5. MAINTENANCE

5.1 Regularly check the drum handler chassis and wheels for

rigidity. Ensure that the rear castor is firmly secured to the

chassis.

5.2 Regularly check the pawl and ratchet for wear. Replace when

necessary.

5.3 Regularly check the drum handlers connecting components

such as retaining pins, nuts and washers for lubrication and/

or wear.

5.4 Keep handle free from grease and oil to prevent accidents.

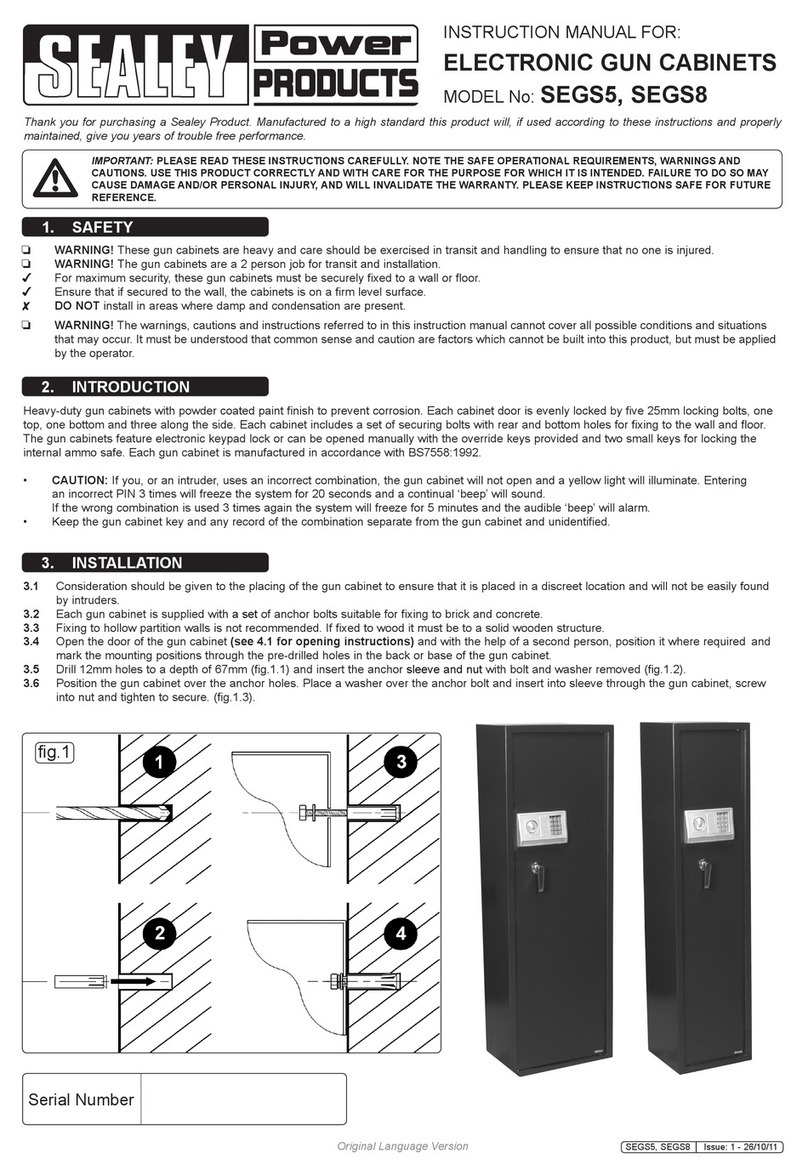

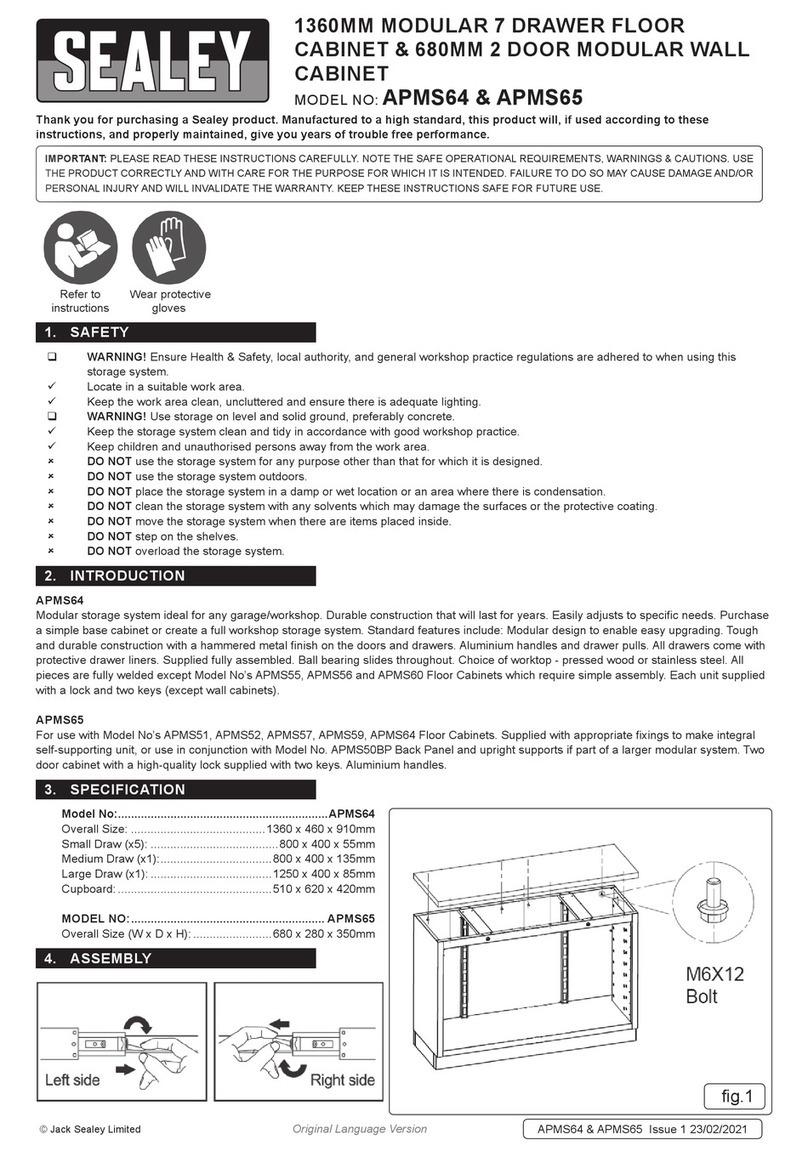

4.1 Clamping Drum.

4.1.1 The opening section of the hoop (Fig.3.15) is sprung loaded to

remain open when not clamped to a drum.

4.1.2 Position the Drum Handler so that the supporting hoop

(Fig.3.3) encompasses the drum to be lifted.

4.1.3 Pull the location levers (Fig.3.10) to release the handle (Fig.3.4)

and position the supporting hoop in the middle of the drum.

4.1.4 Release the location levers to lock the handle in this position.

4.1.5 Turn the fastening lever (Fig.3.6) so the teeth are pointing

upwards, take the slack up on the chain and place it in the

groove (Fig.4) on the fastening lever ensuring that it is fully

located as in Fig.4.1.

4.1.6 Pull the fastening lever sharply clockwise until the chain is tight

and the ratchet pawl has locked the ratchet as in Fig.5.

4.1.7 Check that the drum is now securely held in place. If the chain

is not tight repeat procedure 4.1.5 to 4.1.6 but take more slack

out of the chain. The drum is now ready to be lifted.

4.2 Lifting Drum.

4.2.1 Pull the handle (Fig.3.4) downwards, this will lift the drum.

4.2.2 When the drum is at the required height, slowly release the

handle and the location levers will automatically lock the

handle in place.

4.3 Transportation.

4.3.1 Push or pull the drum handler using the handle to the required

destination. Apply pressure left or right to steer the handler.

CAUTION! Ensure that there are no obstructions in your path,

make sure the floor surface is suitable to take the weight of the

fully laden drum handler.

4.4 Lower & Release Drum.

4.4.1 To lower the drum, apply downward pressure to the handle (Fig.3.4).

4.4.2 Pull the two location levers (Fig.3.10) at the same time.

4.4.3 This will release the handle and drum which may now be

lowered to the ground, when the drum reaches a firm surface,

release the location levers.

4.4.4 Turn the fastening lever clockwise slightly to disengage the

ratchet pawl.

4.4.5 Release the fastening lever and remove the chain and hang it

on the hook (Fig.3.17).

4.4.6 Pull the drum handler away from the drum.

4.5 Rotate the Drum.

4.5.1 The drum handler can rotate the drum from vertical to

horizontal position.

4.5.2 To turn the drum from vertical to horizontal disengage pins

(Fig.2) and turn through 90° to lock them in the disengaged

position and then turn the drum through 90° to the horizontal

position.

4.5.3 Rotate the pins again until they engage with the supporting

hoop to secure the drum in the horizontal position. Note!

Before rotating drum make sure drum has been lifted

sufficiently high enough allowing it to turn without interference

from the ground.

4.6 Adjustment.

4.6.1 If the supporting hoop is too high to hold the middle of the

drum while the handle is at its highest point or the drum cannot

be lifted to the required height when the handle has reached

its lowest point it will be necessary to adjust the height of the

supporting hoop.

4.6.2 Choose another hole (Fig.3.13&16) on the lifting arm (Fig.3.11)

and or the hanger plates (Fig.3.12) remove the hanger plate

bolts from the original position an relocate them in the new

position ensuring that the same hole is chosen for each side.

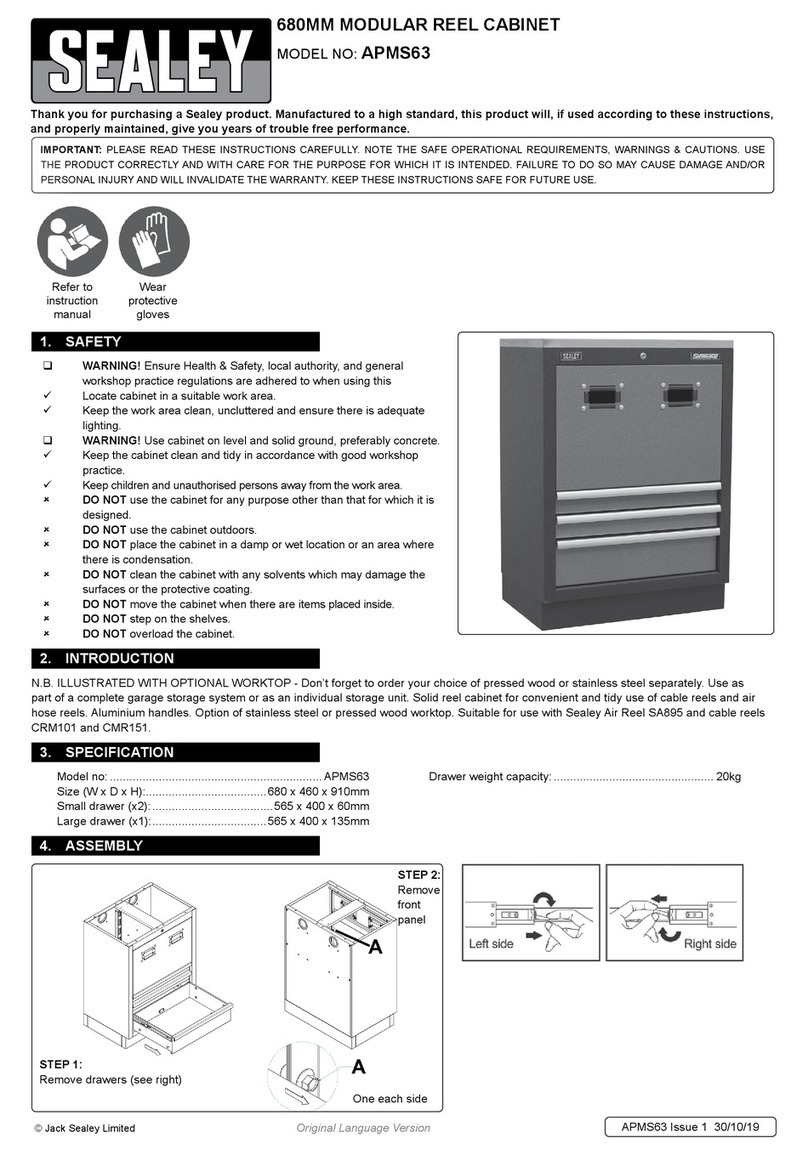

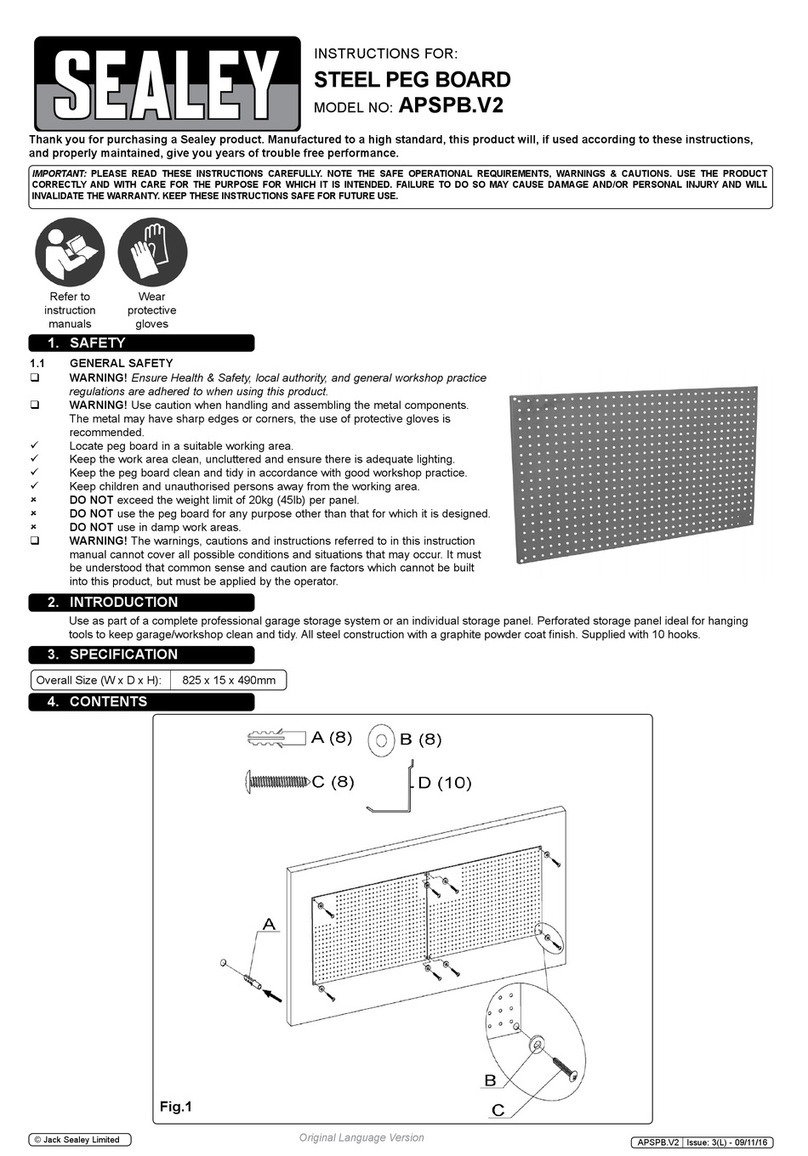

4. OPERATION Fig.4

Locate chain

in fastening lever.

Fig.4.1

Chain pulled tight

and secured by

ratchet pawl

Fig.5

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

email

Original Language Version DH02.V2 Issue: 2 - 15/03/10