Refer to Instruction

Manual

Wear a Face

Shield

Wear Protective

Gloves

Wear Protective

Clothing

Wear a Mask

© Jack Sealey Limited Original Language Version

INSTRUCTIONS FOR:

PORTABLE SODA BLASTING KIT

4.5 AND 18kg CAPACITY

MODEL NO’S: PSB10,PSB40

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions

and maintained properly, give you years of trouble free performance.

1. SAFETY

WARNING! Turn off, or disconnect from, air supply before servicing or performing any maintenance and when unit is not in use.

Failure to comply with this instruction may damage the unit and will invalidate your warranty.

WARNING! Wear approved ear, eye, hand and respiratory protection when operating the blaster. A full range of personal safety equipment

is available from your Sealey dealer.

Maintain correct balance and ensure firm footing.

Spillages of abrasive material, which may be slippery, must be cleaned up immediately to avoid injury.

Locate blaster in a suitable, well ventilated work area. Keep area clean and tidy and free from unrelated materials, and ensure that

there is adequate lighting.

Maintain the machine in good condition.

Replace or repair damaged parts. Use recommended parts only. Non-authorised parts may be dangerous and will invalidate the warranty.

Keep the unit clean for best and safest performance.

Remove ill fitting clothing. Remove ties, watches, rings, other loose jewellery and contain long hair.

Always keep the blast nozzle directed at the workpiece.

If a failure or malfunction occurs disconnect from air supply immediately.

Keep all other persons away from the working area. Contact with high pressure blast or inhaling the dust generated is dangerous.

DO NOT use the blaster for any purpose other than that for which it is designed.

DO NOT operate the blaster if any parts are missing or damaged as this may cause failure and/or personal injury.

DO NOT attempt to clear a blocked nozzle while the unit is pressurised.

DO NOT allow untrained persons to operate the blaster.

DO NOT get the blaster wet or use in damp or wet locations or areas where there is condensation.

DO NOT leave the blaster operating unattended.

DO NOT operate the blaster when you are tired, under the influence of alcohol, drugs or intoxicating medication.

DO NOT stand or sit on the blaster.

DO NOT direct air from the air hose at yourself or others.

DO NOT operate system with air supply exceeding 100psi.

DO NOT refill the unit or attempt any maintenance whilst the cylinder is pressurised.

2. INTRODUCTION

Pressurised tank for maximum power. Supplied with 1.5mtr hose & ceramic nozzle with shut off valve. Also includes bayonet air line coupling and

airflow regulator. Soda blasting is especially suitable in the classic car and motorcycle markets as soda will not etch glass and will not warp or

remove metalwork. Surface will be left smooth. Soda also leaves a rust inhibitor behind for up to six weeks. Suitable for use with Sealey Blasting

Soda Model No. SBG25KG.

3. SPECIFICATION

Model No:...........................PSB10....................... PSB40

Maximum Media Capacity: ..............4.5kg ..........................18kg

Maximum Filled Weight: ................10kg...........................30kg

Air Pressure: . . . . . . . . . . . . . . . . . . . . . . . . . 35-90psi.....................35-90psi

Air Consumption:......................7cfm...........................8cfm

Air Inlet Size: .........................1/4”BSP..................... 1/4”BSP

Ceramic Nozzle Size: ..................2.4mm ....................... 2.4mm

Maximum Pressure: ...................100psi ........................100psi

Nett Weight:..........................5.5kg ..........................13kg

4. ASSEMBLY

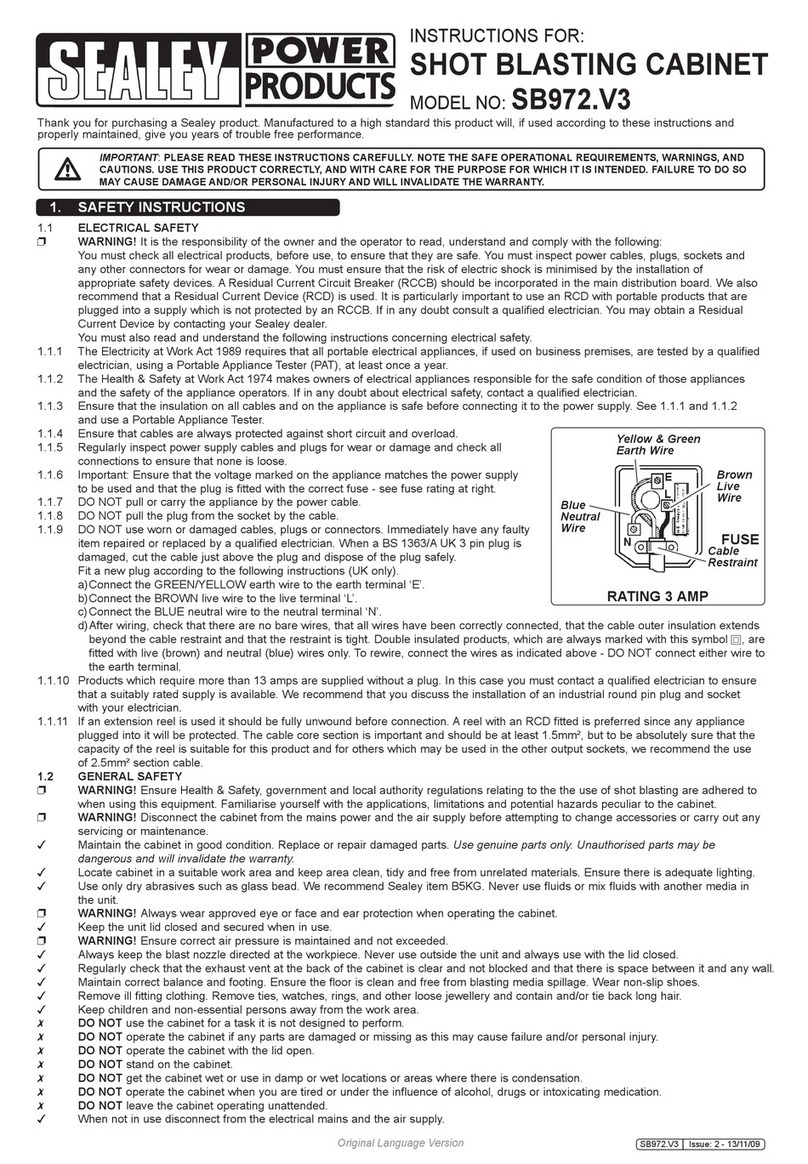

4.1. Assemble the soda blaster as in g.1. Apply PTFE tape to all air connections before tightening.

4.2. Connect the valve block (g.1.1) to the cylinder by means of the cylinder nut (g.1.2).

4.3. Screw in the safety valve (g.1.3), delivery valve (g.1.4) and push t connector (g.1.10).

4.4. Connect the regulator bracket (fig.1.5) to the cylinder by means of the hex. headed bolts provided. Place the neck of the regulator

(fig.1.15) through the bracket and secure with the regulator nut (fig.1.6). Screw in the pressure gauge (fig.1.7), push fit connector (fig.1.10)

and inlet valve. The inlet connector (fig.1.9) screws into the inlet valve.

4.5. Connect the regulator to the valve block using the air inlet tube (fig.1.11). Connect the delivery tube (fig.1.12) to the delivery valve.

NOTE: The delivery valve may be tted to outer end of the delivery tube, against the nozzle, if preffered.

4.6. To assemble the wheels on the PSB40, pass the axle through the axle supports, place a washer, wheel, washer and ‘R’ clip in that order on

either side

4.7. Check that all the air connections are tight and free from leaks

4.8. Ensure that the compressor employed has an adequate output to power the soda blaster, and that the piping is of a sufficient diameter to

allow free air flow. DO NOT use a lubricator in the air supply system.

PBS10, PBS40 Version: 1 - 25/02/16