P:\INST INSTRUCTIONS\EXIT DEVICES\INST-S6200 Rev A 04-22 Page 4

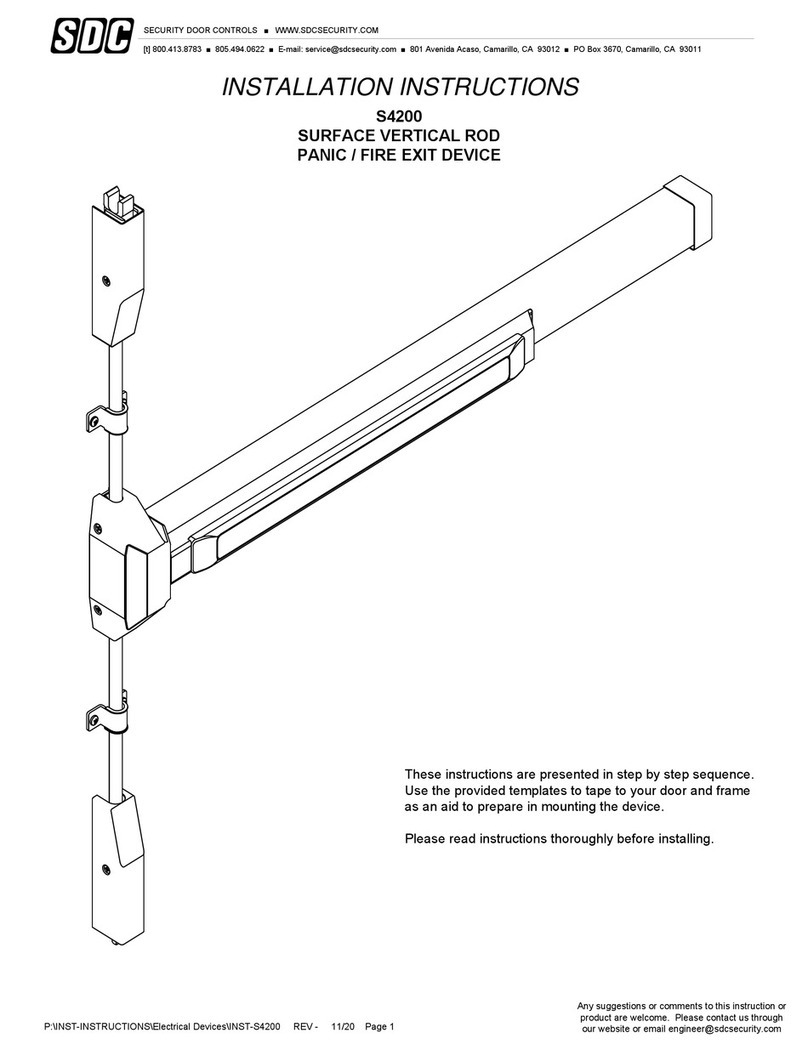

“A”

Hinge Stile edge of door

Mark mounting

holes thru end

cap bracket after

device is leveled.

Mounting

Bracket

Chassis

End cap

bracket

Figure 2

VIEW “B”

Insert Trim Actuator Shaft

Into Device Cam

*

*

SECURITY DOOR CONTROLS ■ WWW.SDCSECURITY.COM

[t] 800.413.8783 ■ 805.494.0622 ■ E-mail:

[email protected] ■ 80

1 Avenida Acaso, Camarillo, CA 93012 ■ PO Box 3670, Camarillo, CA 93011

STEP 2: INSTALL BRACKETS, DEVICE & TRIM

1. Remove chassis cover from chassis assembly and end cap from end cap bracket.

2. Cut the length if required.

User information; This model device has three different lengths:

Approx. 33" = For use on 3' wide door openings.

Approx. 40" = For use on 3.5' wide door openings.

Approx. 44" = For use on 4' wide door openings.

a. The device length are pre-cut for use of 36", 42" and or 48" wide doors, no additional

cutting is necessary. If narrow door installation is required, cut device at section “A”

to door width minus 2" for proper fit.

b. Remove device from door, remove end cap and end cap bracket and cut where

required.

3. Mount device horizontally via the drilled holes and secure with supplied

mounting hardware. Attach device to trim or sexbolt.

4. If installing trim verify that the actuator shaft is fully inserted

into the device cam (Refer to view “B”).

5. Install end cap bracket to device, level

device and mark before mounting.

6. Install mounting brackets to top and bottom

of door.