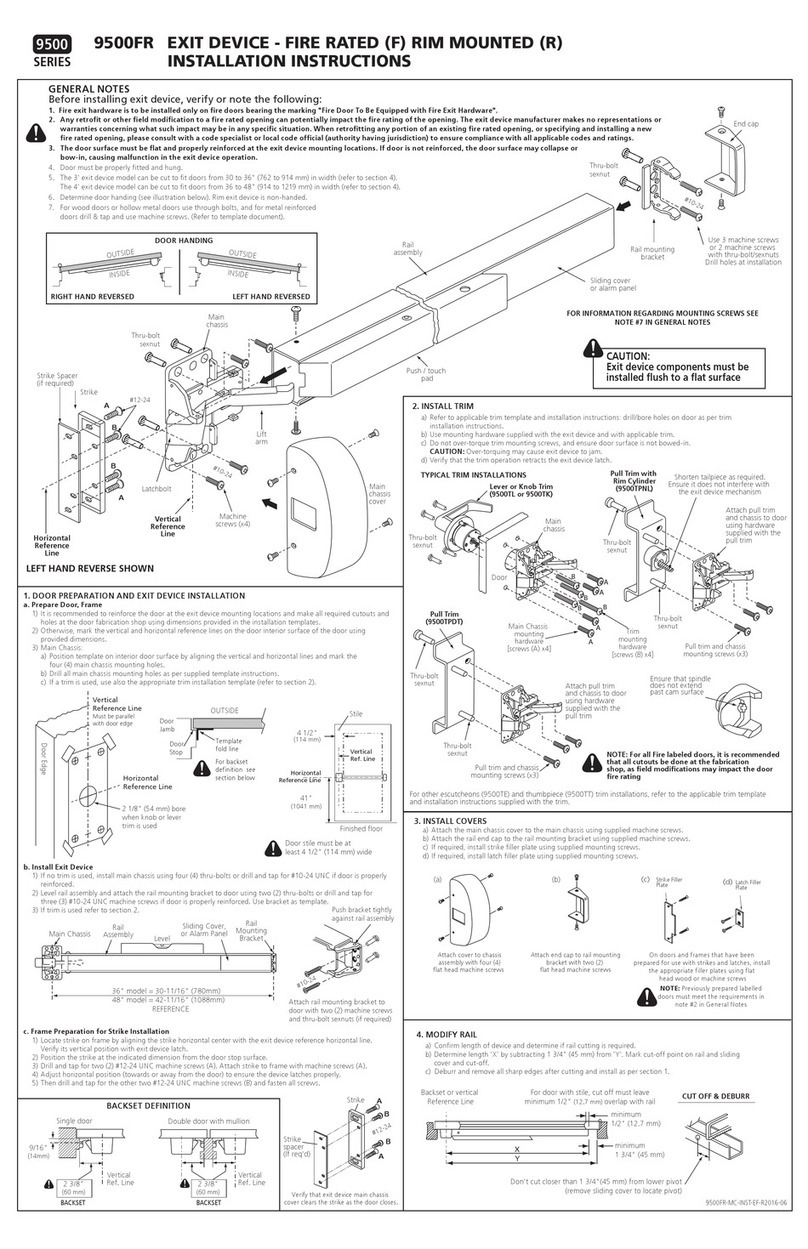

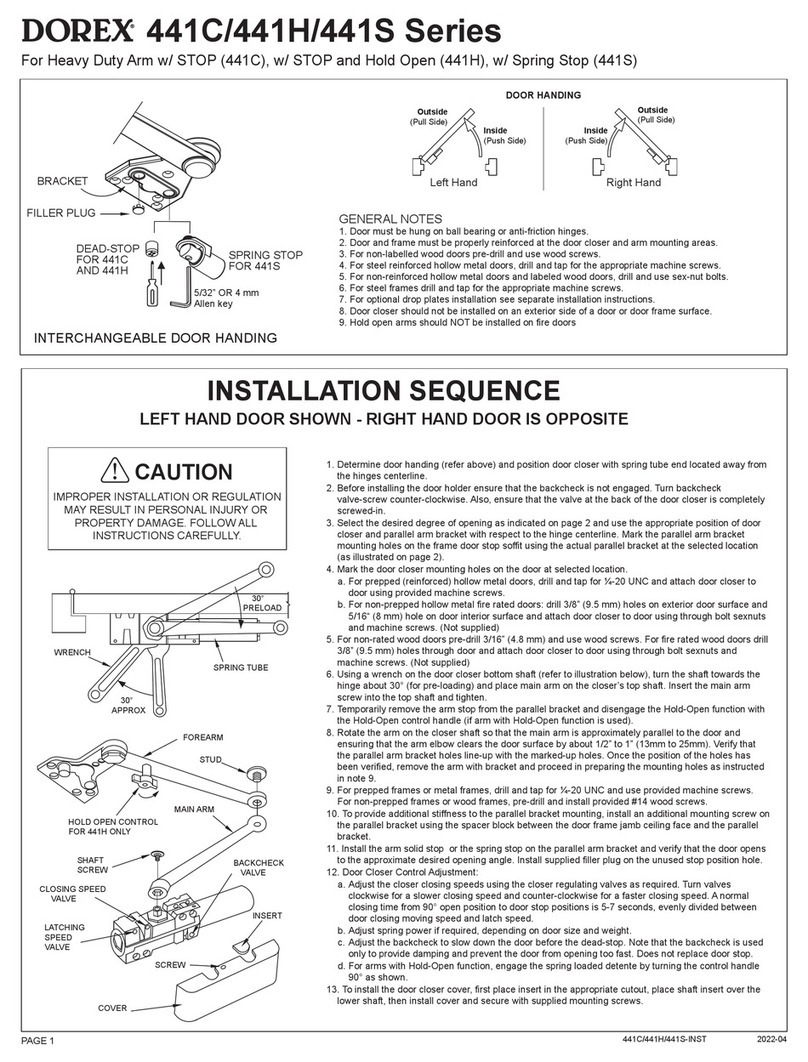

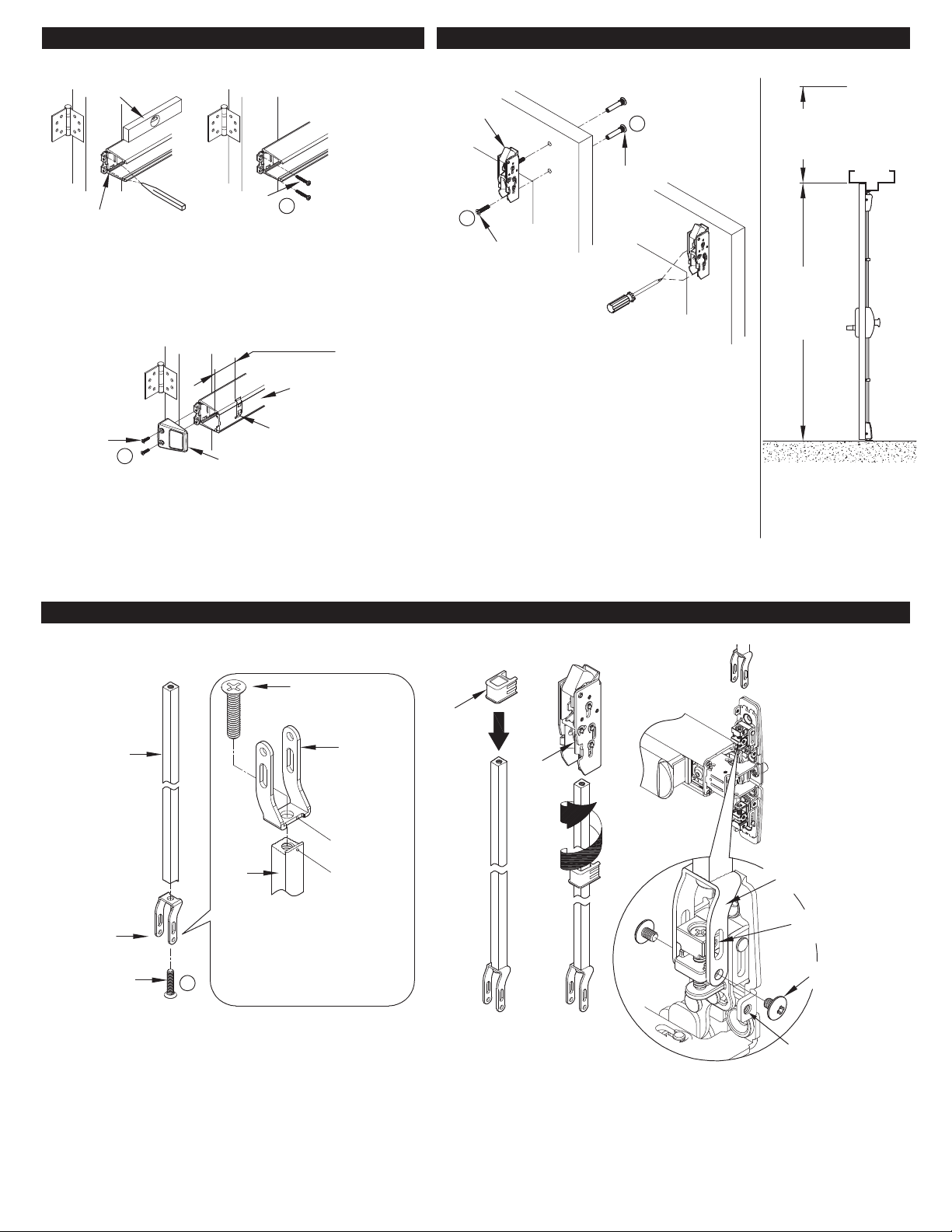

01. DRAW HORIZONTAL CENTERLINE ( )

5 / 12

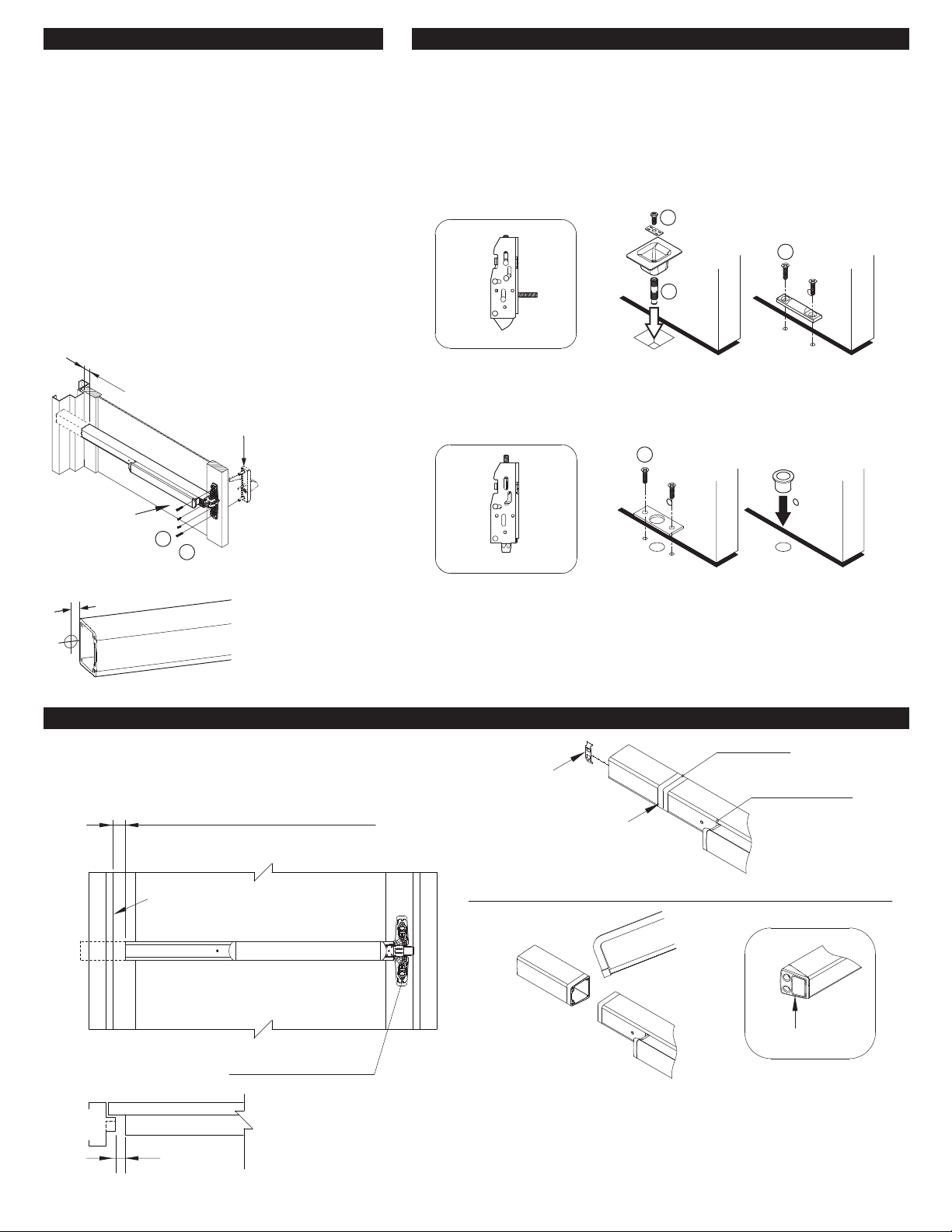

02. LOCATE TEMPLATES AND PREPARE DOOR 03. INSTALL TOP STRIKE AND SHIM

Mark horizontal centerline on inside face of door 39 ⁵/8"

from finished floor as shown. (Continue horizontal center

line to outside face of door if trim is used)

Hinge

Side

C

L

39 ⁵/8"

to Finished

Floor or

Threshold

RHR shown

(LHR opposite)

C

L

Stile

width

Backset

Backset

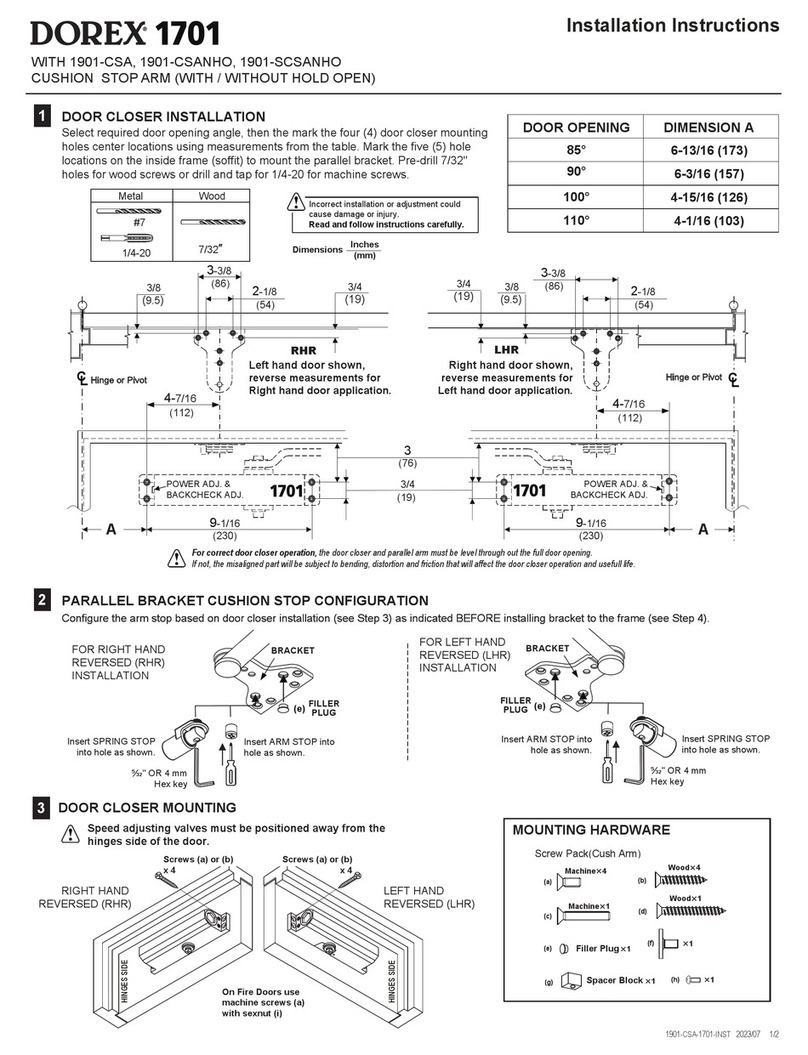

Min. stile

Beveled edge door Rounded edge door

Min. stile

Backset

E

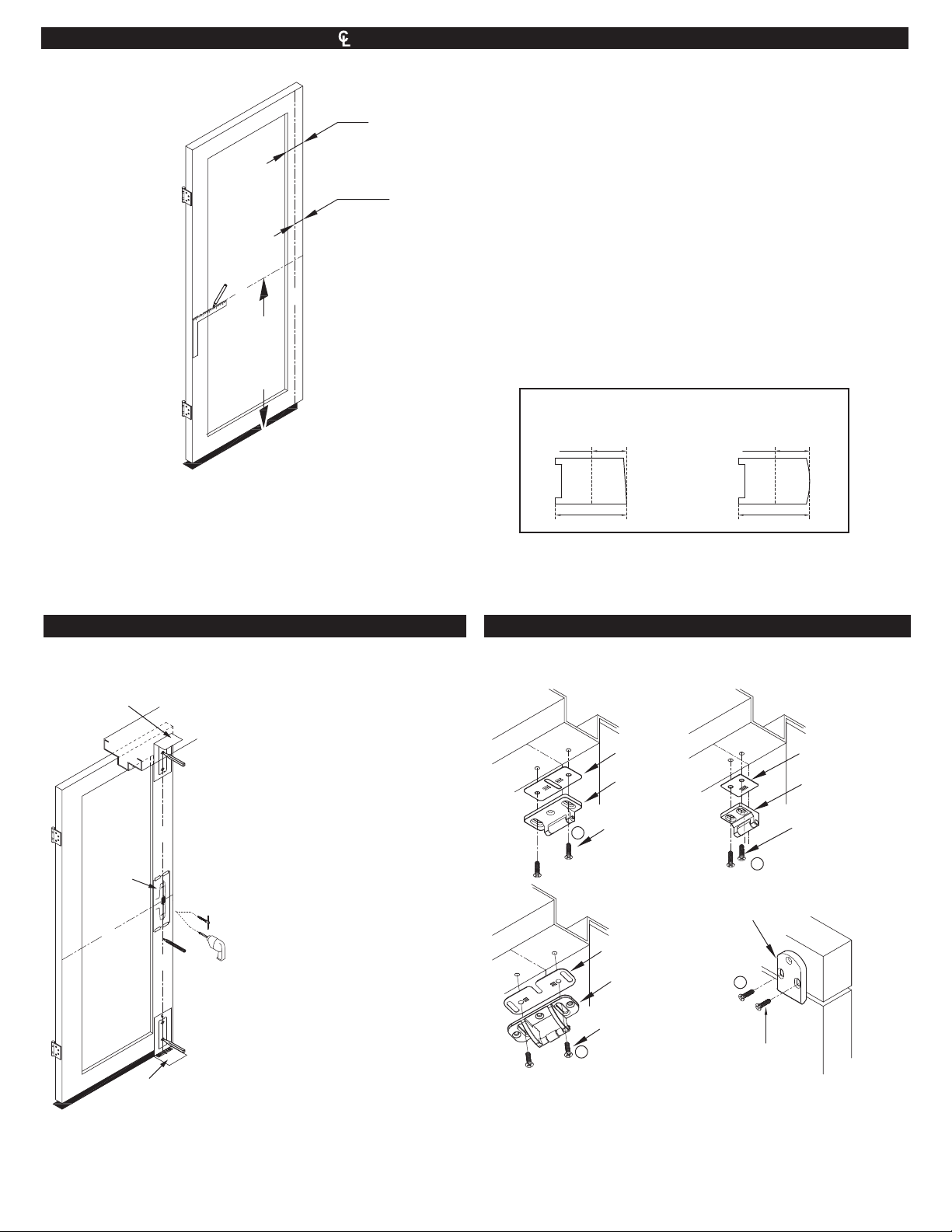

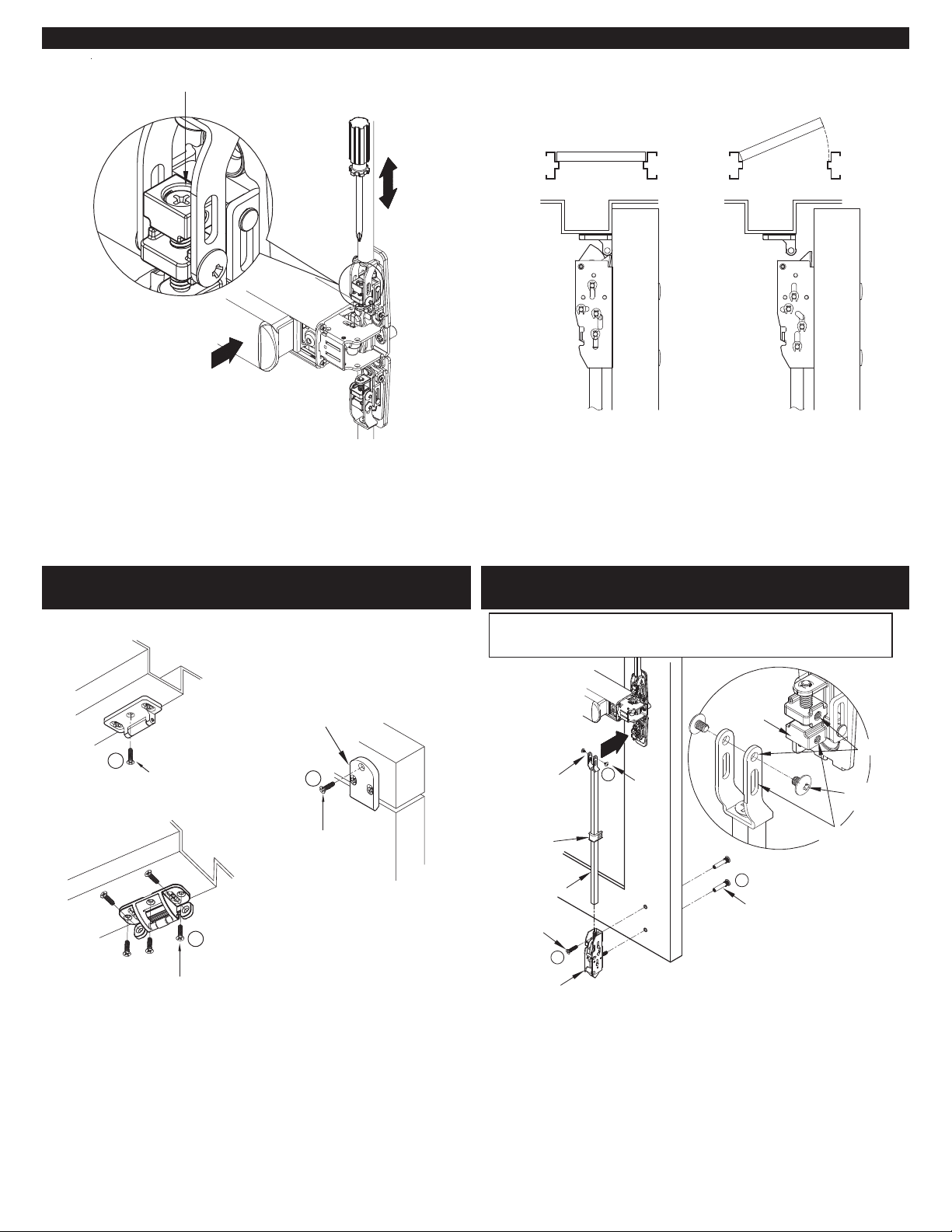

Install a screw through each slot.

Shim

Strike Screws

Strike Screws

Shim

Strike Screws

E

E

Shim

Strike Screws

E

DXAS106 DXAS203

Default for DX2PV

DXAS215

DXAS108

Default for DX2FV

The BACKSET and STILE widths are directly related to:

1. Door Construction: door material, single door, double doors with or

without mullion.

2. Frame Construction: frame material, type and size of door stop on

frame.

3. Top strike length.

Before preparing the door for the exit device center case (chassis), study the

position of the top and bottom latches and the top and bottom strikes.

Refer to the supplied templates or consult with your sales representative for

additional data for door/frames configurations that it are not shown in the

installation instructions.

Backset measurement and Aluminum Door Stile

The backset is measured from the edge of the door as shown below.

The required minimum stile is 2-1/8" with (additional) 1/2" glass stop.

Aluminum doors with a 2-1/8" stile width cannot have a door stop on the

door lock side edge.

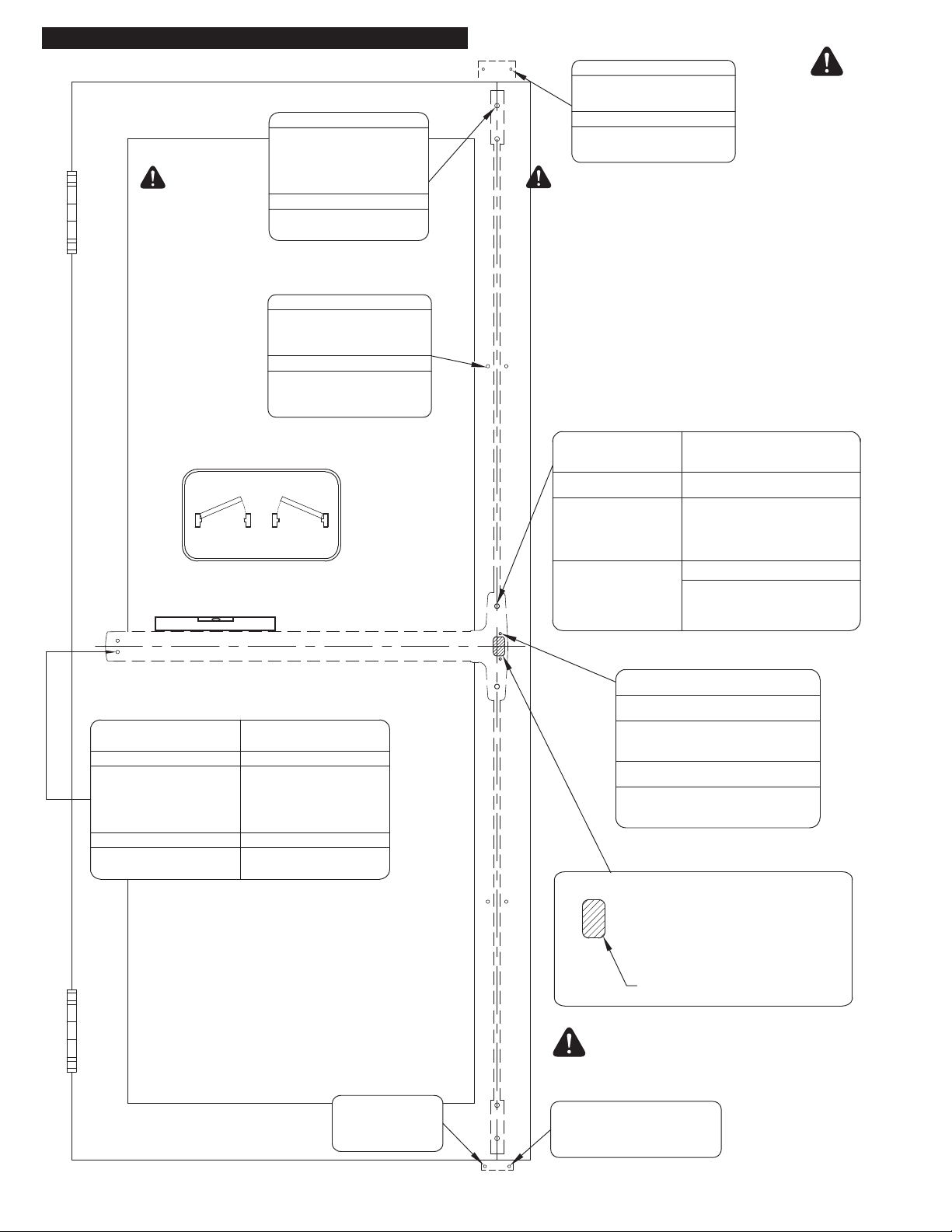

1. CAUTION: Prior to using supplied

templates, verify that the templates are

printed to full scale, by measuring some of

the indicated dimensions.

2. Position the center case template in line

with the marked horizontal and vertical

centerlines as shown. Tape the template on

the door and mark the cut-out and mounting

holes centers on the door’s interior side.

3. If trim is used, prepare the door exterior

side using the template and installation

instructions for that trim.

4. With door closed, fold the appropriate top

latch and strike template on the door stop

and inside door surface as shown, ensuring

the vertical centerline aligns with the exit

device vertical centerline. Tape template on

the door and frame, then mark the mounting

hole centers.

5. Fold the appropriate bottom latch and strike

template on the door bottom surface and

floor as shown, ensuring the vertical

centerline aligns with the exit device vertical

centerline. Tape template on the door and

floor and mark the mounting hole centers.

6. Drill and tap required holes and cut the

required cut-outs as indicated on page 4 of

the door preparation document.

7. Attach appropriate strikes as per step 3.

C

L

C

L

C

L

Top Latch

and Strike

Template

Bottom Latch

and Strike

Template

Center

Case

Template

* A ¹⁄4" gap is required

between the bottom of

the door and the finished

floor or threshold.