3. OPERATION

WARNING! It is the user’s responsibility to ensure the safe use of the blow torch.

3.1. and must

beusedinconjunctionwiththepressureregulatorsupplied.Thetorchwillworkwithpressuresbetween1-7Atm.SeeTablebelowfor

description of power/energy consumption.

3.1.1. Ensure that the rubber hose for connecting the torch to the regulator/gas cylinder is in good condition.

3.1.2. For LPT7 the burners connect directly to the torch. For LPT14 select either the short or long extension and connect it to the torch.

Thenselectthedesiredburnerforthetaskinhandandattachittothetorch(orextension)ensuringthatthejointsareproperlyseated

and fully tightened.

3.1.3. Attach the regulator to the gas cylinder and connect the torch using the rubber hose ensuring that the hose connections are properly

seated and fully tightened.

3.1.4. LEAK TESTING Beforelightingthetorchallconnectionsmustbeleaktestedusingathicksoapsolutionsuchaswashingupliquidor

ideally a proprietary leak detection spray. Close the burner control on the torch. Open the gas cylinder tap and then the regulator.

Sprayeveryjointontheregulator,hoseandtorchwithleakdetectionuidandcheckforleaks.Tightenanyjointsasnecessaryand

retest.Ifanyjointsstillleakturnothegas,disassembleandinvestigate.OnLPT14checkconditionof“Oring”seals.Donotproceed

tolightingthetorchuntilalljointsaregastight.

2.3. IGNITION

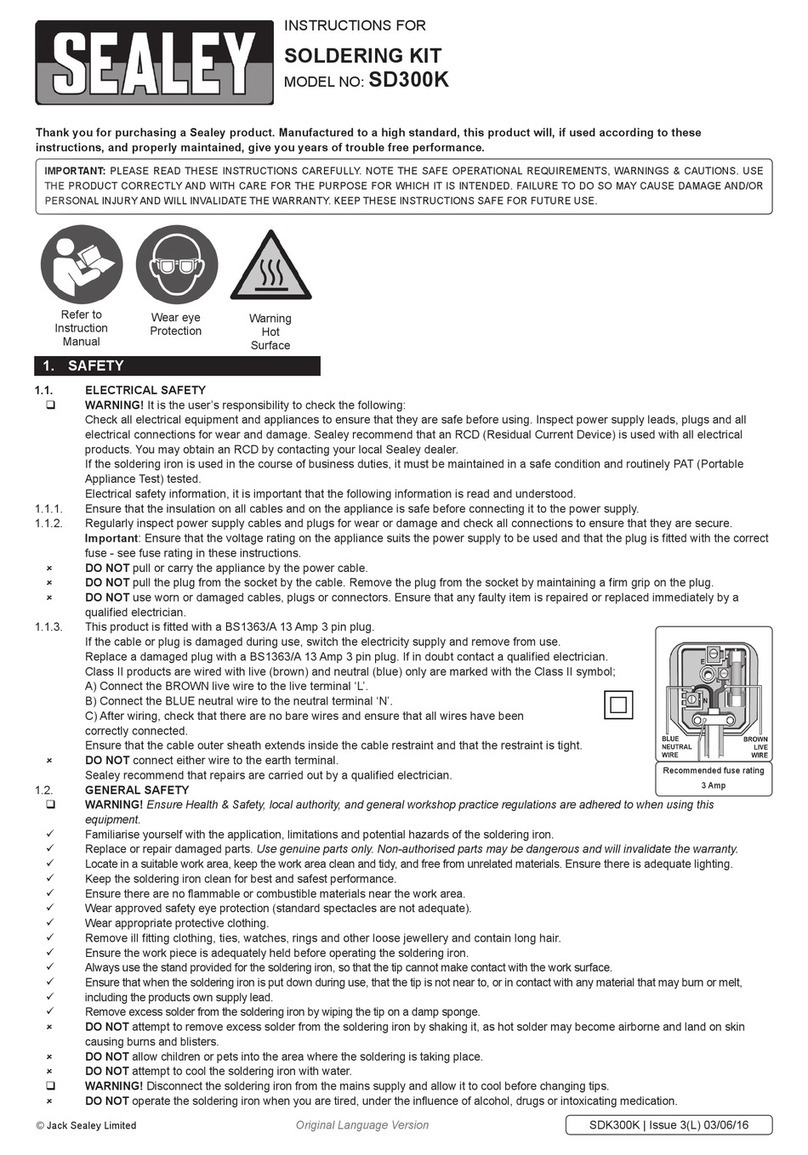

NOTE:Pilotlightcontrol.TheburnersontheLPT7arettedwithapilotlightcontrolintheformofabrasssleeveontheburnertube

whichwillslideovertheairinletholesatthebaseoftheburnerstem(seeg.2.3.).Thishastheeectofturningablueametoamore

visibleyellowamewhenonlyapilotlightisrequired.(OnlythepipeheatingburnerontheLPT14hasthisfeature.)

3.1.5. Ensurethattheburnercontroltap(g.2.1.)isturnedo.

3.1.6. Openthegascylindertaprstandthenscrewtheregulatortapdownwardstoopenit.

3.1.7. Open the control tap (1) a small amount only until the gas can be heard escaping .

3.1.8. Drawyourameigniteruptotheundersideofthetorchburneropening.

3.1.9. Once the torch “pilot”has ignited remove and extinguish the source of ignition.

3.2. Iftheameissetforayellowpilotlightslidethepilotlightsleeveawayfromtheairinletholessothattheame

burns blue.

3.2.1. Forincreasedameintensitydepressthetrigger.(g.2.2.)

3.2.2. Releasethetriggertoreturntheametothe“pilot”light.

3.2.3. Flameintensitycanbecontrolledusingtheburnercontroltap(g.2.1.).Asthetapisopeneduptheamegetslarger.Asthetap

approaches fully open the trigger is overridden and only comes back into play again when the tap is partly closed.

3.2.4. Turnthecontroltap(1)otoextinguishthetorchcompletely,andthenturnthegascylindertapo.

4. MAINTENANCE

WARNING! Before commencing service or maintenance turn all gas

tapsoanddisconnectthetorchfromthegassupply.

NOTE:Fromtimetotimetheburnernozzleandinjectormayrequire

cleaning. Refer to relevant section below.

4.1. LPT7 MAINTENANCE

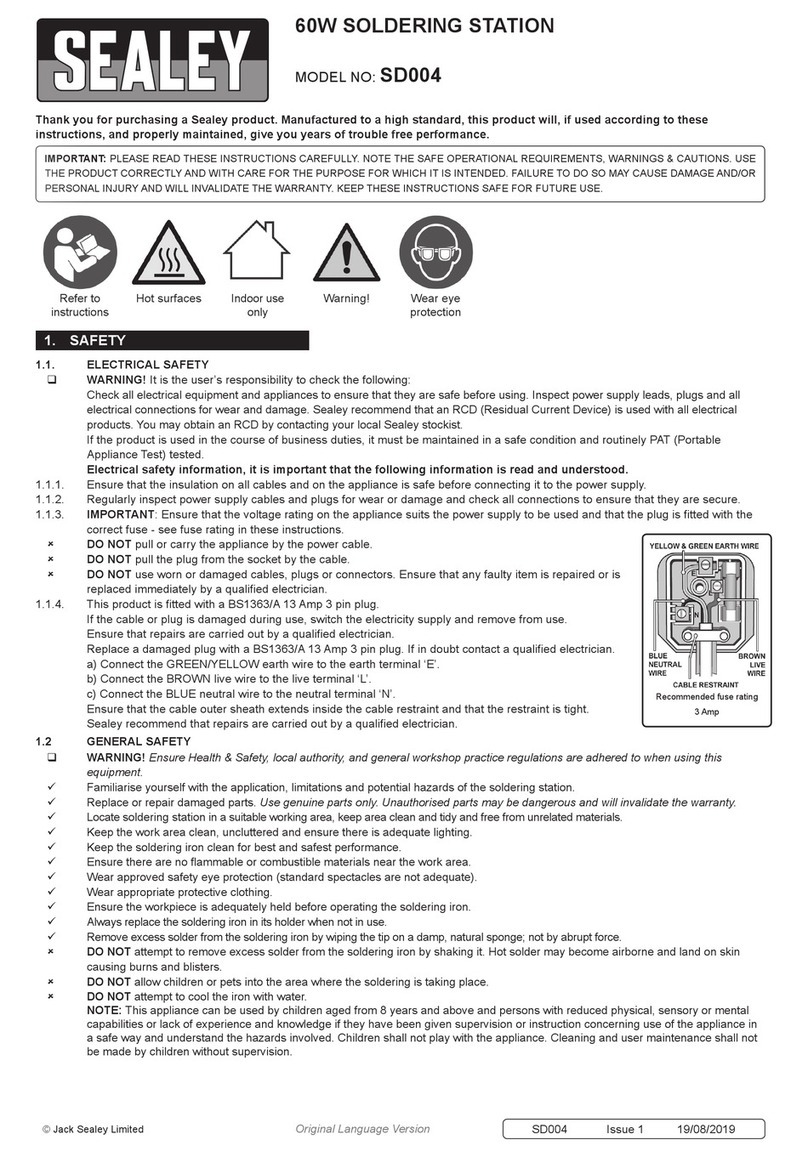

4.1.1. TodismantlethenozzleTodismantlethenozzleandinjectorfromaburner

insert a 4mm hex key into the hexagonal hole to be seen in the base of

eachburnerstem.Unscrewthenozzlefromthestem.Unscrewtheinjector

from the nozzle using a 7mm socket or spanner. Wash the nozzle and

injectorcarefullyinpetrolorsimilarcleaninguid.Donotdislodgethelter

gauzetobefoundinthebaseoftheneinjectors.Blowouttheinjectorwith

compressedairfromthelterendonly.WARNING!DO NOT clean the

injectorwithathinsteelwireasthismayenlargetheholeintheinjector

making it unsafe to use and invalidating your warranty. Reassemble

ensuringthatthelooseconnectornutisheldinplacebytheinjector/nozzle

assembly.

4.2. LPT14 MAINTENANCE

Thenozzle/injectorassembliesaremountedatthebaseofeachburner

headandservetoconnecttheheadstothetorchextensions.Unscrewthenozzle/injectorfromtheburnerheadusinga13mm

spanner.Unscrewtheinjectorfromthenozzleandproceedasabove.

© Jack Sealey Limited Original Language Version

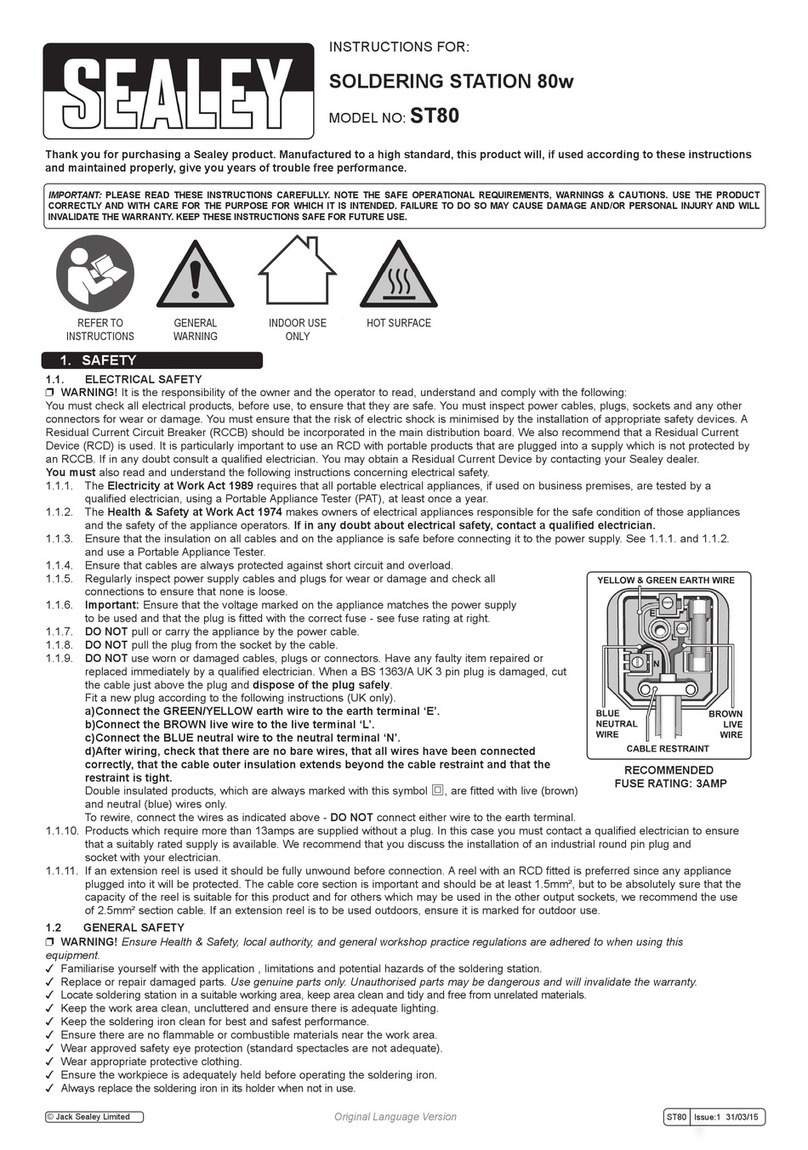

BURNER

DIAMETER mm POWER

kW CONSUMPTION

gr/hr

10 1.4 100

14 1.7 120

17 2140

20 2.1 150

25 3.7 265

35 6.3 450

45 19.5 1400

50 28 2000

60 35 2500

76 54 3850

45 TURBO 29.5 2100

50 TURBO 33 2350

60 TURBO 54 3850

01284 757500 sales@sealey.co.uk www.sealey.co.uk

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior

notice.

Important: No Liability is accepted for incorrect use of this product.

Warranty:Guaranteeis12monthsfrompurchasedate,proofofwhichisrequiredforanyclaim.

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste.All tools, accessories and packaging should be sorted,

taken to a recycling centre and disposed of in a manner which is compatible with the environment. When the product

becomescompletelyunserviceableandrequiresdisposal,drainanyfluids(ifapplicable)intoapprovedcontainersand

dispose of the product and fluids according to local regulations.

REGISTER YOUR

PURCHASE HERE

LPT7,LPT14Issue:4(H,F)30/05/23