INSTRUCTIONS FOR:

PLATFORM SCAFFOLD TOWER

EXTENSION PACK 4

Model No. SSCL4

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

WARNING! Take care when using and moving scaffolding,

extended ladders and other such equipment in the vicinity

of power cables - risk of potentially fatal electric shock.

WARNING! Ensure Health and Safety, local authority, and

general workshop practice regulations are adhered to when

using this equipment.

3Familiarise yourself with the application and limitations of the

scaffold, as well as the potential hazards.

3Maintain the equipment in good condition.

7DO NOT use the equipment if any parts are damaged or missing

as this may cause failure and/or personal injury.

3Replace or repair damaged parts. Use genuine parts only.

Non-authorised parts may be dangerous and will invalidate the

warranty.

3Keep the work area clean, uncluttered and ensure there is

adequate lighting.

WARNING! Use scaffold on level and solid ground and ensure

the brakes are applied and/or that the scaffold is anchored and

held firmly in place by some means.

WARNING! DO NOT erect or use the scaffolding on sloping or

unstable ground.

WARNING! Never over-reach when on the scaffolding.

3Keep children and unauthorised persons away from the working

area.

7DO NOT use the scaffolding for any purpose other than that for

which it is designed.

7DO NOT allow children to climb the scaffolding.

7DO NOT use the equipment when you are tired, under the

influence of alcohol, drugs or intoxicating medication.

3When not in use store in a safe, dry, childproof area.

7DO NOT use the equipment without side guardrails, knee rails

and toeboards fitted. Use all the components supplied.

3When used outside, mobile scaffold towers should, wherever

possible, be secured to a building or other reliable structure.

3It is good practice to tie in all scaffold towers of any height,

especially when left unattended or in exposed windy conditions.

Use only the recommended wall anchors.

3Beware of strong wind conditions. Do not erect or use a

freestanding tower if the wind is likely to exceed 7.7 m/sec

(17mph or Beaufort force 4).

3Take care when using mobile scaffold towers in hangers or

uncovered buildings as windforce may be increased due to

funnelling effects.

7DO NOT climb a tower from the outside. Never climb on the

horizontal or diagonal braces. You should only climb the tower on

the inside using the ladder end frames.

7DO NOT lean ladders against the tower. Never use ladders or

boxes to gain additional height.

3Ensure that all personnel, tools and materials are removed from

the tower prior to moving it. Only move the scaffold tower

manually on a firm level surface, which is free of any obstacles.

Only move it longitudinally or diagonally. Do not exceed normal

walking speed. Raise the stabilisers 12 mm (½”) from the ground.

After moving re-lock the castors, check that the tower is level

and ensure that the stabilisers are secure and have a firm footing.

7DO NOT exceed the safe working load of the platform. The

maximum capacity of the working platform for an evenly

distributed load is 1.5 kN/m² (according to HD1004 – scaffold

tower Class 2)

7DO NOT jump on to or off the platforms.

7DO NOT use any lifting equipment on the mobile scaffold tower.

2. INTRODUCTION

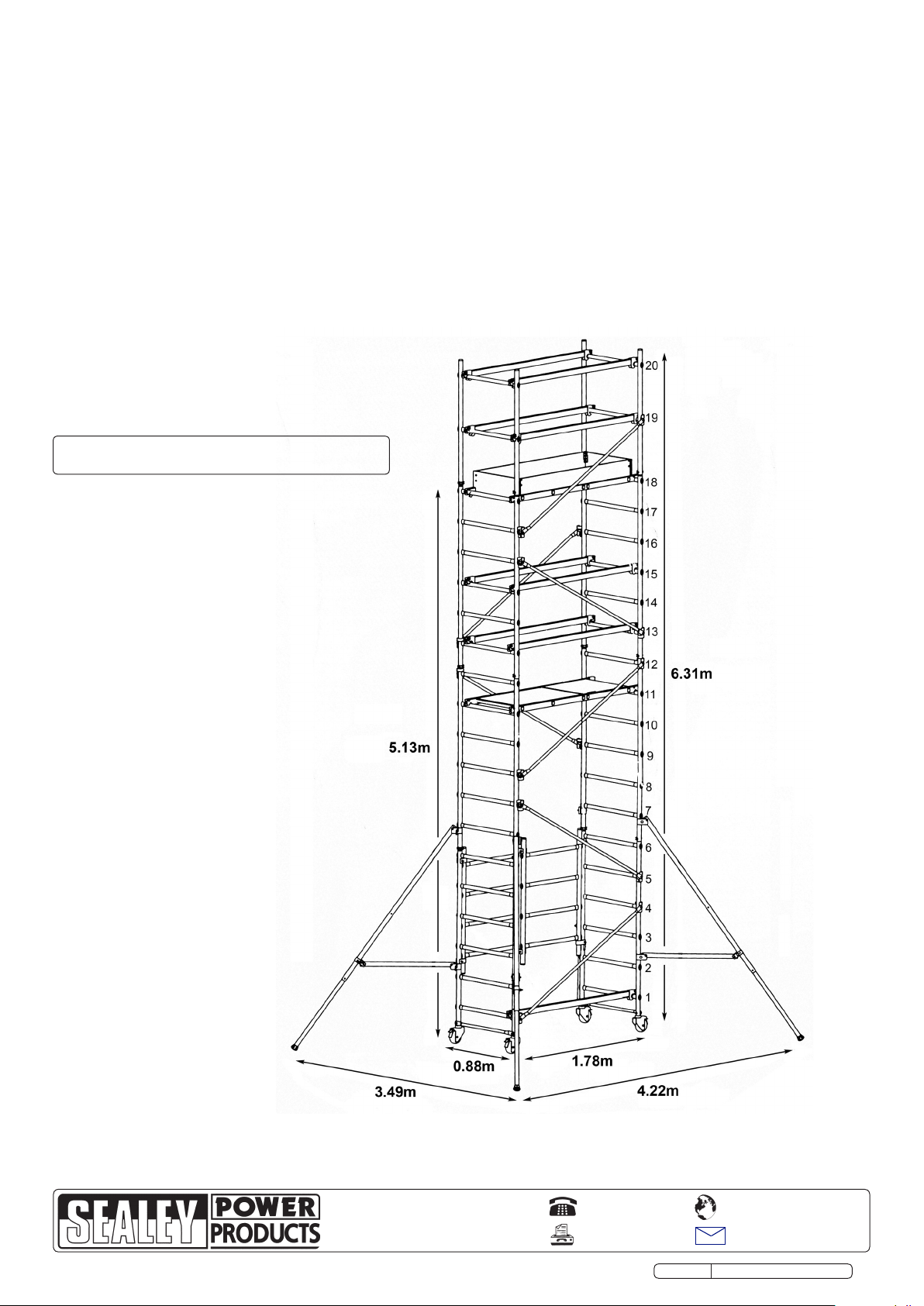

Extension Kit to be used with SSCL1 & SSCL3. Further increases the

platform height to 5.15mtr and the working height to 7.0mtr.

Manufactured from robust aluminium with anodized finish for durable

corrosion resistance.

3. SPECIFICATION

Model No: ...................................................................................... SSCL4

Width: ......................................................................................... 1780mm

Width with support legs: ............................................................. 3810mm

Depth............................................................................................ 860mm

Maximum Working Height: ............................................................7.0mtr*

Maximum Platform Height:..........................................................5.15mtr*

Maximum capacity...........................................................................200kg

Weight: ..............................................................................................10kg

*Only when used with SSCL1 & SSCL3

7DO NOT bridge between the mobile scaffold tower and buildings.

3Stabilisers and ballast weights shall always be fitted where

specified. Ballast is used at the base to stabilise towers from

overturning. Ballast must be of solid material (i.e. NOT water or

loose sand) and should be positioned so as not to overload

individual legs. Ballast should be secured from accidental removal.

3Keep equipment clean and inspect before and after use for

damage. Use serviceable equipment only. All working parts e.g.

castors, adjustable legs; stabiliser clamps should be lubricated

lightly with oil. Repairs should only be carried out by the supplier

or other competent person approved by the supplier.

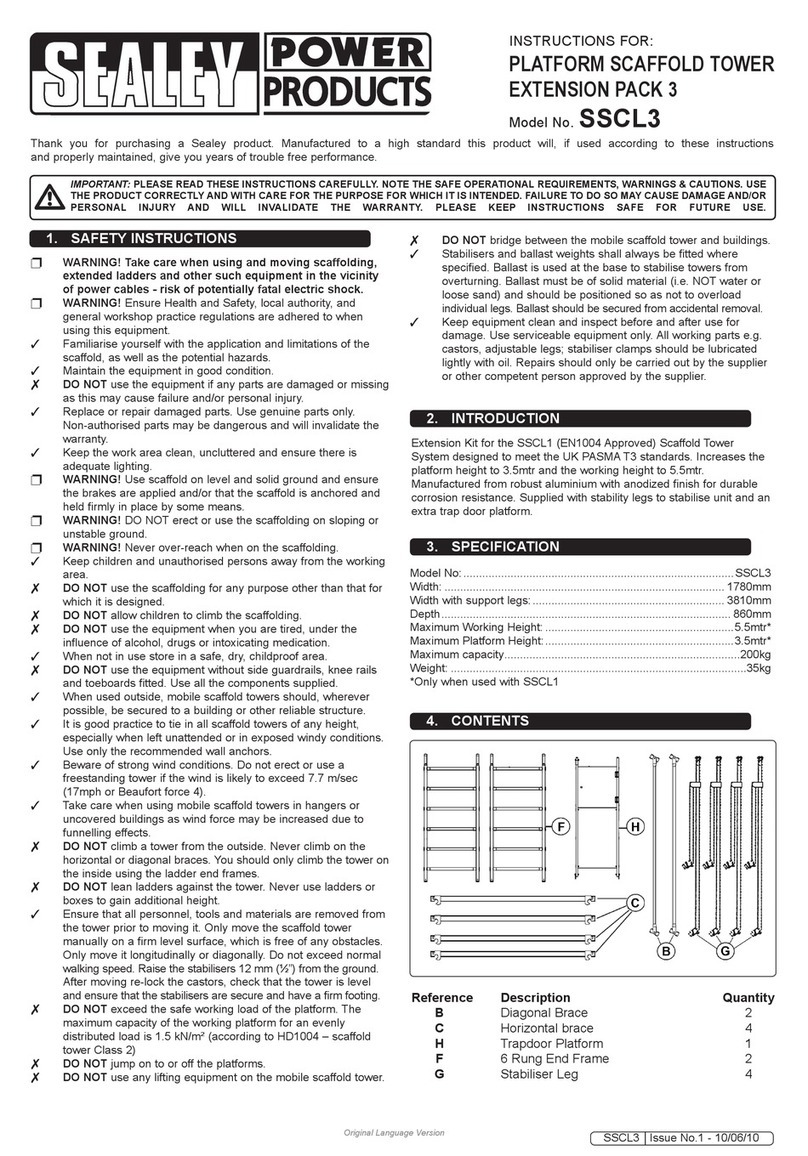

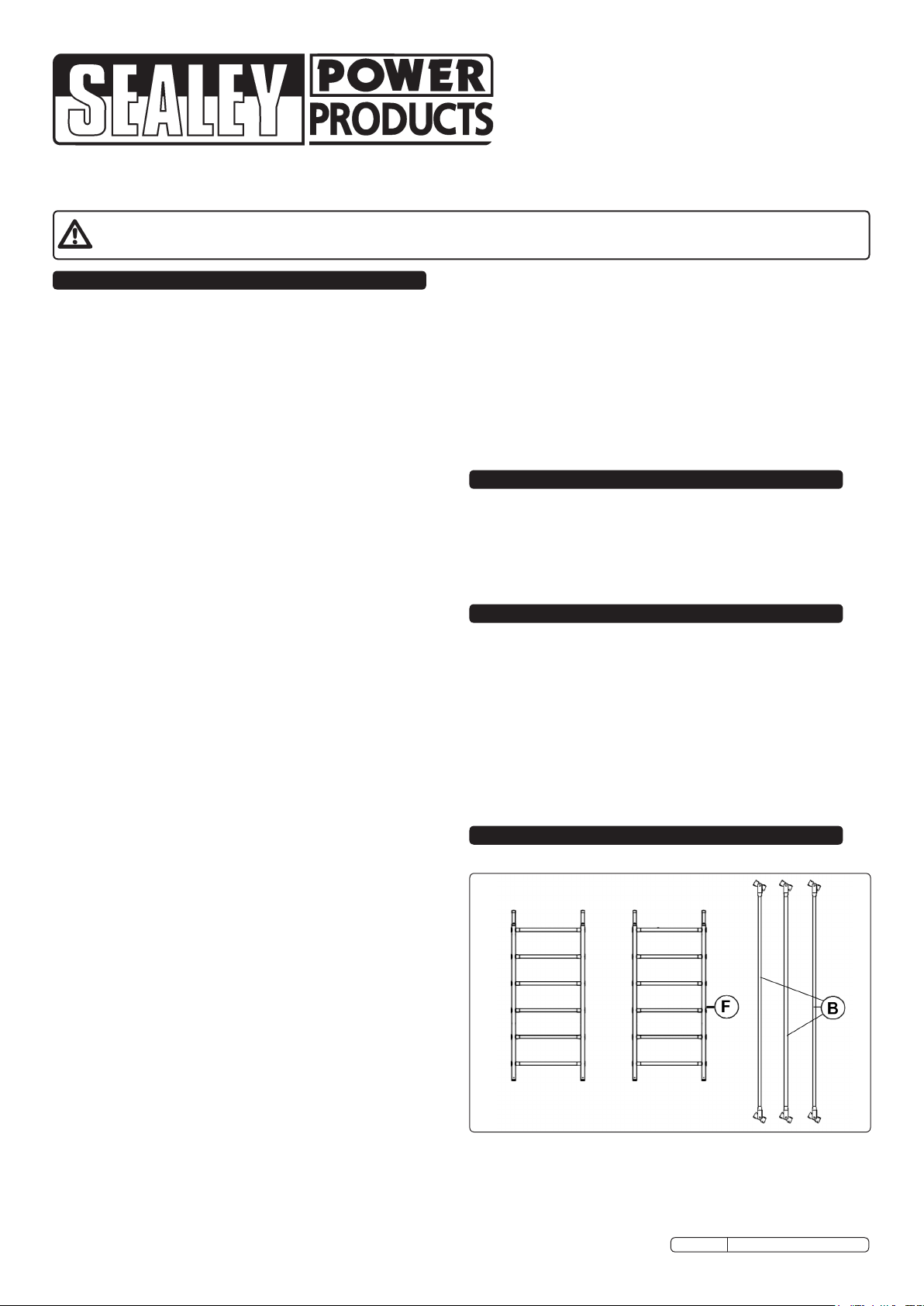

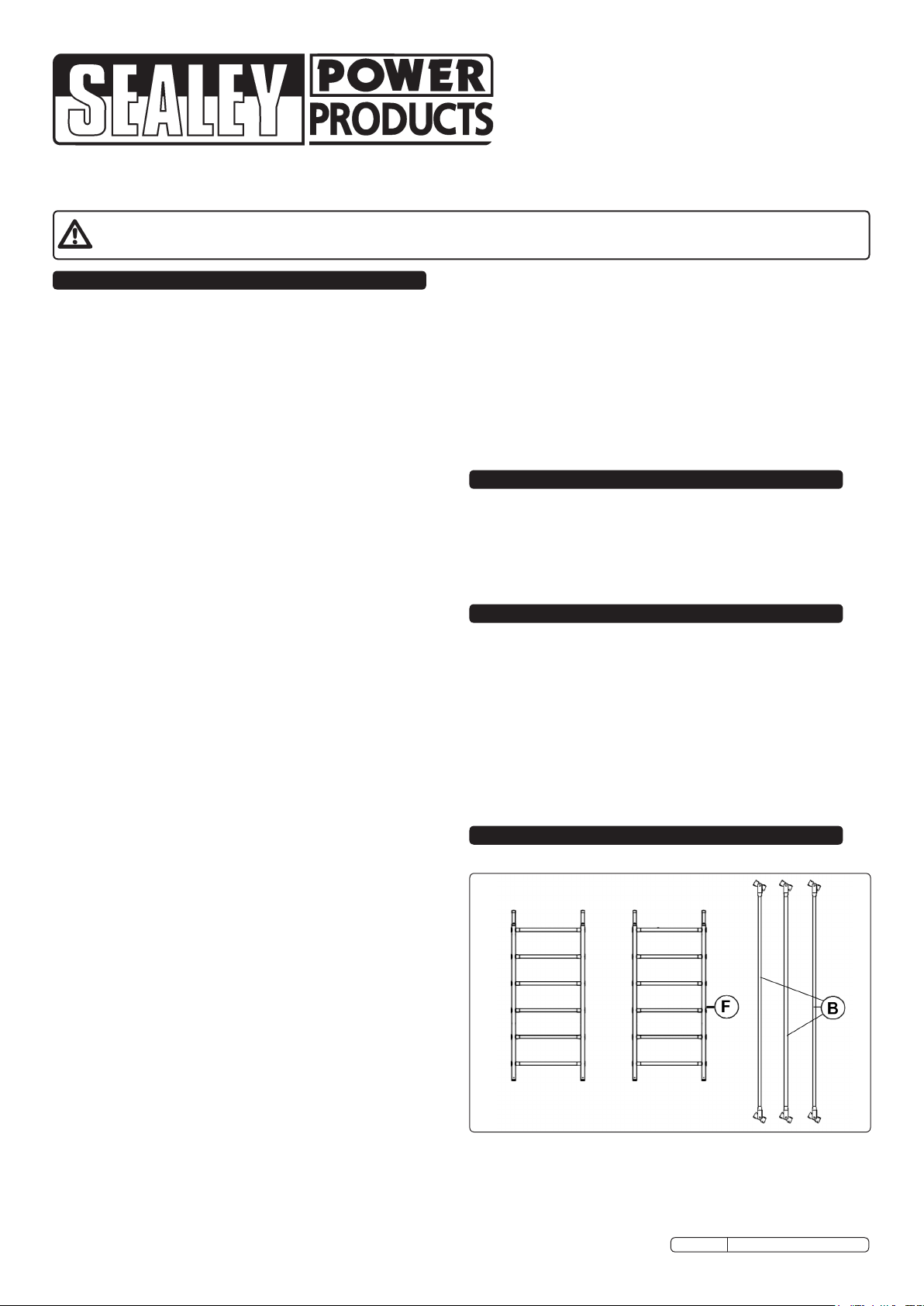

4. CONTENTS

Reference Description Quantity

BDiagonal Brace 3

F6 Rung End Frame 2

Original Language Version

SSCL4 Issue No.1 - 08/06/10