WARNING! Disconnect the nibbler from the air supply before changing the punch and die, servicing or

performing maintenance. Replace or repair damaged parts.

Use genuine parts only. Non-authorised parts may be dangerous and will invalidate the warranty.

5.1. Lubricate the air nibbler daily with a few drops of the air tool oil supplied, dripped into the air inlet

before use. (To re-order air tool oil use Sealey part Nos. ATO/500 or ATO1000.)

5.2. Loss of power or erratic action may be due to the following:

a) Excessive drain on the air line. Moisture or restriction in

the air pipe. Incorrect size or type of hose connectors. To

remedy check the air supply and follow instructions in

chapter 3.

b) Grit or gum deposits in the nibbler may also reduce

performance. If your model has an air strainer (located in

the area of the air inlet), remove the strainer and clean

it. Flush the nibbler out with gum solvent oil or an equal

mixture of SAE No 10 oil and kerosene. Allow to dry

before use. If you continue to experience problems,

contact your local Sealey service agent.

5.3. For a full service contact your local Sealey service agent.

5.4. When not in use, disconnect from air supply, clean nibbler

and store in a safe, dry, childproof location.

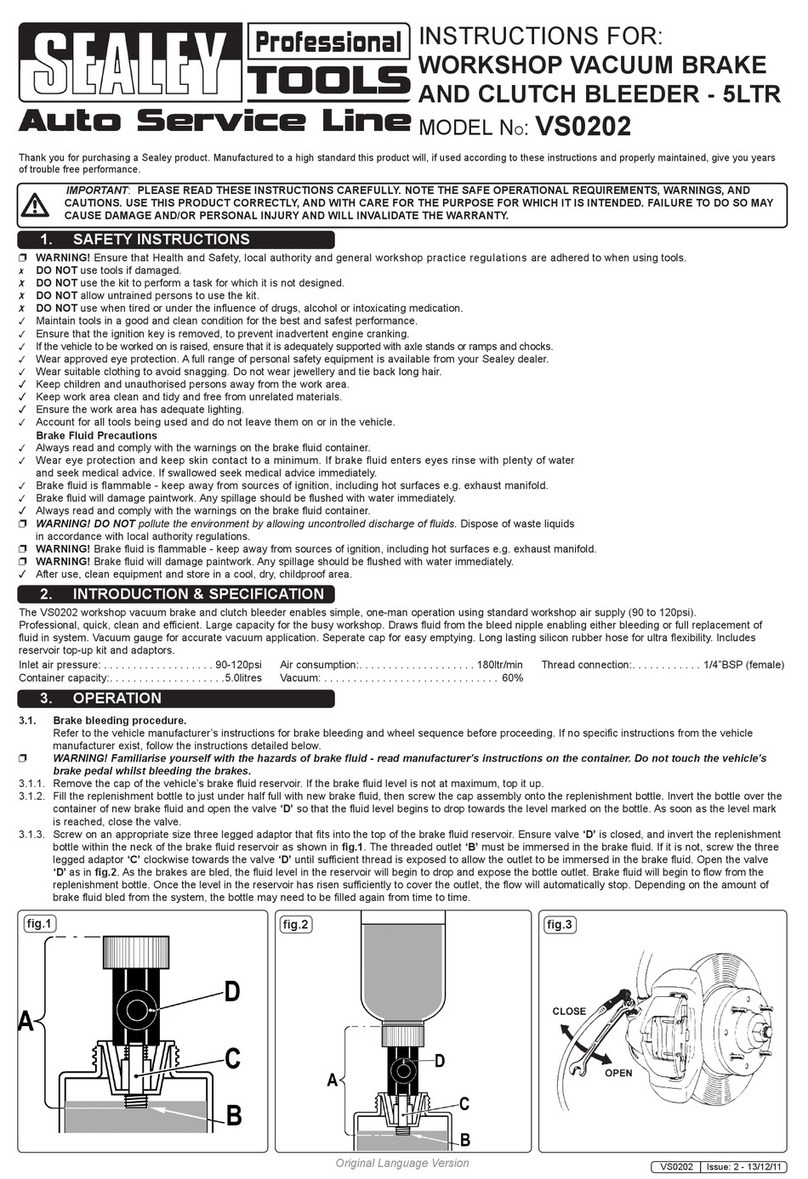

5.5 Changing the punch and die. (see fig.3)

5.5.1 Loosen the locknut (see fig.3-2) and unscrew the die (with the locknut on it) from the main body of the

nibbler. Place a 9mm spanner onto the hex section of the die collar as shown in fig.3 and undo and

remove the die collar and punch.

5.5.3 Remove the old punch from the collar and insert the new one. Screw the collar and punch back into

place and tighten with the spanner.

5.5.4 Slide the die and locknut over the punch and screw it back into the main body of the nibbler until the

bottom of the punch is flush with the bottom of the die. Rotate the die into the position required by the

workpiece. Hold the die steady with a 15mm spanner on its flats and retighten the locknut (see fig.3-2).

4. OPERATING INSTRUCTIONS

5. MAINTENANCE

WARNING! Ensure you read, understand and apply safety instructions before use.

4.1 The nibbler should be set up for use before connecting to the air line.

4.2 In order to improve access to the workpiece, the die can be rotated through 360º. To do this, loosen

the locknut with a 22mm spanner (see fig.3-2). Rotate the die (see fig.3-1) on the punch until it is in the

right position for the job in hand. Hold the die steady with a 15mm spanner on its flats and retighten the

locknut (see fig.3-2).

4.3 Ensure that your workpiece is properly secured and marked out.

4.4 Connect the nibbler to the airline.

4.5 Start the nibbler by squeezing the throttle lever.

4.6 Introduce the sheet metal into the slot in the end of the die. Apply light pressure only to move the tool

in the desired direction through the material.

4.7 Do not allow the nibbler to run freely for any length of time as this will damage the bearings.

SA28 .V2 Issue No.1 20/05/11

Original Language Version

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

email

fig.3