Bodyguard® 1500

PASS (Personal Alert Safety System) Instructions for Use

Bodyguard® is a registered trademark of Dräger 3361121 (A3-D-P) Page 1 of 2

1 For your safety

1.1 General safety statements

● Before using this product, carefully read the instructions for use.

● Strictly follow the instructions for use. The user must fully understand

and strictly observe the instructions. Use the product only for the

purposes specified in the Intended Use section of this document.

● Do not dispose of the instructions for use. Ensure that they are

retained and appropriately used by the product user.

● Only fully trained and competent users are permitted to use this

product.

● Comply with all local and national rules and regulations associated

with this product.

● Only trained and competent personnel are permitted to inspect, repair

and service the product. Dräger recommends a Dräger service

contract for all maintenance activities and that all repairs are carried

out by Dräger.

● Use only genuine Dräger spare parts and accessories, or the proper

functioning of the product may be impaired.

● Do not use a faulty or incomplete product, and do not modify the

product.

● Notify Dräger in the event of any component fault or failure.

1.2 Definitions of alert icons

Alert icons are used in this document to provide and highlight text that

requires a greater awareness by the user. A definition of the meaning of

each icon is as follows:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

could result in physical injury or damage to the product or

environment. It may also be used to alert against unsafe practices.

NOTICE

Indicates additional information on how to use the product.

2 Description

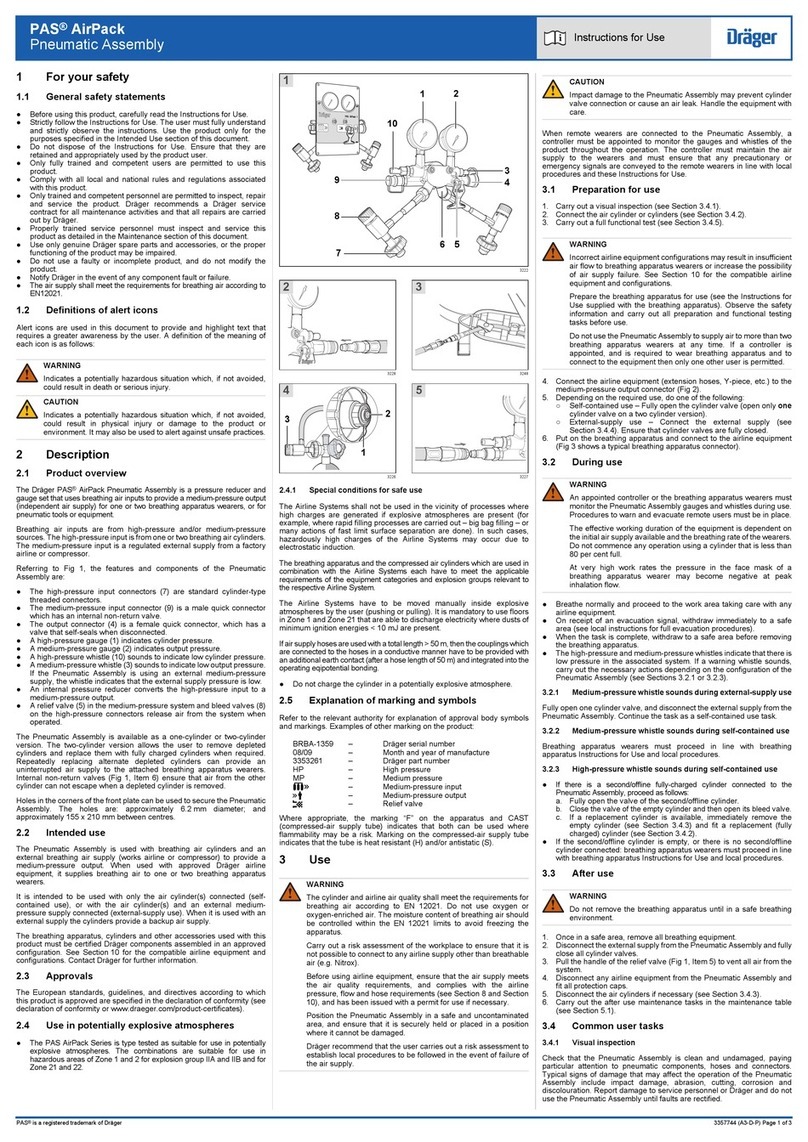

2.1 Product overview

The Bodyguard®1500 is a battery powered Personal Alert Safety System that

provides audible and visible alarm signals. Audible signals are loud and easily

recognized with varying alarm patterns to distinguish between different

warning conditions. The alarm is from an electronic sounder that uses the tally

slots as amplification chambers to provide clear and loud alarm signals.

Visible signals are provided by red, blue, green and amber LEDs on the casing.

During use the unit displays a flashing green LED that indicates active mode,

and pulsing blue LEDs that are used as a visual identification signal (or buddy-

beacon) for fellow team members.

The unit is configured as either a button version or a button version with a

tally cancel. The main difference between the version types is the alarm

cancelling method:

● Button version – the buttons on the side of the unit are used to arm and

cancel automatic alarms (a tally is not supplied with button versions).

● Button version (with tally cancel) – the buttons on the side of the unit

are used to arm and cancel automatic alarms. The tally is intended for

use during maintenance. Inserting the tally prevents audible alarms

from sounding during maintenance.

The unit is fixed on to the outside of protective clothing or equipment using

one of three different fixing options. The standard fixing is a low-profile

harness clamp. An alternative (supplied with the unit) is an adaptor which

attaches the unit to a universal accessory clip. An optional alternative

(supplied as an accessory) is a crocodile clip with combined wire D-ring.

2.1.1 Distress alarms

The main function of the unit is to provide automatic and manual distress

alarms. The automatic distress alarm uses an internal motion sensor and

timer to measure the time that wearer has been motionless, in order to

indicate that the wearer may be unconscious or trapped. The automatic

distress alarm activates a pre-alert ( ) and a full alarm ( ) at

predetermined timed intervals when the wearer does not move in excess

of normal breathing movement. The manual alarm is operated by pressing

the yellow button ( ), to allow the wearer to signal for help or attention.

2.1.2 Thermal exposure alarm

Protective clothing insulates the wearer from the thermal environment,

making it difficult to appreciate the level of heat or thermal exposure. The

Bodyguard®1500 includes a thermal sensor that monitors exposure and

starts a timer at a set start temperature (the default start temperature is

40 °C). Once the timer has started, two thermal exposure alarms activate

at time-weighted temperature thresholds. The alarms warn the user of a

relatively long period of exposure to slightly elevated temperatures, or of a

short period of exposure in high temperature situations.

The thermal sensor can be disabled or the start temperature can be

configured to meet the individual operational needs of the user using

Dräger PC Link (see Section 2.1.3).

2.1.3 Radio frequency link

The radio frequency (RF) link allows one or more units to be paired with a

Dräger Bodyguard® TX Gauge on a breathing apparatus. When paired with

a TX Gauge, the Bodyguard®1500 will automatically switch on if it is within

1 m of the paired TX Gauge when the gauge is switched on. The paired

Bodyguard®1500 cannot be switched off until the TX Gauge is switched

off. See Section 3.4.3 for details of pairing the unit.

The Bodyguard®1500 is equipped with radio frequency communication

circuitry that enables wireless reading and reprogramming of the unit. This

information includes unit identity, a record of events (datalog), parameter

maintenance and firmware reprogramming. The parameter settings that

are configurable include enabling/disabling of alarms, motion alarm times,

alarm sounds, etc. The alarm parameters described in this document are

the default settings for the unit.

Reprogramming the unit requires Dräger PC Link. Contact Dräger for

details.

2.2 Intended use

The Bodyguard®1500 is intended for use by firefighters, other emergency

services, and industrial users engaged in fire fighting, rescue and other

hazardous duties with a TX Gauge. The unit provides clear, distinct and

easily recognized alarm signals that indicate wearer immobilization, a call

for help or attention, or warn of excessive thermal exposure. Distress

alarms can be used by rescue teams to pinpoint the position of the source

of the alarm. The unit may be used as a stand-alone device.

2.2.1 Limitations on use

A limitation of the automatic distress alarm is that the motion sensor

detects movement or vibration to which the wearer is subjected, and may

not activate if the wearer is motionless on a moving platform (for example,

on moving or vibrating machinery).

Special conditions for safe use:

The recessed label is made from aluminium foil. The end user shall

exercise care to ensure that the label is not subject to impact or abrasion

during use as this may cause incendive sparks.

The metal fixing clamp is an isolated conductive part with a capacitance of

6 pF, exceeding the values permitted by Table 9 of EN60079-0:2012 for

Group II equipment. This should be taken into consideration by the user as

an electrostatic discharge risk in determining suitability for use.

2.3 Approvals

The European standards, guidelines, and directives according to which

this product is approved are specified in the declaration of conformity (see

declaration of conformity or www.draeger.com/product-certificates).

2.4 Marking and symbols

CAUTION

Do not use marker pens or apply paint, and do not scratch or

engrave the unit, as this may damage the unit or invalidate

approvals. It is recommended that any personal marking of the unit

is made using adhesive labels.

BRXX-1234 Dräger serial number

Left-hand button and active LED

Right-hand button

Low battery LED

Radio frequency (RF) communication symbol

!

3 Use

CAUTION

The tally from a Bodyguard®1500 with a tally cancel must be

removed before the automatic distress alarms will activate. Ensure

that the tally is removed before commencing operations.

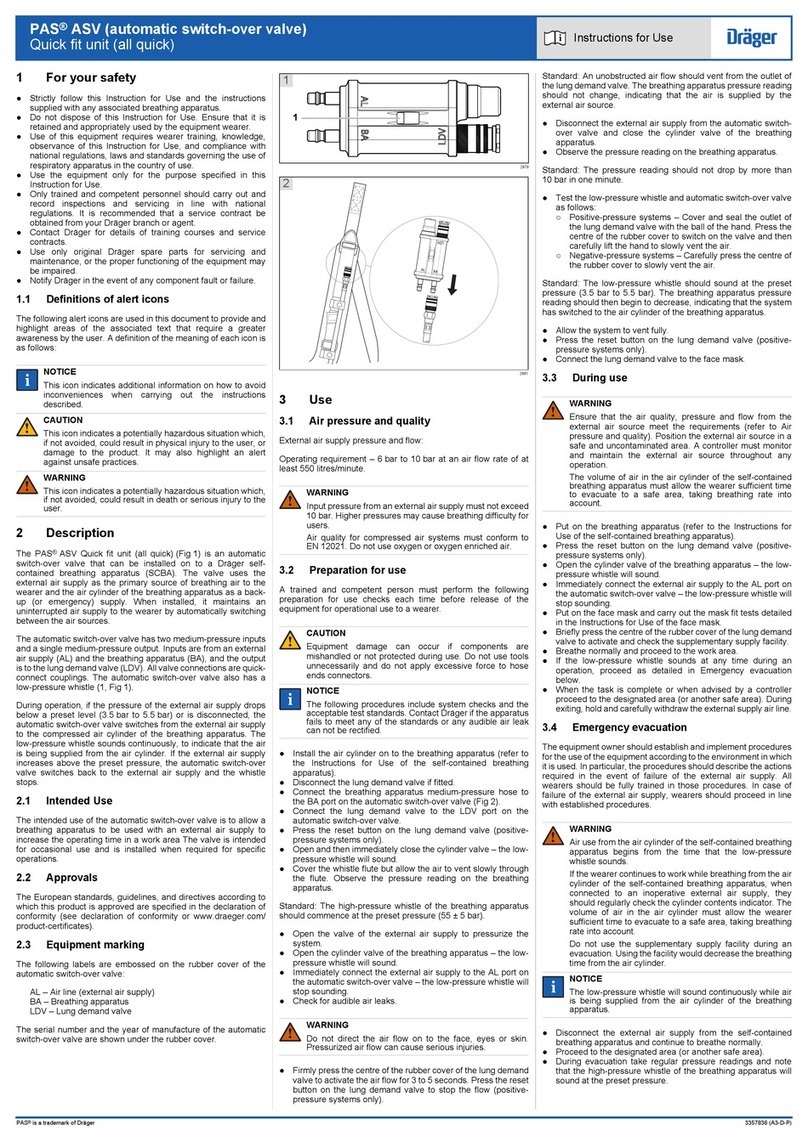

3.1 Preparation for use

3.1.1 Initial assembly

The rear cover and batteries are supplied loose (unfitted) with the unit.

Install them before first use (see Section 3.4.2).

If the unit is supplied with the crocodile clip accessory, fit the clip as follows:

1. Remove the harness clamp from the rear cover (Fig 2).

2. Install the batteries and rear cover as normal (see Section 3.4.2).

3. Connect the crocodile clip accessory (Fig 3). Gently tighten (nip up)

the screw using a T10 driver. Dräger recommend a torque of 0.8 Nm

(0.6 lbf ft) – do not over tighten.

If fitting the unit to a universal accessory clip, fit the adaptor as follows:

1. Install the batteries and rear cover as normal (see Section 3.4.2).

2. Fit the universal accessory clip adaptor and secure in place with the

harness clamp (Fig 4).

NOTICE

Only secure the universal accessory clip adaptor to the unit with

the harness clamp. Do not use a screw, such as the one supplied

with the crocodile clip accessory.

3.1.2 Preparation for use

1. Install the batteries if necessary (see Section 3.4.2).

2. Pair unit with a TX Gauge if necessary (see Section 3.4.3).

3. Carry out a functional test (see Section 3.4.1).

WARNING

Fitting the unit inside protective clothing would insulate the thermal

sensor from the thermal environment and delay alarm activation,

risking over exposure to high temperatures. Fix the

Bodyguard®1500 outside any protective clothing and ensure that

the sensor is clear of obstructions.

NOTICE

The optimum fitting positions are on the front of the wearer at the

shoulder (Fig 5 and Fig 6) or waist (Fig 7). The shoulder position may

expose the thermal sensor to slightly higher temperatures, and is

recommended for fire fighting operations.

The shoulder fitting position allows the unit to be paired with a TX

Gauge while wearing a breathing apparatus. See Section 3.4.3 for

details of pairing the unit.

4. Fit the unit to a breathing apparatus harness strap or to protective

clothing.

3.2 During use

3.2.1 Switching the unit on and off

To switch on the unit:

● If the unit is being used as a stand-alone device press the left-hand

button.

● If the unit is paired with a TX Gauge, open the breathing apparatus

cylinder valve. The unit will switch on automatically.

To switch off the unit:

● If the unit is being used as a stand-alone device simultaneously press

the left-hand and right-hand buttons.

● If the unit is paired with a TX Gauge, switch off the TX Gauge (see the

TX Gauge instructions for use) and then simultaneously press the left-

hand and right-hand buttons.

3.2.2 Operating modes and functions

Use and activation of alarms, and any evacuation and recovery

procedures, should be in line with existing command and control

procedures.

Sleep mode – When the unit is switched off it enters a sleep mode

(awaiting an activation signal). The automatic alarms are disabled and all

LEDs are off. The manual distress alarm can be activated from sleep

mode.

Active mode – When the unit is switched on, and passes the self check,

a start-up signal occurs (four beeps, and brief illumination of all LEDs) and

then the unit enters the active mode indicated by a flashing green LED

(every second). Automatic alarms are enabled and the buddy-beacon

signal is on.

Error alert – If the unit fails the self check during start-up, or if a hardware

failure occurs during use, the error alert activates (five beeps plus high-

frequency flash of the amber LED).

Pre-alert ( ) – No movement sensed for 21–25 seconds. Activates a

repeating, increasing-volume, triple-beep alarm tone accompanied by

alternating red and blue LEDs.

Automatic distress alarm ( ) – No movement sensed for 8 seconds

of pre-alert. Activates the full alarm signal.

Manual distress alarm ( ) – Pressing the button activates the full alarm

signal.

Low battery alert ( ) – Flashing amber LED and beep every five

seconds.

Thermal exposure alarm 1 – Lower time/temperature threshold reached.

Activates a short repeating double-beep alarm tone and flashing red LEDs.

Press the right-hand button ( ) to silence the alarm.

Thermal exposure alarm 2 – Higher time/temperature threshold reached.

Activates the full alarm signal.

Buddy-beacon – Blue LEDs pulsing at low frequency.

Full alarm signal – A high-pitched pulsating alarm signal accompanied by

alternating red and blue LEDs.

!

1

4110

1 Active LED 6 LED panel

2 Low battery LED 7 Manual alarm button

3 Right-hand button 8 RF communication point

4 Tally (option) 9 Left-hand button

5 Thermal sensor

3

4

12

6

7

5

8

9

3338

2

3324

3

5470

4

3339

5

5471

6

3337

7