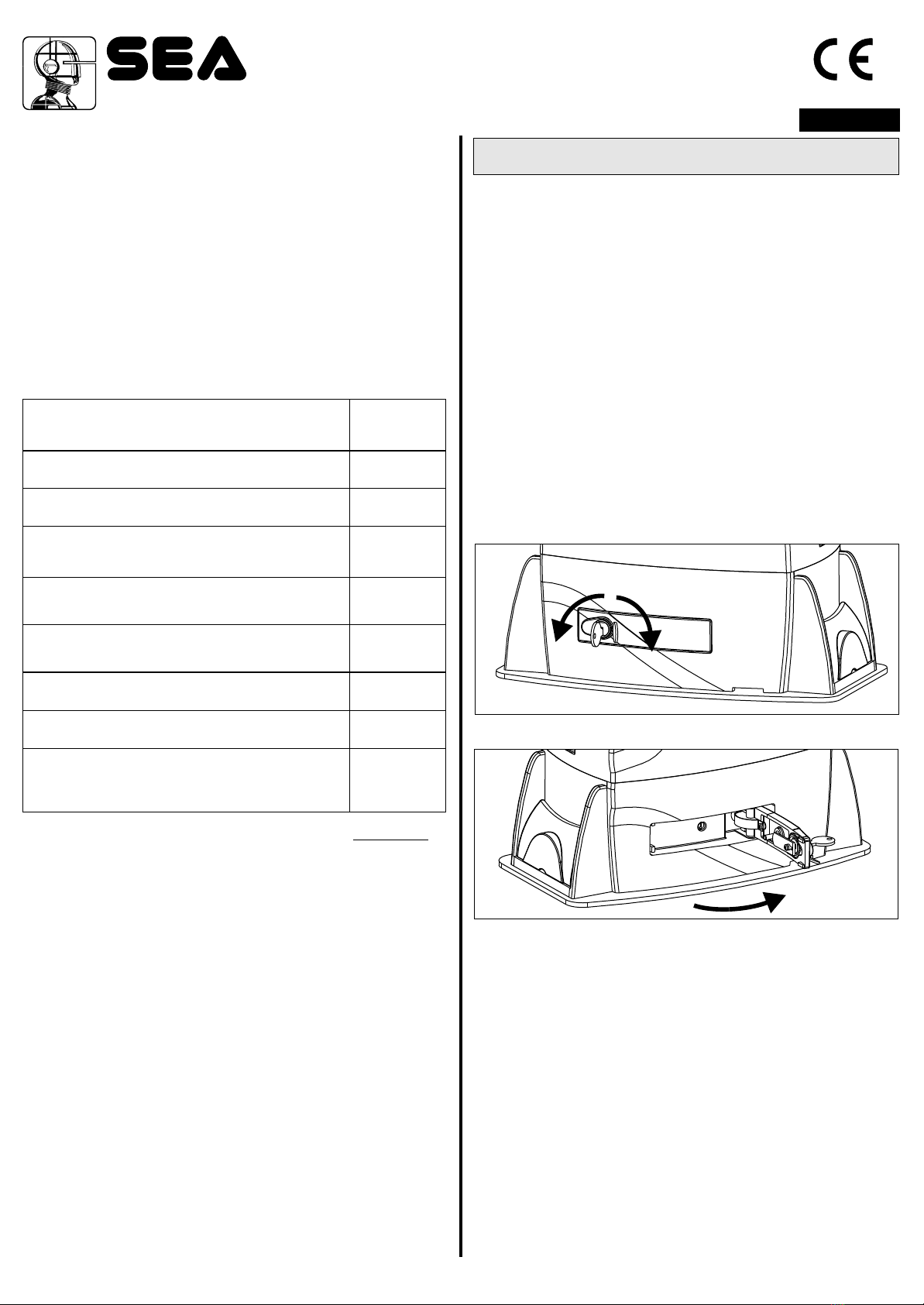

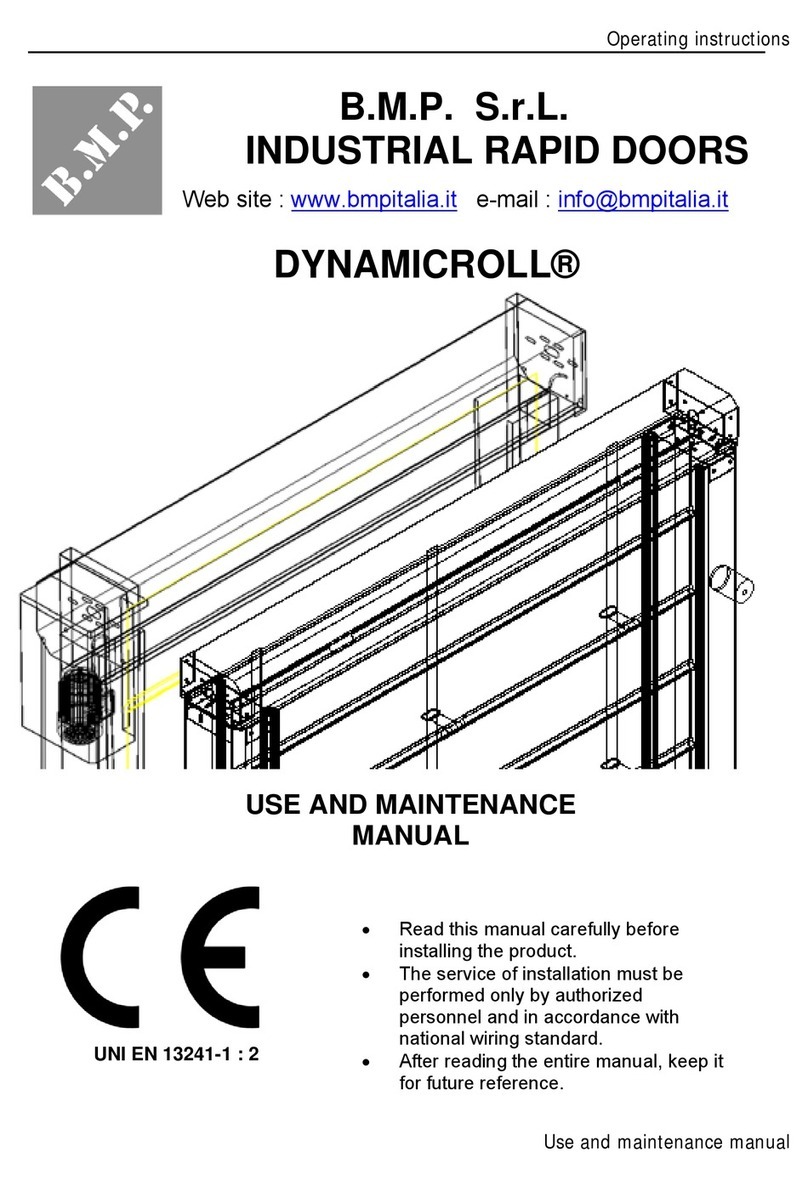

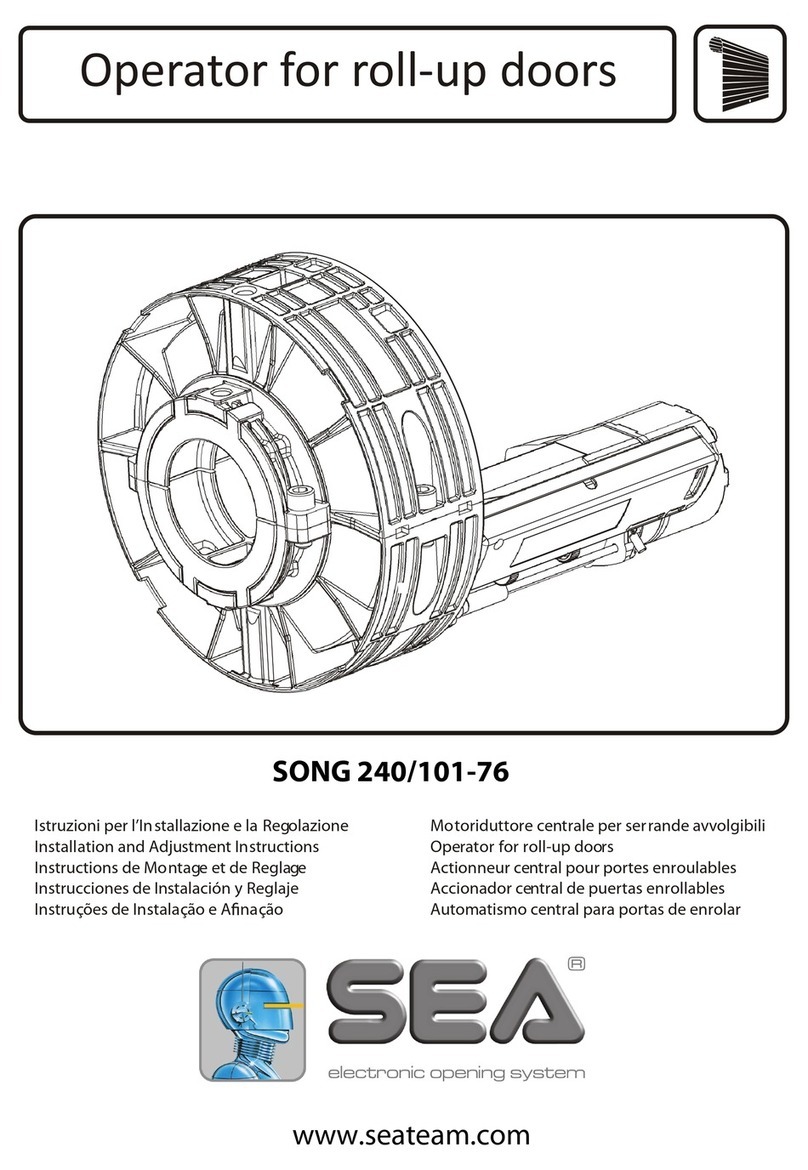

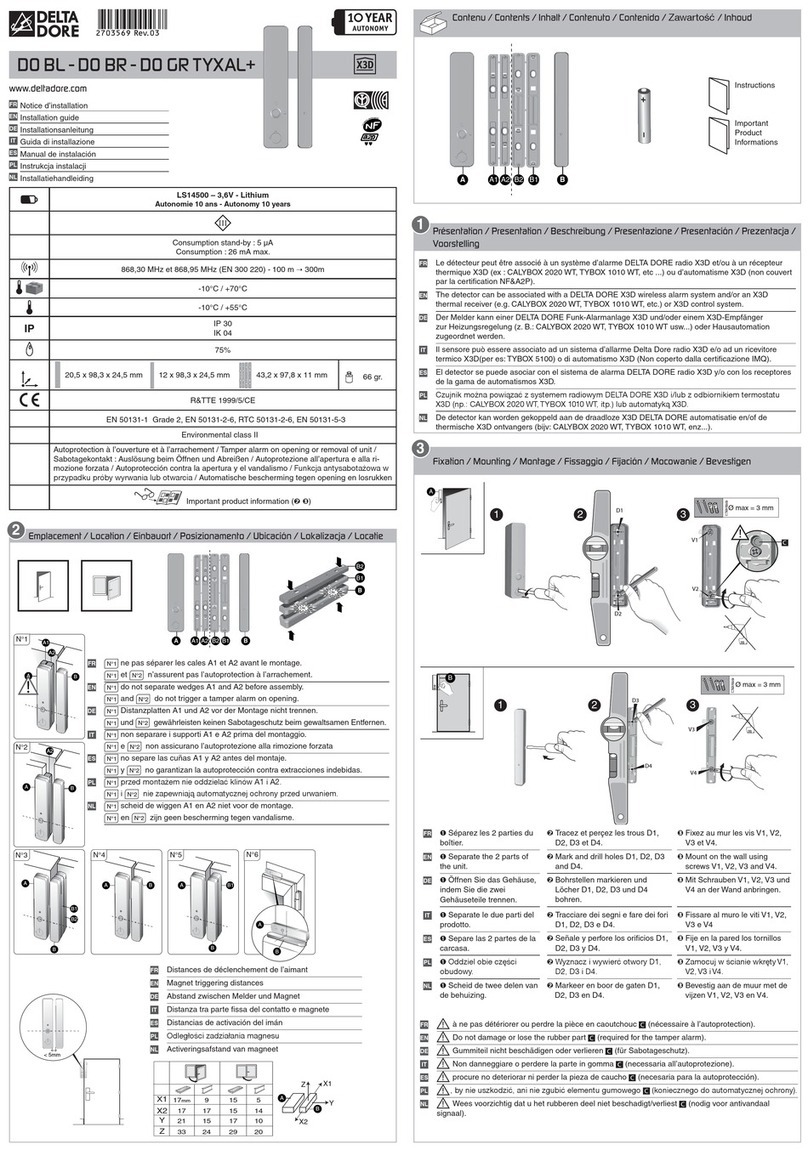

INSTRUCTIONS DE MONTAGE ET CONNEXION

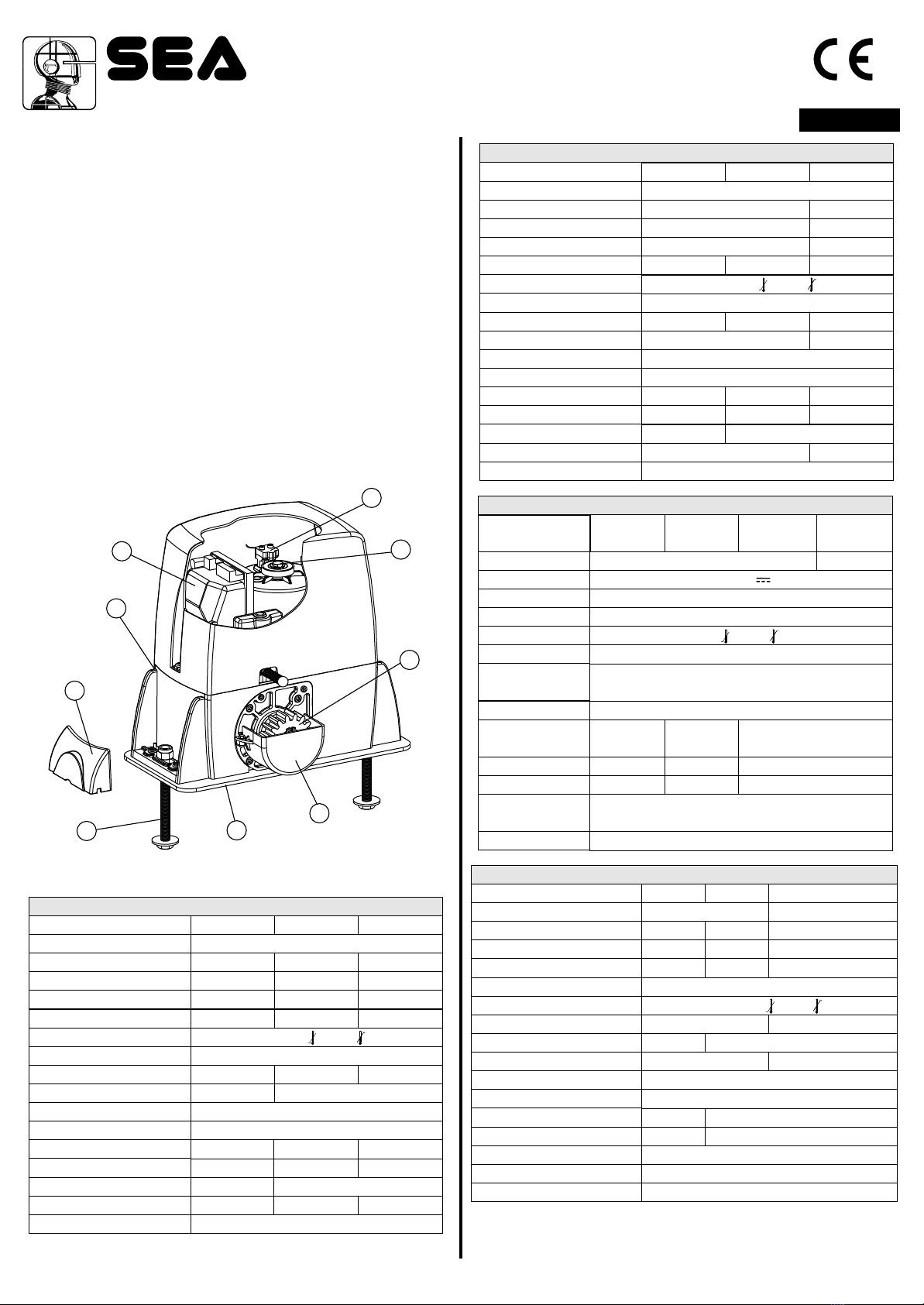

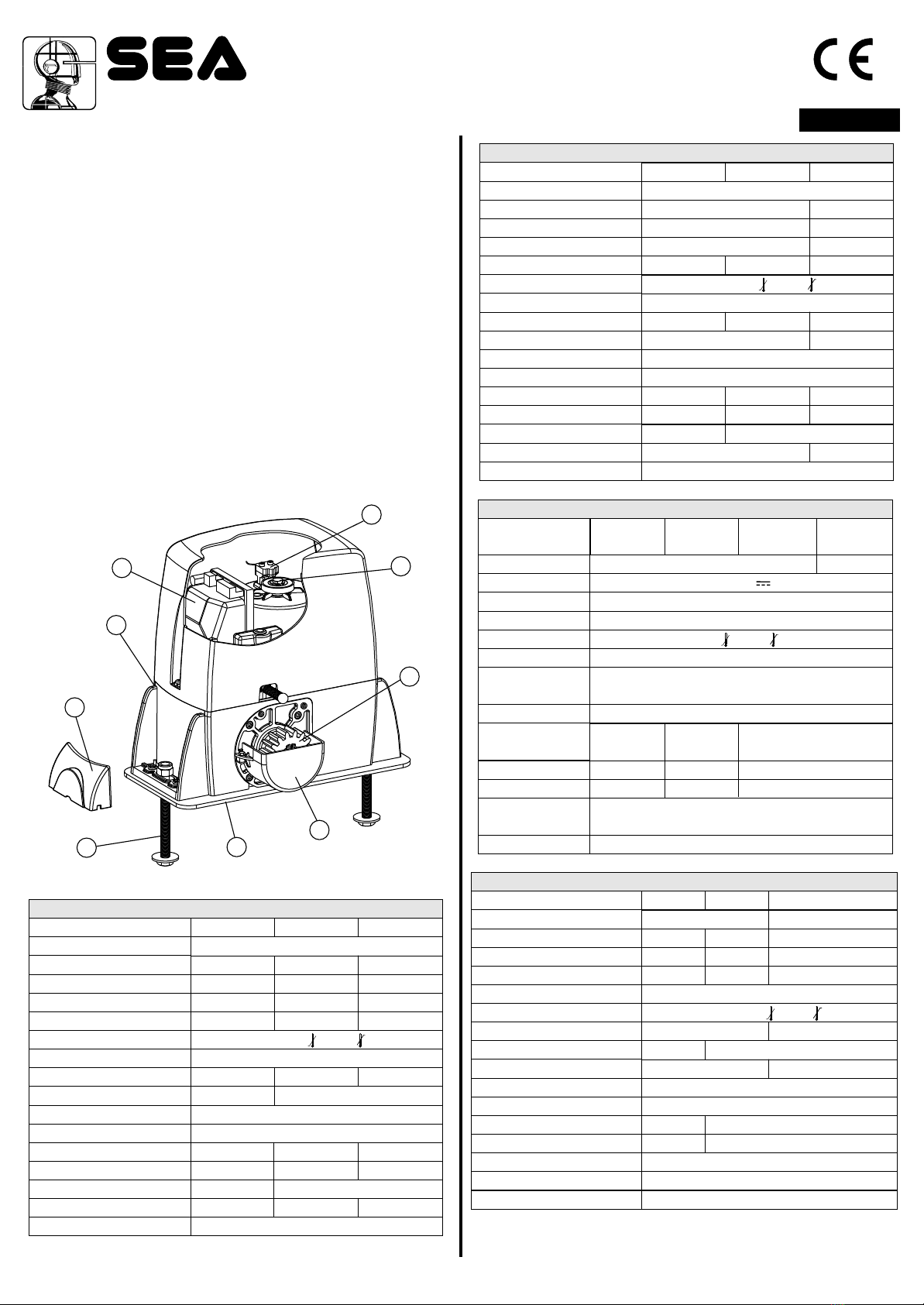

1Plaque de fondation réglable

2Boulons d’ancrage

3Protection pignon

4Couvercle vis de réglage

5Pignon

6Levier déverrouillage réducteur

7 Vis réglage friction mécanique

(Où présent)

8Armoire électronique

9Encoder magnétique (Où présent)

NOMENCLATURE COMPOSANTS PRINCIPAUX

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

SATURN - BOXER

Exemple: Saturn.

230 V 50/60 Hz

330W 550W 750W

1,6 A 2,6 A 3,0 A

10 F 12,5 F 12,5 F

35% 35% 30%

-20°C +55°C

150°C

12 kg 13 kg 14,5 kg

Electronique Electronique/Mécanique

IP55

0,15 (0,18) m/s

30 Nm 55 Nm 70 Nm

600 kg 1000 kg 2000 kg

6 m 10 m

No Oui Oui

Inductif ou Mécanique

~

mmm

600 1000 2000

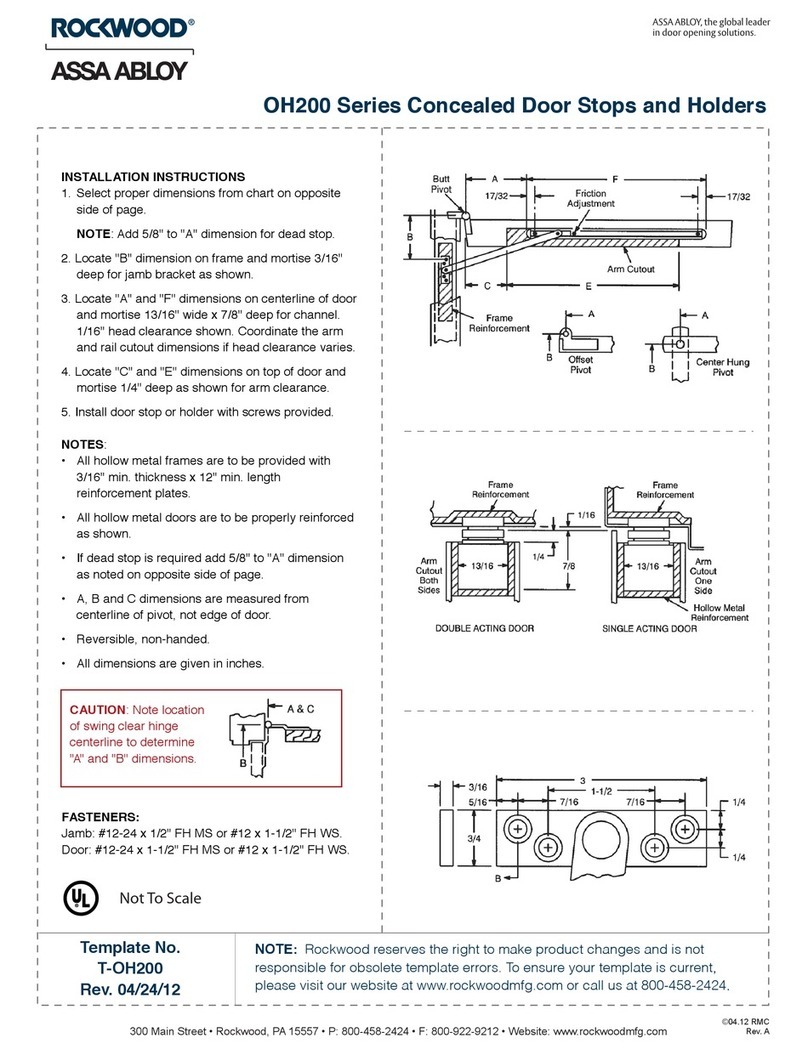

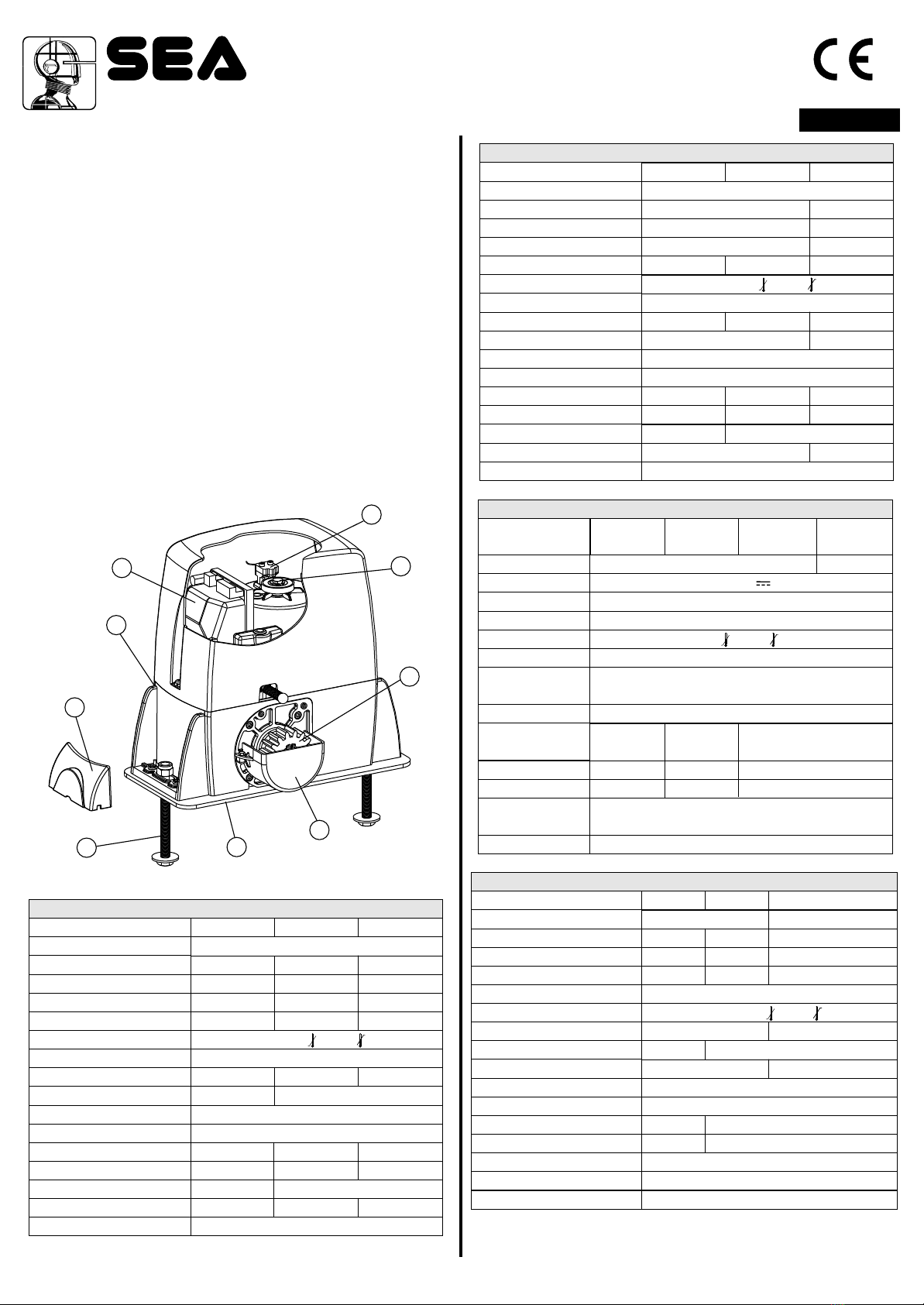

SATURN 600-1000-2000 (230V)

DONNEES TECNIQUES

Alimentation

Puissance

Courant absorbé

Condensateur de décollage

Fréquence d’utilisation

Temperature ambiante

Intervention de Thermoprotection

Poids

Friction anti - écrasement

Dégré de protection

Vitesse pignon Z16 (Z20)

Couple max

Poids Max. du portail

Longueur Max. du portail

Friction Mécanique

Fin de course

La friction est présente seulement sur la version OIL

1000 2000

550W 750W 400W

2,6 A 3,0 A 1,0 A

10 µf 12,5 µf -

55%

-20°C +55°C

150°C -

14 kg 15 kg

Electronique/Mécanique Mécanique

IP55

0,15 (0,18) m/s

55 Nm 70 Nm

1000 kg 2000 kg

10 m

Oui

Inductif ou Mécanique

2000 TRIPHASÉ

230V (±5%) 50/60Hz

230V/380V(±5%) 50/60Hz

BOXER 1000-2000-2000 Triphasé

600 1000 2000

SATURN 600-1000-2000 (115V)

115 V (±5%) 50/60 Hz

400W 500W

3,2 A 5,0 A

50 µf 70µf

20% 25% 40%

-20°C +55°C

150°C

12 kg 13kg 14,5kg

Electronique Electr./Méc.

IP55

0,15 (0,18)m/s

50 Nm 55Nm 70Nm

600 kg 1000kg 2000kg

6 m 10 m

No Oui

Inductif ou Mécanique

DONNEES TECNIQUES

Alimentation

Puissance

Courant absorbé

Condensateur de décollage

Fréquence d’utilisation

Temperature ambiante

Intervention de Thermoprotection

Poids

Friction anti - écrasement

Dégré de protection

Vitesse pignon Z16 (Z20)

Couple max

Poids Max. du portail

Longueur Max. du portail

Friction Mécanique

Fin de course

DONNEES TECNIQUES

Alimentation

Puissance

Courant absorbé

Condensateur de décollage

Fréquence d’utilisation

Temperature ambiante

Intervention de Thermoprotection

Poids

Friction anti - écrasement

Dégré de protection

Vitesse pignon Z16 (Z20)

Couple max

Poids Max. du portail

Longueur Max. du portail

Friction Mécanique

Fin de course

Remarque: La fréquence d'utilisation est valide seulement

pour la première heure à temperature ambiante (20°C).

16

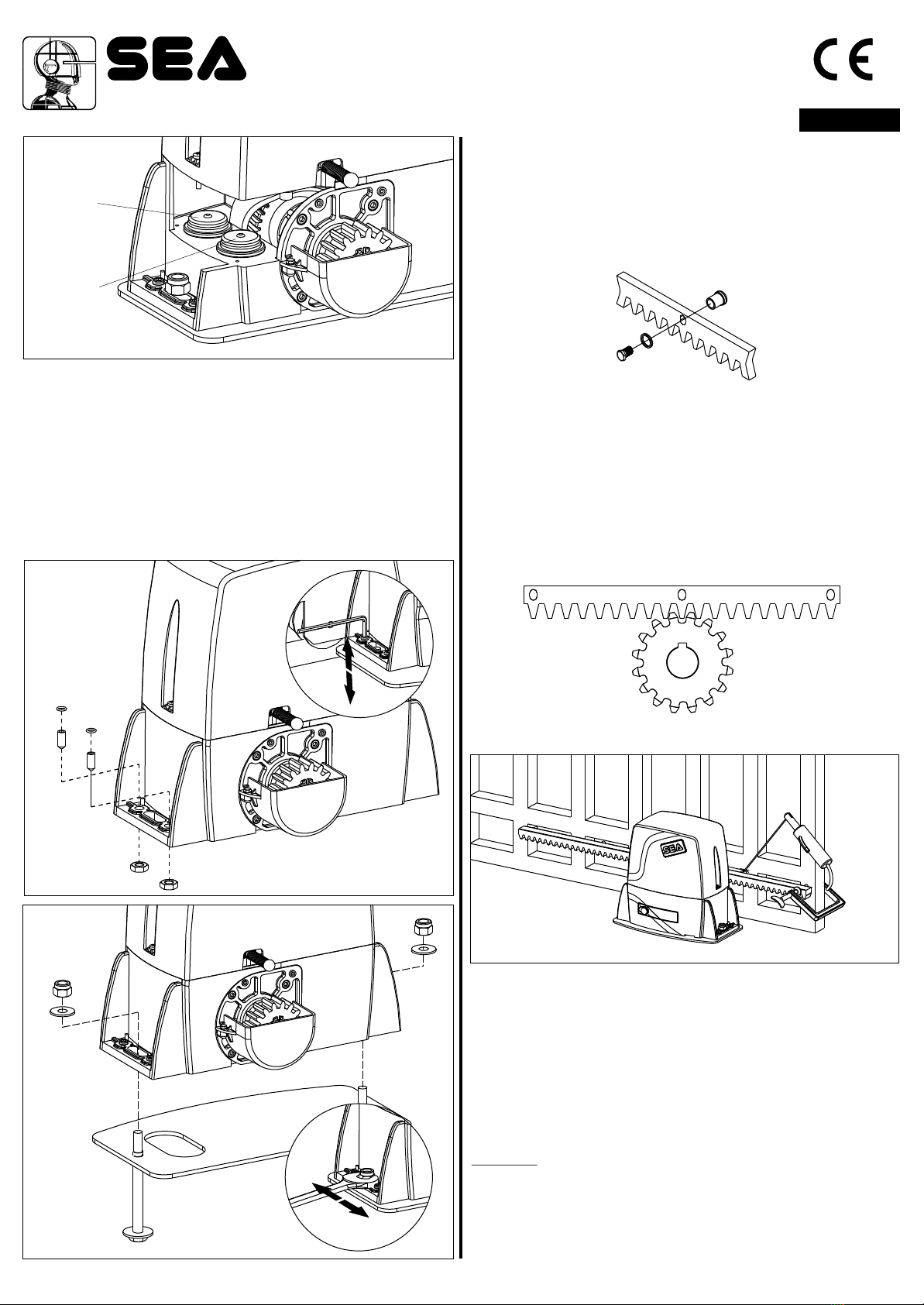

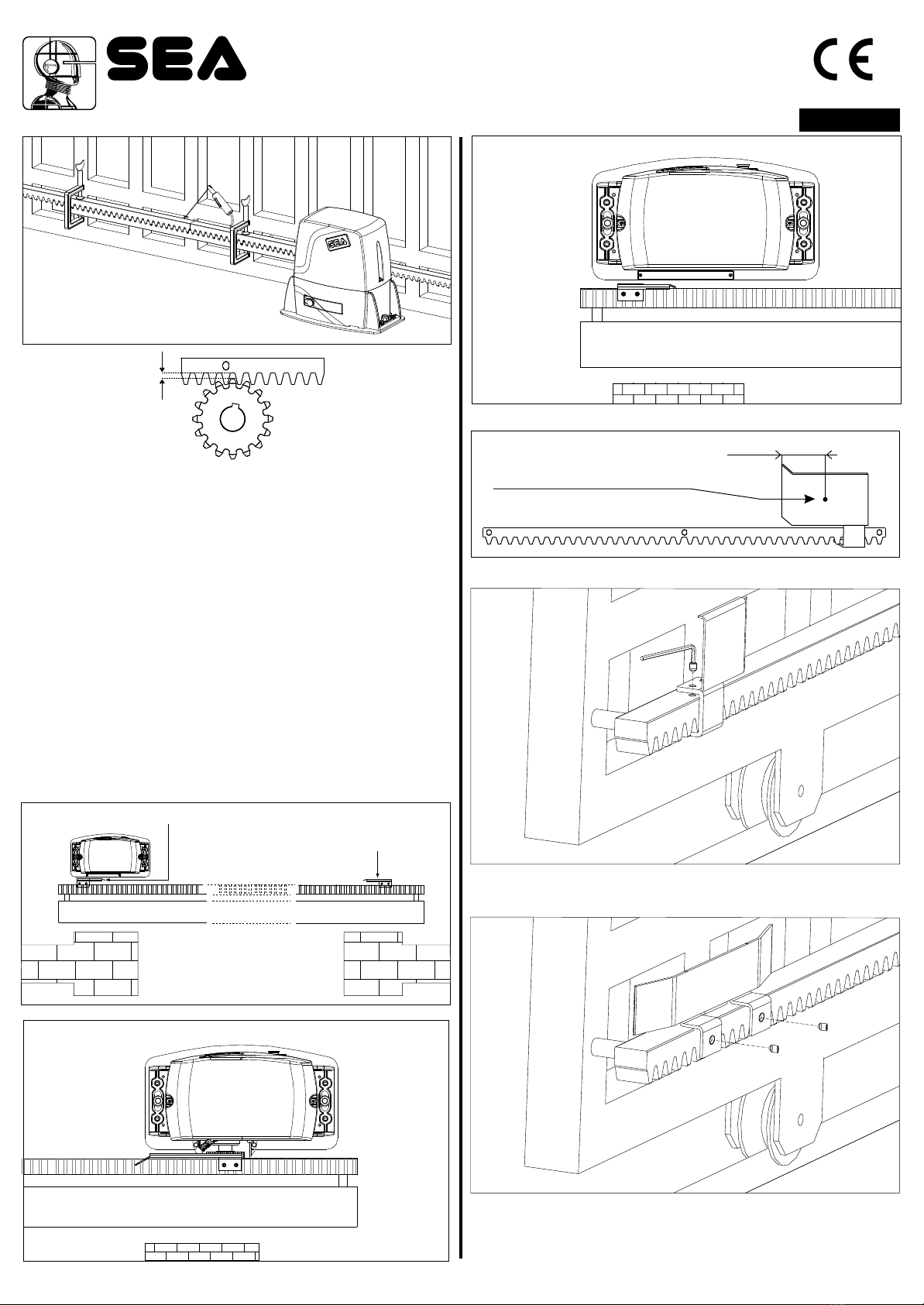

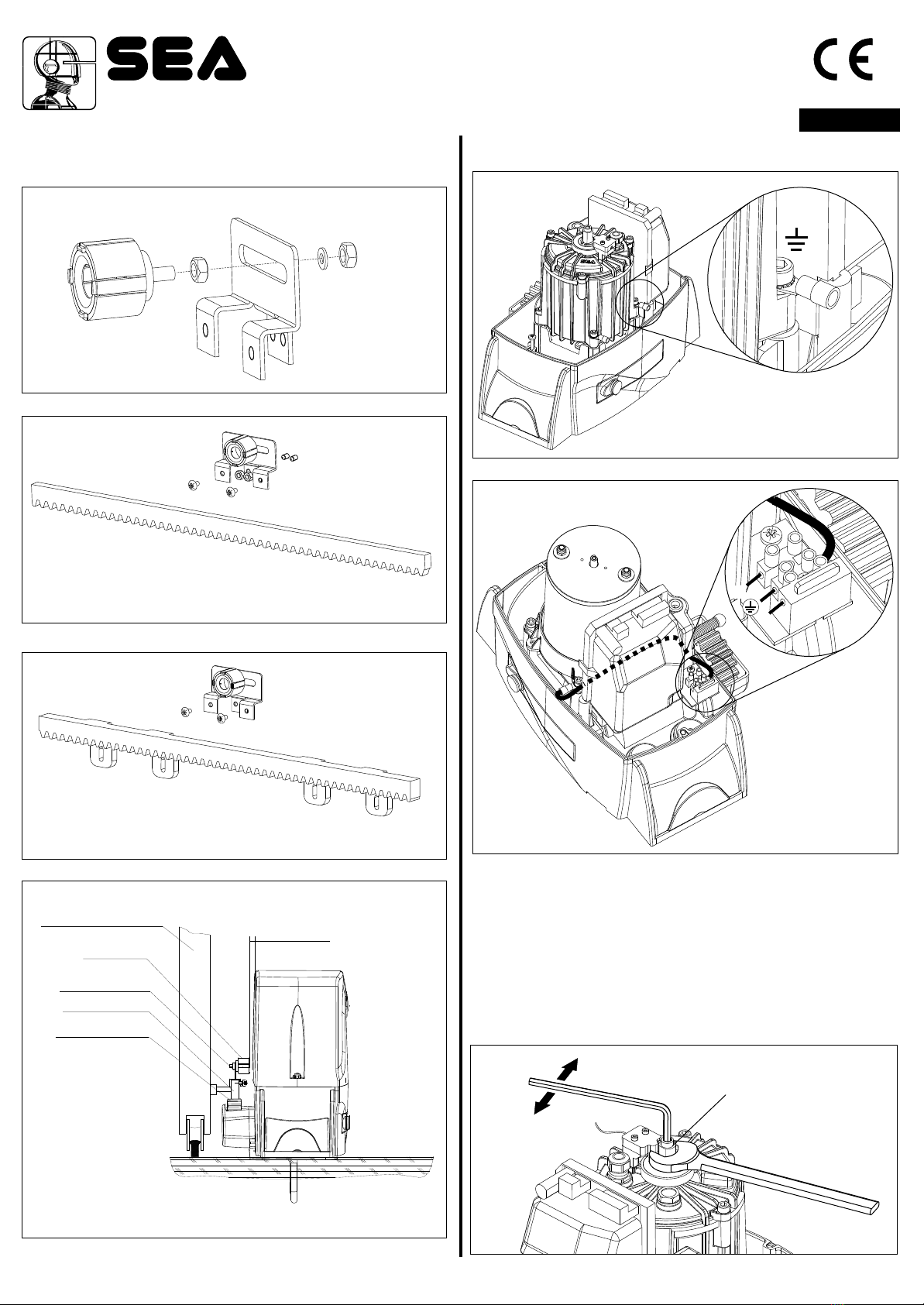

Le SATURN et le BOXER sont des moteurs conçus pour

l’automatisation de portails coulissants avec lubrification des

engrenages à la graisse ou en bain d’huile selon la version

utilisée.

L’irréversibilité des moteurs permet une fermeture parfaite et

sure du portail, évitant l’installation d’une serrure électrique et en

cas de coupure de courant le dispositif de déverrouillage situé

sur la partie frontale du moteur permet l’ouverture et la fermeture

manuelles. Les opérateurs sont équipés d'un dispostif

d’embrayage électronique et d’un embrayage mécanique

réglable (si présent), qui prévoit l’ajustement de la poussée sur

le portail. En outre le dispositif électronique d’inversion

(optionnel), réalisé à l’aide de l’encodeur, fait de Saturn et

Boxer des opérateurs sûrs et fiables permettant de façon

simple le respect des lois en vigueur dans les pays où ce produit

est installé.

cod. 67410324

FRANÇAIS

9

7

5

3

1

2

4

6

8

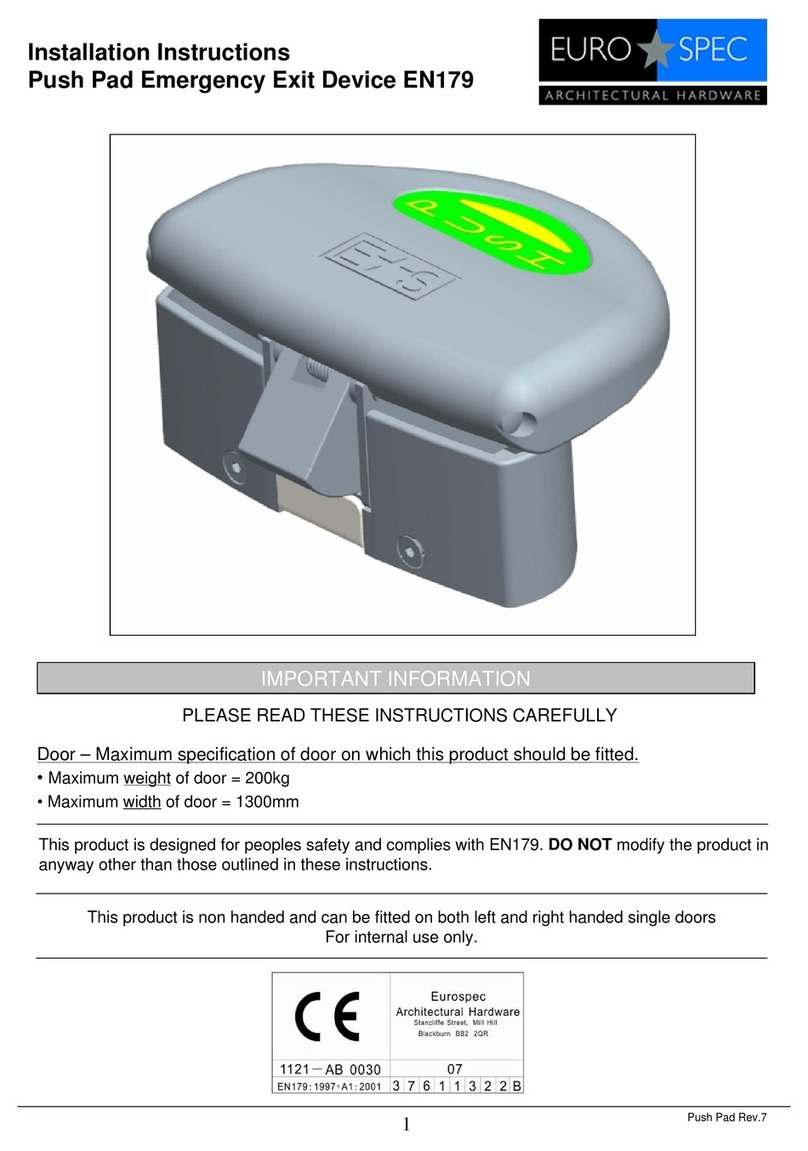

Electronique

Inductif/Mécanique

DONNEES

TECNIQUES

Alimentation

Fréquence d’utilisat.

Temperature amb.

Poids

Friction anti -

écrasement

Dégré de protection

Vitesse pignon

Couple max

Poids Max. du portail

Longueur Max.

du portail

Fin de course

Moteur

Puissance absorbée

REV 07 - 12/2015

1500 24V

(230V)

230V~ 50/60 Hz

24V

100W

60%

14,3 kg

Ip55

0 - 60 Nm

1200 kg

10 m

-20°C +55°C

1500 24V

(115V)

SATURN 500 SUPER FAST 24V - 1200 FAST 24V (230V) - 1500 24V (230V)-(115V)

1200 FAST 24V

(230V)

500 SUPER FAST

24V (230V)

115V~ 50/60 Hz

0,40 m/s Max

(Z20)

0 - 65 Nm0 - 45 Nm

1500 kg500 kg

0,32 m/s Max

(Z16)

0,25 m/s Max

(Z13)