1 Introduction..............................4

2 Cautions, Notes and Symbols . . . . . . . . . . . . . . . .5

3 Warranty & Safety Information...............6

3.1 Measures forYour Protection................6

3.2 Measures forYour Operational Safety .........7

4 Specifications ............................8

5 Installation...............................9

5.1 Before installation........................9

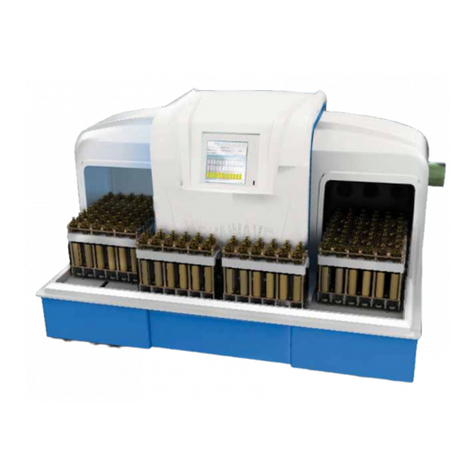

5.1.1 Overview ........................9

5.1.2 Unpacking........................10

5.1.3 Inspection .......................10

5.2 Hardware Installation guidelines .............10

5.2.1 InstallingThe BOD Racks .............10

5.2.2 Cable Connections..................10

5.3 before Software Installation.................11

5.3.1 Computer System Requirements .......11

6 Software Operation ........................12

6.1. Overview of Software.....................12

6.1.1 SoftwareTabs .....................12

6.1.2 Operational Buttons .................13

6.1.3 Hardware Detection .................13

6.2 ProcessTab............................14

6.2.1 Information Field ...................14

6.2.2 Process Sample Field................15

6.2.2.1 Edit sequence tool ................16

6.2.2.2 Process table fields ...............16

6.3 ResultsTab ............................17

6.3.1 Definitions........................17

6.4 UtilitiesTab ............................18

6.4.1 Configuration Process ...............19

6.4.2 Position (Robot) ....................19

6.4.3 Calibrate Pumps ...................20

6.4.3.1 Inhibitor and Seed pumps ..........20

6.4.3.2 Dilution water pump ..............20

6.4.3.3 Waste pump ....................21

6.4.4 Priming/Cleaning...................21

6.4.5 ProODO Probe.....................21

6.4.5 Calibration of the BOD probe ..........22

6.5 Admin-ToolsTab.........................23

6.5.1 Robot ...........................23

6.5.2 Rack Parameters...................24

6.5.3 Calibration of theAutofill Sensor(s) ......26

6.5.4 Instrument Memory Parameters ........27

6.5.5 QC Controls.......................27

6.5.6 Parameters .......................28

7 Guidelines on BOD/CBOD Analysis ............29

7.1 Priming ...............................29

7.2 Peristaltic pump calibration.................29

7.3 Probe Calibration ........................29

7.4 Typical BOD testing Procedure ..............29

7.4.1 Sample Pretreatment: ...............29

7.4.2 DilutionWater Preparation: ...........30

7.4.3 Seed Preparation: ..................30

7.5 QC sample (GGA standard): ................30

7.6 SeedVOL (ml): .........................30

7.7 SampleAnalysis.........................31

7.7.1 Day 0 ...........................31

7.7.2 Day 5 or 7........................31

7.7.3 Process troubleshooting..............32

7.8 Turning off the instrument..................32

8 Probe Operation and Maintenance ............33

8.1 Initial setup ............................33

8.2 Maintenace and storage ...................34

8.2.1 Sensor Maintenance - Dissolved Oxygen .....34

8.2.1.1 Cleaning the OBOD Sensor cap.......34

8.2.1.2 OBOD Sensor Cap Replacement ......34

8.2.1.3 Configuring for the new sensor cap ...35

8.2.1.4 Rehydrating the sensor cap .........36

8.2.1.5 Sensor maintenance - temperature ...36

8.2.2 Sensor Storage .......................36

8.2.2.1 Sensor short-term storage ..........36

8.2.2.2 Sensor long-term storage...........36

9 BOD-300 Peristaltic Pump ..................37

9.1 Peristaltic Pump replacement ...............37

9.2 New Dilution Pump Calibration ..............37

9.3 New Seed Pump Calibration ................38

10 Troubleshooting.............................39

Table of Contents