INSTRUCTIONS FOR

STUD WELDING KIT 230V

MODEL NO: SR2000

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

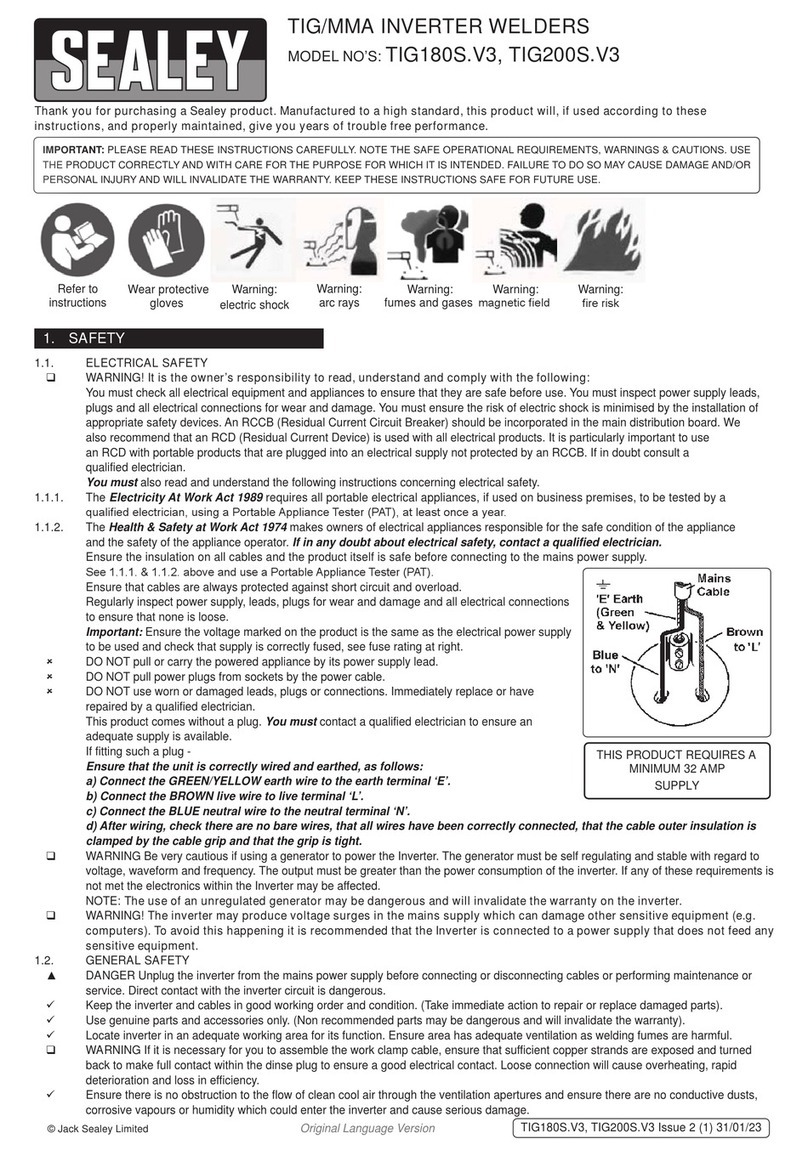

1.1. Electrical Safety

WARNING! It is the user’s responsibility to check the following:

Check all electrical equipment and appliances to ensure that they are safe before using. Inspect power supply

leads, plugs and all electrical connections for wear and damage. Sealey recommend that an RCD

(Residual Current Device) is used with all electrical products. You may obtain an RCD by contacting your

local Sealey dealer.If the kit is used in the course of business duties, it must be maintained in a safe

condition and routinely PAT (Portable Appliance Test) tested.

9Electrical safety information, it is important that the following information is read and understood.

9Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply.

9Regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure that they are secure.

9Ensure that the voltage rating on the appliance suits the power supply to be used and that the plug is tted with the

correct fuse - see fuse rating in these instructions.

8DO NOT pull or carry the appliance by the power cable.

8DO NOT pull the plug from the socket by the cable.

8DO NOT use worn or damaged cables, plugs or connectors.

9 This product is tted with a BS1363/A 13 Amp 3 pin plug.

If the cable or plug is damaged during use, switch o the electricity supply and remove from use.

9 Replace a damaged plug with a BS1363/A 13 Amp 3 pin plug. If in doubt contact a qualied electrician.

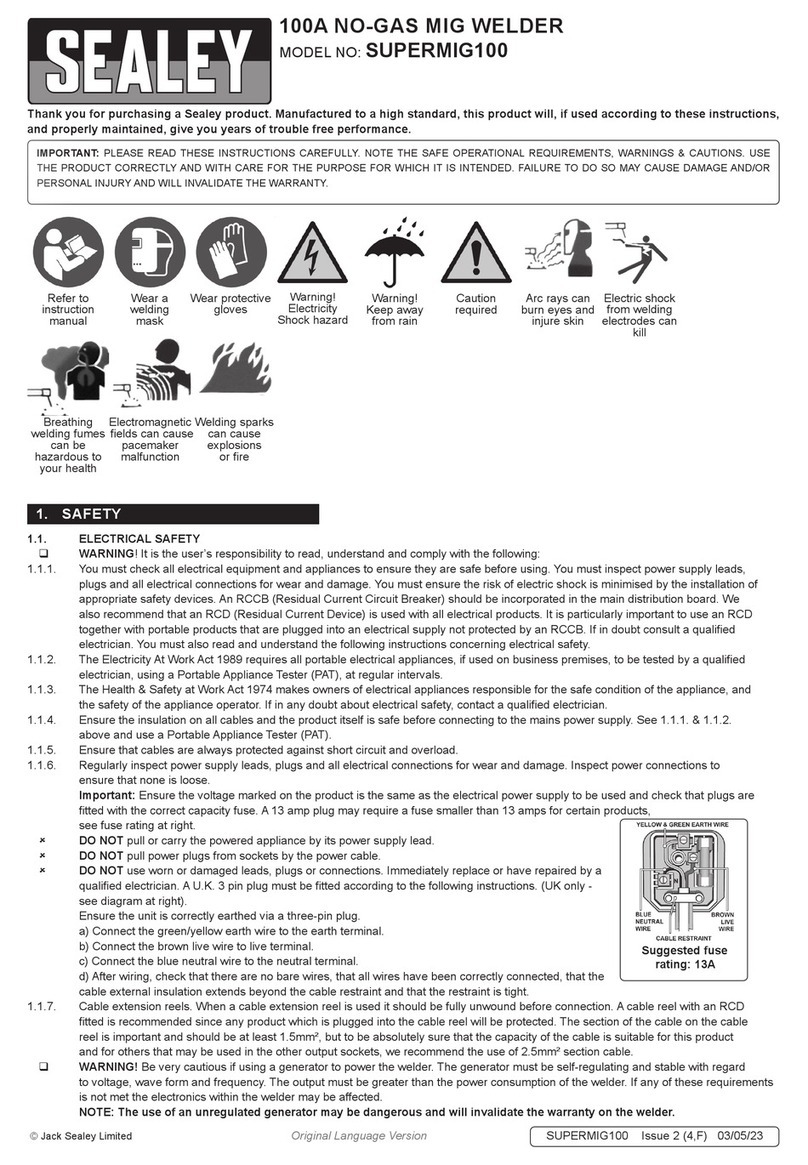

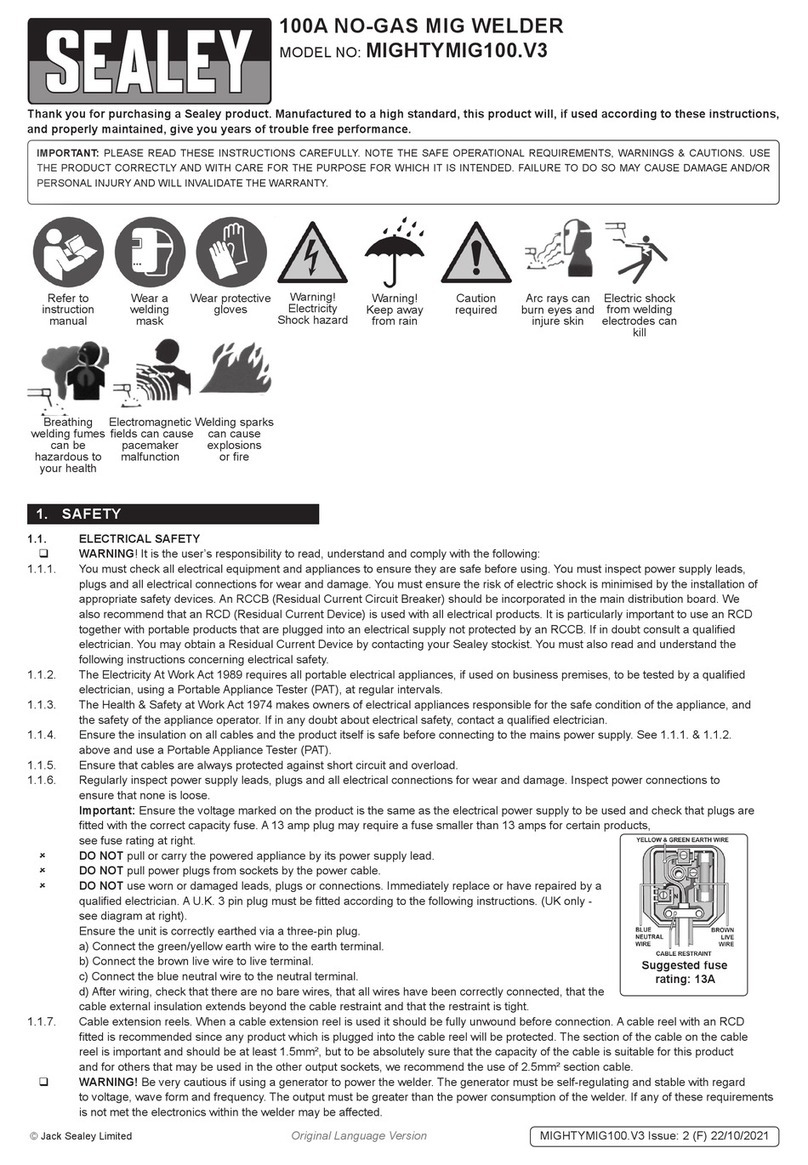

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to the live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

Ensure that the cable outer sheath extends inside the cable restraint and that the restraint is tight.

9 Sealey recommend that repairs are carried out by a qualied electrician.

9Only use one single extension cable at a one time. DO NOT daisy chain extension cables. Unwind the

extension cable fully.

1.2. General

8DO NOT touch heating parts with bare hands.

8DO NOT touch live electrical parts or electrodes with bare skin or wet clothing.

8DO NOT operate in the vicinity of containers under pressure, or in the presence of explosive dust, gases or fumes.

8DO NOT cover or stick objects into any of the ventilation holes on the equipment.

WARNING! The magnetic elds created by high currents may aect the operation of pacemakers. Wearers

of vital electronic equipment or those who have metallic surgical implant should consult their Doctor before using equipment.

8DO NOT wear clothing with metallic components e.g. belt buckles, buttons, zips when working with the equipment as it can

cause such items to heat up.

9Remove any metallic components e.g. keys, chains, tools etc. while you operate the equipment and DO NOT wear any metallic

objects such as jewellery, watches, piercings etc. on your body.

8DO NOT use the equipment in the rain or in humid conditions or immerse it in water.

8DO NOT leave the equipment unattended whilst turned on.

8DO NOT attempt to repair or service the equipment.

9Ensure area is adequately ventilated and dry.

9Ensure ambient temperature is between -10 to 40 °C

9Avoid using in bright sunshine or rain.

8DO NOT use the equipment in an environment where the air is polluted with conductive dust or gases.

WARNING! Fumes and smoke from hot/burning paints, adhesives etc. are toxic. Wear a suitable mask in such circumstances.

2. INTRODUCTION

Supply: 230V-13A (13A Plug tted). Professional quality stud welder for fast, ecient body repairs. Removes dents quickly, without

holes or the need to remove interior trim. No burn through means that removal of studs and washers is easy and preparation work

before repainting is minimised. Suitable for use on steel or aluminium and can weld studs, washers and tabs. Patented quick puller

attachment allows removal of smaller dents without the need for studs or washers. Supplied in heavy-duty storage case.

Indoor use only

Recommended fuse rating

13 Amp

SR2000 Issue 1 15/06/18

Original Language Version

© Jack Sealey Limited

Refer to

instruction

manual

Wear protective

gloves

Wear eye

protection

Wear face

mask

Wear ear

protection

Wear protective

clothing

Do not use in

the vicinity of a

pacemaker

Wear welding

mask