10

6.2 Grounding instructions

1. All Grounded, Cord-connected Tools:

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce the risk of electric shock.

This tool is equipped with an electric cord having an

equipment-grounding conductor and a grounding

plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipment-grounding

conductor to a live terminal.

Check with a qualified

electrician or service personnel if the grounding

instructions are not completely understood, or if

in doubt as to whether the tool is properly

grounded. Failure to comply may cause serious

or fatal injury.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug.

Repair or replace damaged or worn cord

immediately.

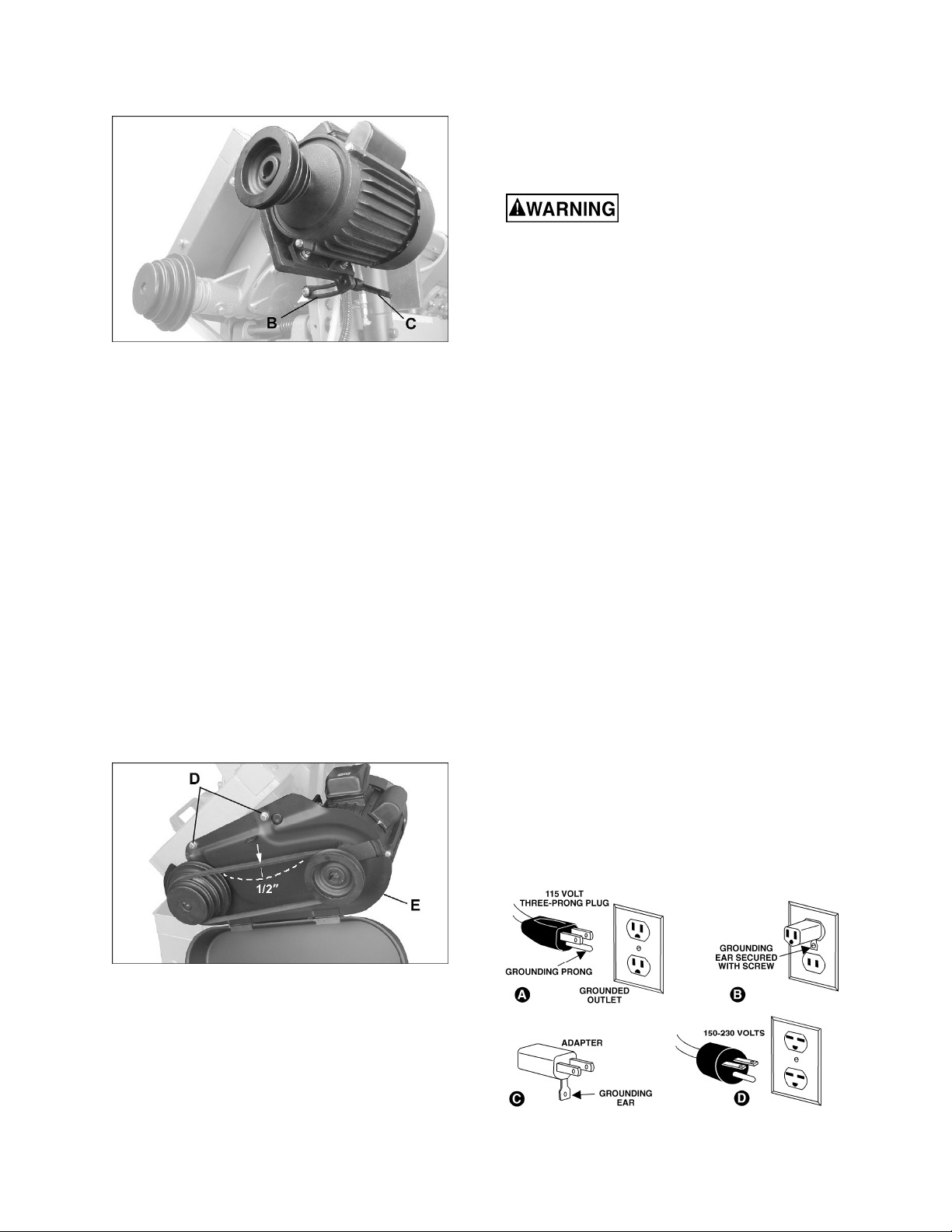

2. Grounded, cord-connected tools intended for use

on a supply circuit having a nominal rating less than

150 volts:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in A, Figure

6-1. An adapter, shown in Band C, may be used to

connect this plug to a 2-pole receptacle as shown in

Bif a properly grounded outlet is not available. The

temporary adapter should be used only until a

properly grounded outlet can be installed by a

qualified electrician. The green-colored rigid ear,

lug, and the like, extending from the adapter must

be connected to a permanent ground such as a

properly grounded outlet box. Whenever the

adaptor is used, it must be held in place by a metal

screw.

In Canada, the use of a temporary adaptor is not

permitted by the Canadian Electrical Code, C22.1.

3. Grounded, cord-connected tools intended for use

on a supply circuit having a nominal rating between

150 - 250 volts, inclusive:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in D, Figure

6-1. Make sure the tool is connected to an outlet

having the same configuration as the plug. No

adapter is available or should be used with this tool.

If the tool must be reconnected for use on a different

type of electric circuit, the reconnection should be

made by qualified service personnel; and after

reconnection, the tool should comply with all local

codes and ordinances.

6.3 Extension cords

The use of extension cords is discouraged. Try to

position equipment near the power source. If an

extension cord becomes necessary, use only three-

wire extension cords that have three-prong

grounding type plugs and three-prong receptacles

that accept the tool's plug. Replace or repair

damaged or worn cord immediately.

Make sure your extension cord is good condition,

and is heavy enough to carry the current your

product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and

overheating.

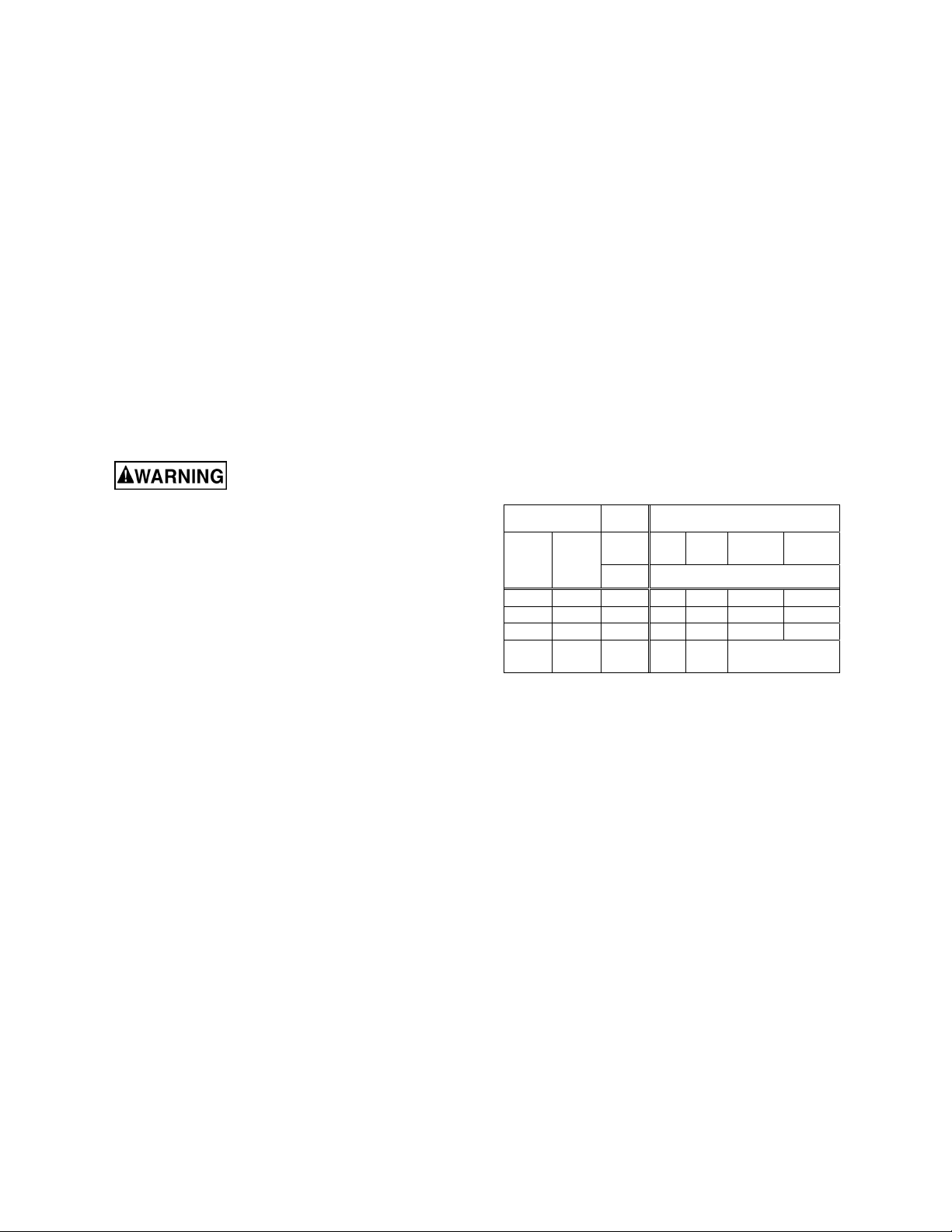

Table 2 shows the correct size to use depending on

cord length and nameplate ampere rating. If in

doubt, use the next heavier gage. The smaller the

gage number (AWG), the heavier the cord.

Amp rating Volts Total length of cord in feet

More

Than

Not

More

Than

120

240

25

50

50

100

100

200

150

300

AWG

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

Not

Recommended

Extension Cord Recommendations

Table 2

6.4 Voltage conversion

Before wiring, make sure saw is disconnected from

power source or the fuses have been removed or

breakers tripped in the circuit to which the saw will

be connected. Use appropriate Lock-Out/Tag-Out

procedures.

To change the HBS-916 voltage input to 230 volt:

1. Main motor – Open motor junction box cover.

Follow diagram inside cover to reconnect the

incoming leads.

2. Coolant pump – Remove chip pan, remove

junction box cover on pump, and follow diagram

inside junction box cover to change the leads.

3. Power cord – Replace the provided 115V plug

with a UL/CSA listed 230V plug. Or “hardwire”

the machine directly to an electrical panel.

(Make sure a disconnect is available for the

operator.)