Seakeeper 5500 GYRO User manual

Rev2JULY2013

INSTALLATIONMANUAL

MODEL5500GYRO

THIS PAGE INTENTIONALLY LEFT BLANK

INSTALLATION

MANUAL

Product:Document#:Rev:

MODEL5500GYRO902142

MODEL5500GYRO

INSTALLATIONMANUAL

JULY2013

Contents:

Section1–MechanicalInstallation&PC‐120Guide

Section2–ElectricalInstallation&PowerConfigurations

forSeakeeperGyroStabilizers

Section3–CoolingInstallation

Section4–Startup

Section5–InstallationChecklistandRequiredSupplies

44425PECANCOURT,SUITE151

CALIFORNIA,MARYLAND,20619,U.S.A

PHONE:410‐326‐1590

FAX:410‐326‐1199

E-MAIL: customerservice@seakeeper.com

THIS PAGE INTENTIONALLY LEFT BLANK

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO9021421of15

Section1:MECHANICALINSTALLATION

1.0Introduction

Thisdocumentisintendedtogivedetailsandguidancetoaboatbuilderorequipmentinstallertoinstall

theSeakeeper,Inc.Model5500StabilizingGyro.Thegyroiscapableofproducingloadsupto14.7kN

(3300lbs.)oneachfoundationsaddleandcarefulconsiderationshouldbegiventofoundationdesignto

insureitiscapableoftransferringtheseloadsintothehull.Itisassumedthatpersonnelinvolvedin

installationarefamiliarwithGRPstructuresaswellastheuseofhighstrengthadhesivesthatwillbe

usedtobondthegyrotothehullstructure.Theinstallershouldreviewthefollowinglistofdrawingsto

ensuretheinstallationprocedureisfullyunderstood.

ReferenceDrawings

90012InstallationFixtureAssembly

90219Model5500GyroInstallationDetails

90212Model5500GyroHardwareScopeofSupply

90149GyroCableBlockDiagram

90156GyroCoolingSchematic

FIGURE1–MODEL5500GYRO

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO9021422of15

Section1:MECHANICALINSTALLATION

1.1Precautions

Gyroflywheelissupportedbyprecisionbearings.Makecertainwhileunpackingandliftinggyro

assemblytoNOTdroporimpartmechanicalshockasdamagetobearingscouldresult.

Whilehandling/installinggyroassembly,protectexposedhydraulicbrakecylinderrods(See

Figure1)fromscratchesordamageasthiscouldleadtoprematuresealfailureandoilleaks.

Whilehandling/installinggyroassembly,donotallowelectricalfittingsthatexitbottomofgyro

enclosuretocomeincontactwithanysurfaceorobjectasthiscoulddamagethefittingsand

potentiallyaffectthevacuumintegrityoftheenclosure.

Exercisecaretoprotectgyropaintedfinishasdamagetofinishcouldleadtoearlyappearance

degradationofinstalledgyro.

DoNOTremoveforwardbrace(seeFigure1).

1.2SelectionofGyroInstallationLocation

Selectionofmountinglocationofgyroshouldconsiderthefollowingdesirablefeatures:

Thegyromustbeinstalledaftofamidshipstominimizehigh

accelerationloadingsduetohull/waveimpactsduringoperationat

highspeedorinlargewaves.

Overheadaccessorsufficientclearanceforremoval/re‐installationofgyroenclosurefor

overhaulinfutureyears.

Gyroshouldbeinstalledinadryspacetominimizeeffectsofcorrosion.

Clearanceforreplacementofgimbalanglesensorongyroportside(seeFigure2).

Clearanceforfilling/purgingbrakehydraulicoil(seeFigure2).

Clearanceforfillingwater/glycolcoolingcircuit(seeFigure2).

Clearanceforreplacementofbrakehydrauliccylinders(seeFigure2).

Spaceforrecommendedsound/safetyenclosure.

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO9021423of15

Section1:MECHANICALINSTALLATION

FIGURE2–INSTALLEDGYROCLEARANCECONSIDERATIONS

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO9021424of15

Section1:MECHANICALINSTALLATION

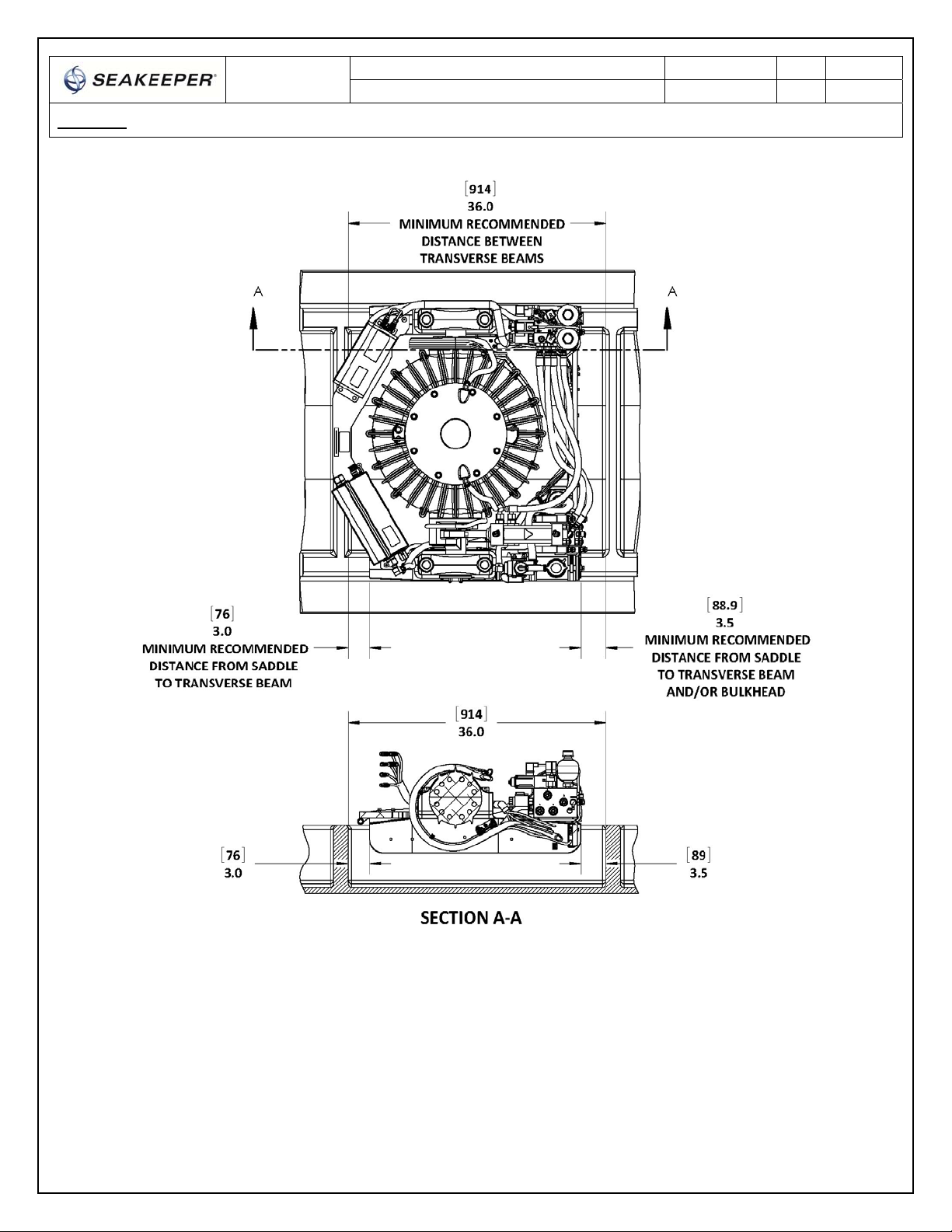

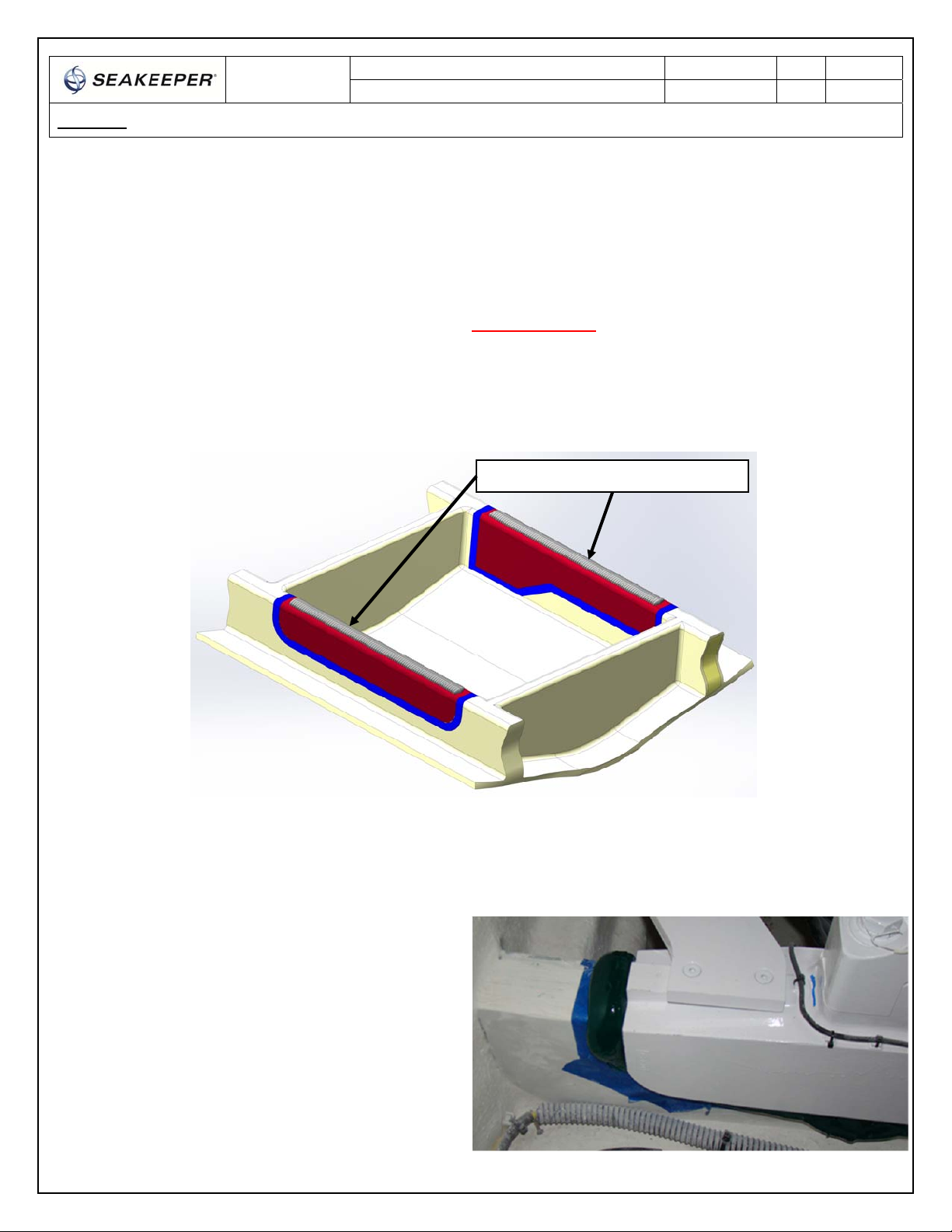

FIGURE3–TRANSVERSEBEAMSCLEARANCECONSIDERATIONS

RefertoFigure3forrecommendedclearancestotransversebeams.Ifatransversebeamislocated

undertheforwardbrace,itmustbe3”(76mm)fromtheedgeofthesaddlebeamstoprovidethe

necessaryclearancefortheswingofthemotorpowercableduringgyroprecession.Clearancesaftof

thegyroareshowntoprovideaccessformaintenance.

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO9021425of15

Section1:MECHANICALINSTALLATION

SafetyEnclosure

Thereisalargetorqueaboutthegimbalaxiswhenthegyroisprecessing.Therefore,thegyro

mustbehousedinanenclosureoracompartmentorinstalledinacagesopersonnelorgear

cannotcomeintocontactwiththegyrowhileitisprecessing.

Thegyroshouldbetreatedwiththesamerespectonegivesahighspeedrotatingpropeller

shaftorengineshaft.

Noise/Soundproofing/Ventilation

Gyronoisehasbeenmeasuredundersteadystateconditions(nowaveload)inSeakeeper'slabandin

our43fttestboat.Thesteadystatenoiseistypicallyintherangeof70‐75dBunweighted.Asthe

frequenciesemittingthehighestsoundpressuresarelow(likeothermarinemachinery),itis

recommendedthatthegyrobeinstalledinacageinamachineryspacethatisalreadytreatedwith

soundproofing.

Ifthegyrostabilizerhastobelocatedoutsideamachineryspace,itshouldbeinstalledinasound

dampingenclosuretopreventlowfrequencynoise(approximately133Hz)fromenteringtheliving

spaces. Inthiscase,theenclosurecanbeopenatthebottombetweenthehullstringers. Asmall

exhaustfanshouldbeinstalledinthetopoftheenclosuretopullambientairthrutheenclosuresothe

airintheenclosuredoesnotheatup.Thiswillensurethattheownerdoesnotgetnuisanceshutdowns

duetotheMotorDriveandBearingtemperaturealarmsinsomeoperatingconditions(highambientair

temperature,highseawatertemperature,highseastate,etc).

Thefanshoulddeliveraminimumof35cuft/min(60cum/hr)whichshouldexchangetheairinthe

enclosureaboutonceperminute.Small,massproduced,axialandcentrifugalcoolingfansareavailable

witheitherACorDCinputpower,ballbearings,extendedtemperaturerange,lownoiseratings,long

MTBF,marinized,etc.Locatetheinletatthebottomoftheenclosureandmountthefanatthetopas

anexhaustfan.Acentrifugalfanmaybebesttominimizeoutletarea.Thefanpowerrequirements

wouldtypicallybeintherangeof20watts. WhenusingaDCfan,wireittothesamebreakerthat

providespowertotheGyroControlBoxsothefanturnsonandoffatthesametimeasthecontroller.

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO9021426of15

Section1:MECHANICALINSTALLATION

1.3UnpackingCrate

1) ReferenceSeakeeperDrawingNo.90212,Model5500HardwareScopeofSupplyforitemsthat

shipwiththegyro.

2) Removeelectricalcomponents,cables,andmisc.itemsandsetaside.

3) Removepackingmaterialsthatsecuregyroassemblyinsidethecrate.

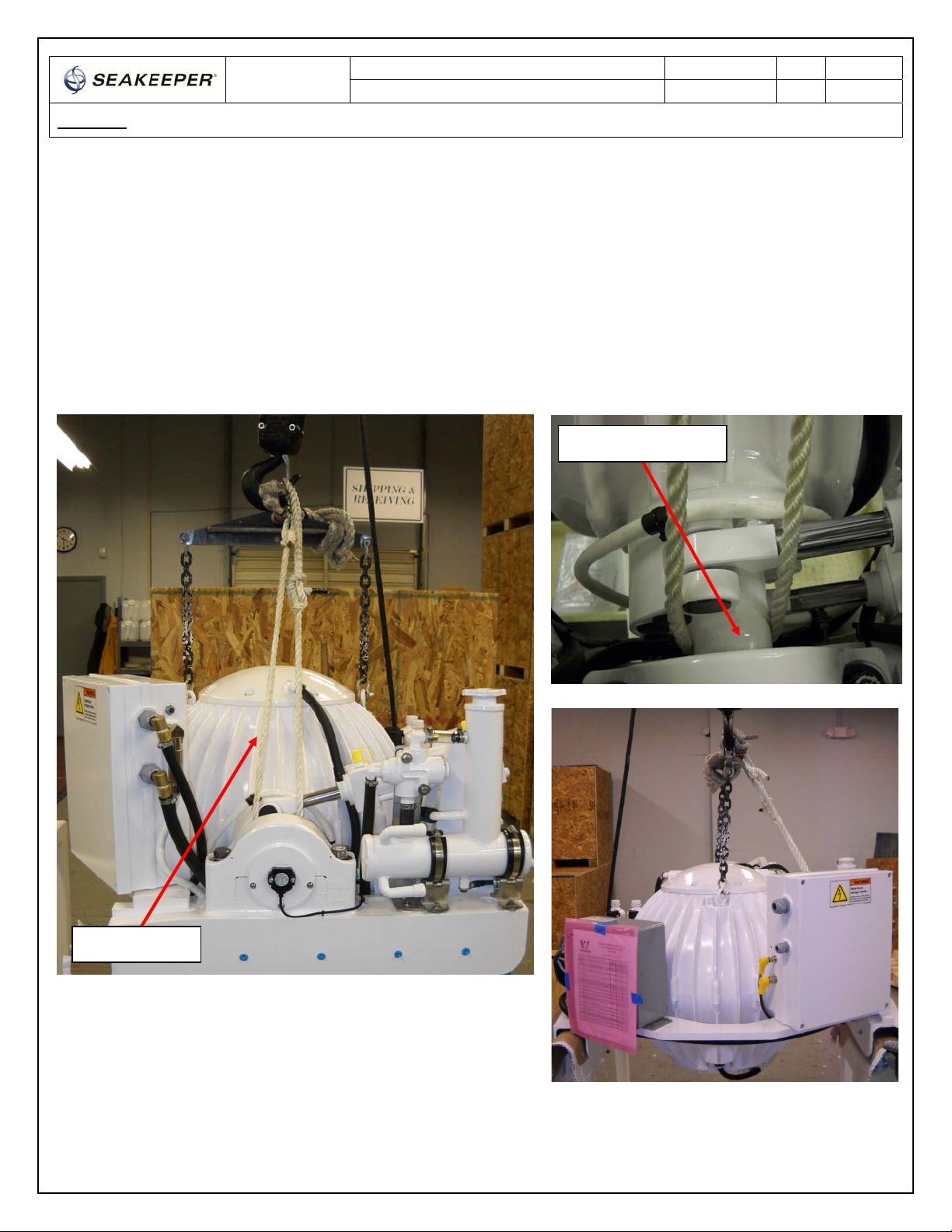

4) Attachspreaderbartothetwoliftingeyeslocatedonthetopofthegyroenclosure.Alsoattach

alevelinglinethatconnectsspreaderbartobrakegimbalshaft.Gyroweighs485kg(1069lbs).

SeeFigure4below.

FIGURE4–LIFTINGARRANGEMENT

LevelingLine

BrakeGimbalShaft

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO9021427of15

Section1:MECHANICALINSTALLATION

1.4PreparationofHullStructure

RefertoSeakeeperDrawingNo.90219,Model5500GyroInstallationDetails.Importantdimensional

andloadinformationisgiveninthisdrawingthatwillimpactthedesigndetailsofthestructurethatwill

receivethegyroaswellasselectionofadhesivetobondthegyrointothehull.Thefoundation

“saddles”ofthegyroaredesignedtobebondeddirectlytothecompositehullstructureofthevesselto

effectivelydistributegyroscopicloads.

Notethatanypaintorgel‐coatpresentinbondareashouldberemovedsothatadhesivewillbond

directlytolaminatefibersandresin.

Acompletebondisrequiredbetweentheinsidesurfaceofthesaddlesandthehullstructure.Toaidin

determiningthequantityofadhesiverequired,thesurfaceareaofPortsaddlebondareais340in2

(2194cm2).Thestarboardsaddlebondareais310in2(2002cm2).

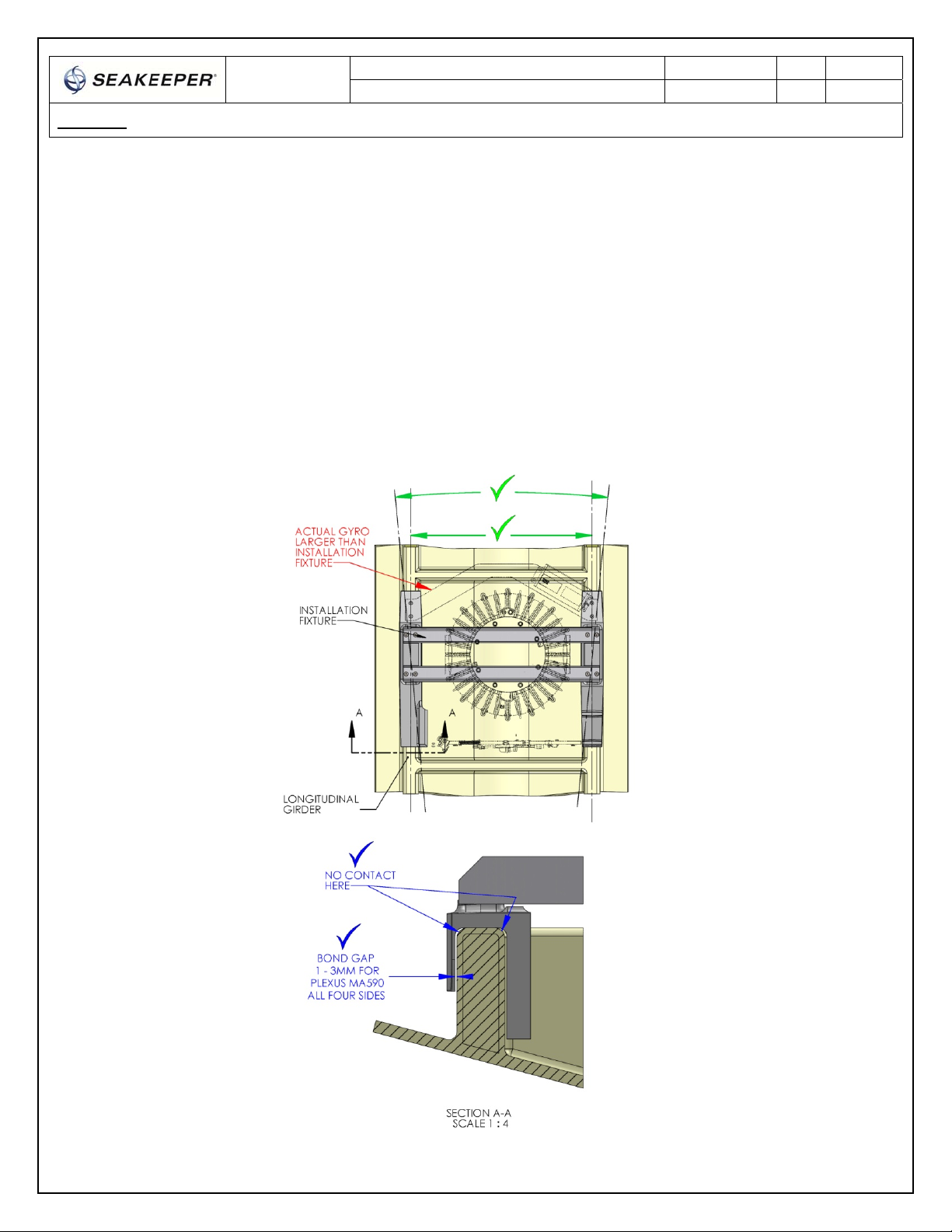

Seakeeperhasanoptionalinstallationfixtureavailable,P/N90012,thatisintendedtoduplicatethegyro

foundationgeometryinordertocheckclearancesandalignment.Thefixturewillallowthebuilder/

installertolay‐upandadjustthefoundationdimensionstocreatealow‐clearancefitbetweenthegyro

foundationsaddlesandthehullstructure.Shearstrengthoftheadhesivewillbemaximizedifthecured

thicknessbetweenthevesselstructureandgyrosaddlesisatthethinnerendoftheadhesive

manufacturersrecommendedrange.Therefore,thefixtureshouldbeusedtoconfirmthattheoverall

dimensionsofthefoundationsaresquareandlevelandthattheadhesivegapiswithintheadhesive

manufacturer’smaximumrecommendedthickness‐seeFigure5.

Thehullstructuresupportingthegyroshouldbeinstalledsothegyroisparalleltothewater‐planein

theport/starboardandforward/aftdirections.

Note:DoNOTusetheinstallationfixturetoestablishgyroenvelope

dimensions.RefertoDrawingNo.90219forenvelopedimensions.

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO9021428of15

Section1:MECHANICALINSTALLATION

FIGURE5–INSTALLATIONFIXTURE

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO9021429of15

Section1:MECHANICALINSTALLATION

1.4.1FiberglassHullPreparation

1) PositioninstallationjigonhullgirdersnotingrecommendedclearancesfromFigures2&3.

Checklongitudinalgirdersarealignedandspacedproperly.

Confirmfixtureislevelwhenvesselislevel.

Checkfitofsaddleovergirders.

Confirmbondgapnottoosmall,nottoolarge.

Notefixtureissmallerthanactualgyro.

FIGURE6–CHECKINGFOUNDATION

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO90214210of15

Section1:MECHANICALINSTALLATION

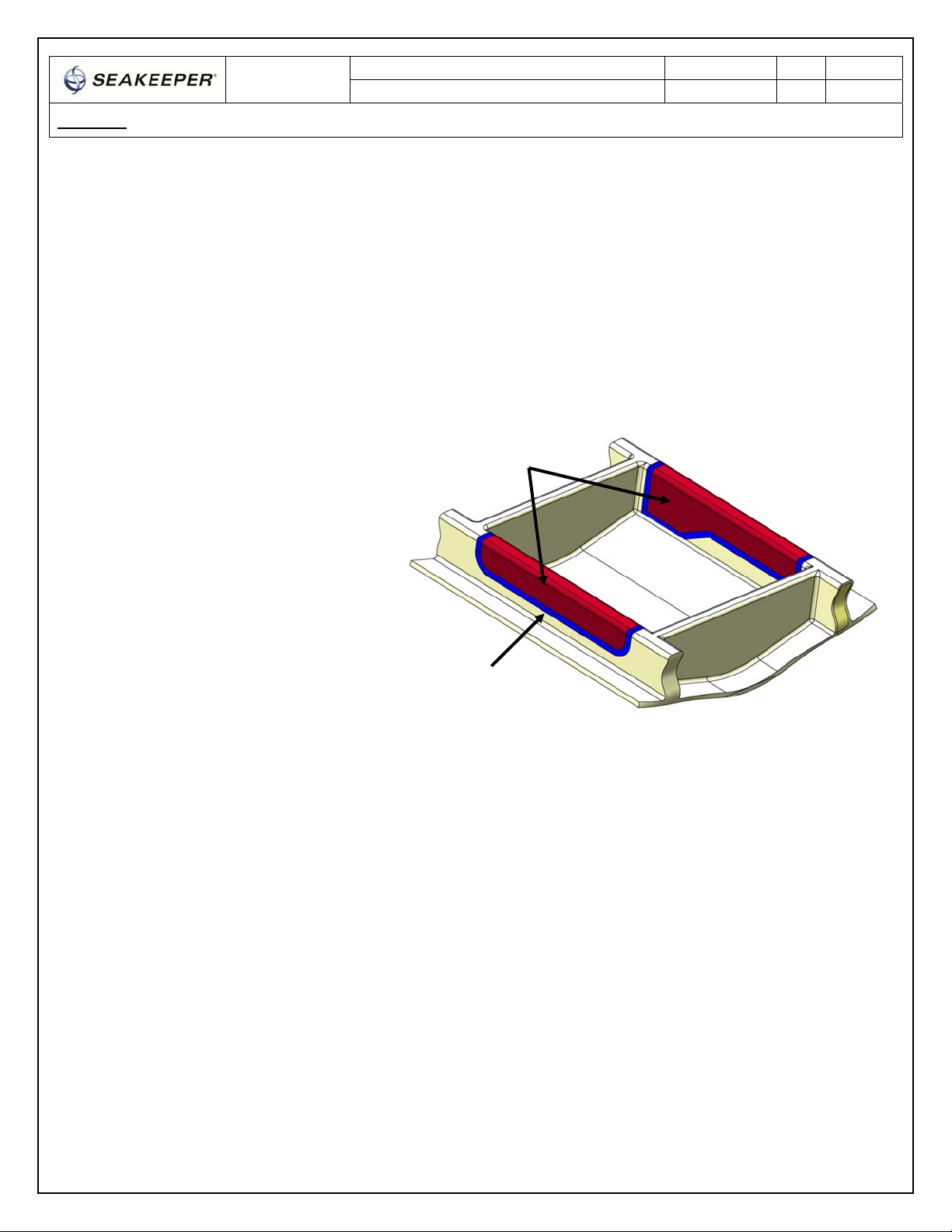

2) Maskhullareaaroundfoundationsaddlesforeasyclean‐upandtocreateoutline(highlightedin

blue)ofsurfaceareatoreceiveadhesiveasshowninred,Fig7.

3) Raisejigclearoffoundation.

4) Thoroughlycleanwithalcoholoracetoneallareas(highlightedinred,Fig7)ofgirderstobe

bondedtoremoveanycontaminates.Usenewpapertowelsforcleaning,notshoprags.

5) Removeallpaintandgel‐coatfrombondsurfacessothatadhesivewillbonddirectlytolaminate

fibersandresinasshowninFigure7.

6) Thoroughlysandgirderbond

surfaceswith80grit

sandpaper.(IMPORTANT–

BONDSTRENGTHMAYBE

REDUCEDIFTHISSTEPIS

SKIPPED.)

7) Wipesurfacescleanfromdust

withalcoholoracetoneusing

newpapertowels,notshop

rags.

8) Re‐positioninstallationjigon

girdersanddouble‐checkthat

theadhesivegapiswithinthe

adhesivemanufacturer’s

maximumrecommended

thickness.(Notegapwillbe

largerduetoabsenceofgel‐

coat.)

1.4.2Aluminum/SteelHullPreparation

1) Followsteps1‐4offiberglasshullpreparation.

2) Removealloxidationviasandingwith80gritsandpaper/grinding.(IMPORTANT–BOND

STRENGTHMAYBEREDUCEDIFTHISSTEPISSKIPPED.)

3) Wipesurfacescleanfromdustwithalcoholoracetoneusingnewpapertowels,notshoprags.

4) IfusingPlexusMA590adhesive,applyPlexusPC‐120surfaceconditionertothebonding

surfaces.Theseinstructionsarelocatedattheendofthissection.

5) ThegyroshouldbeinstalledwhenPC‐120isconfirmeddry.

Notewheninstallinggyroonaluminum/steelhull,thesandingandPC‐120(if

usingPlexusMA590adhesive)applicationforbothhullandgyrosaddles

shouldbedoneasclosetothesametimeaspossible.Thiswillminimize

oxidationonbondsurfacesandhelpimproveadhesivebondstrength.

Cleanallareasof

girderstobe

bonded–no

paint,nogel‐coat

Tapegirders

aroundfixtureto

makeclean‐up

easier FIGURE7‐MASKING&CLEANINGHULL

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO90214211of15

Section1:MECHANICALINSTALLATION

1.5CleanGyroSaddles

1) PositionGyronearfoundation.

2) Checkthatthescrewsthatattachforward

andaftbracesaretightasthesemaintain

foundationalignmentduringbonding

process.

3) Notethateachofthesaddleshastwo

stand‐offpads(SeeFigure8)locatedon

thetopundersidesurface.DoNOT

removethesepadsastheyaremeantto

maintainasmallgapatthetopofthe

saddletoinsurethatalladhesivedoesnot

getforcedawaybytheweightofthegyro.

4) Performdryfitofgyroassemblyoverhullstructure(noadhesive)toconfirmthatfitisgood.

5) Confirmadhesivegapiswithinadhesivemanufacturer’srequirements.

6) Raisegyroclearoffoundation.

7) Thegyrocontainsholesonthesidesofthe

saddlesforinjectingadhesiveasasecondary

meansofapplyingadhesive.Thegyroshipswith

plugsintheseholes,20places.Checkthatall

plugsareinplaceasshowninFigure9.Plugs

shouldremainintheholesuntilstep1.6.2is

completed.

FIGURE9–ADHESIVEINJECTIONHOLESPLUGGED

Stand‐OffPads

FIGURE8–STANDOFFPADS

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO90214212of15

Section1:MECHANICALINSTALLATION

8) Thoroughlycleanwithalcoholoracetonetheinsidesurfacesofgyrofoundationsaddles(see

Figure10)toremoveanycontaminates.Usenewpapertowelsforcleaning,notshoprags.

FIGURE10–FOUNDATIONPREPARATIONFORBONDING

9) Thoroughlysandallgyrobondsurfaceswith80gritsandpaper.(IMPORTANT–BOND

STRENGTHMAYBEREDUCEDIFTHISSTEPISSKIPPED.)

10) Wipesurfacescleanfromdustwithalcoholoracetoneusingnewpapertowels,notshoprags.

11) IfusingPlexusMA590adhesive,applyPlexusPC‐120surfaceconditionertoinsidesurfacesof

gyrofoundationsaddlesinaccordancewithmanufacturerinstructions.Theseinstructionsare

locatedattheendofthissection.

12) Tapeoffthecounter‐boresateachofthefourgimbalbearingbolts(4places)andholesfor

forwardbracemountingbolts(4places)tokeepadhesiveoutofscrewthreadsasshownin

Figure10.

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO90214213of15

Section1:MECHANICALINSTALLATION

1.6InstallGyro

1) IfusingPlexusMA590adhesive,thegyroshouldbeinstalledwhenPC‐120isconfirmeddry.

Applyadhesivetothehullstructure(SeeFigure11)inamannerthatallgapsbetweenthe

saddlesandthehullstructurewillbefilledwithadhesivewhenthegyroisloweredintoposition.

ExcessadhesivewillbeneededtoinsureaCOMPLETEBOND–someadhesivewillgetsqueezed

outandmustbecleanedoffanddiscarded.IfusingthePlexusMA590AdhesiveInstallationKit

fromSeakeeper,itisrecommendedtoapply2fullcartridgestothetopofeachhullstringer.

Workdeliberateandfastasittakessometimetoapplytheadhesivetothestructure.MA590

hasa90minuteworkingtimeatroomtemperature(23°C/73°F).Thisworkingtimecanreduce

to40‐50minutesatelevatedtemperatures.

2) Oncetheadhesivehasbeenapplied,lowergyroontohullstructure.

3) Visuallyinspecttheentireperimeterofeachsaddletoconfirmthatadhesivehasfilledallthe

gapsonthesaddlesides.Ifadhesivehas

beenappliedcorrectly,itwillsqueeze

outaroundthesidesofthesaddlesas

showninFigure12.Ifadhesivehasfilled

allthegaps,gotostep6.Ifusingthe

PlexusMA590adhesivefromSeakeeper

andtheadhesivedoesnotappearin

certainareas,injectusingtheprovided

nozzleasshowninFigure13.(Note

adhesiveshowninpictureisfor

illustrativepurposesonly.MA590colorwillbegray.)

Applylargebeadontopofgirders

FIGURE11–APPLYINGADHESIVETOHULL

FIGURE12–ADHESIVESQUEEZEOUT

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO90214214of15

Section1:MECHANICALINSTALLATION

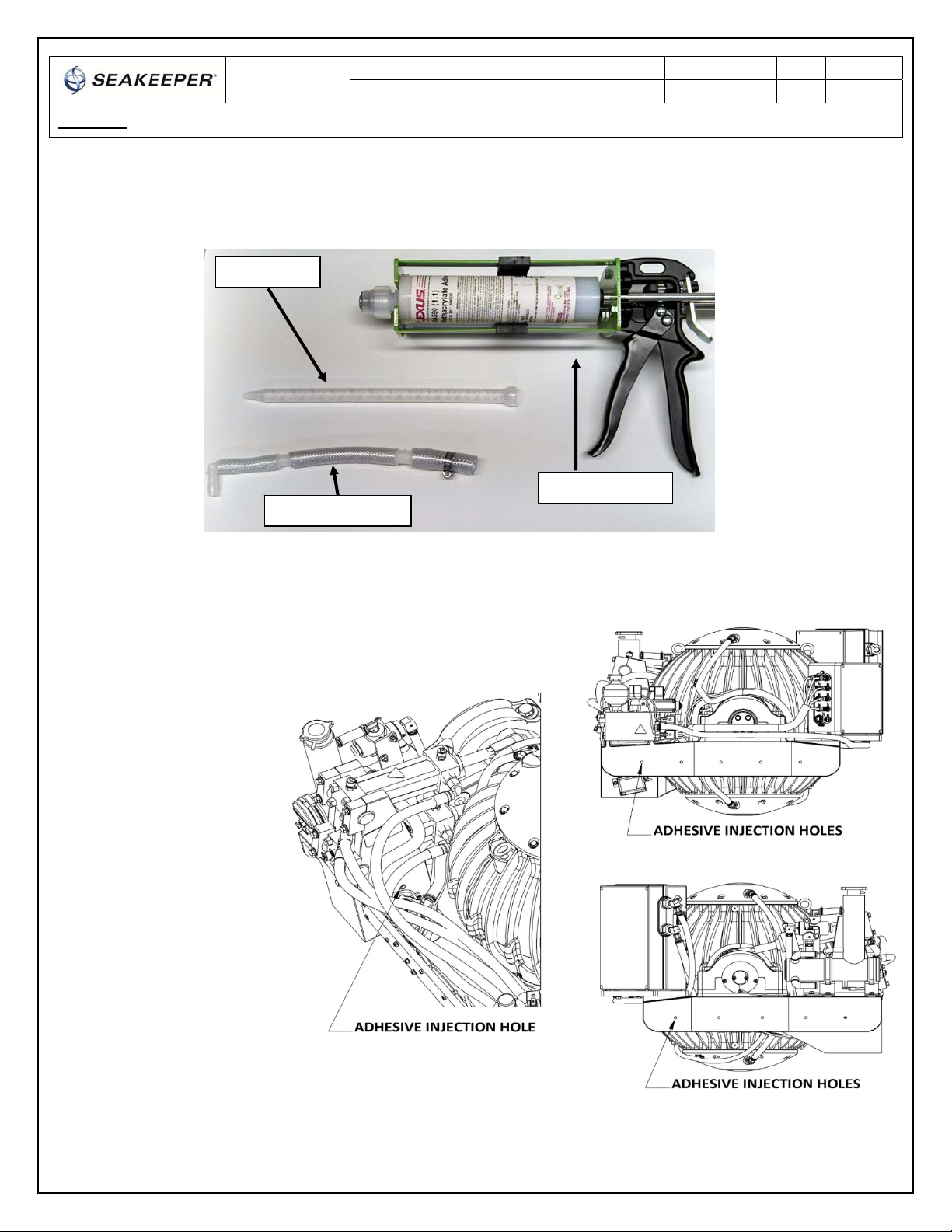

4) Attachinjectionnozzlewithclamptomixingtip.

Thereareatotalof20

adhesiveinjection

holes,with5holeson

boththeinboardand

outboardsidesof

eachsaddleasshown

inFigure14.

FIGURE14–ADHESIVEINJECTIONHOLES

FIGURE13– ADHESIVEINSTALLATIONSUPPLIES

AdhesiveGun

In

j

ectionNozzle

Mixin

g

Ti

p

INSTALLATION

MANUAL

Product:Document#:Rev:Page:

MODEL5500GYRO90214215of15

Section1:MECHANICALINSTALLATION

5) Ifneeded,insertthetipofthe

injectionnozzleintotheappropriate

holeinthesideofthesaddleas

showninFigure15.Pumpin

adhesiveuntilitfillstheobserved

gaporareathatlacksadhesiveinthe

gapbetweenthesaddlesideandthe

hullstructure.Theinjectionprocess

isonlyusedtorecoverfrom

inadequateorun‐evenadhesive

application.Thismethodshouldnot

beusedastheprimarymeansof

applyingadhesive.

6) Discardplugsandcleanupanyexcessadhesive.Allowadhesivetocurepermanufacturer’s

recommendations.DoNOToperategyrobeforeadhesivehasfullycured.

7) Afteradhesiveiscured,itisrecommendedtosealtheedgesofsaddlewithsealantorpaintto

minimizecorrosionintrusionintobondjoint.

8) Bondingofgyrointohullisnowcomplete.Proceedtoinstallationofelectricalcomponentsand

coolingplumbing.

1.7Doc#90213PlexusPC‐120ApplicationInstructions

Removeplugandinserttipof

injectionnozzleintohole

FIGURE15 –INJECTINGADHESIVE

THIS PAGE INTENTIONALLY LEFT BLANK

Table of contents

Other Seakeeper Boating Equipment manuals

Seakeeper

Seakeeper 26 User manual

Seakeeper

Seakeeper 30HD User manual

Seakeeper

Seakeeper 3 User manual

Seakeeper

Seakeeper 16 GYRO User manual

Seakeeper

Seakeeper 7000 GYRO User manual

Seakeeper

Seakeeper 7000 GYRO Service manual

Seakeeper

Seakeeper 8000 GYRO User manual

Seakeeper

Seakeeper 26000 GYRO User manual

Seakeeper

Seakeeper 1 User manual

Seakeeper

Seakeeper 3 User manual

Popular Boating Equipment manuals by other brands

Humphree

Humphree HCS-5 installation manual

Vetus

Vetus BOW4512D Operation manual and installation instructions

Dock Doctors

Dock Doctors SLIDING BOARDING STEP Assembly instructions

Mastervolt

Mastervolt Mass Combi 12/2000-100 Quick installation

SeaView

SeaView PM5-FMD-8 installation instructions

Hobie

Hobie Mirage 360 manual