9 Beforeattemptingtomovethedehumidier,emptythecontentsofthecollectiontank.

9Use top carrying handle when moving unit.

9 Switchoanddisconnectitfromthemainsbeforeattemptinganycleaningorothermaintenancework.

9 Ensurethatthedehumidieriscorrectlyturnedowhennotinuse,andstoredinasafe,dryarea,outofreachofchildren.

NOTE: This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities or lack

of experience and knowledge, unless they have been given supervision or instruction concerning the use of the appliance by a person

responsible for their safety. Children should be supervised to ensure that they do not play with the appliance.

1.3. SAFETY PRECAUTIONS ON SERVICING

WARNING:Anypersonwhoisinvolvedwithworkingonorbreakingintoarefrigerantcircuitshouldholdacurrentvalidcerticatefrom

an industry-accredited assessment authority, which authorizes their competence to handle refrigerants safely in accordance with an

industry,recognizedassessmentspecication.

WARNING: Servicing shall only be performed as recommended by the equipment manufacturer. Maintenance and repair requiring

theassistanceofotherskilledpersonnelshallbecarriedoutunderthesupervisionofthepersoncompetentintheuseofammable

refrigerants.

WARNING: If you don’t understand something or need help, please contact Sealey.

1.3.1. Checks to the area

1.3.1.1. Priortobeginningworkonsystemscontainingammablerefrigerants,safetychecksarenecessarytoensurethattheriskofignitionis

minimized. For repair to the refrigerating system, the following precautions shall be complied with prior to conducting work on

the system.

1.3.2. Work procedure

1.3.2.1. Workshallbeundertakenunderacontrolledproceduresoastominimizetheriskofaammablegasorvapourbeingpresentwhile

the work is being performed.

1.3.3. General work area

Allmaintenancestaandothersworkinginthelocalareashallbeinstructedonthenatureofworkbeingcarriedout.Workinconned

spacesshallbeavoided.Theareaaroundtheworkspaceshallbesectionedo.Ensurethattheconditionswithintheareahavebeen

madesafebycontrolofammablematerial.

1.3.4. Checking for presence of refrigerant

1.3.4.1. The area shall be checked with an appropriate refrigerant detector prior to and during work, to ensure the technician is aware of

potentiallyammableatmospheres.Ensurethattheleakdetectionequipmentbeingusedissuitableforusewithammable

refrigerants, i.e. no sparking, adequately sealed or intrinsically safe.

1.3.5. Presence of re extinguisher

1.3.5.1. Ifanyhotworkistobeconductedontherefrigerationequipmentoranyassociatedparts,appropriatereextinguishingequipment

shallbeavailabletohand.HaveadrypowderorCO2reextinguisheradjacenttothechargingarea.

1.3.6. No ignition sources

1.3.6.1. No person carrying out work in relation to a refrigeration system which involves exposing any pipe work that contains or has

containedammablerefrigerantshalluseanysourcesofignitioninsuchamannerthatitmayleadtotheriskofreor

explosion.Allpossibleignitionsources,includingcigarettesmoking,shouldbekeptsucientlyfarawayfromthesiteof

installation,repairing,removinganddisposal,duringwhichammablerefrigerantcanpossiblybereleasedtothesurrounding

space.Priortoworktakingplace,theareaaroundtheequipmentistobesurveyedtomakesurethattherearenoammable

hazardsorignitionrisks.“NoSmoking”signsshallbedisplayed.

1.3.7. Ventilated area

1.3.7.1. Ensure that the area is in the open or that it is adequately ventilated before breaking into the system or conducting any hot

work. A degree of ventilation shall continue during the period that the work is carried out. The ventilation should safely

disperse any released refrigerant and preferably expel it externally into the atmosphere.

1.3.8. Checks to the refrigeration equipment

1.3.8.1. Whereelectricalcomponentsarebeingchanged,theyshallbetforthepurposeandtothecorrectspecication.Atalltimesthe

manufacturer’s maintenance and service guidelines shall be followed. If in doubt consult the manufacturer’s technical department

for assistance.

1.3.8.2. Thefollowingchecksshallbeappliedtoinstallationsusingammablerefrigerants:

9The charge size is in accordance with the room size within which the refrigerant containing parts are installed.

9The ventilation machinery and outlets are operating adequately and are not obstructed.

9If an indirect refrigerating circuit is being used, the secondary circuit shall be checked for the presence of refrigerant.

9Marking to the equipment continues to be visible and legible. Markings and signs that are illegible shall be corrected.

9Refrigeration pipe or components are installed in a position where they are unlikely to be exposed to any substance which may

corrode refrigerant containing components, unless the components are constructed of materials which are inherently resistant to being

corroded or are suitably protected against being so corroded.

1.3.9. Checks to electrical devices

1.3.9.1. Repair and maintenance to electrical components shall include initial safety checks and component inspection procedures. If a fault

exists that could compromise safety, then no electrical supply shall be connected to the circuit until it is satisfactorily dealt with. If the

fault cannot be corrected immediately but it is necessary to continue operation, an adequate temporary solution shall be used. This

shall be reported to the owner of the equipment so all parties are advised.

1.3.9.2. Initial safety checks shall include:

9those capacitors are discharged: this shall be done in a safe manner to avoid possibility of sparking.

9that there no live electrical components and wiring are exposed while charging, recovering or purging the system.

9that there is continuity of earth bonding.

2. i INTRODUCTION

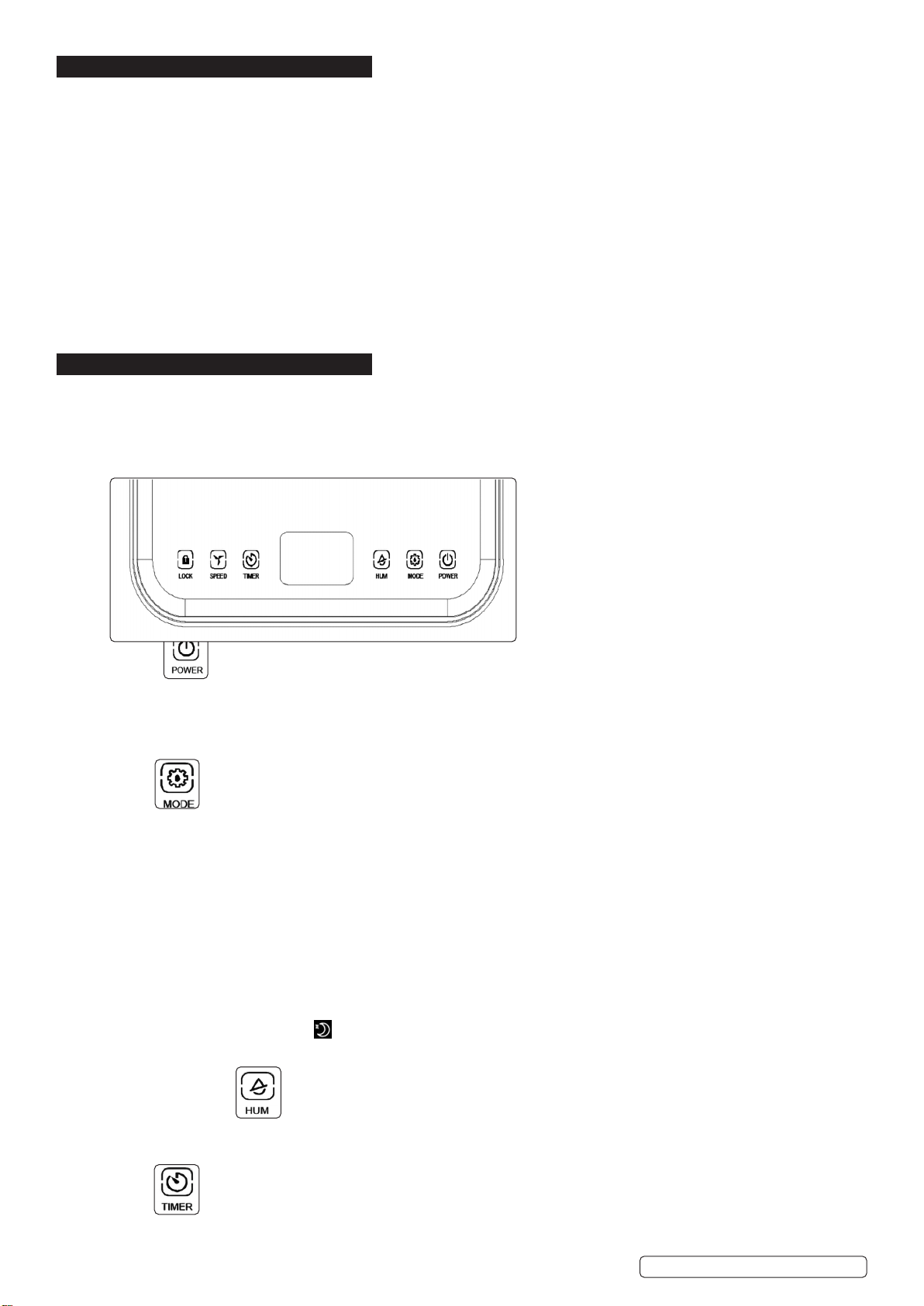

Compact, efficient, low noise portable unit that extracts up to 10L of water per day. Removes excess moisture from air to prevent build-up of mildew

and mould. Features adjustable 24 hour timer, water-full indicator and auto defrosting. Digital control panel, LED display and 3-colour indicator to

show different RH% levels. Refrigerant is environmentally friendly R290. Supplied with 3A3-pin plug and drain hose for continuous operation.

Original Language Version

© Jack Sealey Limited SDH102.V2 Issue 1 21/07/22