Date: June 9, 2003 Subject: 4–TEC SC Models No. 2004-1

YEAR MODEL PACKAGE MODEL NUMBER PREDELIVERY

KIT P/N

SERIAL

NUMBER

2004 GTX†4–TEC

SUPERCHARGED N.A. 6160 294 000 636 All

† GTX is a trademark of Castrol Ltd. used under license

TABLE OF CONTENTS

P

PP

Pa

aa

ag

gg

ge

ee

eP

PP

Pa

aa

ag

gg

ge

ee

e

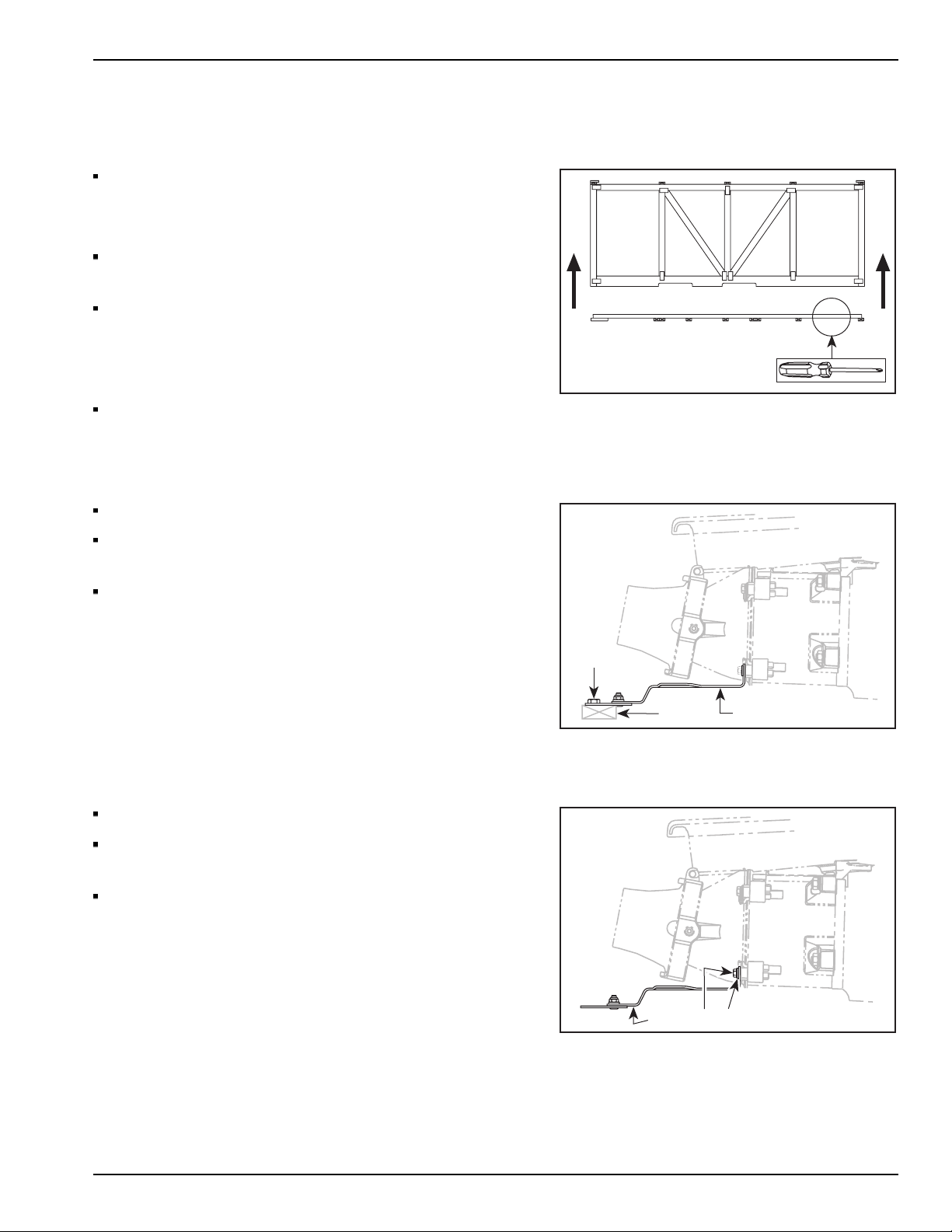

UNCRATING...................................... 3

Crate Cover.......................................... 3

Lifting the watercraft............................... 3

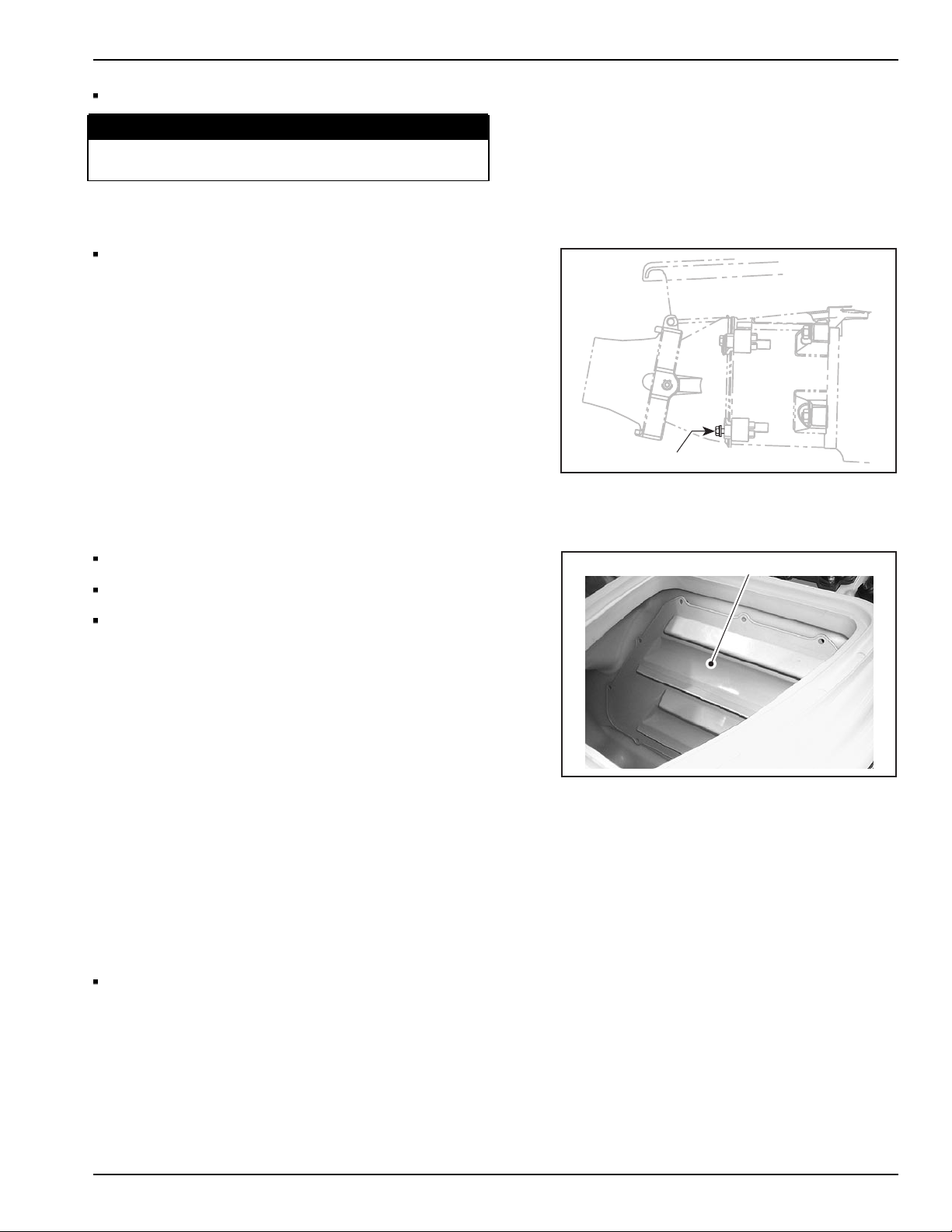

Shipping Bracket.................................... 3

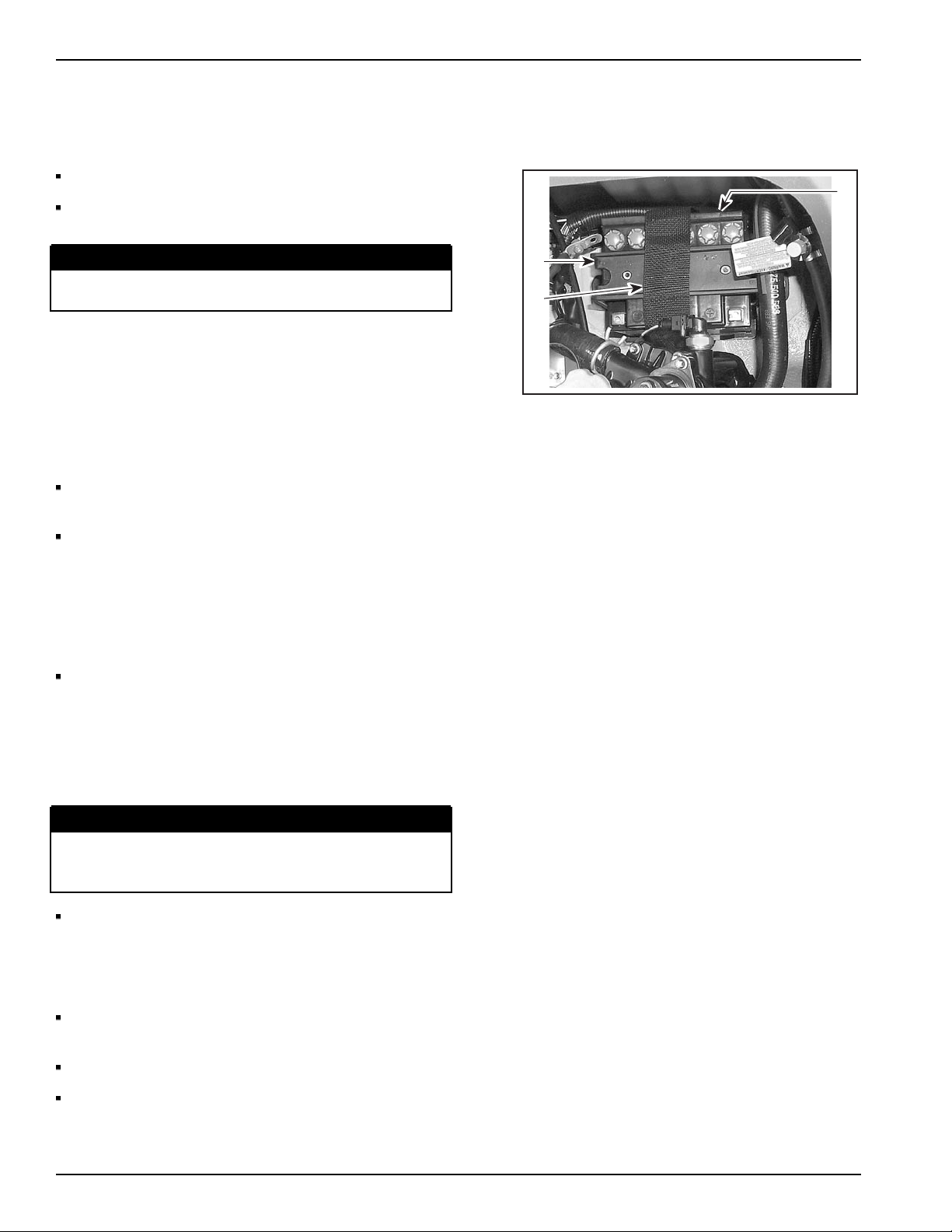

SET-UP............................................. 4

Battery Preparation................................. 4

Battery Installation ................................. 4

Venturi ............................................... 5

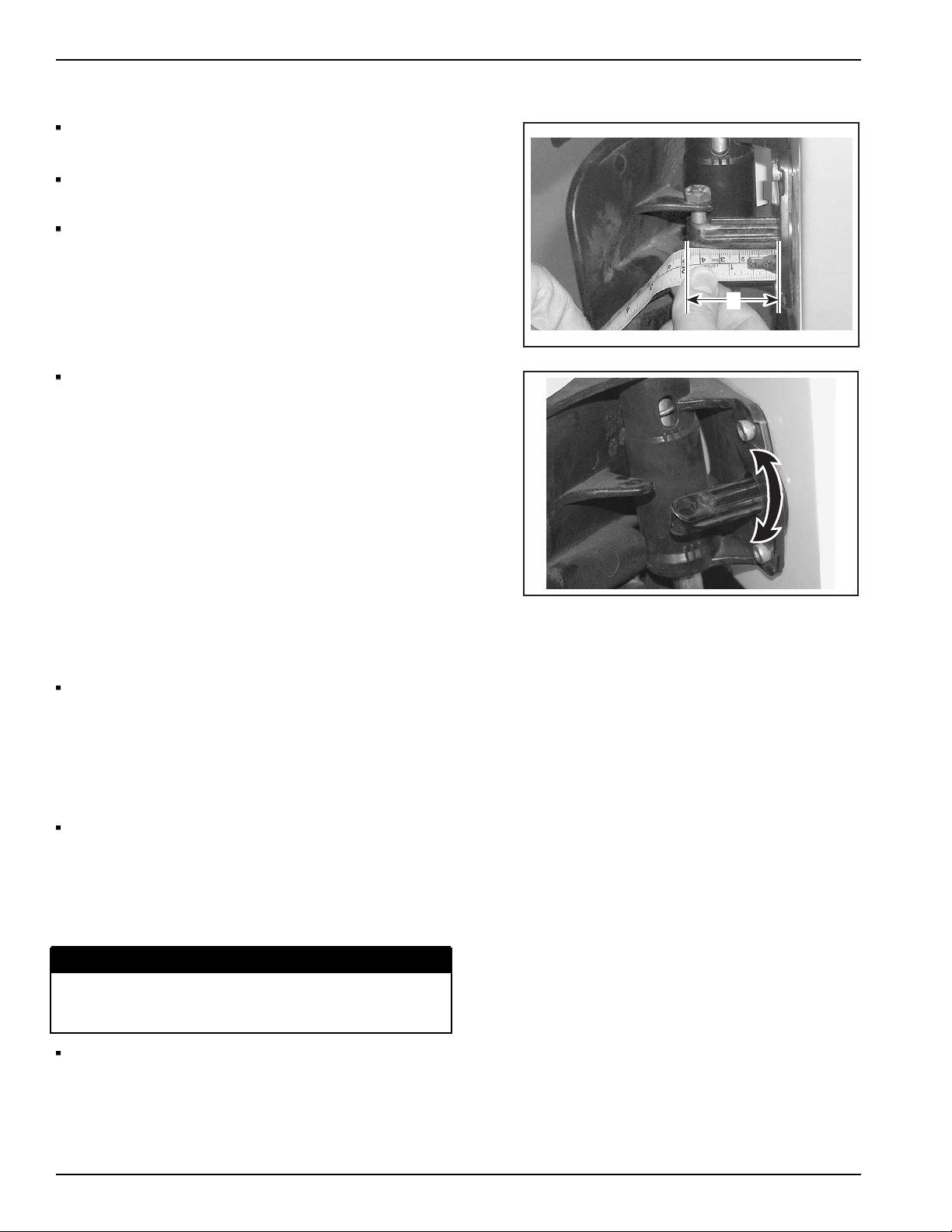

Access Door ........................................ 5

FINAL PREPARATION........................... 5

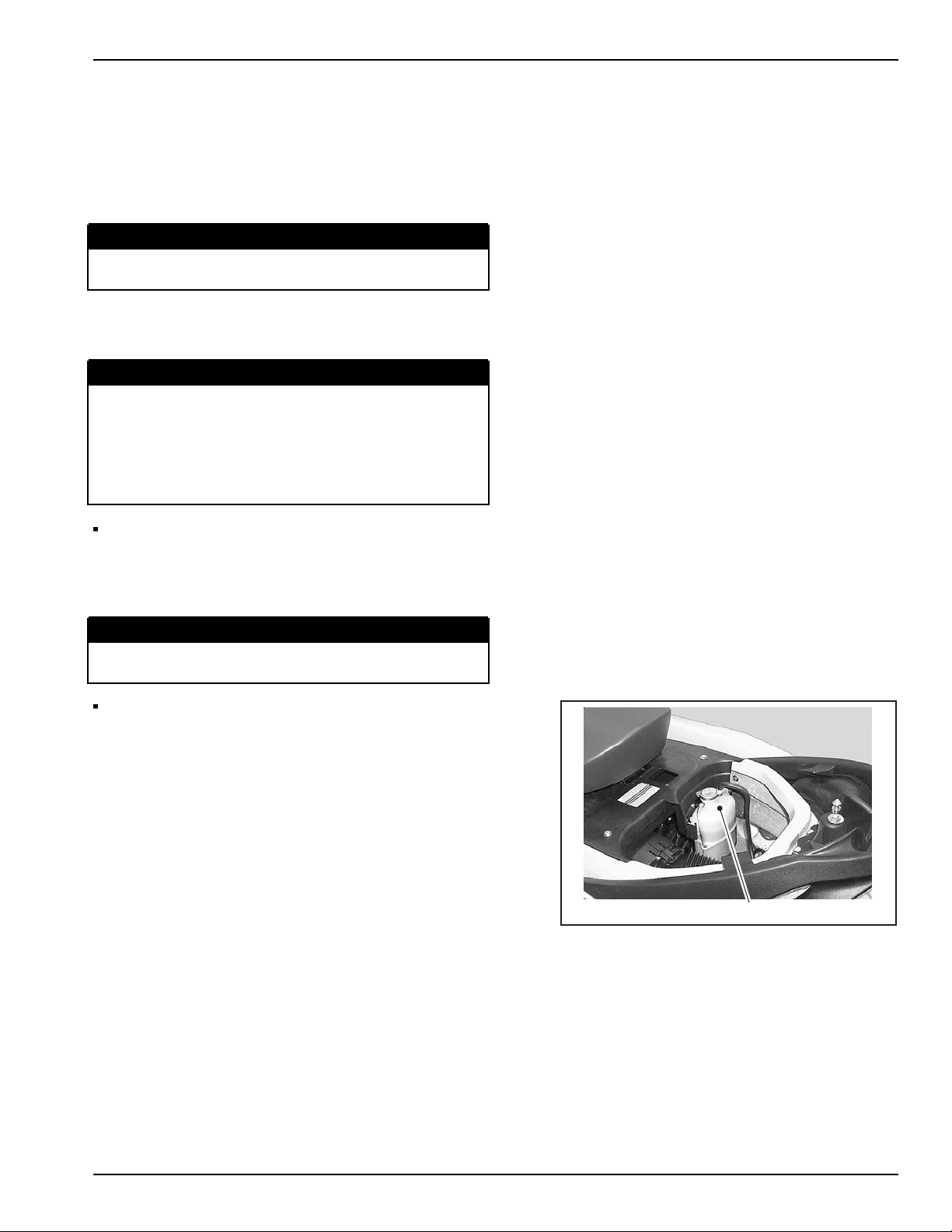

Steering Alignment................................. 5

O.P.A.S. System Alignment....................... 6

Recommended Fuel ............................... 6

Fuel System Pressurization ....................... 7

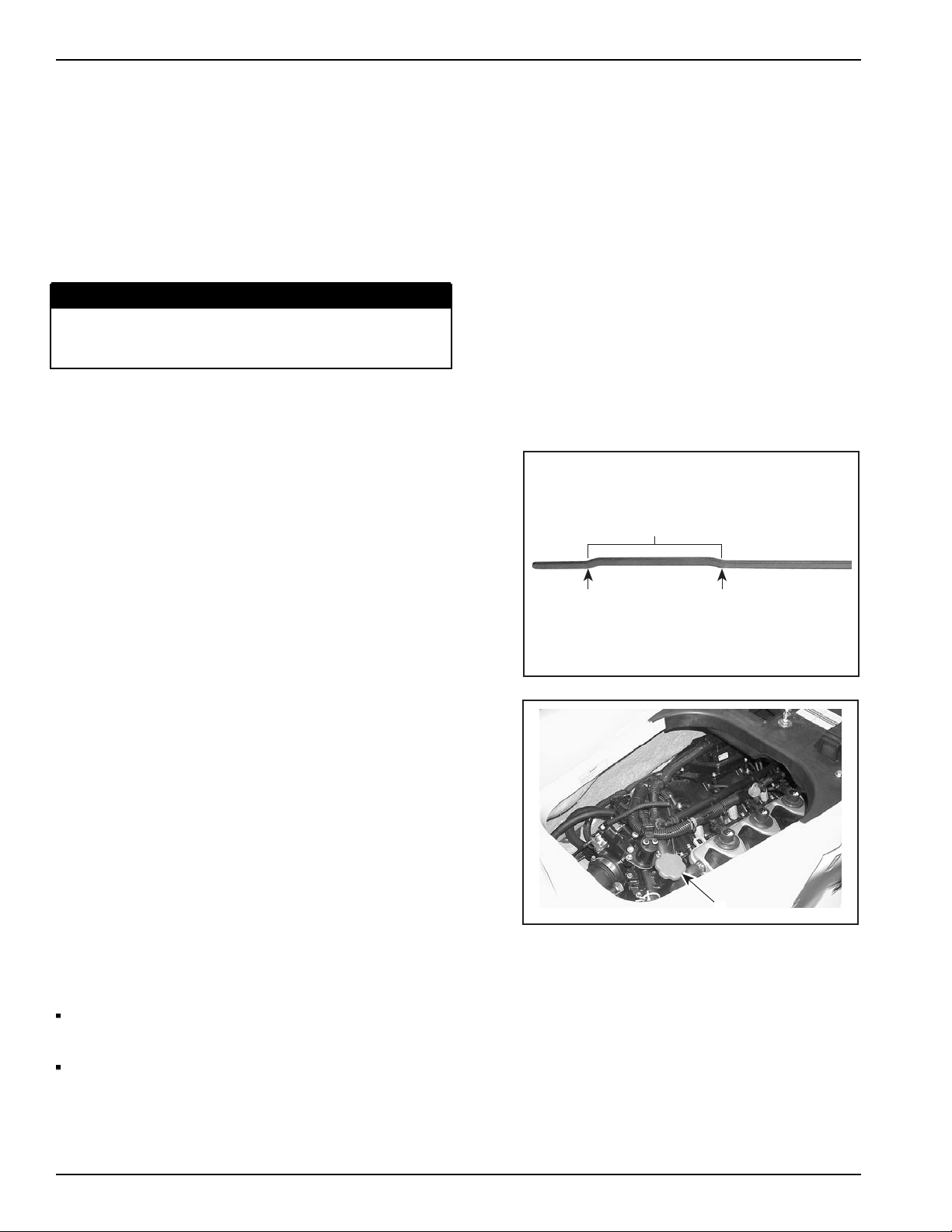

Coolant Level ....................................... 7

Watercraft Identification........................... 8

Programming Keys With B.U.D.S. ............... 9

Oil..................................................... 9

Ending a B.U.D.S. Session.......................10

Throttle Cable......................................11

FINAL INSPECTION............................12

General Instructions...............................12

DELIVERY TO CUSTOMER...................12

Decal Protective Films............................12

Cleaning the Watercraft ..........................12

General Instructions...............................13

Fuel System........................................13

Handlebar Tag......................................13

Break-In Period ....................................13

SPECIFICATIONS ...............................14

Technical Data .....................................14

Printed in Canada (sbl2004-002 DR) 2004-1 1 / 15

®™Trademarks of Bombardier Inc. or its subsidiaries.

©2003 Bombardier Inc. All rights reserved.