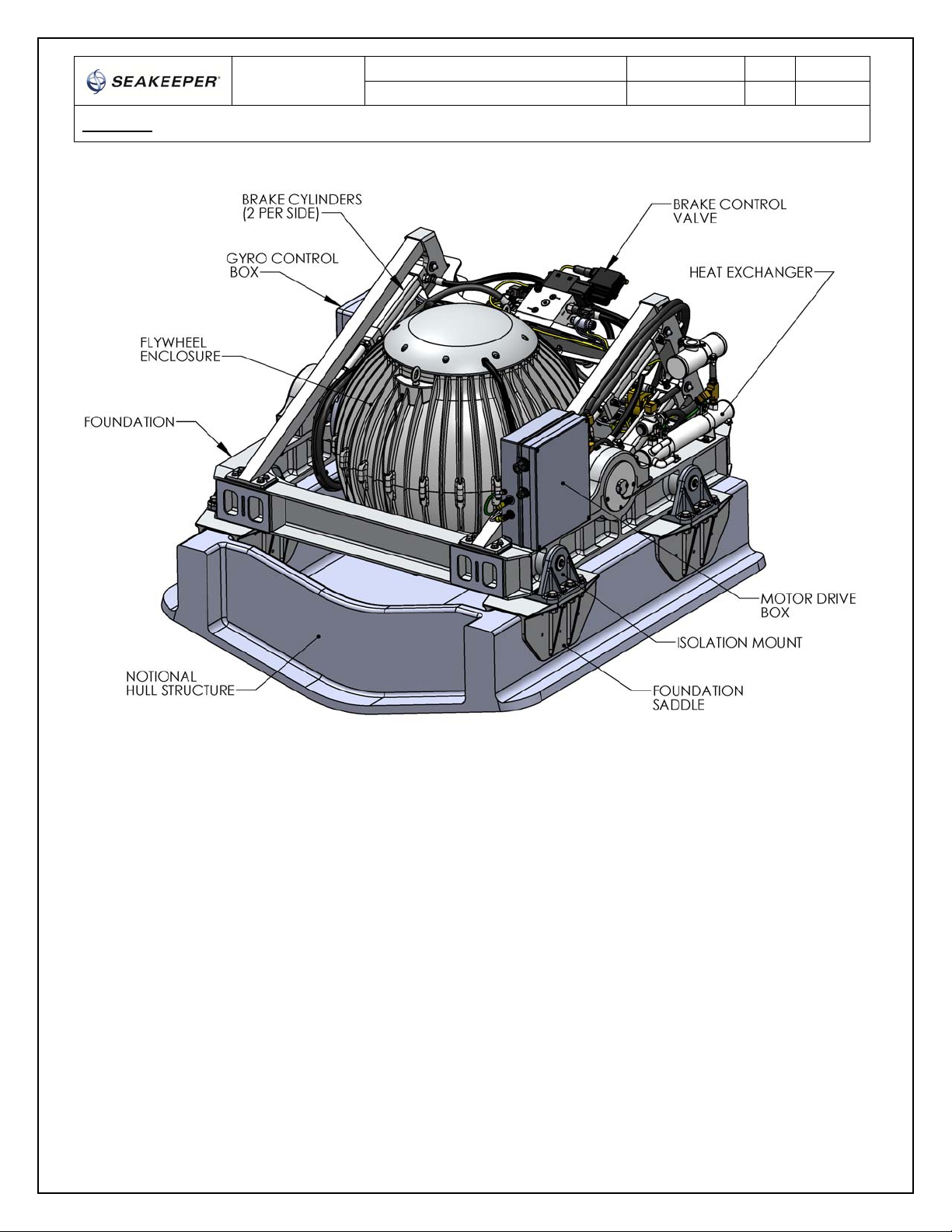

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL26000GYRO9018324of23

Section1:MECHANICALINSTALLATION

SafetyEnclosure

Thereisalargetorqueaboutthegimbalaxiswhenthegyroisprecessing.Therefore,thegyromustbe

housedinanenclosureoracompartmentorinstalledinacagesopersonnelorgearcannotcomeinto

contactwiththegyrowhileitisprecessing.

Thegyroshouldbetreatedwiththesamerespectonegivesahighspeedrotatingpropellershaftor

engineshaft.Thegyromustbeinstalledsocontactisnotpossiblewhiletheflywheelisspinning.

Noise/Soundproofing/Ventilation

Gyronoisehasbeenmeasuredundersteadystateconditions(nowaveload)inSeakeeper'stestfacility.Thesteady

statenoiseistypicallyintherangeof72‐74dBunweighted.Asthefrequenciesemittingthehighestsound

pressuresarelow(likeothermarinemachinery),itisrecommendedthatthegyrobeinstalledinacageina

machineryspacethatisalreadytreatedwithsoundproofing.

Ifthegyrostabilizerhastobelocatedoutsideamachineryspace,itshouldbeinstalledinasounddamping

enclosuretopreventlowfrequencynoise(approximately133Hz)fromenteringthelivingspaces.Inthiscase,the

enclosurecanbeopenatthebottombetweenthehullstringers.Asmallexhaustfanshouldbeinstalledinthetop

oftheenclosuretopullambientairthrutheenclosuresotheairintheenclosuredoesnotheatup.Thiswillensure

thattheownerdoesnotgetnuisanceshutdownsduetotheMotorDriveandBearingtemperaturealarmsinsome

operatingconditions(highambientairtemperature,highseawatertemperature,highseastate,etc).

Thefanshoulddeliver35cuft/min(60cum/hr)whichshouldexchangetheairintheenclosureaboutonceper

minute.Small,massproduced,axialandcentrifugalcoolingfansareavailablewitheitherACorDCinputpower,

ballbearings,extendedtemperaturerange,lownoiseratings,longMTBF,marinized,etc. Locatetheinletatthe

bottomoftheenclosureandmountthefanatthetopasanexhaustfan.Acentrifugalfanmaybebesttominimize

outletarea.Thefanpowerrequirementswouldtypicallybeintherangeof20watts.WhenusingaDCfan,wireit

tothesamebreakerthatprovidespowertotheGyroControlJunctionBoxsothefanturnsonandoffatthesame

timeasthecontroller.