Short Instructions

Please do also see the general advice in chapter 1.

Step Description

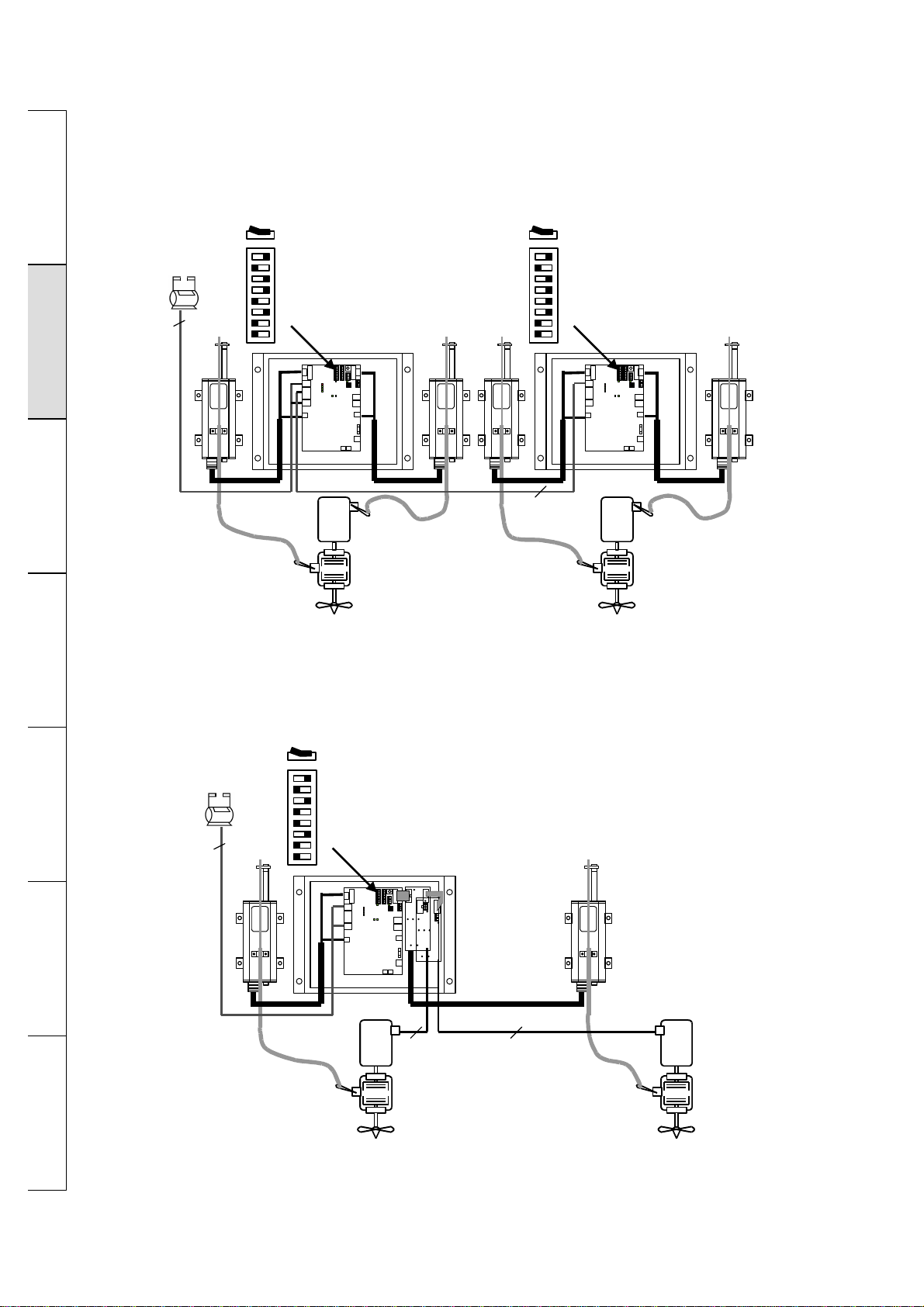

1Select engine type (chapter 2 "overview")

Assembly

2Adjust SYSCON switch board in accordance with engine type (chapter 2 "overview")

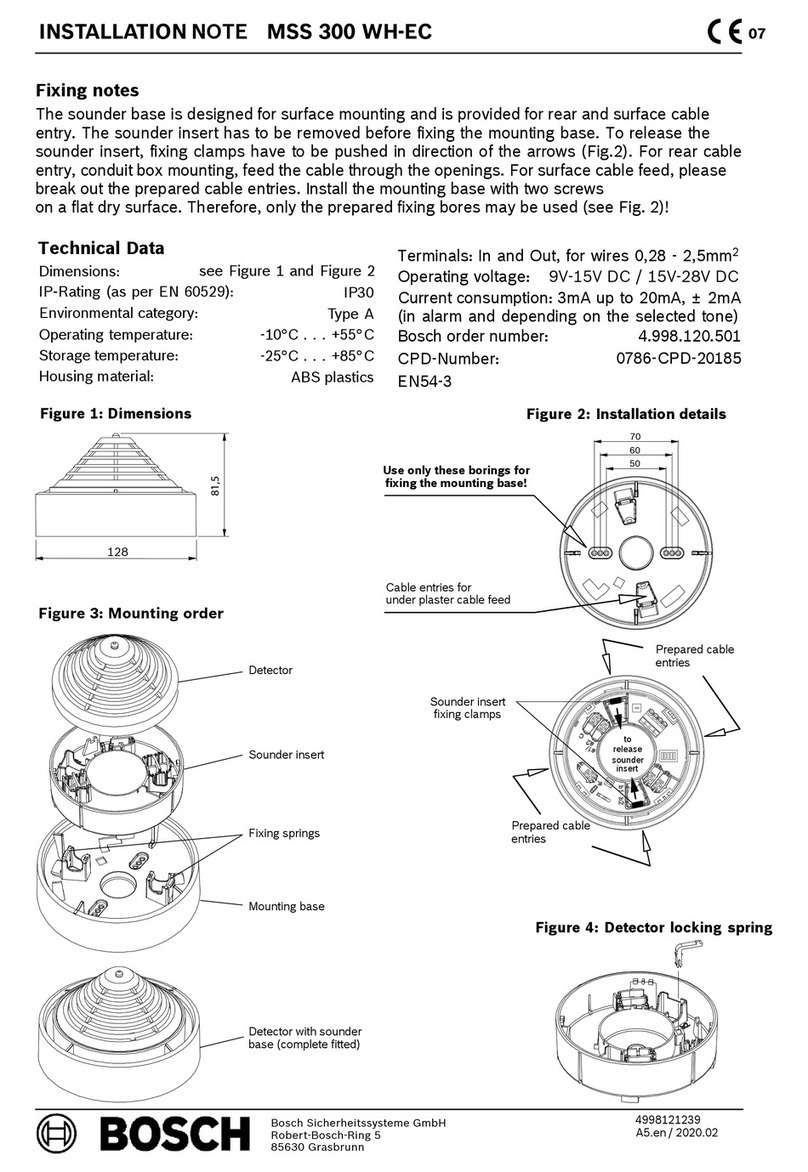

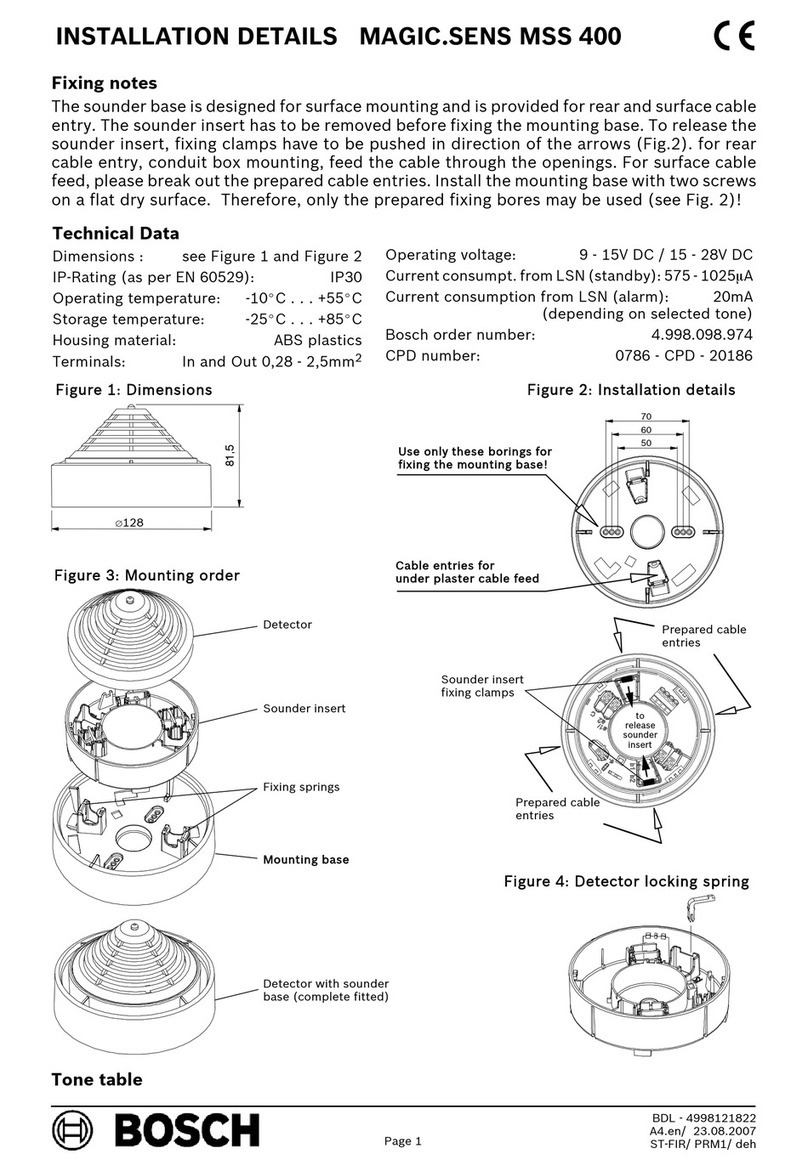

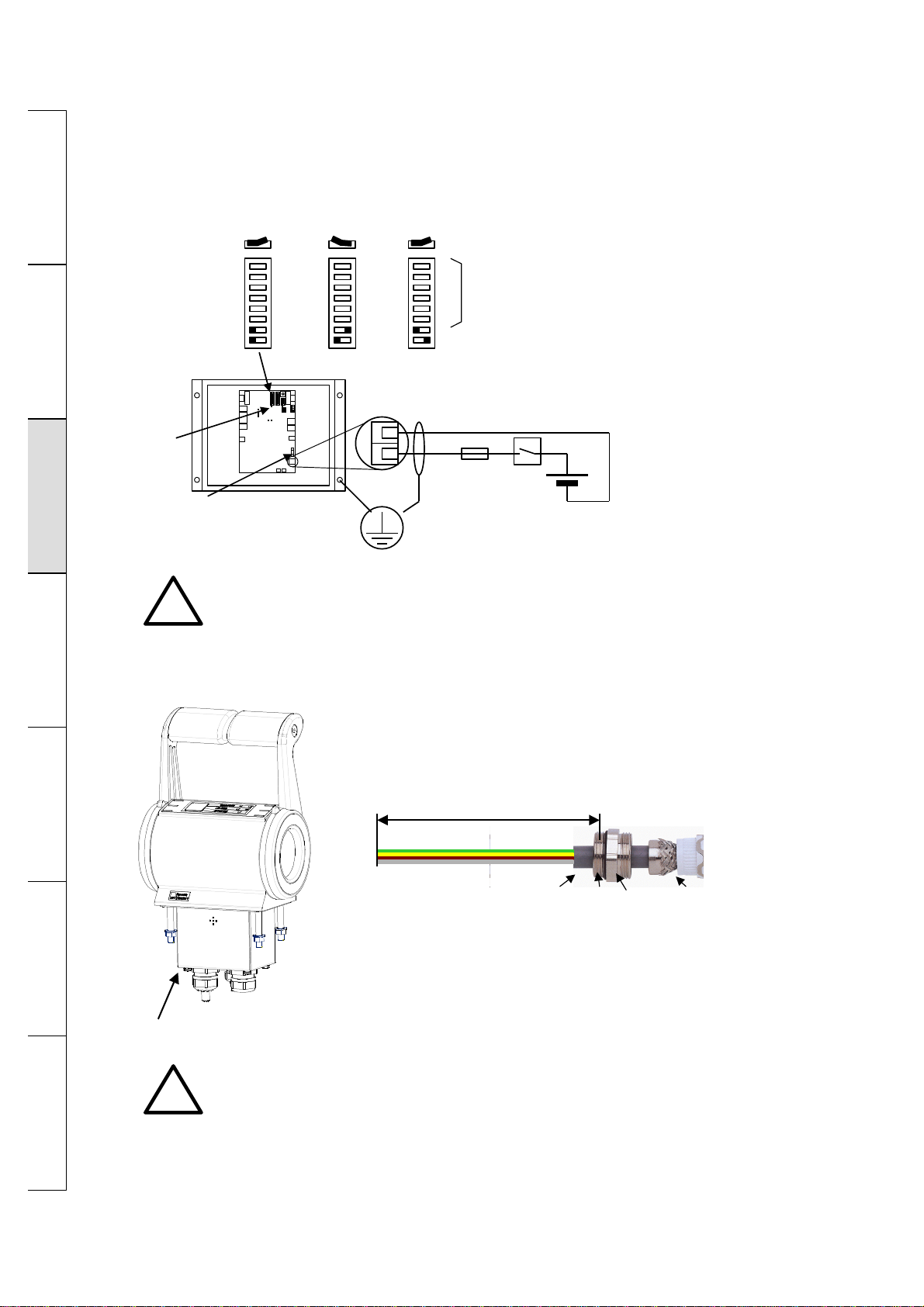

3-Wire components and adjust switches

-Power supply (chapter 3.1)

-Control head (chapter 3.2)

Attention: Enter the control head ID and write it down.

-Throttle and gear control ("mechanical" chapter 3.3, "electrical" chapter 3.4)

-Extra functions if necessary (alarm, engine start interlock, idle speed relay, chapter 3.5

ff.)

Commissioning

4Enter control heads (chapter 4.2)

Enter additional functions of control heads if applicable.

5For mechanical throttle control: enter nominal value for idle speed (chapter 4.3)

6For mechanical gear shifting: adjust position ahead / astern

(chapter 4.4)

7Enter extra functions if necessary (power boost, increased idle speed, see chapter 4.3,

synchronization, buzzer in neutral, change of control station, see chapter 4.2).

Mooring Trial

8Adjustment of delay times for gear shifting (chapter 4.4)

Adjustment of power boost if applicable (chapter 4.3)

Adjustment of increased idle speed if applicable (chapter 4.3)

Sea Trial

9Adjustment of reversing delay times (chapter 4.4)

How to operate the system is described in chapter 5.

In case of malfunction, an error analysis as explained in chapter 6 has to be carried out.

Imprint: The copyright of this user manual remains the property of Bosch Rexroth AG.

Included are instructions and technical drawings which may not be reproduced or

copied either in part or whole, nor may they be used for evaluation or distributed for

competition purposes.

The diagrams and drawings used in this manual are for guidelines only and are not be

used for the actual design.

This edition supersedes all previous ones.

Order No.: 883 890 060 3

Bosch Rexroth AG

Department Marine Technique

Bartweg 13

30453 Hannover

P. O. Box 91 07 62

30427 Hannover

Tel.: +49 (0)5 11-2136-2 51

Fax.: +49 (0)5 11-2136-1 62

Internet: http://www.boschrexroth.de