5. OPERATION

WARNING! Ensure that you read, understand and apply the safety and operational instructions before connecting the meter. Only

when you are sure that you understand the procedures is it safe to proceed with testing.

WARNING! Risk of electrocution. High voltage circuits, both ac and dc are very dangerous and should be measured with great care.

Operating temperature range 0°C to 40°C.

Remember to turn on meter before use and to turn it off when measurement is completed.

NOTE: IF “OL” appears in the display during a measurement, the value exceeds the range you have selected. Change to a higher range.

NOTE: On some low ac and dc ranges, with the test probes not connected to a device, the reading may show a random fluctuating reading.

This is normal and is caused by the high input sensitivity. The reading will stabilise and give a proper measurement when connected to a circuit.

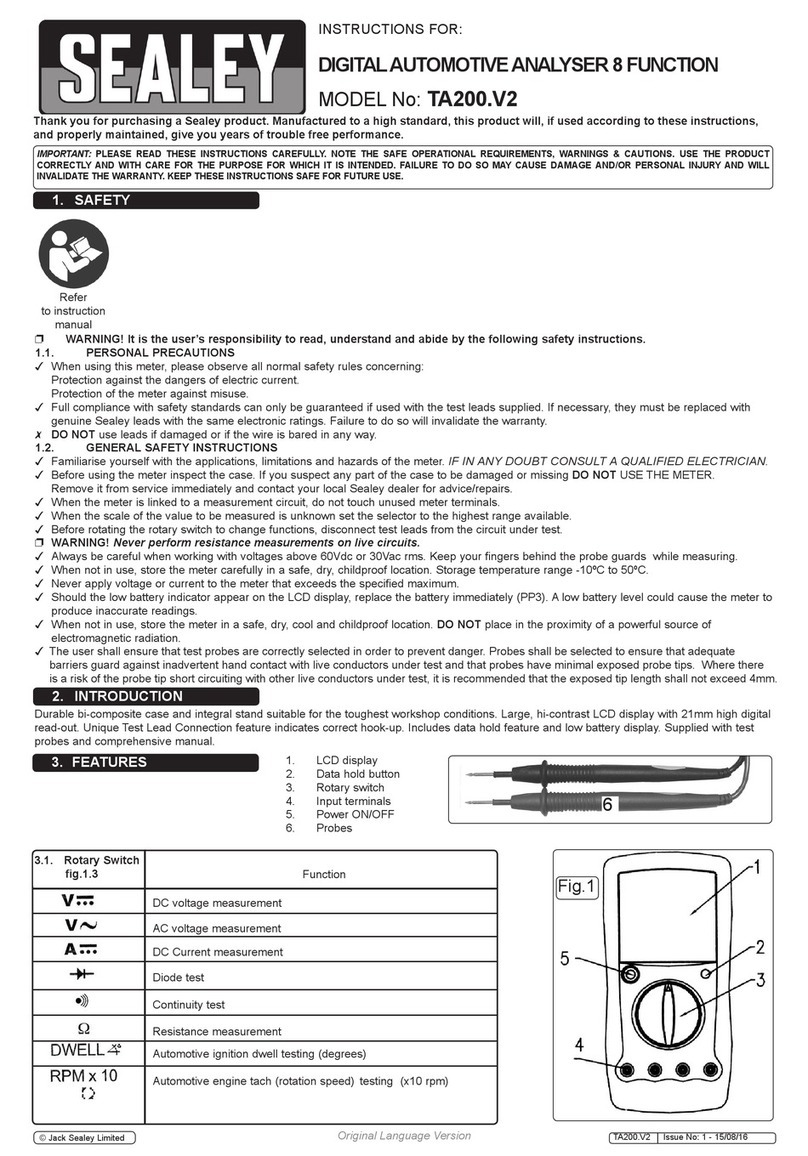

5.1. ALTERNATE FUNCTION BUTTON (FIG.1.2)

5.1.1. Press the Alternate Function button to toggle between ac and dc in the voltage & current measurements. Press the Alternate

Function button to toggle between Continuity and Diode Test.

5.2. DWELL BUTTON (FIG.1.3)

5.2.1. To manually scroll through to the correct number of cylinders press the Dwell button.

5.3. DATA HOLD, (FIG.1.10)

5.3.1. The data hold function allows the meter to freeze a measurement reading for later reference.

5.3.2. Press the data hold button once to freeze the reading in the display. The indicator “hold” will appear in

the display.

5.3.3. Press the data hold button again to return to normal operation.

5.4. RANGE BUTTON (FIG.1.8)

5.4.1. The range is automatically selected by the meter.

5.4.2. To manually select a range within a function, press the range button.

5.4.3. To exit the range mode and return to autoranging, press and hold the range button for two seconds.

NOTE: If the range is too high, the meter will be less accurate.

If the range is too low, the meter displays ‘OL’ (Over Limit).

5.5. RPM MODE BUTTON (FIG.1.4)

5.5.1. Press rpm mode button to toggle between 4 stroke and 2 stroke / DIS (Distributerless Ignition

System).

5.5.2. Press and hold for two seconds to toggle between Negative (-) and Positive (+) Trigger slope.

5.5.3. Press the button repeatedly to adjust the trigger level if the meter reading is to high or unstable.

NOTE: The Trigger level has five steps and is different for each function combination.

5.6. BACKLIGHT BUTTON (FIG.1.9)

5.6.1. To turn the backlight on press the backlight button, to turn off press the backlight button again.

5.7. AC OR DC VOLTAGE MEASUREMENTS

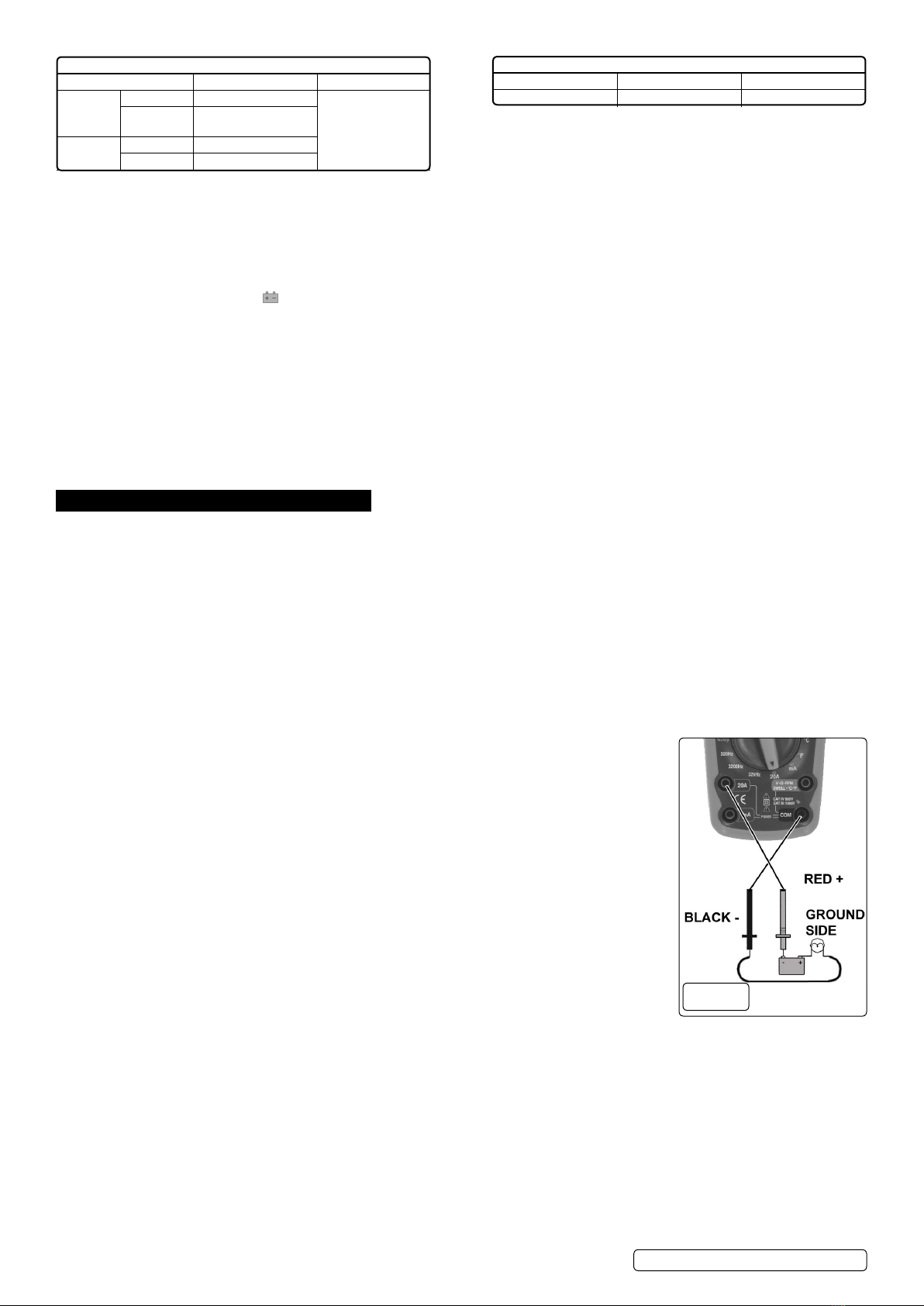

5.7.1. Insert the black test probe into the negative “COM” terminal and the red test probe into the positive main positive terminal (fig.1.10)

terminal.

5.7.2. Turn the rotary switch to the ‘V’ position.

5.7.3. Press the Alternate Function button to select ac or dc voltage.

5.7.4. Touch the test probes to the circuit under test and read the voltage display.

g.2

Audible Continuity

Audible Threshold Resolution Test Current

<35Ω100mΩ<0.7mA

Input Protection: 250Vdc or Vac rms

RPM (Tach)

Range Resolution Accuracy

rpm 4

600-3200 1rpm

± 2.0% of rdg +4

dgt

6000~12000 10rpm

rpm 2/DIS 300~3200 1rpm

3000~6000 10rpm

Eective Reading: >600rpm

Overload Protection: 500Vdc or RMS ac

Display:..................3.5 digit (3200 counts) LCD display with function and unit sign annunciator.

Analogue Bar Graph:.......34 segments with measurements 12 times per second.

Polarity:..................Automatic, (-) negative polarity indication.

Over Range Indication:.....“OL” mark indication.

Low Battery Indication:.....The is displayed when the battery voltage drops below the operating level.

Measurement Rate:........2 times per second, nominal.

Operating Environment:....0°C to 50°C (32°F to 122°F) at <70% relative humidity.

Storage Environment:......-20°C to 60°C (-4°F to 140°F) at <80% relative humidity.

Temperature Coefficient:....0.2 x (specified accuracy) / °C (<18°C or >28°C).

Power:...................Single standard 9 Volt battery (PP3).

Battery Life:...............200 hours typical with alkaline battery.

Fuse:....................20A/250V, 5.5 x 32mm fast acting ceramic type.

....................0.5A/250V, 5 x 20mm fast acting ceramic type.

Dimensions:..............167 (H) x 79 (W) x 50 (D) mm.

Weight Approx:............366g.

Accuracy is given at 18°C to 28°C (65°F to 83°F) less than 70% relative humidity.

TA302 Issue 3 (HF) 02/10/18

Original Language Version

© Jack Sealey Limited