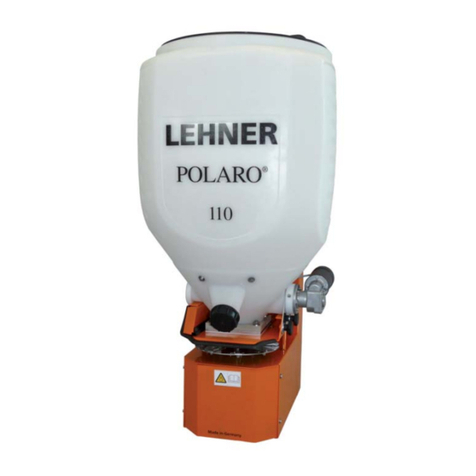

LEHNER POLARO Datasheet

Other LEHNER Spreader manuals

LEHNER

LEHNER SuperVario X Guide

LEHNER

LEHNER AgroDos Datasheet

LEHNER

LEHNER POLARO User manual

LEHNER

LEHNER SuperVario Guide

LEHNER

LEHNER POLARO E Datasheet

LEHNER

LEHNER SuperVario User manual

LEHNER

LEHNER MiniVario E Datasheet

LEHNER

LEHNER Vento User manual

LEHNER

LEHNER POLARO User manual

LEHNER

LEHNER Polaro L Datasheet

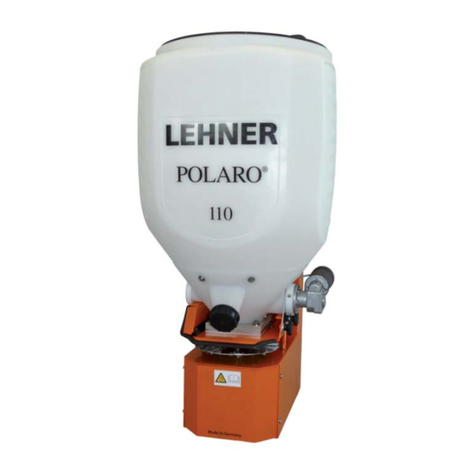

Popular Spreader manuals by other brands

Fisher

Fisher POLY-CASTER 78601 owner's manual

Fayat Group

Fayat Group DYNAPAC S100 operation & maintenance

Art's-Way Manufacturing

Art's-Way Manufacturing X700 Operator's manual & parts list

Ferris

Ferris Pathfinder Series Operator's manual

Herculano

Herculano H2RS9 instruction manual

TurfEx

TurfEx RS7200 Owner's/operator's manual