DOCUMENT # 90020, REV 5 MODEL 7000 GYRO INSTALLATION MANUAL-MAR09

Page 5of 9

Preparation Of Hull Structure-

Reference Seakeeper Drawing No. 90002, Model 7000 Gyro Model 7000 Gyro General

Specifications, Design Loads and Env. Dimensions. Important dimensional and load information is

given in this drawing that will impact the design details of the structure that will receive the gyro as well

as selection of adhesive to bond the gyro into the hull.

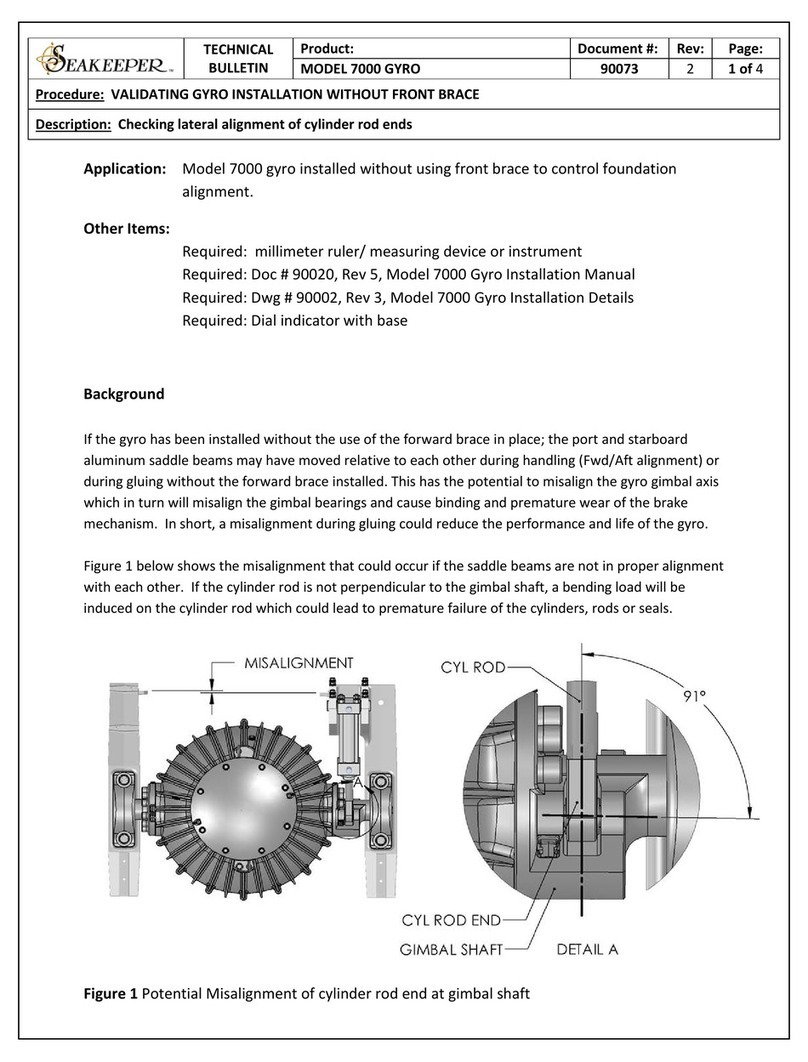

The foundation “saddles” of the gyro are designed to be bonded directly to the composite hull

structure of the vessel to effectively distribute gyroscopic loads. A complete bond is required between the

inside surface of the saddles and the hull structure. To aid in determining quantity of adhesive required,

the surface area of Port saddle bond area is 2194 cm2. The starboard saddle bond area is 2002 cm2.

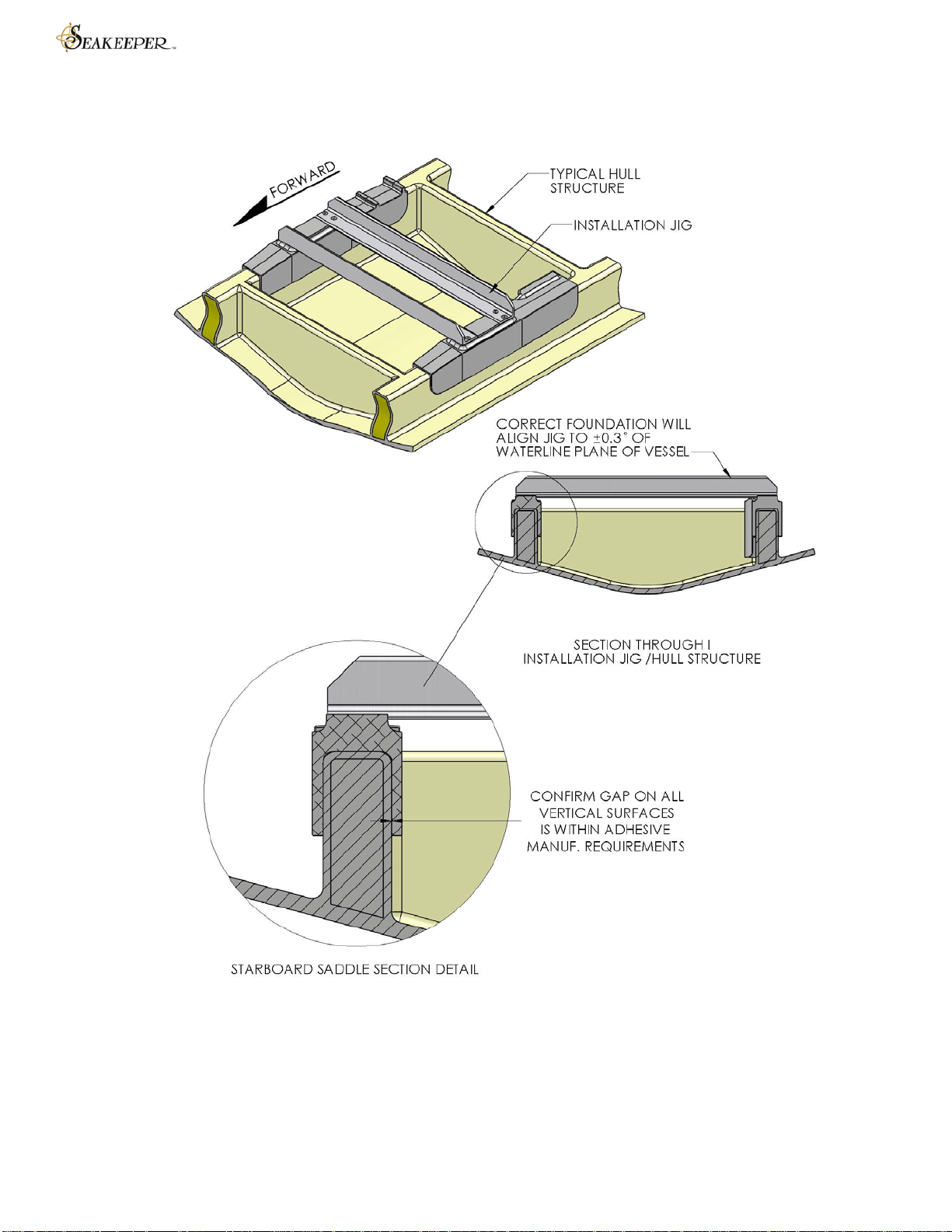

Seakeeper has an optional installation jig available, P/N 90012, that is intended to duplicate the

gyro foundation geometry in order to check clearances and alignment. The jig will allow the builder /

installer to lay-up and adjust the foundation dimensions to create a low-clearance fit between the gyro

foundation saddles and the hull structure. Shear strength of adhesive will be maximized if the cured

thickness between vessel structure and gyro saddles is minimized. Therefore, the jig should be used to

confirm that the overall dimensions of the foundations are square and level and that the adhesive gap is

within the adhesive manufacturer’s maximum recommended thickness. See figure 2 below.

Gyro supporting structure in hull should align installation jig and therefore the installed gyro to

within +/- 0.3° of the waterline plane of the vessel in any direction.

Seakeeper recommends that a safety enclosure be installed around the gyro to prevent accidental

entanglement of personnel or equipment while gyro is in operation. Installer may also choose to make

the enclosure of sound damping materials to reduce noise output from gyro. If sound damping enclosure

option is pursued, a small circulation / exchange fan is recommended to keep air temperatures inside

sound enclosure the same as ambient air in the compartment in which the gyro is installed.

There is a large torque about the gimbal axis when the gyro is precessing. Therefore, the gyro must

be housed in an enclosure or a compartment or installed in a cage so personnel or gear cannot come

into contact with the gyro while it is precessing.

The gyro should be treated with the same respect one gives a high speed rotating propeller shaft or

engine shaft. The gyro must be installed so contact is not possible while the flywheel is spinning.