........................................................05

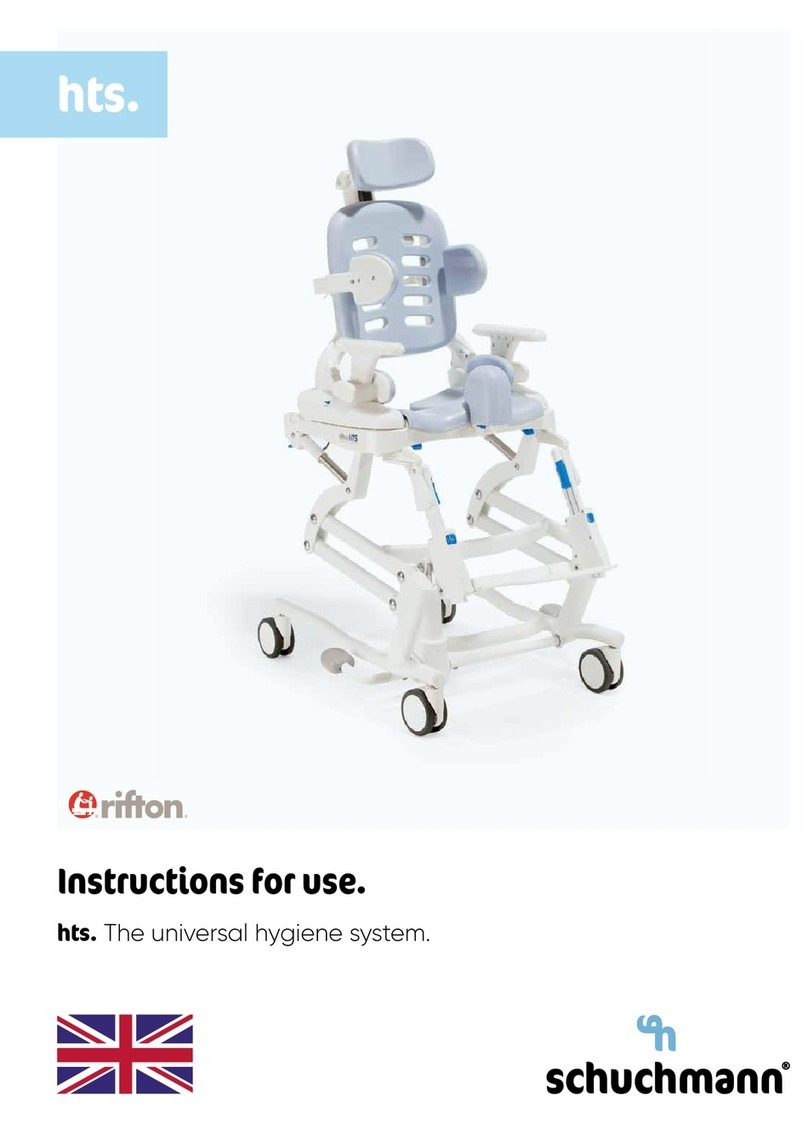

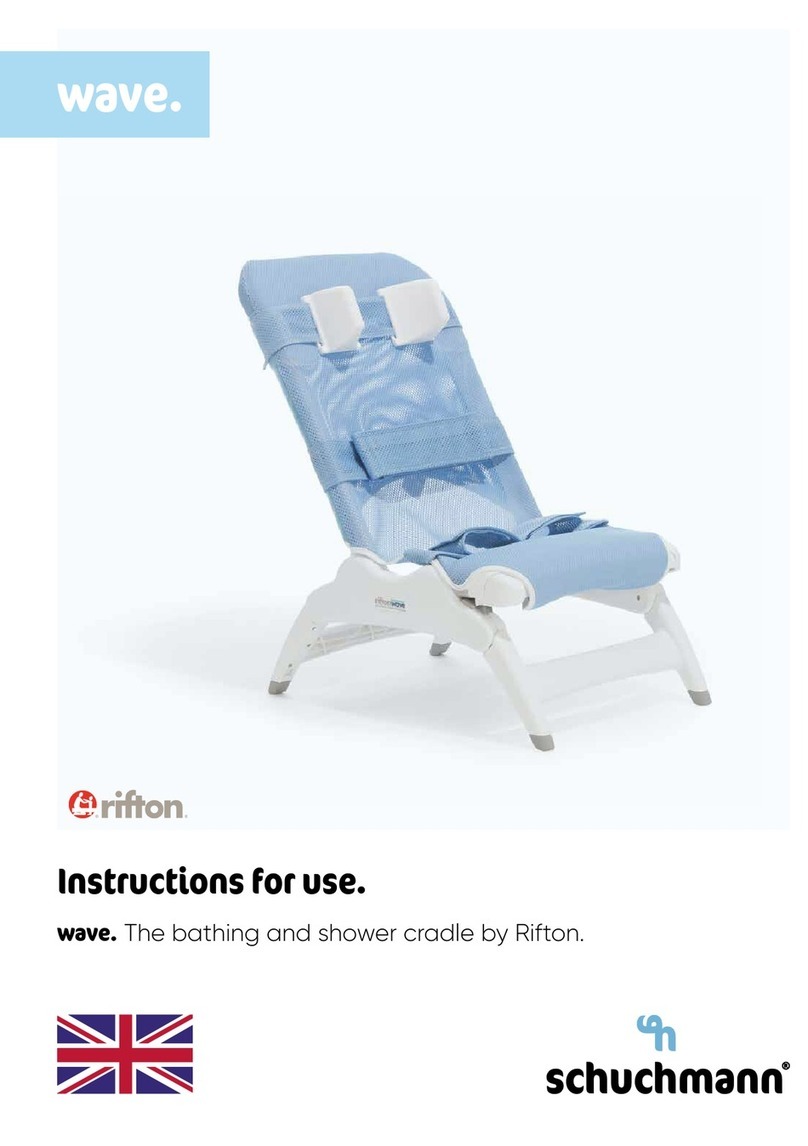

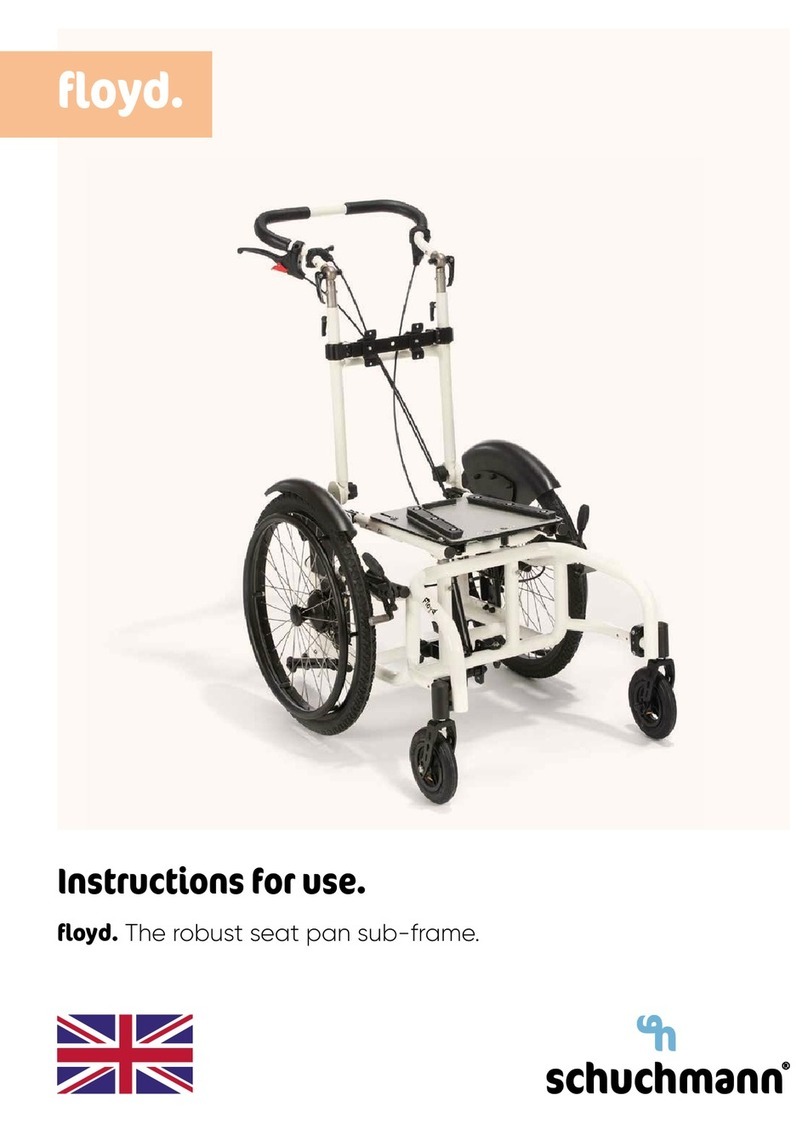

2. Product description. .................................................................... 06

2.1 Material information ................................................................................................06

2.2 Handling and transport ........................................................................................06

2.3 Application areas, use according to the intended purpose .............06

2.3.1 Indication ...........................................................................................................06

2.3.2 Contraindications .........................................................................................06

2.4 Use not in accordance with the intended purpose / warning gui-

delines............................................................................................................................07

2.5 Equipment for basic model.................................................................................08

2.6 List of accessories....................................................................................................08

2.7 Product overview......................................................................................................08

2.8 General setting instructions................................................................................09

2.9 Utilisation training ....................................................................................................09

2.10 Climbing stairs .........................................................................................................09

3. Settings. ..................................................................................... 10

3.1 Seat tilt............................................................................................................................10

3.2 Back angle adjustment with snap joint.........................................................10

3.3 Back angle adjustment with central quick adjustment......................... 11

3.4 Seat height adjustment ........................................................................................ 12

3.5 Seat depth adjustment ......................................................................................... 12

3.6 Back unit adjustment ............................................................................................. 13

3.7 Push handles................................................................................................................ 13

3.8 Push bar......................................................................................................................... 13

4. Handling of wheels. .................................................................... 14

4.1 Rear wheels with drum brake ..............................................................................14

4.2 Quick release axle.................................................................................................... 15

4.3 Wheelbase (integrated).........................................................................................15

4.4 Guide wheels .............................................................................................................. 15

4.5 Clothing guard – removable .............................................................................. 16

5. Accessories. ................................................................................ 16

5.1 Tilting device ................................................................................................................ 16

5.2 Swing-away anti-tip mechanism..................................................................... 16

5.3 Knee lever brake ........................................................................................................ 17

5.4 Footrests........................................................................................................................ 17