Copyright:

This manual is protected by copyright. The author is

SCHUNK GmbH & Co. KG. All rights reserved.

Technical changes:

We reserve the right to make alterations for the purpose of

technical improvement.

Document number:1510527

Edition:02.00|03/11/2022|en

SCHUNK GmbH & Co. KG

Spann- und Greiftechnik

Bahnhofstr. 106 – 134

D-74348 Lauffen/Neckar

Tel.+49-7133-103-0

Fax +49-7133-103-2399

schunk.com

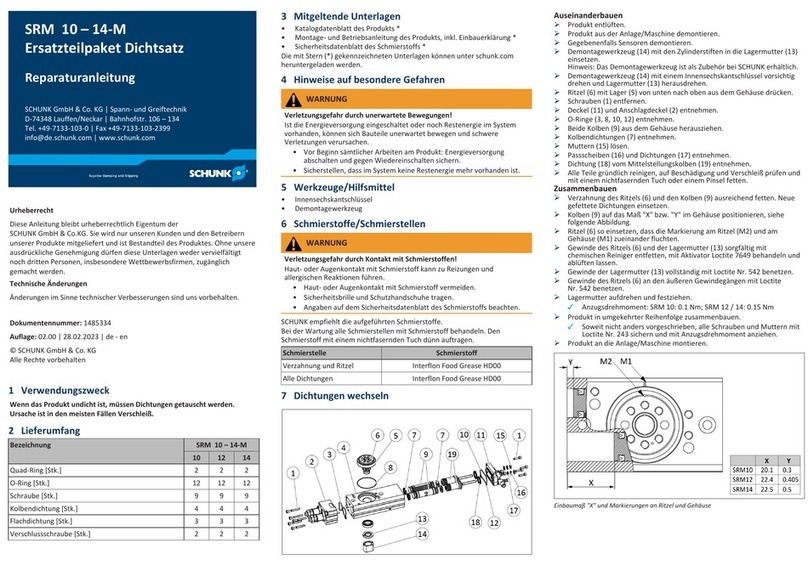

3.1Permitted shank types

1. Shank type according to DIN 1835-1 form A and DIN 6535

form HA

2. Shank type according to DIN 1835-1 form B and DIN 6535

form HB (up to Ø 20 mm)

3. Shank type according to DIN 1835-1 form B and DIN 6535

form HB (from Ø 25 mm)

4. Shank type according to DIN 1835-1 form E and DIN 6535

form HE

Tool shanks with reliefs (type 2, 3 and 4) can impair the

balancing grade and concentricity of the overall system.

4Operation

4.1Basic information

WARNING

Risk of injury due to ejected parts!

The max. speed of rotation of the machine/automated

system must be reduced when using long, projecting or

heavy tools and with extensions.

WARNING

Risk of injury and material damage due to the expansion

sleeve bursting!

If not used as intended, the expansion sleeve may burst. This

can cause metal shards and oil to be ejected from the

product under high pressure, resulting in serious injury.

•Never heat the product in heat shrink devices;

only perform a tool change using the integrated

clamping screw.

•Do not exceed the specified operating temperature.

CAUTION

Risk of injury from tools with sharp edges!

Sharp edges on tools can cause cuts.

•Wear protective gloves when assembling the tool.

NOTICE

Material damage due to burrs and dirt!

•The tool must be free of burrs and dirt at the shank.

NOTICE

Material damage due to incorrect minimum clamping

depth!

Too small a clamping depth of the tool leads to a loss of

accuracy and torque on the product.

•Observe the minimum clamping depth of the tool.

NOTICE

Potential impairment of the clamping function and damage

to the product!

If the product is not used as intended, the clamping function

may be impaired or the product may get damaged.

•Only operate the clamping screw by hand.

•Do not adjust the tool length when the tool is clamped.

4.2Mounting tool

1. Unclamp the product by loosening the clamping screw.

NOTE: The clamping screw is not secured against falling

out!

2. If required, the tool length can be adjusted by screwing the

integrated length adjustment screw in or out. Observe the

adjustment travel of the length adjustment

screw }Chap.3.

3. Ensure that the set-screws for adjusting the concentricity

do not protrude into the clamping bore and thus obstruct

the joining of the tool.

4. Insert the tool to the minimum clamping depth or stop.

5. Screw the clamping screw in by hand until it reaches the

stop. Observe the maximum specified tightening

torque }Chap.3.

4.3Assembling the product

1. Position the product with tool correctly in the machine

interface and tighten.

NOTE: Observe the machine manufacturer's specifications!

2. Check that the product is in the correct position and

securely clamped in the machine.

IMPORTANT!Safe clamping of the product in the machine

must be ensured!

4.4Adjusting concentricity

Use a suitable measuring device with a resolution of 0.001

mm to adjust the concentricity. NOTE: When using an

intermediate sleeve, the concentricity cannot be adjusted.

1. Mount the tool }Chap.4.2.

2. Mount the product }Chap.4.3. NOTE: The concentricity is

ineffective if the product is not mounted in the machine

during this process.

3. Slightly screw in all set-screws for the concentricity

adjustment. Observe the specified preload

torque }Chap.3.

4. Check the concentricity.

5. Screw in set-screw(s) on the opposite side of the highest

deflection to correct the run-out error. Observe the

specifications for the max. tightening torque of the set-

screws for the concentricity adjustment }Chap.3.

NOTE: Do not change the remaining set-screws in the

process.

6. Check the concentricity and correct again if necessary

4.5Tool change

1. Unclamp the product by loosening the clamping screw.

NOTE: The clamping screw is not secured against falling

out!

2. Loosen all set-screws for the concentricity adjustment.

3. Remove tool.

4. Mount new tool }Chap.4.2.

5Maintenance and storage

If you have any questions regarding maintenance, our technical

after-sales service is available during our business hours:

Service telephone: +49-7133-103-2956

service.toolholder@de.schunk.com

All repair work may only be performed by SCHUNK!

5.1Cleaning the clamping bore

Clean the clamping bore during every tool change with a

cleaning agent containing solvents and a cleaning brush.

5.2Checking the clamping force

Check the clamping force before initial use, after approx. 100

tool changes and at least every 3 months.

1. Unclamp the product by loosening the clamping screw.

NOTE: The clamping screw is not secured against falling

out!

2. Insert the test shaft to the minimum clamping depth.

3. Screw the clamping screw in by hand until it reaches the

stop. Observe the maximum specified tightening

torque }Chap.3.

4. The clamping force is no longer sufficient if the test shaft

can be pulled out of the product with little effort using two

fingers.

In this case, send the product to SCHUNK for inspection.

5.3Lubricating the clamping screw

CAUTION

Allergic reactions if lubricating grease comes into contact

with the skin.

•Wear protective gloves to lubricate the clamping screw.

It is necessary to adapt the cleaning and lubrication of the

clamping screw to the ambient conditions. Especially in the

case of high clamping frequencies, high operating

temperatures, and abrasive dirt or dust. For optimum

lubrication of the clamping screw, we recommend copper

paste MOLYKOTE CU 7439. (100 g tube, ID 9247204).

1. Unscrew the clamping screw from the product.

IMPORTANT!The actuating piston underneath is not

secured against falling out and must not be removed!

2. Clean the clamping screw and actuating thread and check

for damage to the thread flanks. Replace if necessary.

3. Lubricate the clamping screw and actuating thread.

4. Screw the clamping screw into the product.

5. Check the clamping force }Chap.5.2.

5.4Storage

– Lightly oil the entire surface of the product.

– Only store the product in an unclamped state and protected

against corrosion.

– Store the product in a suitable transport container.

– Protect the product from excessive temperature fluctuations.

NOTE: Before recommissioning, clean the product and check

for damage, functionality and tightness!

6Disposal

– Follow local regulations on dispatching product components

for recycling or proper disposal.

– Alternatively, you can return the product to SCHUNK for

correct disposal.