PAINT SPRAY RESPIRATOR DELUXE MODEL

AND FILTER KIT FOR SSP1605

MODEL NO: SSP1605, SSP1605FP

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Ensure all Health and Safety, local authority, and general workshop practice regulations are strictly adhered to when

using this product.

IMPORTANT! NOT FOR USE WITH TOXIC PAINTS SUCH AS ISOCYANATE.

WARNING! DO NOT use in an oxygen decient atmosphere (below 19% by volume).

WARNING! DO NOT use in an oxygen enriched atmosphere (above 25% by volume).

9 Respirator selection must be undertaken by a competent person who is aware of the intended conditions of use. Only t the

respirator under the supervision of a competent person.

9 If in doubt as to suitability of the equipment for the work to be undertaken, consult your supplier.

9 Before use, check that the mask is clean and in good condition. If you detect deterioration of valve diaphragms, or other rubber

components, replace immediately.

9 Check that the correct cartridge is tted to suit the hazard and that all components are correctly assembled and in a clean condition.

9 Change the main lter cartridge frequently. The eective life of a main lter should be determined by a competent person who is

aware of the conditions of use.

9 Ensure you use recommended parts only, unauthorised parts may be dangerous and will invalidate any warranty.

9 Only when worn correctly tted will the mask provide the prescribed degree of protection.

9 Ensure the face-piece ts comfortably on the face.

WARNING! Mask may not t correctly if facial hair passes under the face-seal.

9 Upon leaving the contaminated area, remove excess contamination from clothes before removing the respirator.

9 After each working period, the respirator must be cleaned and prepared for the next period of use.

9 Ensure you use only recommended lters.

8DO NOT use detergents, thinners, solvents or petroleum-based disinfectant to clean the respirator. Clean the unit with warm soapy

water only.

8DO NOT allow water to get into the main lter.

9 Care must be taken to ensure the rubber seal on the inside of the lter holder is not damaged.

9 Ensure you keep records of respirator maintenance.

9 When not in use, store the cleaned respirator in a sealed plastic bag in a clean, dry atmosphere out of direct sunlight and out of the

reach of children.

2. INTRODUCTION

Twin cartridge half mask with low resistance exhalation valve for easy breathing. Fully adjustable four-point suspension harness with quick

release. Comfortable and durable thermoplastic rubber face mask oering a superior t to most face shapes and conforms to EN140.

Reective strips for increased visibility in low light areas. Fitted with twin lters that conrm the correct tting of the mask and conform to

EN14387:2004+A1:2008. Ideal for a variety of painting, welding, construction and wood cutting tasks. Filter Kit - Set of A2P3 cartridges for

SSP1605.

3. SPECIFICATION

Model No (lters):................................................SSP1605FP

Nett Weight: ..............................................................0.235Kg

4. OPERATION

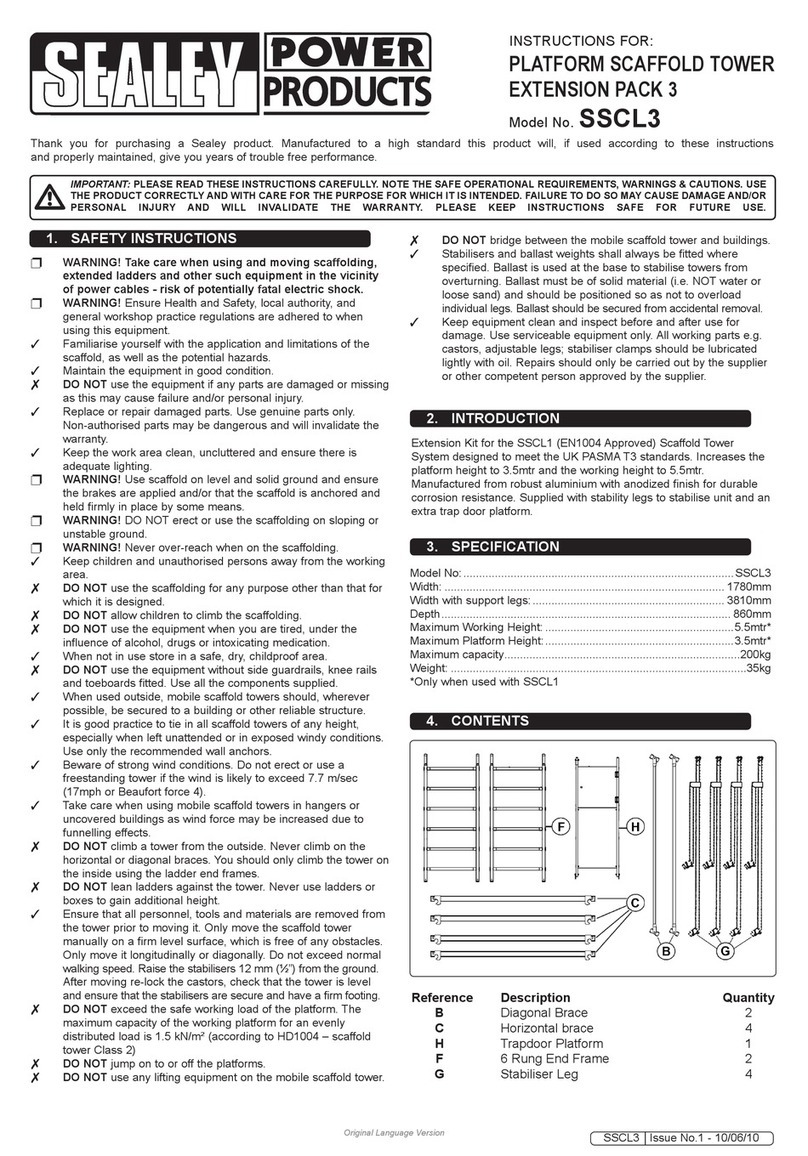

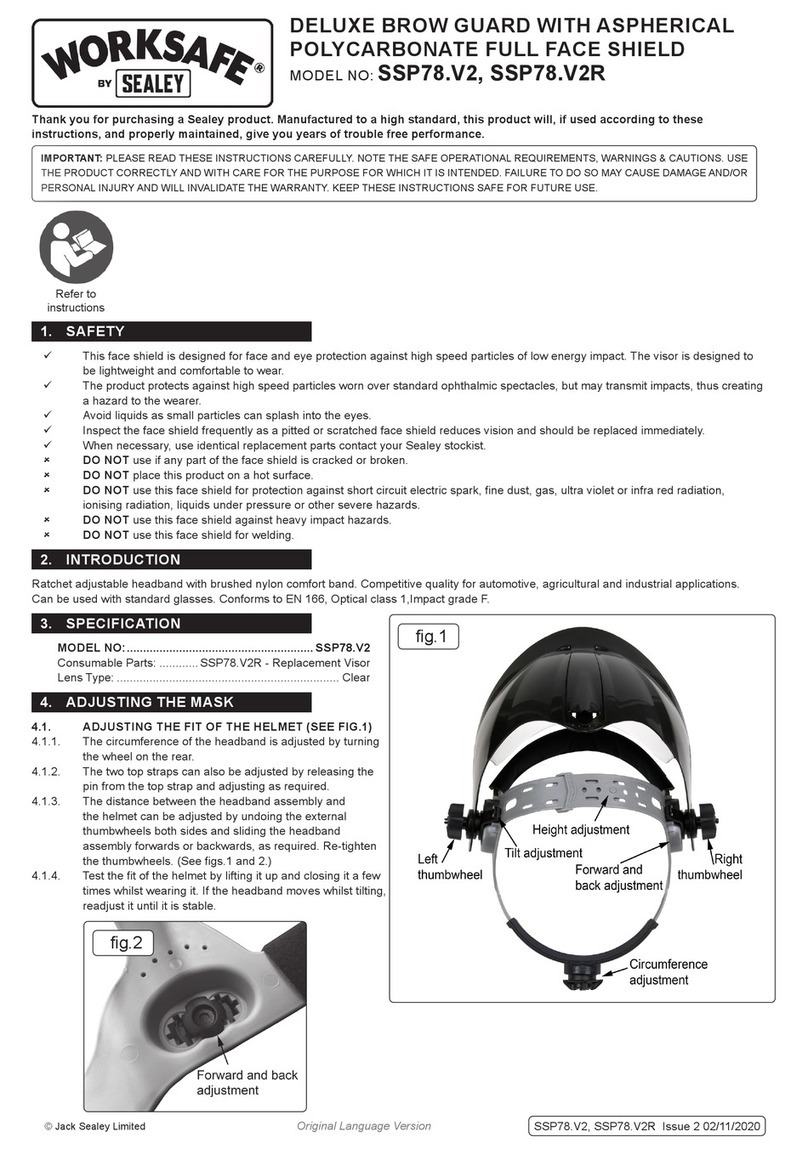

4.1. CHANGING THE FILTER

Note: If you remove either of the lters and put them back on, check

the foam seal has not been damaged.

4.1.1. Align the arrows (g.1), press and twist the lter to the right until

it clicks.

4.2. DURING USE.

4.2.1. In the interest of safety, change the lter frequently.

4.2.2. The eective life of the lter should be determined by a

competent person who is aware of the conditions of use.

4.2.3. Upon leaving the contaminated area, remove excess

contamination from clothes before removing the respirator. g.1

SSP1605,SSP1605FP Issue 1 16/01/19

Original Language Version

© Jack Sealey Limited

Refer to

instructions