INSTRUCTIONS FOR

GALVANIZED SHED 2.3 X 2.3 X 1.9M

MODEL NO: GSS2323 & GSS2323G

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when building this shed.

9Keep the work area clean, uncluttered and ensure there is adequate lighting.

9Keep children and unauthorised persons away from the working area.

8DO NOT use the shed for any purpose other than that for which it is designed.

9Use appropriate safety clothing including eye protection.

8DO NOT attempt to assemble in windy weather.

Note: The assembly of this product will require assistance.

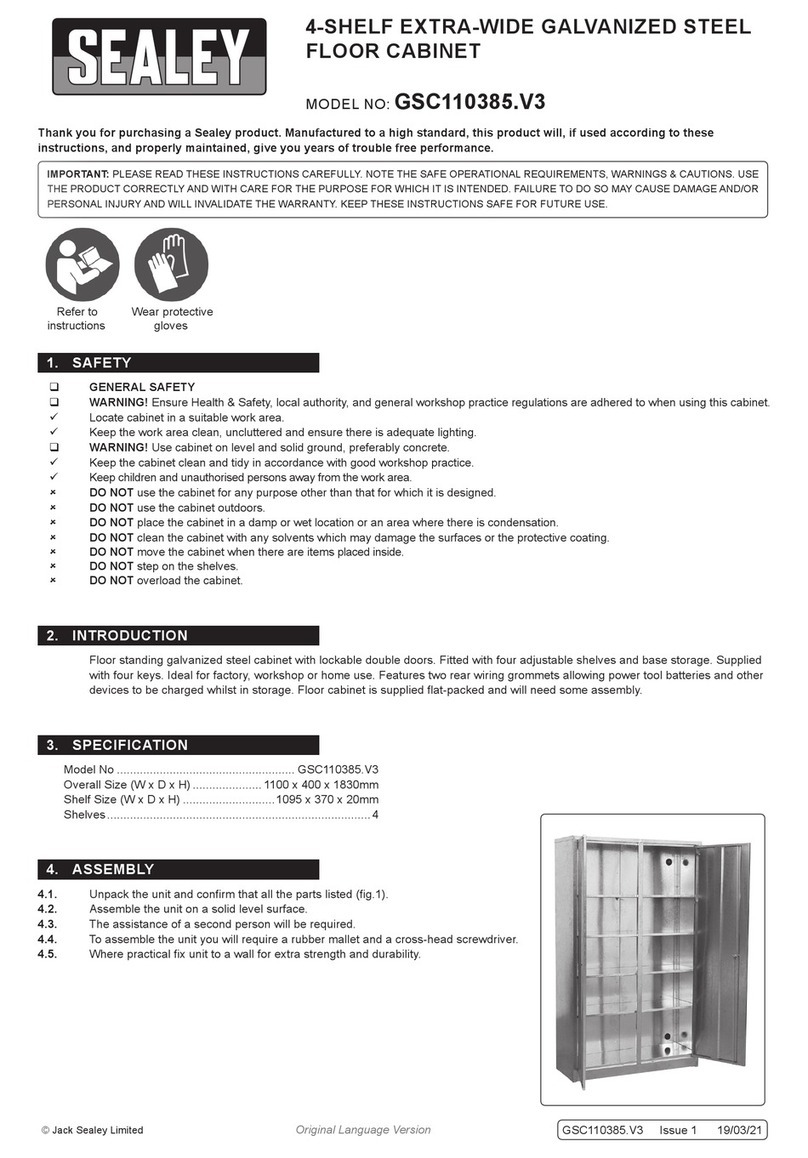

2. INTRODUCTION

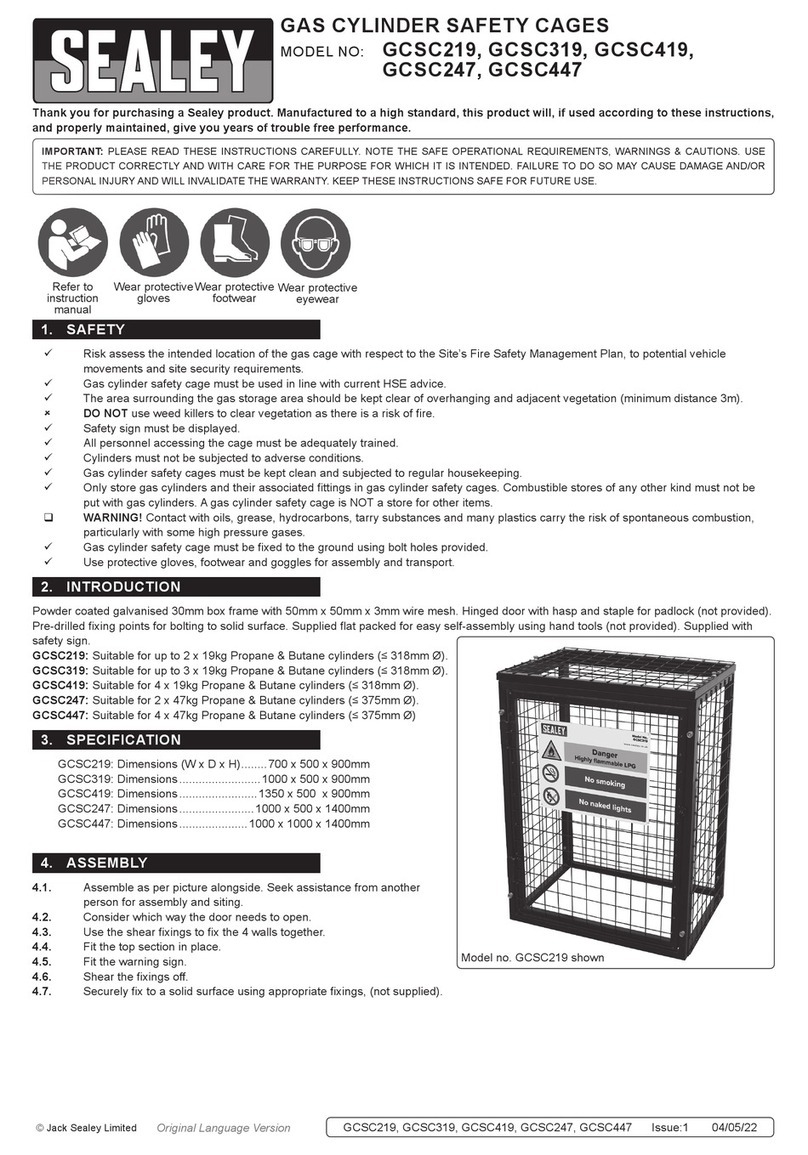

Galvanized steel panels easily assembled to form a rigid and secure gable roofed shed. Has a single door which is secured by cross bolt and

eyelet that accepts a padlock (not included) for additional security. Supplied with bolt-down fixing kits.

3. SPECIFICATION

Model no’s:...........................................GSS2323/GSS2323G

Colour: .................................................................silver/green

Roof type:....................................................................... apex

Doors: ..................................................................................1

Overall size (W x D x H*): .................2300 x 2300 x 1900mm

* minimum wall height

4. CONCRETE PLINTH

Concrete slab: Please ensure that your site is level. It is recommended that your slab is 100mm thick and you use builders plastic and F52

reinforcing mesh. We recommend that you make your slab 100mm bigger than the base dimensions of your shed. This will allow for a 50mm

edge around your shed. We recommend that you slope the 50mm edges downward by 10 mm so that rain water will drain away from your shed.

GSS2323/G | Issue:2(SP) 13/04/17

Original Language Version

© Jack Sealey Limited

Refer to

instruction

manual

Wear eye

protection

Wear safety

footwear

Wear

gloves