4. OPERATING TIPS

5. PROTECTIVE FEATURES

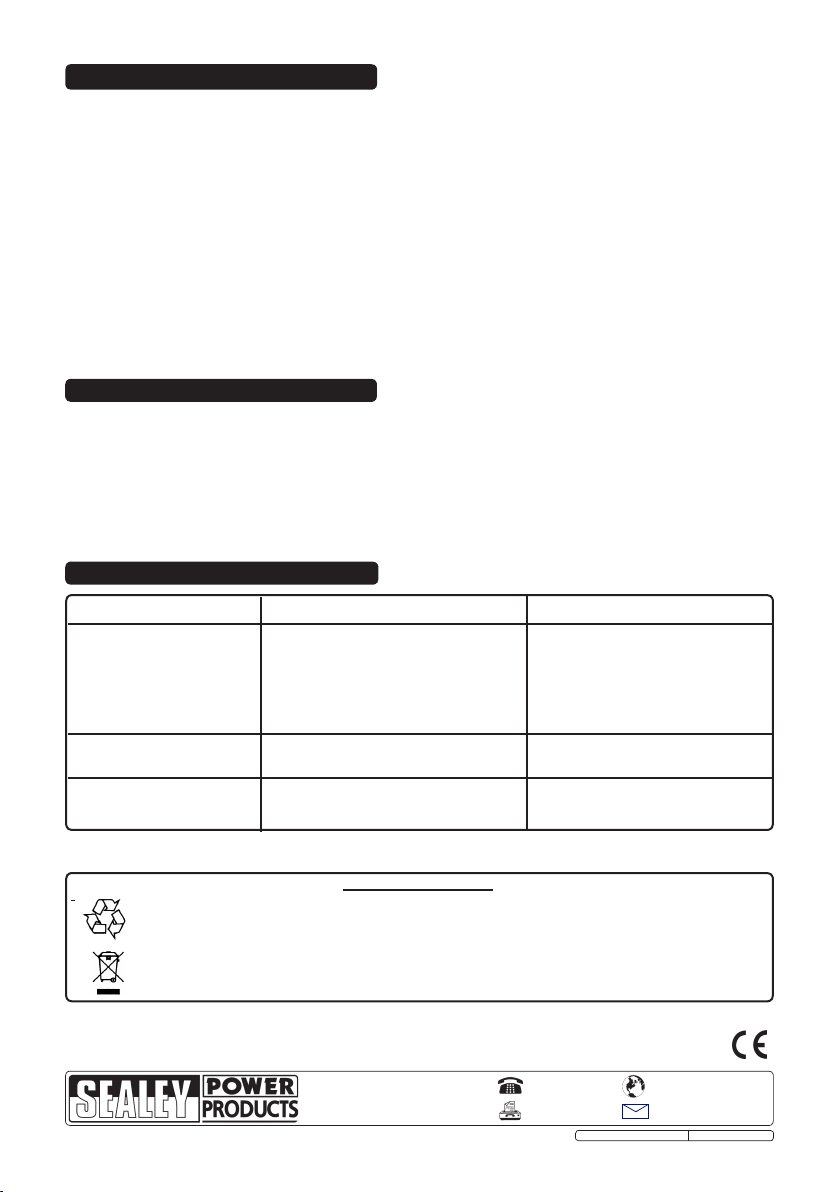

6. TROUBLE SHOOTING

5.1 The inverter monitors the following potentially hazardous conditions:

5.1.1 Low Battery Voltage - This condition is not harmful to the inverter but could damage the power source. An alarm will sound

when input voltage drops to 10.6 volts. The inverter automatically shuts down when input voltage drops to 10 volts.

When the condition is corrected, the unit may be restarted.

5.1.2 Over Voltage Protection -When input voltage exceeds 15.5 volts, the inverter automatically shuts down. When the

condition is corrected, the unit may be restarted.

5.1.3 Overload Protection - The inverter will automatically shut down when the continuous draw exceeds the wattage rating of

the inverter.

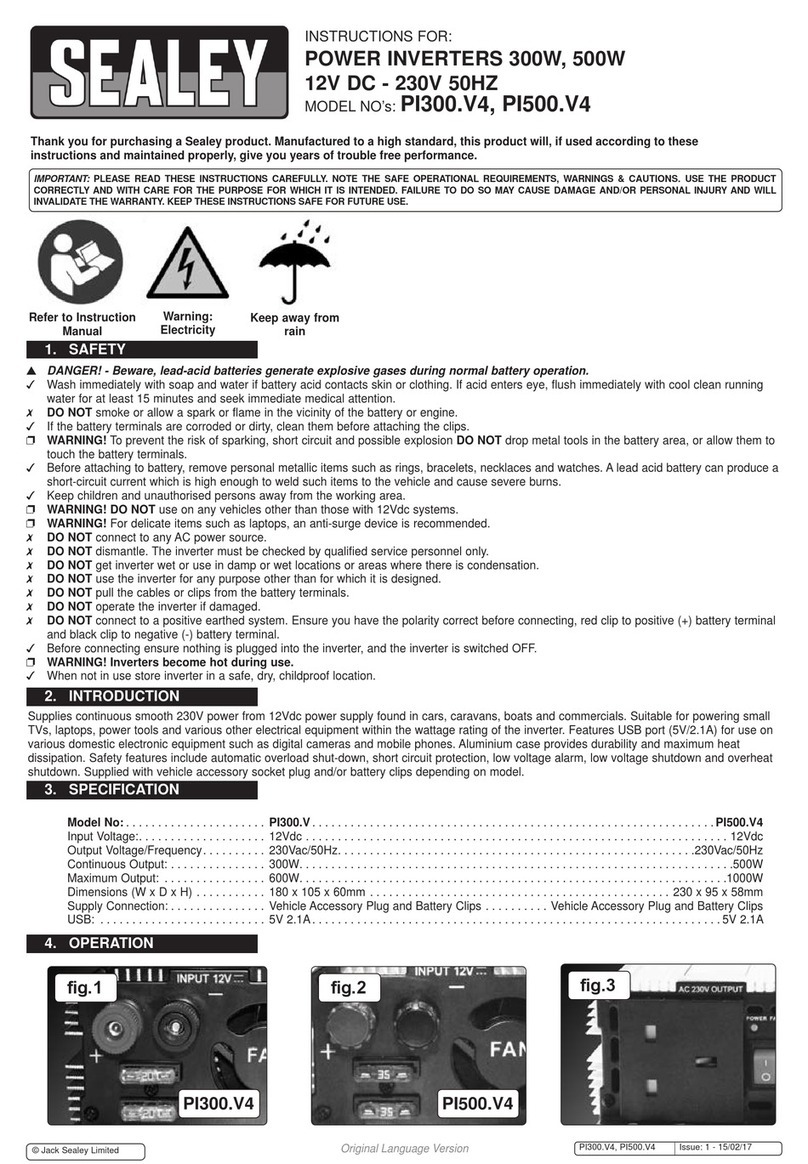

Problem Possible Cause Suggested Remedy

Lack of power output. 1. Poor DC contact. 1. Check all DC contacts.

No AC output, Red LED lit. 2. Battery voltage below 10V. 2. Recharge or replace battery.

or No AC output both Red 3. Load draws too much power. 3. Reduce load.

and Green LED lit. 4. Inverter in thermal shutdown. 4. Allow inverter to cool.

5. Vehicle lighter open circuit. 5. Check vehical fuse.

6. Vehicle requires ignition to be on. 6. Turn ignition key to accessory position.

Low output voltage. Check with voltmeter. Use true RMS voltmeter.

Low battery alarm sounds 1. Bad connection or wiring. 1. Check and tighten all DC connections.

continuously. 2. Low battery voltage. 2. Recharge battery without load.

Environmental Protection.

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be

sorted, taken to a recycle centre and disposed of in a manner which is compatible with the environment.

When the product is no longer required, it must be disposed of in an environmentally protective way.

4.1 Inductive loads, such as TV’s and stereos, require more current to operate than do resistive loads of the same wattage

rating. Induction motors, as well as some televisions, may require 2 to 6 times their wattage rating to start up. The most

demanding in this category are those that start under load, such as compressors and pumps. Testing is the only

definitive way to determine whether a specific load can be started and how long it can run. The unit will simply shut

down if it is overloaded. To restart the unit after a shutdown due to overloading, remove the overload.

CAUTION: The inverter will not operate high wattage appliances or equipment that produce heat, such as hair dryers, microwave

ovens and toasters.

4.2 Battery Operating Time

4.2.1 With a typical vehicle battery, a minimum operating time of 3 to 4 hours can be expected depending on the load draw. It

is recommended that operator start the engine every 2 to 3 hours to recharge the battery. This will prevent any

unexpected shutdown of the equipment and will ensure that there is always sufficient battery capacity to start the

vehicle. The inverter may be used either with the engine running or turned off. However, the inverter must be switched

OFF when starting the car.

4.2.2 The inverter draws less than 0.3 amperes from battery when it is not supplying power to a load. In most cases, the inverter

may be left connected to the battery when it is not in use, If the vehicle will not be used for several days, please

disconnect the unit from the battery.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

email

Original Language Version PI150, PI300.V2, PI1500.V2 Issue: 2 - 12/10/09