SCP SCIENCE NOVAWAVE User manual

NOVAWAVE

A new category of Automated Microwave Digestion

User Manual

Spacer Rack

Required to complete a system

with 14 racks (FA model).

(Qty: One)

Cat. # 010-600-017

Transfer Rack Stand

12 position polycarbonate

support stand for vessels and

Transfer Rack.

(Qty: One)

Cat. # 010-600-040

Transporter

Required to upgrade a

NOVAWAVE SA to FA model.

With Forced Air Cooling and

Auto-Venting stations.

(Qty: One)

Cat. # 010-600-003

Venting Tool

Required to manually release the safety

pressure cap after digesting samples.

(Qty: One)

Cat. # 010-600-080

Fluoropolymer Cap Liners

Required to protect safety caps from sample

contamination.

(pk/6)

Cat. # 010-600-032

Barcode Reader

Barcode reader and probe

to enter Sample ID’s.

(Qty: One)

Cat. # 010-600-034

Options

MANUFACTURED IN CANADA

EU Users:

Contact your local

distributor for disposal

instructions.

Copyright by SCP SCIENCE

All Rights Reserved

This manual contains proprietary information, which shall not be reproduced or transferred to other documents

or disclosed to others without prior written permission from SCP SCIENCE.

Disclaimer: Products are supplied for laboratory use only. SCP SCIENCE presumes that only trained and qualified individuals, familiar with procedures suitable for

the safe operation of these instruments, will handle them. Our customers are solely responsible for the safe operation, handling and use of these products.

CERTIFIED to comply with the following EMC and safety requirements standards:

EN61326-1 :2006, CISPR 11 :2003 + A2 :2006, IEC 61000-4-2:2001, IEC 61000-4-3:2002, IEC 61000-4-4:2004, IEC 61000-4-5:2001, IEC 61000-4-

6:2003, CISPR 11, 47CFR chapter 1 FCC part 18, FCC part 18.305, 21 CFR part 1030.10 c) 1,2,3, FCC OST/MP-5 :1986 and IEC 61010-1:2001(2nd edition).

Power Density Test/Report According to 21 CFR Par 1030.10 C) 1,2,3 and IEC 61010-1 Clause 12.4 ICES-001, CISPR11, EN55011 and EN61326-1.

Canada / International

21800, Avenue Clark-Graham

Baie d’Urfé, QC

H9X 4B6

Tel: +1 (514) 457-0701

Fax: +1 (514) 457-4499

USA

348 Route 11, P.O. Box 3221

Champlain, NY

12919-4816

Tel: 1-800-361-6820

Fax: 1-800-253-5549 (North America only)

Europe

12, Avenue du Québec

Bâtiment Iberis, Silic 642

91965 Courtaboeuf CEDEX, France

Tel: +33 (0) 1 69 18 71 17

Fax: +33 (0) 1 60 92 05 67

China

#2 Building, Room 727

106 Ma Jia Pu East Road

Feng Tai District, Beijing, China 100068

Tel: +86 (10) 58032301

Fax: +86 (10) 58032302

Brazil

Tel: +55 19 8194-8488

Service Department • Technical Support

4| TABLE OF CONTENTS

Table of Contents

1 Introduction 5

Accessories . . . . . . . . . . . . . . . . . . . . . . 6

2 Installation 7

3 Cautions, Notes and Symbols 9

4 Racks and Vessels 10

5 Software Operation 12

Programming a Run . . . . . . . . . . . . . . . . 14

Cycle . . . . . . . . . . . . . . . . . . . . . . . . 14

Sample Position . . . . . . . . . . . . . . . . . . . 17

Entering Sample ID . . . . . . . . . . . . . . . . . . 20

Digestion . . . . . . . . . . . . . . . . . . . . . . . 21

Digestion Method Creation . . . . . . . . . . . . . . 22

Method Creation methods . . . . . . . . . . . . . . 24

Reports . . . . . . . . . . . . . . . . . . . . . . 29

Utilities . . . . . . . . . . . . . . . . . . . . . . . . 30

IR Calibration . . . . . . . . . . . . . . . . . . . . . 31

Users . . . . . . . . . . . . . . . . . . . . . . . . . 33

Settings . . . . . . . . . . . . . . . . . . . . . . . . 35

Updating the Software. . . . . . . . . . . . . . . . . 35

System . . . . . . . . . . . . . . . . . . . . . . . . 36

Diagnostic. . . . . . . . . . . . . . . . . . . . . . . 36

Logout . . . . . . . . . . . . . . . . . . . . . . . . 37

6 Cleaning of System 38

Cleaning of Vessels . . . . . . . . . . . . . . . . . 38

Cleaning of Fluoropolymer Caps and Safety Caps . . . . 38

Pressure . . . . . . . . . . . . . . . . . . . . . . 38

Cleaning the Tunnel . . . . . . . . . . . . . . . . . 38

Cleaning the GUI . . . . . . . . . . . . . . . . . . 38

Cleaning the Rack . . . . . . . . . . . . . . . . . . 38

7 Warranty & Safety Information 39

Safety Messages . . . . . . . . . . . . . . . . . . 40

Safety Messages from the Power Management Board. . 40

Toxic or Hazardous Substances and Elements. . . . . . 42

8 Specications 42

Environmental 42

Electrical . . . . . . . . . . . . . . . . . . . . . . 42

Fuses - Ratings . . . . . . . . . . . . . . . . . . . 42

Safety . . . . . . . . . . . . . . . . . . . . . . . 42

9 Troubleshooting 44

List of Error messages . . . . . . . . . . . . . . . . 44

Version 0.15.1

| 5

1 Introduction

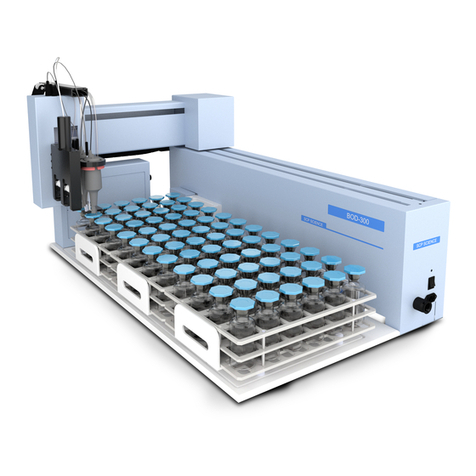

NOVAWAVE is a new, fully automated, sample digestion tunnel with microwave cavities to simultaneously process samples in Quartz or

Fluoropolymer vessels. NOVAWAVE delivers a dramatic improvement in sample throughput and speed of digestion plus a major reduction in

labor and human intervention compared to any other digestion system. Speed and flexibility are built-in with the capability of running a rack of

samples with individual sample temperature programs.

Sample vessels are placed in racks and capped, then the pressure safety system closes over the top of the 12 samples. The rack enters the

tunnel and 12 dynamic microwave mini cavities are formed, delivering energy to each mini cavity according to the digestion method selected.

In the NOVAWAVE FA model, when the rack exits the tunnel, the rack proceeds to the Cooling Station and a second rack enters the tunnel

to begin its digestion sequence. Once the digestions in the second rack are completed, the rack moves to the Cooling Station with the first

rack moving to the Auto-Venting Station. Here, vessels are safely vented automatically when they reach a pre-assigned temperature pre-set in

the method.

Unpacking

The system weighs approximately 150 lbs / 75 kg. The NOVAWAVE is attached to the packaging with 4.5 inch bolts. Remove them prior

to lifting the system out of the box. It is OK to lay the system on its back and install the 4 feet provided. It will take a minimum of two people,

lifting from the bottom to place the system on the horizontal surface where it will be used. Be sure that the surface can accommodate 75 kg.

Save the packing material for further use. Ensure all parts have been delivered; some parts may be in other boxes.

Inspection

Ensure all of the parts are included in the packaging. There may be some accessories that have been packaged in the same box as the

NOVAWAVE. If damage is observed, contact the service department (see page 3 for contact information).

Instrument Description

This manual covers the use and operation of both models of the NOVAWAVE:

Model SA

A Stand Alone NOVAWAVE Microwave Tunnel Digestion System with all available software and operational parameters including the

flexibility of unique, individual method assignments for each sample in a 12 sample rack.

Model FA

A Fully Automated NOVAWAVE Microwave Tunnel Digestion System with all the software and operational parameters employed in the Model

SA; plus the Transporter, Auto-Cooling and Auto-Venting Stations to complete the automation. The Model FA provides unattended, automatic

processing of up to 14 racks totaling 168 samples.

Model SA can be upgraded at any time to a full Model FA through the acquisition of the Transporter and additional racks, vessels and

Fluoropolymer caps.

Speed and flexibility are built-in with the capability of running racks of samples with individual sample temperature programs. Simultaneously,

water and soil samples in the same rack can be digested with an optimized digestion program employed for each sample! Racks can be left

on the Transporter after processing, as in an after-hours run, or removed immediately for sample analysis once the rack leaves the Auto-

Venting Station.

Version 0.15.1

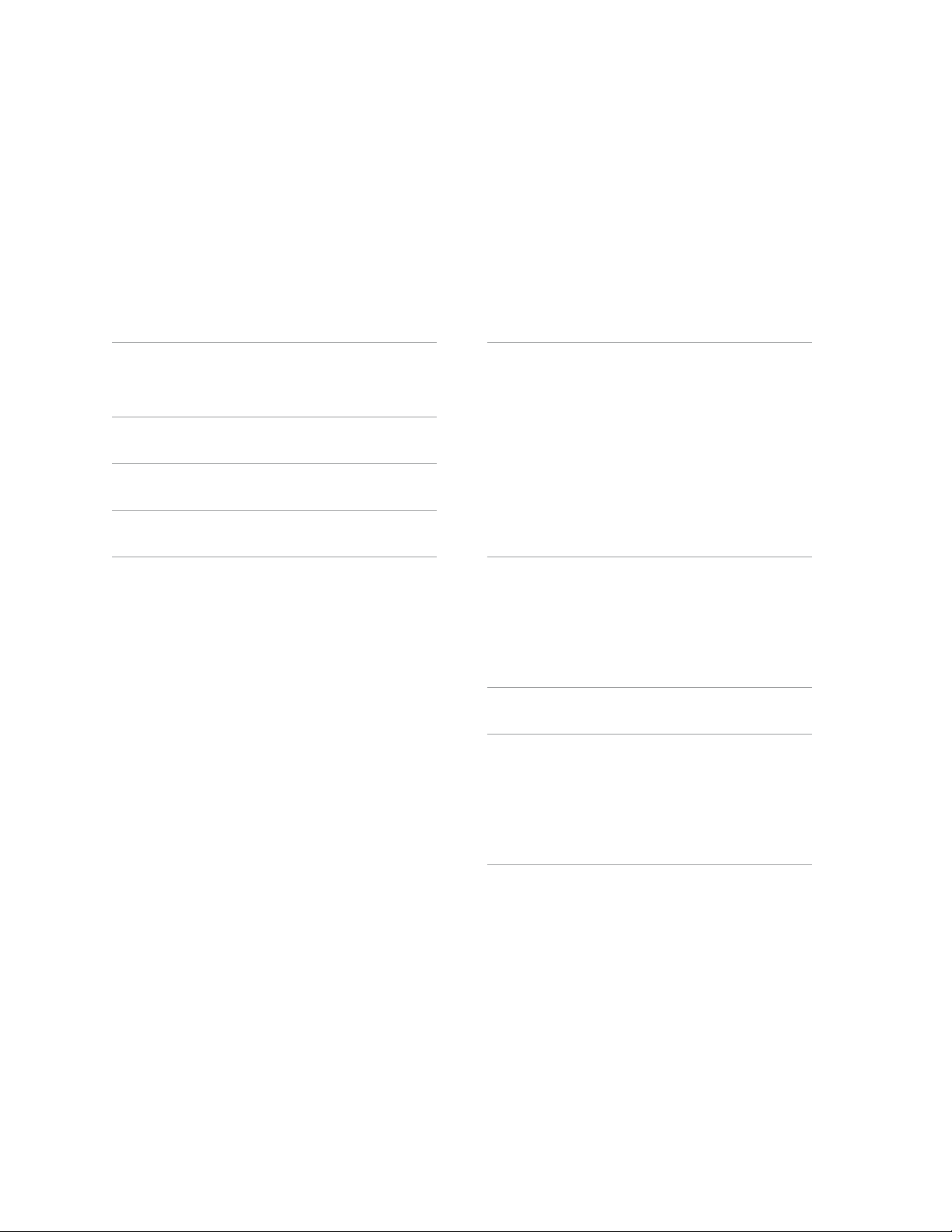

50 ml Quartz Vessels

Calibrated at 50 ml

(Qty: Pack of 6)

Cat. # 010-600-051

75 ml Quartz Vessels

Calibrated at 45

and 50 ml

(Qty: Pack of 6)

Cat. # 010-600-071

50 ml Fluoropolymer

Vessels

Uncalibrated vessels

(Qty: Pack of 6)

Cat. # 010-600-053

+

Support Sleeves

For 50 ml

Fluoropolymer

Vessels

(Qty: One Pack of 6)

Cat. # 010-600-054

75 ml Fluoropolymer

Vessels

Uncalibrated vessels

(Qty: Pack of 6)

Cat. # 010-600-073

+

Support Sleeves

For 75 ml

Fluoropolymer

Vessels

(Qty: One Pack of 6)

Cat. # 010-600-074

Rack for 50 ml Vessels

(Qty: One w/o Tubes)

Cat. # 010-600-056

Rack for 75 ml Vessels

(Qty: One w/o Tubes)

Cat. # 010-600-076

Complete Rack 75 ml

Fluoropolymer Vessels

(Qty: One)

Cat. # 010-600-077

Complete Rack 50 ml

Cal. Quartz Vessels

(Qty: One)

Cat. # 010-600-055

Complete Rack 75 ml

Cal. Quartz Vessels

(Qty: One)

Cat. # 010-600-075

Complete Rack 50 ml

Fluoropolymer Vessels

(Qty: One)

Cat. # 010-600-057

6| NOVAWAVE - A New Category of Automated Microwave Digestion

Accessories

for Quartz

Vessels

Accessories

for Fluoropolymer

Vessels

Fluoropolymer Caps

For quartz vessels

(Qty: Pack of 6)

Cat. # 010-600-030

Fluoropolymer Caps

For Fluoropolymer vessels

(Qty: Pack of 6)

Cat. # 010-600-031

Fluoropolymer Liners

(Qty: Pack of 6)

Cat. # 010-600-032

Fluoropolymer Liners

(Qty: Pack of 6)

Cat. # 010-600-032

Version 0.15.1

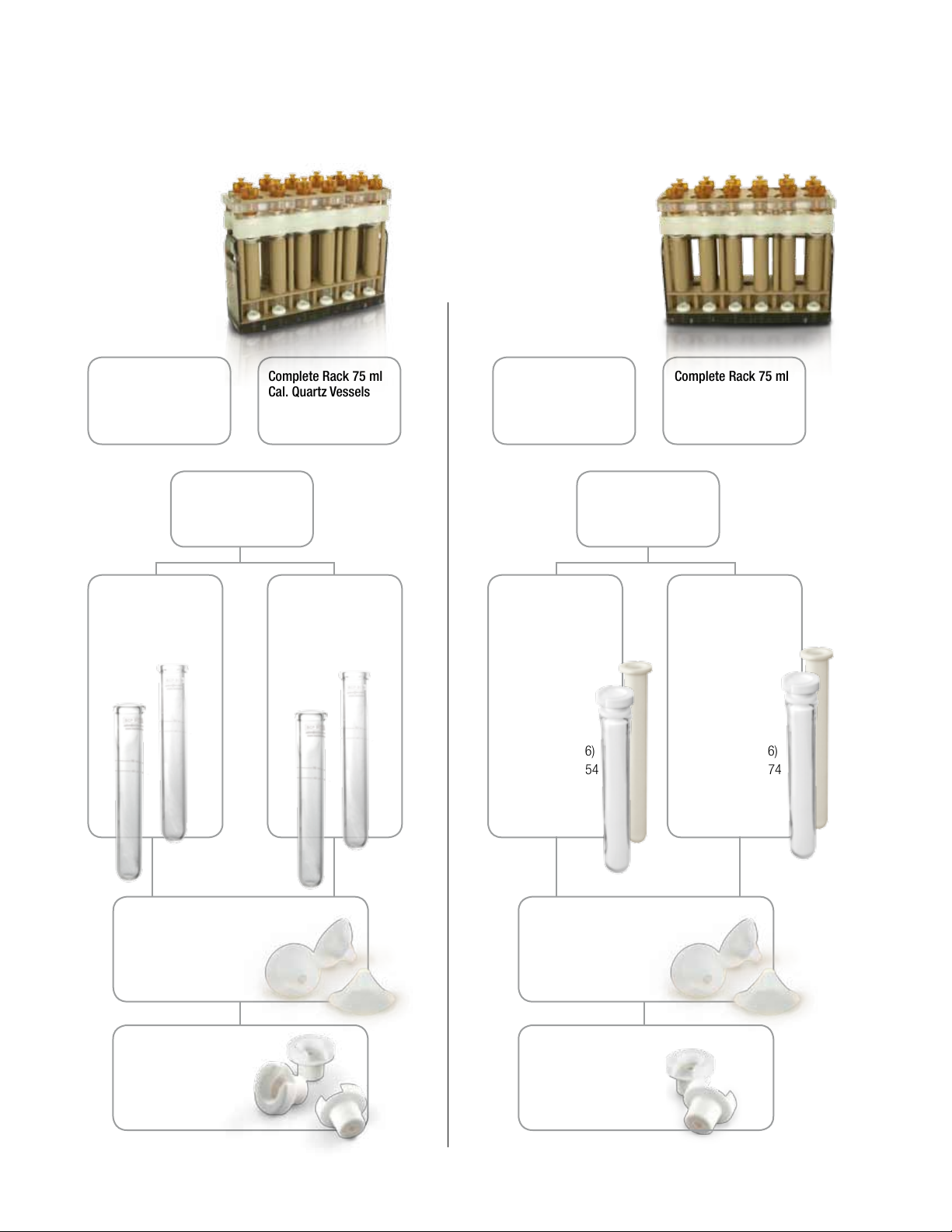

Staging Table Connectors Bottom of Staging Table Correct Position of Staging Table

| 7

2 Installation

NOVAWAVE should be installed on a stable lab counter top which provides easy access considering the height of the lab’s operators. The

exhaust vent of the NOVAWAVE must be connected to a fume hood to prevent noxious fumes from entering the lab in the event of the

venting of a digestion vessel.

Installation Location

To install NOVAWAVE select a location that:

1. Is in close proximity to lab exhaust (a proper laboratory fume hood).

2. Provides a minimum clearance of 3 in. (7.5 cm) space on all sides.

3. Provides adequate bench space for IN and OUT staging tables or NOVAWAVE FA.

4. Provides a mounting surface of inflammable material capable of supporting 75 kg.

5. Is free from vibration of large equipment.

6. Provides close access to a properly grounded electrical outlet (30A, 230V, single phase)(receptacle provided).

7. NOVAWAVE should be operated on a stabilized constant voltage AC power supply, and the voltage must

be within +/-5% of the specified level.

8. Should be lifted from bottom by 2 or 3 people.

9. Do not lift by the side panels or door openings.

NOVAWAVE SA

Install the IN and OUT staging tables by ensuring the tongue of the staging table connectors are installed and fixed to the bottom of the

NOVAWAVE frame. Level the tops by placing a straight edge inside the tunnel. Turn the adjustable feet up or down to the point that the

bottom edge of the straight edge is touching the top of the staging tables. Adjust the front feet until the side panels are level with the table top.

Connect the exhaust tubing to the exhaust port of the NOVAWAVE. The system is now ready to be plugged in.

Version 0.15.1

8| NOVAWAVE - A New Category of Automated Microwave Digestion

NOVAWAVE FA

Place the NOVAWAVE SA in the position where you plan to use the system allowing at least 28 inches (72 cm) on each side for the

Transporter.

Use a straight edge to ensure the top of the Transporter is level with the bottom of the tunnel. This is accomplished by placing the straight

edge in the tunnel parallel to the back wall of the tunnel. Using the leveling feet, adjust the system to the correct height by turning the feet.

Clockwise lowers the table top and counter clockwise lifts the Transporter top. Adjust the back feet first to the point where the straight edge

touches the top of the Transporter top along the entire length of the straight edge. Do this on both the right and left hand sides. Position the

right and left hand sides into place by ensuring the tongues of the Transporter tops are centered within the door openings. Use the straight

edge along the back wall of the tunnel and the back rail of the left hand Transporter module to ensure that the Transporter it is aligned along

the length of travel.

Connect the bridge between the left and right side Transporter modules and ensure that the alignment pins are pushed together snuggly. Raise

or lower the feet on the front of the Transporter to level the right and left Transporter modules.

Install the cooling and venting module on the right hand side of the NOVAWAVE. Install the cooling duct by screwing it in the threaded hole

on the right side of the SA. Connect the flexible duct to a fume hood.

NOTE

It is important to ensure that the exhaust hose is vented into a fume hood or to the outside.

Install the left hand cover unit using the hole and guide pins for alignment.

Precautions To Avoid Possible Exposure To Excessive Microwave Energy

(a) Do not attempt to operate this instrument with the door open since open-door operation can result in harmful exposure to microwave

energy.

It is important not to defeat or tamper with the safety interlocks.

(b) Do not place any object between the instrument front face and the door or allow soil or cleaner residue to accumulate on sealing

surfaces.

(c) Do not operate the instrument if it is damaged. It is particularly important that the tunnel door close properly and that there is no damage

to the:

(1 ) Door (bent), (2 ) door seals and sealing surfaces.

(d ) The instrument should not be adjusted or repaired by anyone except properly qualified service personnel.

Version 0.15.1

| 9

Symbol Description Symbol Description

VVoltage lMains on

~Alternating current 0Mains off

ACurrent Attention, consult accompanying documents

Hz Frequency Caution, hot surfaces

FFast-acting fuse Protective conductor terminal

3 Cautions, Notes and Symbols

Cautions, warnings and notes are included throughout this manual.

CAUTION

A caution is used to emphasize information pertaining to procedures that, if not strictly followed, may result in damage or

destruction to the instrument or improper instrument operation.

WARNING

A warning is used to emphasize information about dangerous or hazardous conditions relating to the operation, cleaning or

maintenance of the instrument that may result in personal injury.

NOTE

A note is used to emphasize procedures or conditions that may be misinterpreted or overlooked, and to clarify potentially

confusing situations.

NOTE

Version 0.15.1

10 |

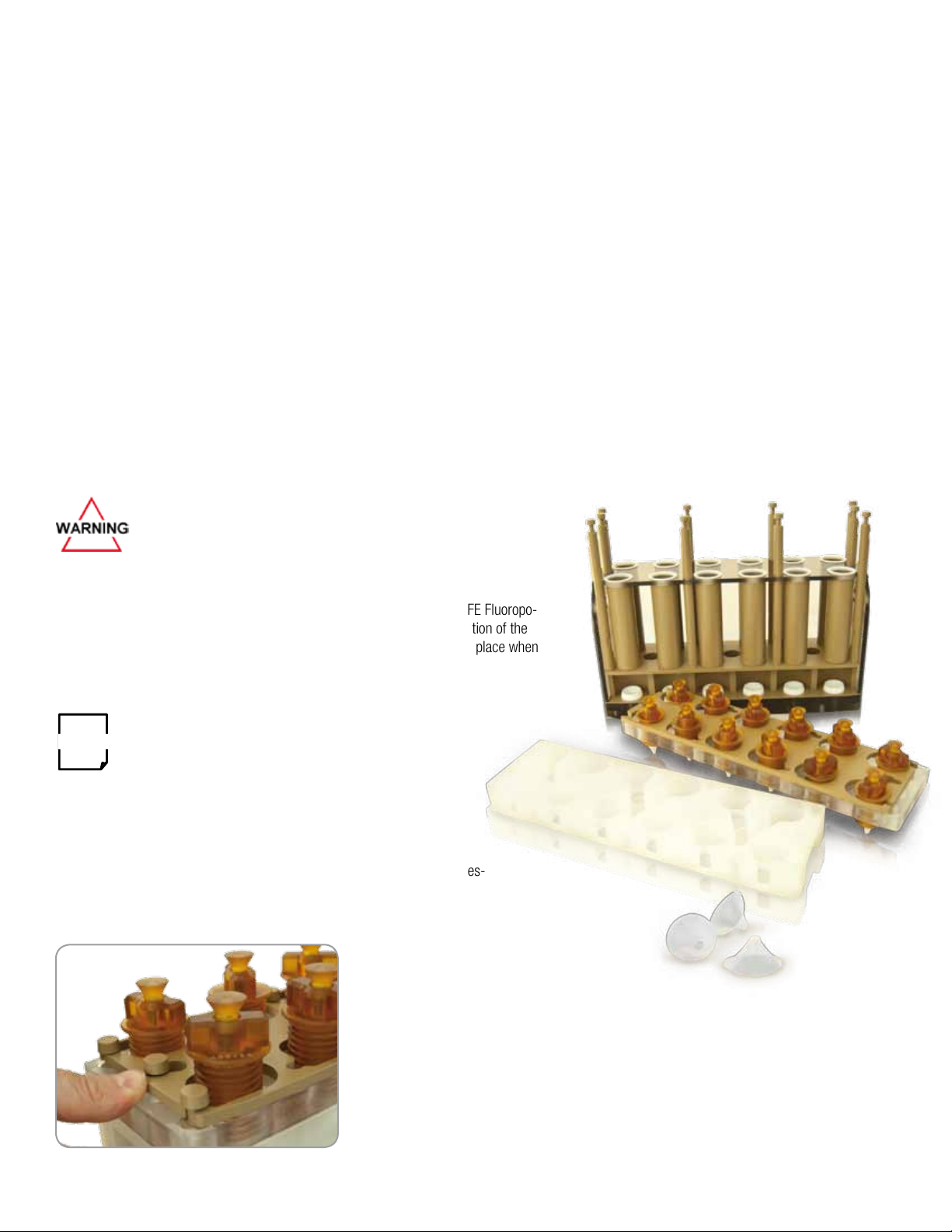

The round bottom quartz digestion vessel allows the analyst to place the vessel directly onto the balance for weighing samples with the tube

support supplied. Once weighed, the digestion media may be added. The 75 ml vessel is calibrated at 45 ml for quick addition of the sample

and 50 ml for acid addition as per EPA 3015. The 50 ml vessel is calibrated at 50 ml for normalization after the digestion. The calibrations are

to Class A specifications +/- 0.25 ml.

Never use a quartz digestion vessel

which appears cracked or damaged.

After weighing the sample in a quartz vessel and adding acid, place the PTFE Fluoropo-

lymer cap on top of the vessel. The Fluoropolymer cap seals on the intersection of the

quartz vessel and tapered edges of the PTFE cap. The PTFE cap is held into place when

the Safety Pressure Cap is screwed into place.

Place the vessels in the ‘Transfer Rack’ (010-600-038).

Place a Fluoropolymer liner in each vessel cap prior to placing the

Safety Pressure Plate on top of the rack.

Push the locking mechanism as shown in the picture below. If the

locking mechanism does not pop into place, unscrew each of the Safety Pres-

sure Caps a ½ turn and try to re-lock the safety pressure plate.

4 Racks & Vessels

NOTE

The Transfer Rack only fits one way. The positions (1 through

12) are marked on the rack. Insert the Transer Rack into the

appropriate size instrument rack, i.e., 50 ml vessels in a 50

ml rack etc.

Version 0.15.1

NOVAWAVE - A New Category of Automated Microwave Digestion | 11

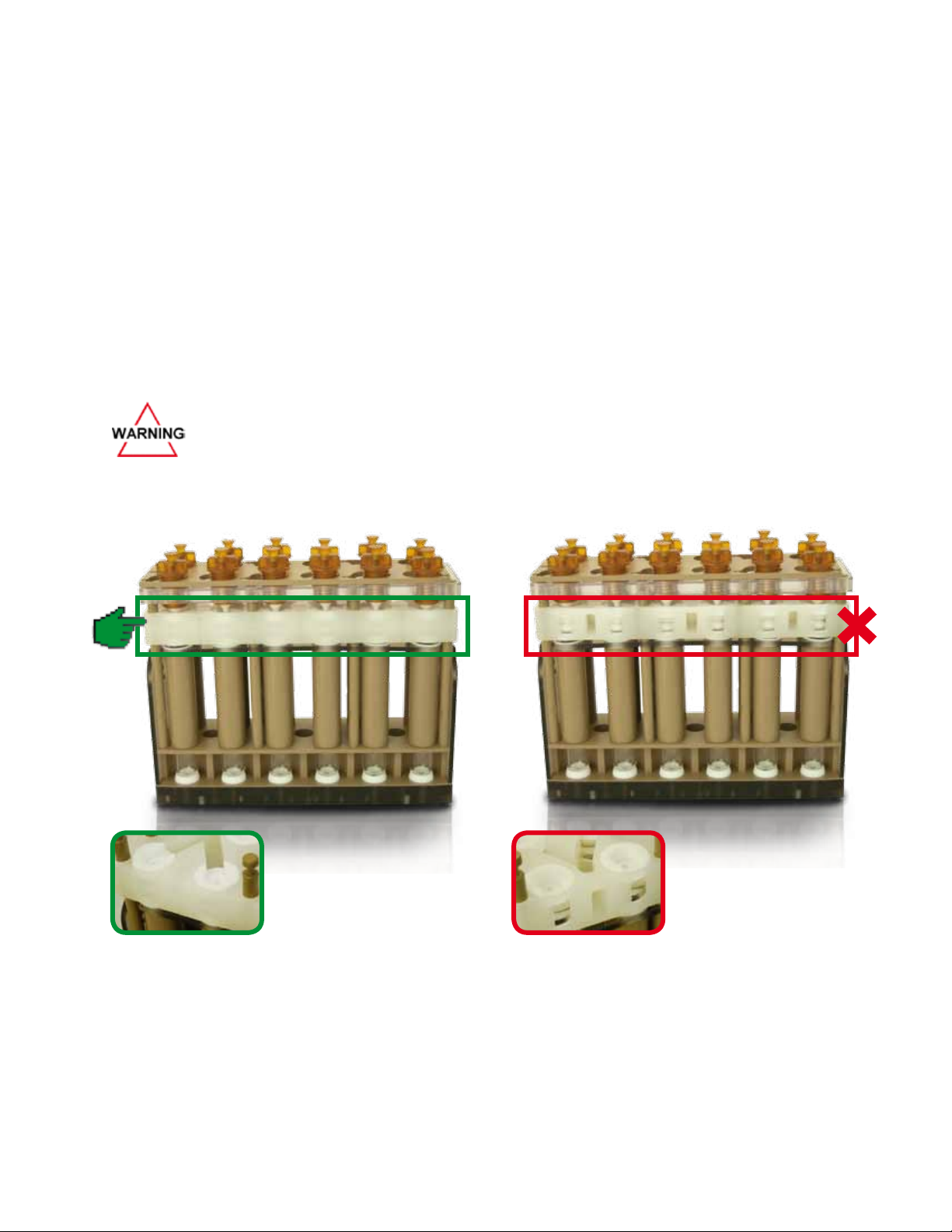

Once the Safety Pressure Plate is in the correct position, tighten each of the Safety Pressure Caps until they do not turn.

The rack is now ready to be inserted in the NOVAWAVE . Place the loaded rack onto the ‘IN Staging Table’. The locking mechanism should

be oriented furthest from the door.

Once prompted by the program, firmly push the rack into the tunnel until the rack is engaged on the ‘IN GEAR’. The NOVAWAVE software

will complete the remaining digestion processes as programmed (See software operation for programming).

To unlock the Safety Pressure Plate, release the ‘Safety Pressure Caps’ using the hand-venting tool in a fume hood. The rack should be cooled

to room temperature prior to releasing the Safety Pressure Caps. Once all of the Safety Pressure Caps have been vented, loosen the safety

pressure caps about 1½ turns. Push on the locking mechanism to release the Locking Mechanism Plate while holding the other end steady

with your other hand. The Safety Pressure Cap Plate may be removed by lifting the entire plate.

Always allow the vessels to cool prior to venting and wear appropriate eye protection and gloves prior to performing

this operation. This should only be done in a fume hood.

Remove and rinse the Fluoropolymer liners and caps. The vessels may be removed from the rack using the Transfer Rack. Using the vessel

volume calibration lines, samples can be normalized directly in the vessel.

Using the Transporter Rack the vessels can be moved to an Auto Sampler for processing.

Correct Wrong

Orientation for Placement in Tunnel

Version 0.15.1

12 |

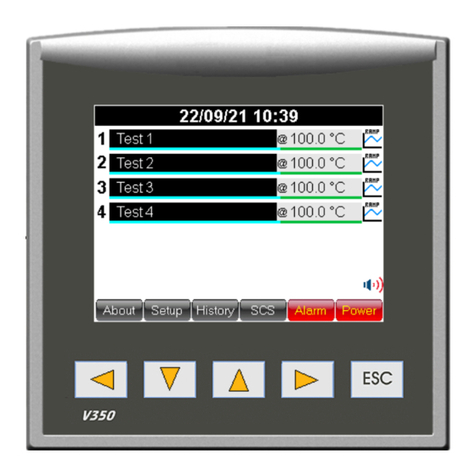

5 Software Operation

NOVAWAVE software has been designed with 3 levels of password protected operations allowing accessibility to various parts of the

software by different individuals. This feature protects the laboratory from inadvertently changing or erasing important settings and / or data.

Version 0.15.1

USER LEVEL

Tab Button Administrator Operator Service

Program Add Cycle Y Y Y

Add Rack Y Y Y

Delete Y N Y

Manual Y Y Y

Start Y Y Y

Show Keyboard Y Y Y

Hide Keyboard Y Y Y

Save Y Y Y

Load Y Y Y

Method Select Y Y Y

Vessel Type Select Y Y Y

Start Digestion Y Y Y

Sample List Y Y Y

Digestion Operational after the ‘Start Digestion’ button is pressed

Stop Y Y Y

Methods Delete Y N Y

New Y N Y

Edit Y N Y

View Copy Y N Y

Reagent Add Y Y Y

Delete Y Y Y

Edit Y Y Y

Reports Delete y N Y

Print Y Y Y

Send Y Y Y

Utilities Status - Initialize Y Y Y

Calibration Y N Y

-Vessel Type Y N Y

-Read New Data Y N Y

-Send to MicroB Y N Y

-Save Y N Y

-Save to USB Y N Y

User Y N Y

-User Group Y N Y

-Change Password Y N Y

-Add new user Y N Y

-Delete selected user Y N Y

Network - Apply Y N Y

Report - day change Y N Y

Diagnostic Log Y Y Y

Operation Y N Y

Logout exit Y Y Y

Reboot Y Y Y

Shutdown Y Y Y

User admin user root

Passwords zxc asd secret

| 13

Version 0.15.1

14 | NOVAWAVE - A New Category of Automated Microwave Digestion

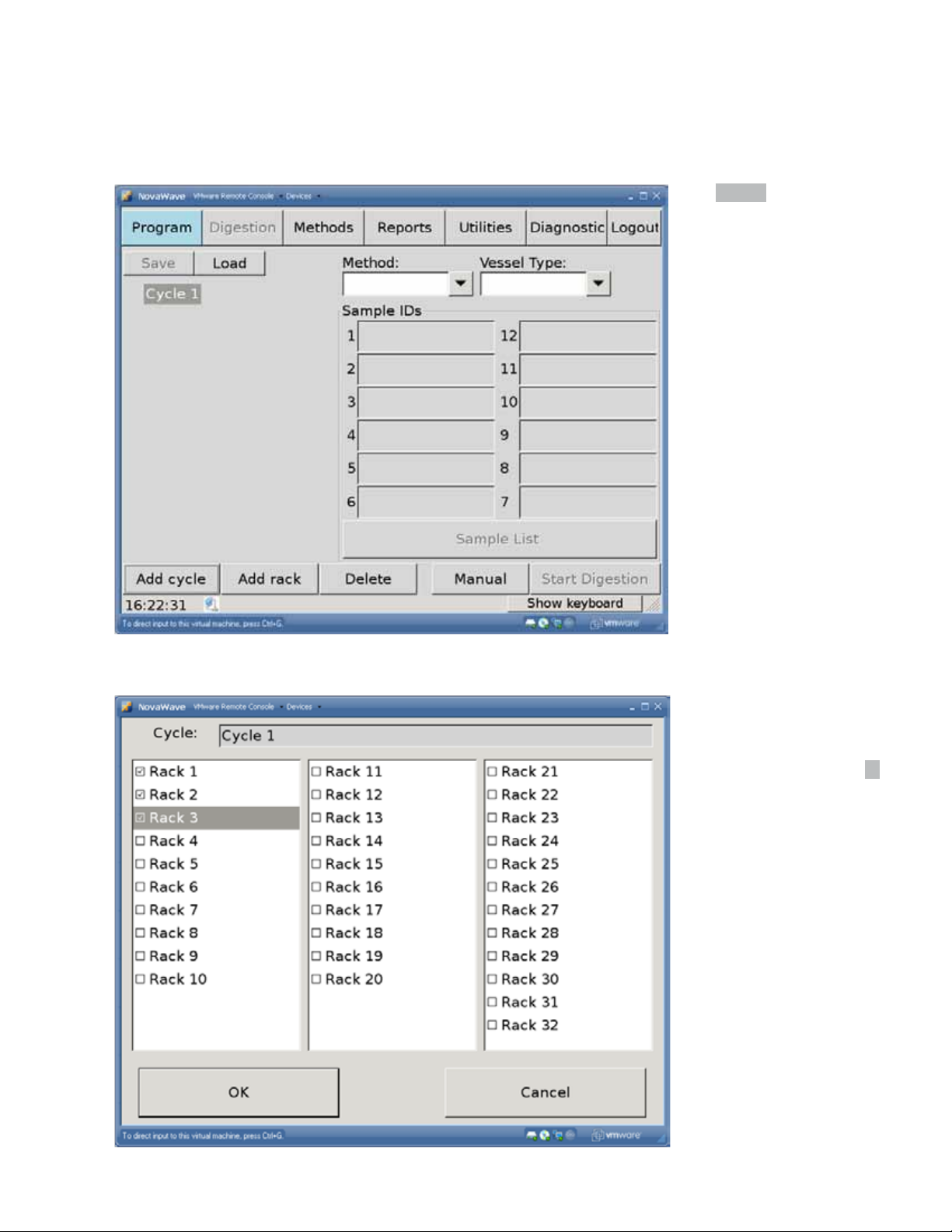

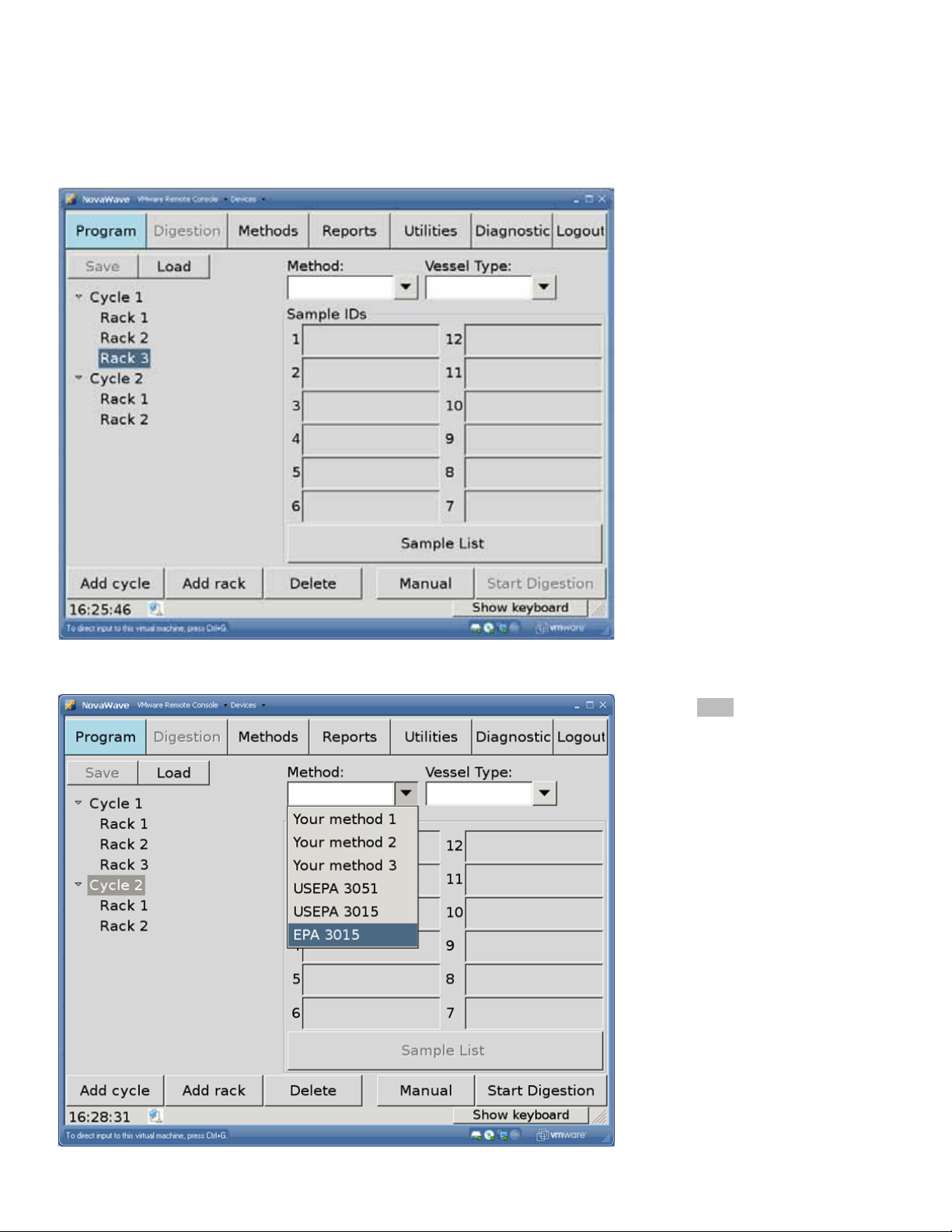

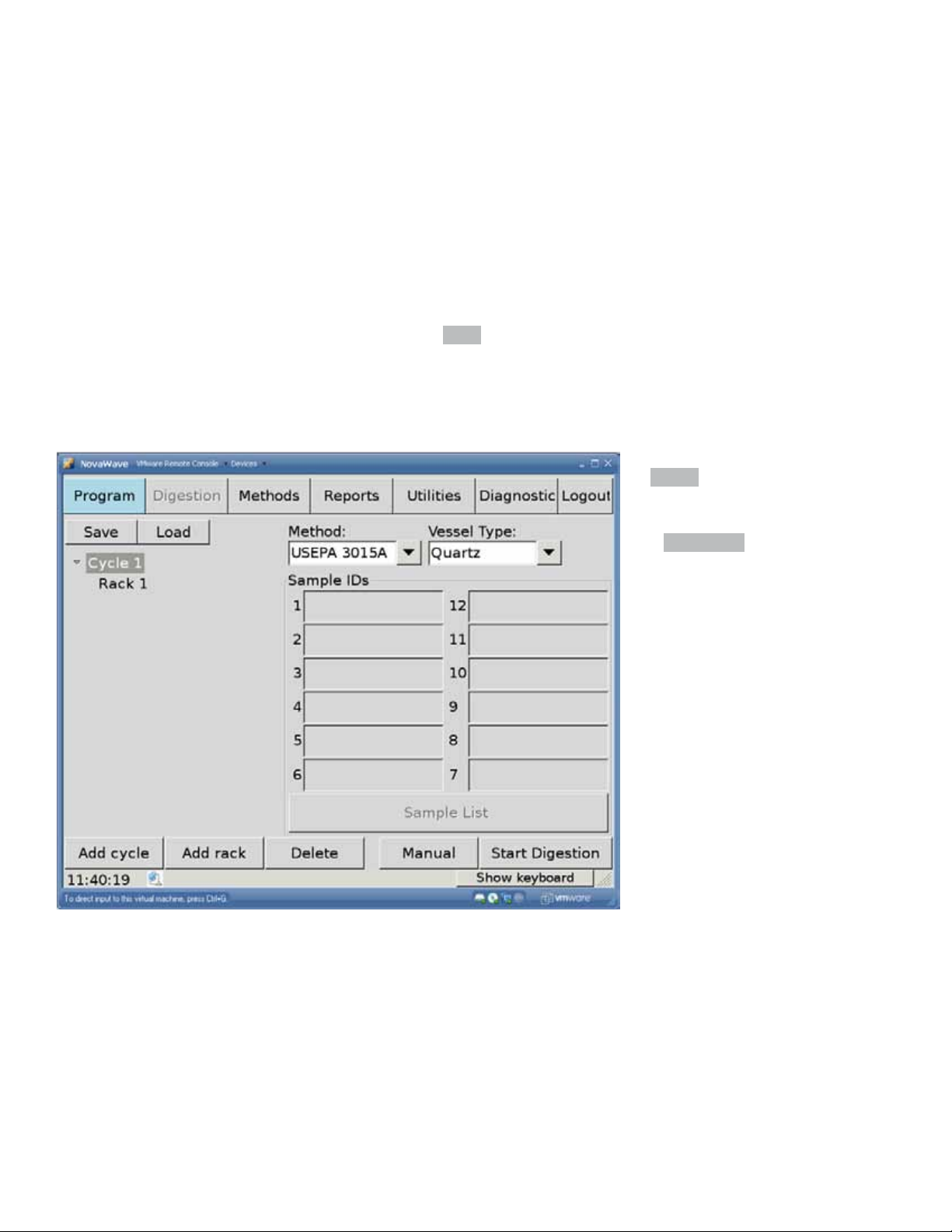

“Program” Run

Cycle

This is the tab where a digestion run is created. It starts by creating a ‘cycle’, where ‘racks’ are then added to the cycle.

A cycle is used when programming several racks with the same method for all of the tubes per rack. It may also be used when a second

digestion is required after the addition of a second reagent.

Press the button ‘Add cycle’.

Stored runs can be loaded by pressing

the ‘Load’ button and selecting a

previously stored run.

‘Delete’ is to remove selected racks or

cycles.

‘Manual’ is to operate the doors and

applicators manual, etc.

‘Start Digestion’ is to start digestion.

Version 0.15.1

NOVAWAVE - A New Category of Automated Microwave Digestion | 15

Highlight the rack number in which the

samples will be digested or extracted.

The racks with a check mark will be

saved to the list. To delete a rack, click

on the rack number to delete. Press OK

to input the selected racks in the cycle

list.

Select ‘Add rack’ up to 32 racks per cycle.

Version 0.15.1

16 | NOVAWAVE - A New Category of Automated Microwave Digestion

It is possible to add several ‘cycles’ with

different rack ID’s for each cycle. It is also

possible to use the same rack ID for each

‘cycle’ selected.

By selecting Cycle 2, and selecting a

method from the Method pull down tab,

the NOVAWAVE will assign the same

selected method for all of the racks in

the cycle selected. Select one of the pre-

programmed methods or user created

methods. (See Methods to Create New

Methods.)

Version 0.15.1

NOVAWAVE - A New Category of Automated Microwave Digestion | 17

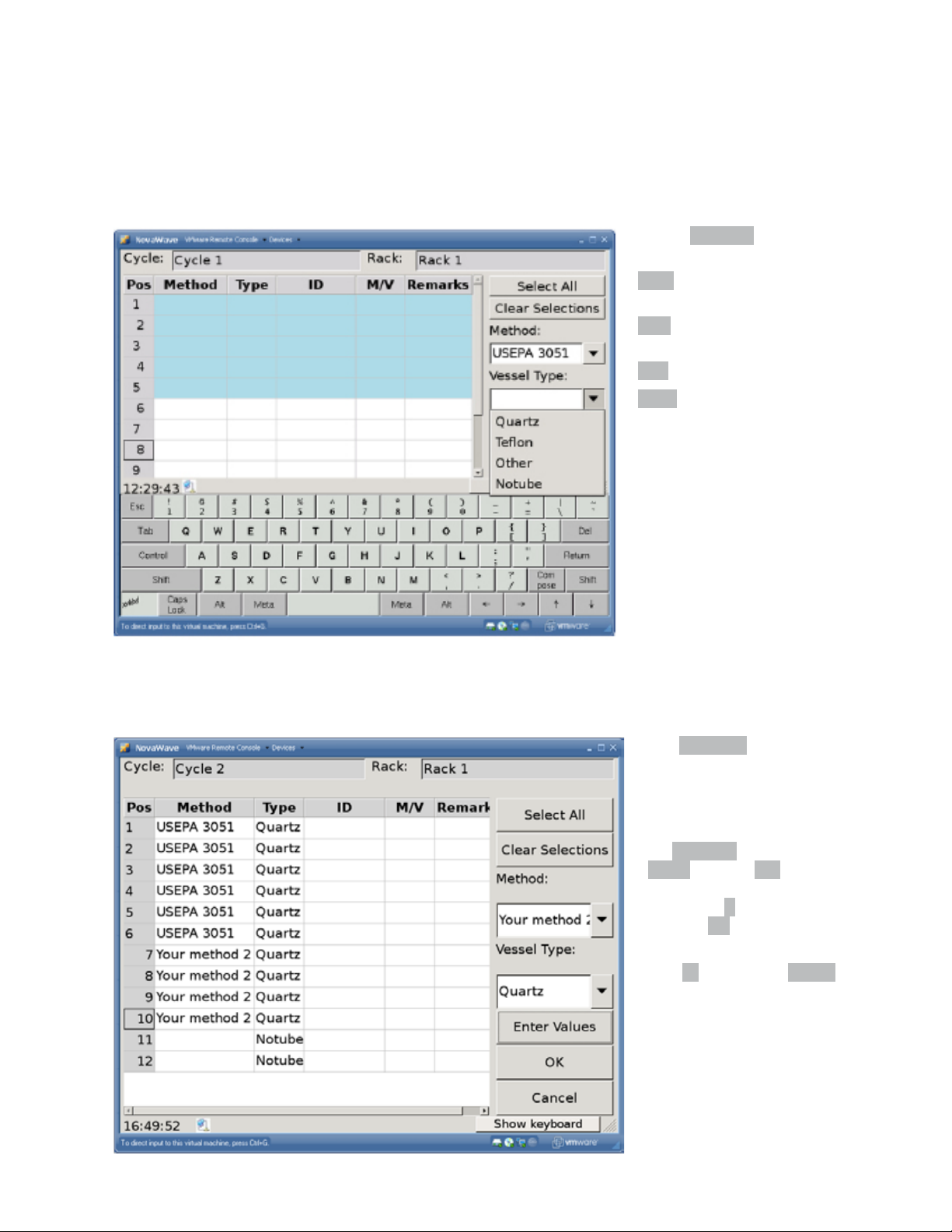

To program a digestion by rack

position, a cycle with racks must

be created first. Highlight the rack

number with the different samples to

digest. Select the Sample List button.

On this page, to select a position

to program, select all of same type

of samples by clicking on the rack

position (Pos) button. Select a method

from the Method pull down tab; select

a vessel type from the Vessel Type

pull down. Click on the Enter Value

tab to populate table. If a second

method is required select the position

to program in the same manner as

above. Method and vessel type may

vary by position. If the vessel position

is not populated the NOVAWAVE

will consider that there is no vessel in

that position.

After a method is selected, a vessel

type needs to be selected for the

system to operate correctly. Select

one of the pre-programmed vessel

types from the Vessel Type pull down

tab. If the Cycle is highlighted, the

vessel type will be assigned to all of

the racks for this cycle.

Quartz vessels are either 50 ml or

75 ml vessels.

Fluoropolymer vessels are either 50

ml or 75 ml vessels.

Other is reserved for future use.

Notube is selected if the position in

the rack is intentionally left blank.

Vessel selection is used to set the IR

temperature sensor parameters.

Sample Position

Version 0.15.1

18 | NOVAWAVE - A New Category of Automated Microwave Digestion

Highlight the rack position by pressing

on the Pos 1...12 for each position of

the positions that are being digested

using the same method.

Select the Method from the pull down

tab.

All of the rack positions that are using

the same method may be highlighted

at the same time.

Pos is the vessel position in the rack.

Method is selected from the pull

down methods tab.

Type is vessel type select quartz or

Teflon®from the pull down tap.

ID is an independent sample

identification.

M/V is the mass or the volume of the

sample.

Remarks is for other comments

required on the samples.

Sample List

Version 0.15.1

NOVAWAVE - A New Category of Automated Microwave Digestion | 19

Select the Vessel Type from the pull down

tab.

Quartz is for either 50 ml and 75 ml Quartz

Vessels.

Teflon is for either 50 ml and 75 ml

fluoropolimer vessel in quartz sleeves.

Other is released for future use.

Notube is for selecting empty vessel or no

digestion to take place.

Press Enter Values.

More information may be inputted from this

screen. Sample ID, M/V mass or volume of

sample. An extra column has been provided

for remarks.

The Sample List page shows which

Method and vessel Type has been se-

lected for this particular cycle and rack.

Input Sample ID as an alpha numeric

value. The M/V mass or volume used

may be inputted with units of measure.

Press OK to return to the Program tab.

Version 0.15.1

20 | NOVAWAVE - A New Category of Automated Microwave Digestion

Entering Sample ID

Individual sample IDs can be entered by assigning them individually from the Sample IDs tab by clicking the Sample List button, or may be

entered using the remote bar code reader from this page by selecting Rack #. The barcode reader plugs into the USB connection at the front

panel. The rack to be programmed must be selected first. The bar code reader will populate a sample ID position and then move to the next

sample. The bar code reader will run through the sequence from the sample ID selected to the next numeric sample. To skip a spot, touch the

position that the particular sample will reside for the digestion.

Other information may be entered in

the Remarks column from the touch

screen keyboard from the Sample List

page.

Press Start Digestion button this will

take the system to the digestion tab.

Table of contents

Other SCP SCIENCE Laboratory Equipment manuals