1.4 MECHANICAL INSTALLATION

Reference Drawings:

•

90559 –Seakeeper 1 Generic Installation Guide

•

90516 –Seakeeper 1 Bolt-In Installation Details

•

90517 –Seakeeper 1 Installation Fixture Kit

•

90599 –Seakeeper 1 Bolt-In Kit

1.4.1 PREPARATION OF VESSEL STRUCTURE

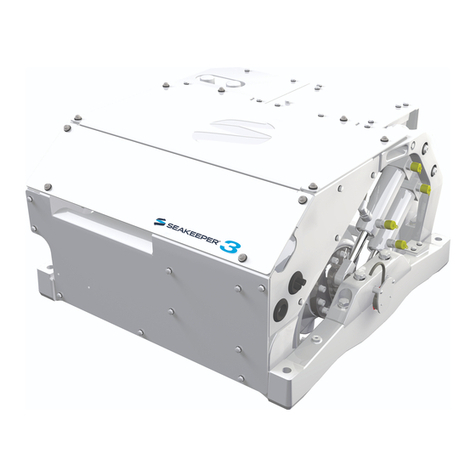

The Seakeeper 1 Generic Installation Guide (90559) shows various structural arrangements to support

the integration of the Seakeeper 1. The Generic Installation Guide offers above and below deck

installation arrangements with fiber-reinforced plastic (FRP) and aluminum structures, which should

provide solutions for most vessels. Depending on the structure to which the Seakeeper is fastened,

blind threaded holes or through-bolting can be utilized. The Seakeeper 1 is affixed to the hull via four

bolts in the Seakeeper 1 frame. Each Seakeeper 1 foundation bolt has a vibration isolation assembly

to minimize the transmission of vibrations to the hull structure.

Refer to Seakeeper Drawing No. 90516 –Seakeeper 1 Bolt-In Installation Details. This drawing contains

critical design dimensions and loads that must be considered in the design of the boat’s structure that

will receive the Seakeeper 1. It is assumed that a proper structural analysis has been performed for

the vessel structure to which the Seakeeper will be fastened to ensure proper strength margins for

the loads the Seakeeper will create during operation.

The vessel structure supporting the Seakeeper should be installed so the Seakeeper is parallel to the

waterline in the transverse direction and within 2 degrees longitudinally. In addition, the four areas

on top of the structure on which the Seakeeper 1 will rest need to be co-planar within .06” (1.5 mm)

to minimize potential distortion of Seakeeper isolation mounts when installed.

Seakeeper offers an installation fixture kit, P/N 90517. The fixture has 4 holes located at the same

centers as the mounting holes on the Seakeeper 1. The fixture locates the hole patterns at the proper

spacing both in the fore-aft direction and the port-starboard direction. See Figure 5 for more details

regarding the Seakeeper 1 template.

Note: Do NOT use the installation fixture to establish the Seakeeper envelope dimensions or

clearances. Refer to Drawing No. 90516 –Seakeeper 1 Bolt-In Installation Guide –for envelope

dimensions. A 3-D model of the Seakeeper 1 is available on the Seakeeper website

(https://www.seakeeper.com/technical-library/) to aid in designing the Seakeeper foundation and the

space around the Seakeeper.