Alfa Romeo 1.4, 1.6, 1.8 & 2.0 Twin Spark + 2.0JTS petrol engines.

5.1 General Guide - Setting & Locking engines.

Timing belt replacement on these Alfa Romeo twin cam engines is

carried out with the crankshaft at TDC No.1 cylinder, established by

using VS1404 TDC Position Tool together with a Dial Gauge

(AK9634M), to determine the piston position.

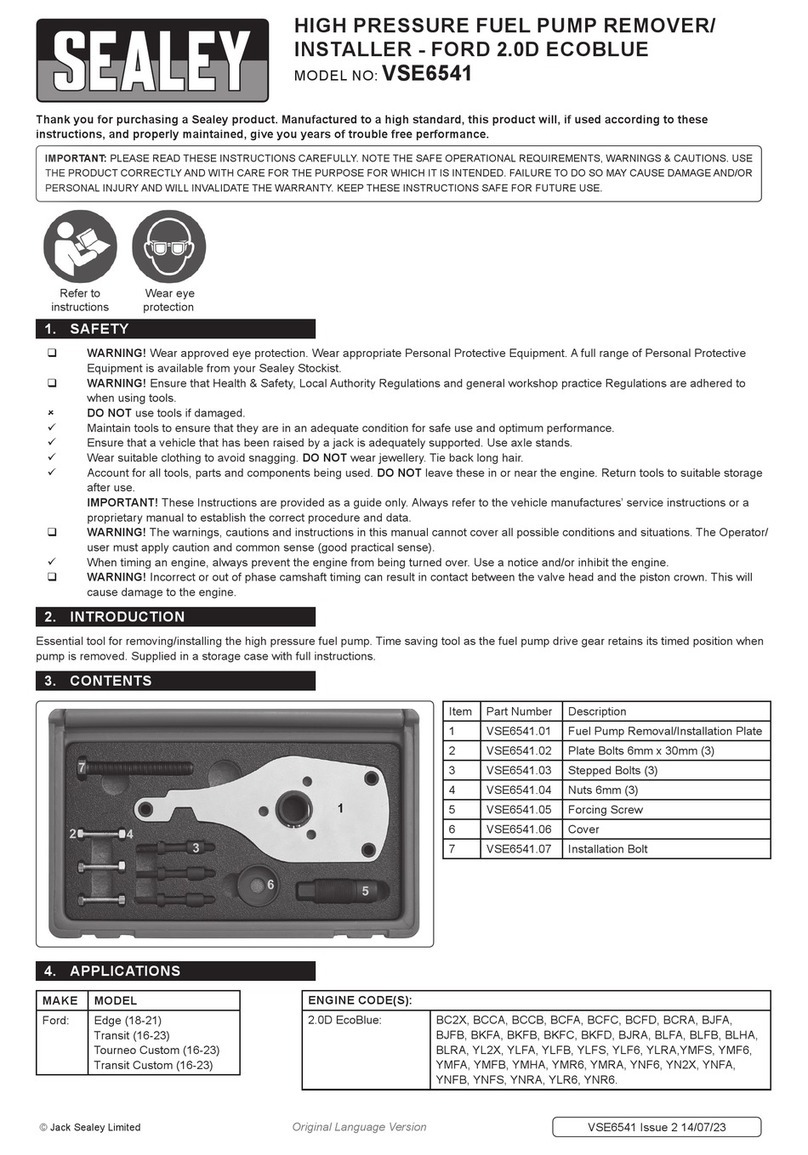

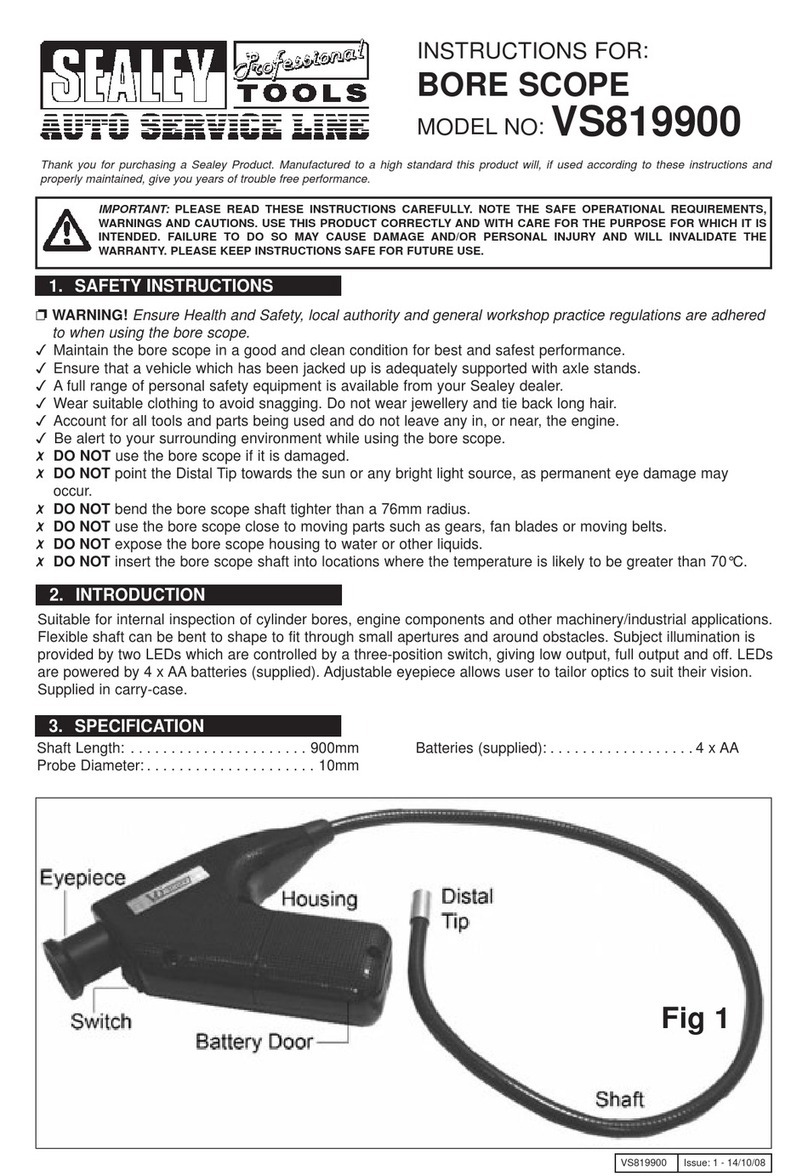

5.1.1 VS1404 TDC Position Tool - Associated Tool - not in kit.

The correct engine/crank TDC position is established using VS1404 tool

together with a suitable Dial Gauge such as AK9634M.

VS1404 Tool determines when the piston of No.1 cylinder is at its

highest point - NOTE: piston must be on its ignition stroke.

Remove the spark plugs and install the Dial Gauge into VS1404 and

secure with the thumbscrew.

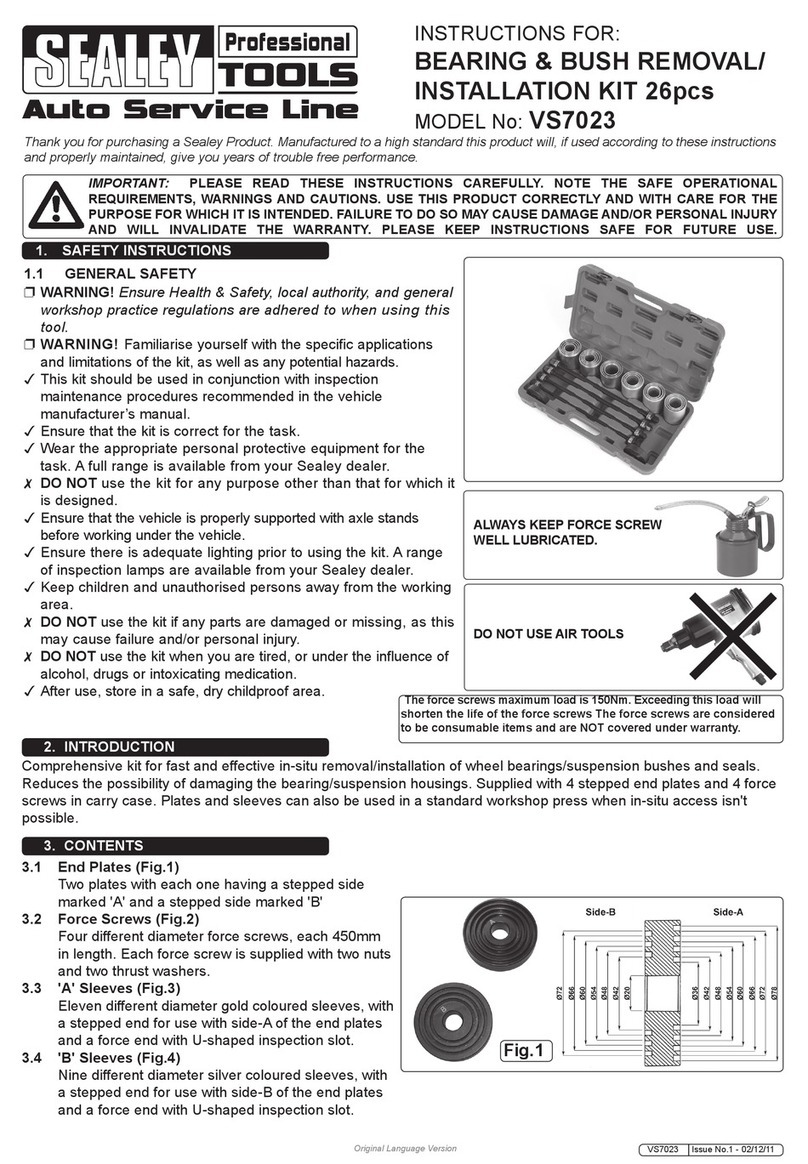

Screw the VS1404 fully into the centre spark plug hole of No.1 cylinder,

taking care not to over tighten (Fig.1).

By turning the crankshaft, in the normal direction of engine rotation, the

piston will raise the indicator pin of VS1404 and in turn, move the

needle of the Dial Gauge.

TDC is achieved when the Dial Gauge needle reaches its highest

reading and starts to move in the reverse direction.

Check that all timing marks align.

Fig.1

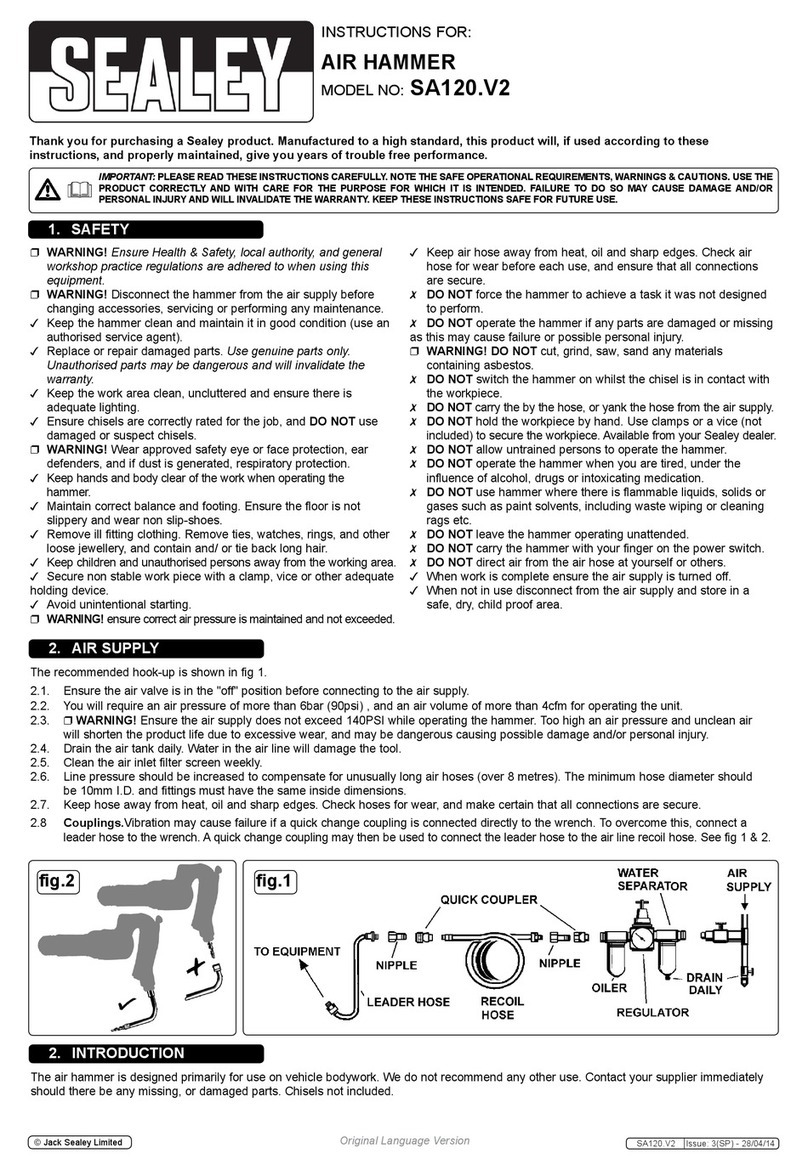

Fig.2

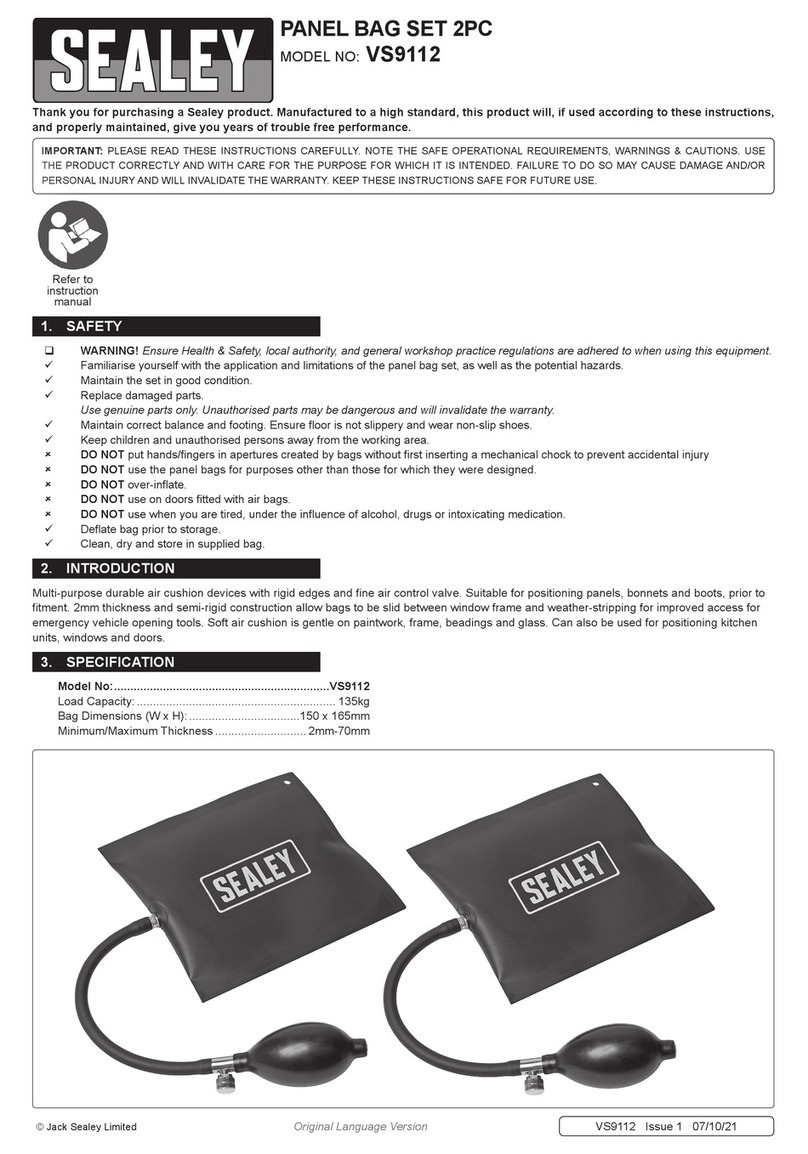

5.1.2 Camshaft timing.

The camshafts are retained in their 'timed' positions by use of Camshaft

Setting Plate Assemblies which are fixed on the engine in place of

designated bearing caps, at specified cylinder locations (Fig.2).

The VS4910 Timing Kit is based on the unique AL-Fi Camshaft

Setting Plate System.

The AL-Fi range of Universal Camshaft Setting Plates provide wide

application coverage across engine ranges by utilising common Support

Blocks - one for all Inlet Camshafts, and one for all Exhaust Camshafts.

Interchangeable Setting Plates are mounted onto these support blocks

The position of the Setting Plates on the Support Blocks is adjustable in

order to provide maximum coverage of engine ranges.

Refer to 4.3 "The AL-Fi System Of Camshaft Setting Plates"

5.1.3 Both camshaft sprockets are released and free to turn on their

camshafts, when fitting new belt.

Marks on the new belt are aligned to marks on the sprockets/pulley and

fitted in the following order: crankshaft, guide, camshaft (exhaust),

camshaft (inlet), tensioner, water pump. Initially the timing belt tension is

adjusted to maximum using Tensioner Adjuster VS1403/04.

The camshaft sprocket bolts are then tightened, and all setting/locking

tools removed and bearing caps re-fitted. The engine is rotated by hand,

and VS1404 re-fitted to ensure return to TDC position.

The tensioner is adjusted so the pointer aligns with hole, the engine is

rotated again and returned to TDC. All timing marks must align.

5.1.4 For 2.0 engines the balancer shaft belt is tensioned using VS1409/03

Adjuster. With the crankshaft at TDC, align the balancer shaft timing

marks and fit the belt. Adjust tensioner to position detailed below.

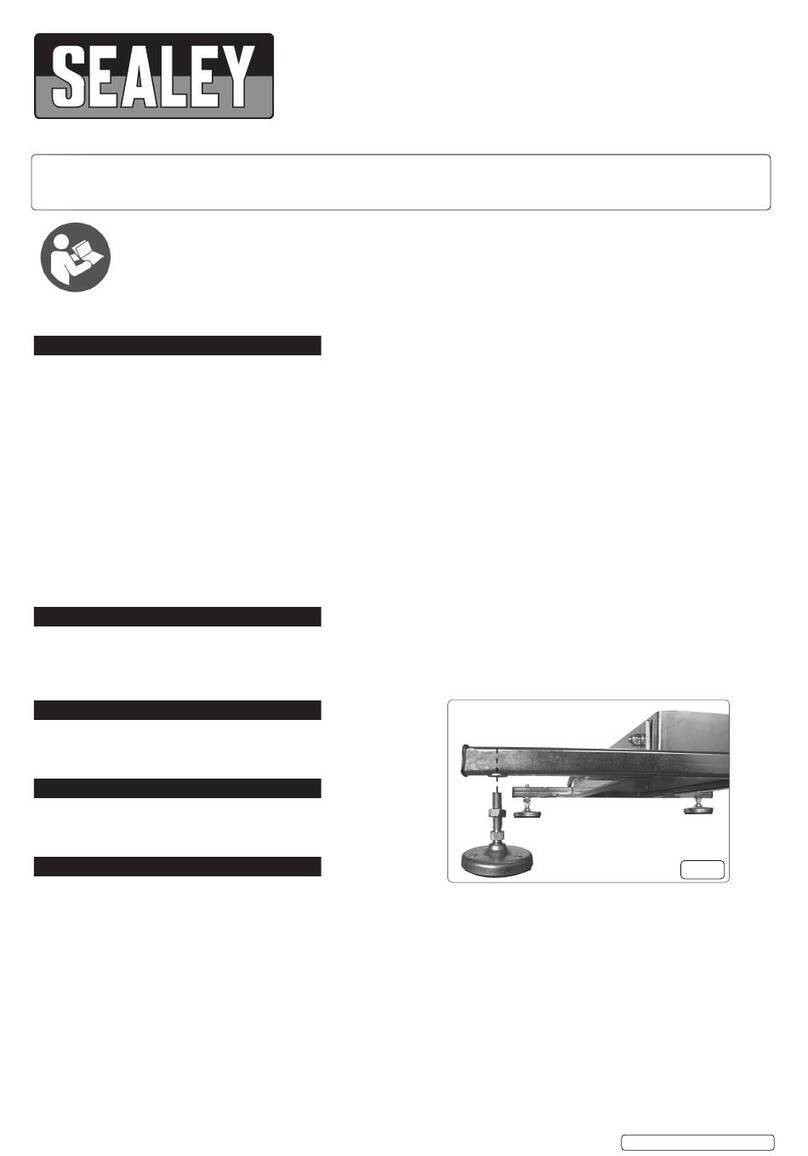

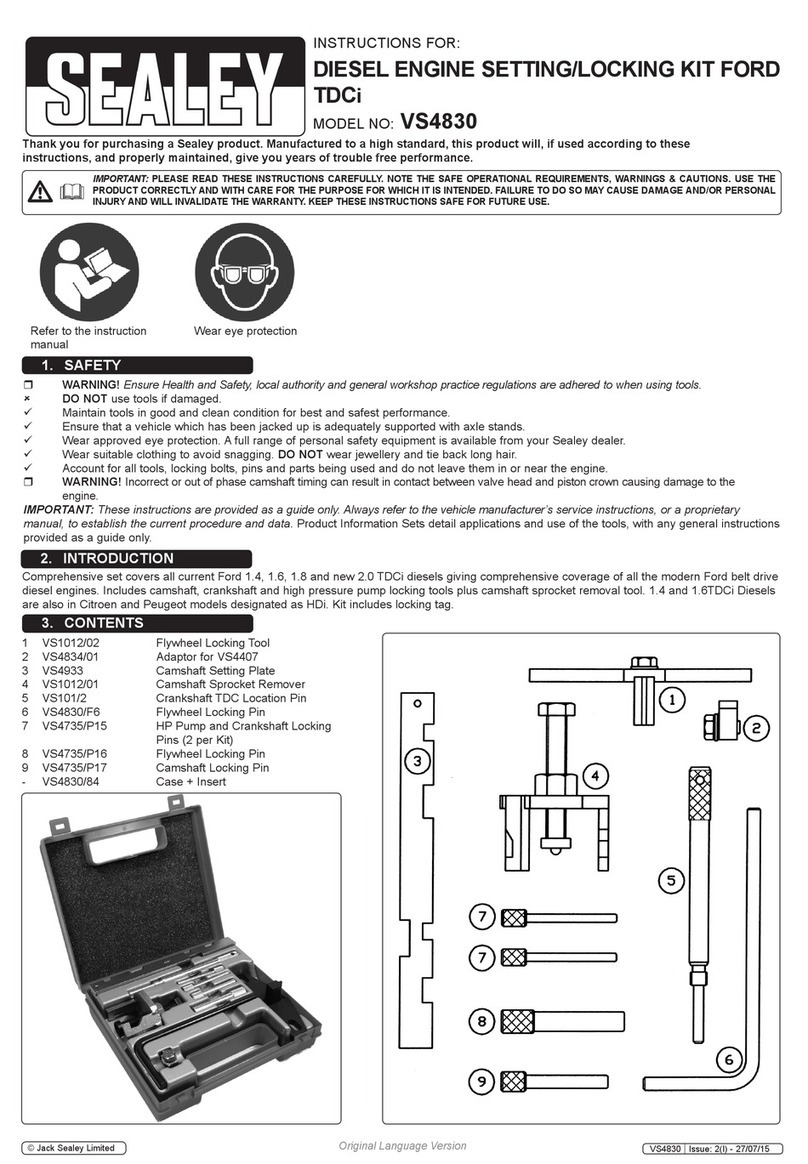

5.2 VS1403/04 Timing Belt Tensioner Adjuster & VS1409/03 Balancer

Shaft Belt Tensioner Adjuster (Fig.3).

1403/04 Adjuster is used for all these twin cam engines. The correct final

adjustment for the timing belt tensioner is with the pointer of the tensioner

aligned with the reference hole - see fig.3.

VS1409/03 adjusts the tensioner of the balance shaft belt on 2.0 engines.

The correct final position is with the hole on the tensioner aligned to the

centre point of the tensioner movement - see fig.3.

Fig.3

© Jack Sealey Limited Original Language Version VS4910 Issue:3 (SP) - 08/07/15

5. INSTRUCTIONS